Oct.

09, 2025

Contents

Understanding Material Machinability in CNC Operations

Factors Affecting Material Machinability

Machinability of Common CNC Materials

Machinability Impact on CNC Operations

Choosing Materials for CNC Projects

Material machinability means how easy it is to cut or shape a material with CNC machines. This is important for how fast you finish work and how smooth the parts look. If you pick a material with high machinability, your tools last longer and you spend less money. Studies show that when tools wear out, you get more mistakes and higher costs.

Factor | Impact on Costs and Tool Wear |

|---|---|

Material Stiffness | Materials with high stiffness can cost 50-250% more, but the total part cost only goes up 15-30% because machining is faster. |

Machining Efficiency | The material you pick changes how long machining takes, how fast tools wear out, and the total cost, not just the price of the material. |

Machinability means how easy it is to cut or shape a material with CNC machines. If a material has good machinability, you can cut it fast and get a smooth finish. You use less energy, and your tools last longer.

Machinability shows how simple it is to work on a material with CNC machines.

It helps you pick the best material for your project.

Machinability affects how quickly you finish a part, how much your tools wear, and how nice the final product looks.

Hardness, toughness, and making a smooth surface all matter for machinability.

If a material is hard to machine, you might need special tools and spend more money.

You can measure machinability in different ways. Here are some common ways:

Metric | Description |

|---|---|

Cutting Tool Life | How long your cutting tool lasts before you need to change or sharpen it. |

Surface Finish | How smooth the finished surface feels and looks. |

Power Consumption | How much energy you use to cut the material. |

Machinability Rating | A score that helps you compare how easy it is to machine different materials. |

You want your CNC projects to be quick, accurate, and not cost too much. Machinability helps you reach these goals. If you pick a material with good machinability, you get better results and save money.

The properties of each material, like hardness and toughness, change how much force you need to cut and how long your tools last.

If you use the right cutting speeds and feed rates, you can make parts with high precision and a smooth finish.

Advanced machining methods, such as high-speed machining, can give you even better results with the right materials.

Tip: Picking materials with good machinability can help you avoid breaking tools and spending too much time on repairs.

When you use materials that are easy to machine, you spend less time fixing machines and changing tools. Predictive maintenance can help you find problems before they stop your machines. This keeps your machines working and your projects on track. Some studies show predictive maintenance can cut unplanned downtime by up to 30%.

Material machinability also changes the quality of your parts. If you pick the right material, your parts fit better and look smoother. You also use less energy and keep your costs low.

Physical properties are important for machining. These include density, melting point, thermal expansion, thermal conductivity, and specific heat. Each property changes how the material acts during CNC machining. For example, some aluminum alloys are light and easy to cut. Materials with low melting points need less energy to machine. If a material expands a lot when heated, it might bend or crack. You should look at these properties before starting your project.

Property | Effect on Machinability |

|---|---|

Density | Lighter materials, like some aluminum alloys, are strong and light. |

Melting Point | Lower melting points make machining easier and use less energy. |

Thermal Expansion | High thermal expansion can cause bending or breaking. |

Thermal Conductivity | Low thermal conductivity can make tools break from heat. |

Specific Heat | Low specific heat means the material heats up fast and wears tools. |

Mechanical properties like hardness and toughness matter for machining. Hardness is how well a material resists scratches or dents. Toughness is how much force a material can take before it breaks.

Harder materials last longer but are harder to cut. You may need special tools for these.

Softer materials are easier to cut but can lose shape if you use too much force.

Skilled machinists use the right settings to get smooth parts from softer metals.

If you pick a very hard material, your tools wear out faster. Softer materials let you use more kinds of tools and often give a smoother finish.

Thermal conductivity shows how well a material moves heat away. This affects tool life and how good your finished part looks.

Materials with high thermal conductivity, like aluminum 6061, move heat away fast. This keeps tools cooler and helps them last longer.

Materials with low thermal conductivity, like stainless steel 304, keep heat in. This can make tools wear out faster and cause rough cuts.

The mix of thermal conductivity and hardness changes how fast you can cut and how smooth the surface will be.

Tip: Always check thermal conductivity to keep your tools working well and get good results.

Material machinability depends on all these things. When you know about them, you can pick the best material for your CNC project and avoid problems with tool wear, cutting force, and surface finish.

Metals are used a lot in CNC machining. Some metals are easier to machine than others. Aluminum 6061 is strong and light. It is easy to machine. Brass C36000 is also easy to machine. It is good if you need corrosion resistance or electrical conductivity. Mild Steel AISI 1018 is another favorite. It has a high machinability rating.

Metal | Grade | Machinability |

|---|---|---|

Aluminum | 6061-T6 | High |

Brass | C36000 | High |

Mild Steel | AISI 1018 | High |

When you machine aluminum, brass, or mild steel, your tools last longer. The parts look smoother. Stainless steels are harder to machine. They can make rough edges. This slows down the process. Tool wear, like flank wear, makes your tools not last as long. It also makes the parts look less smooth.

Aluminum alloys and brass help you get smooth parts.

Stainless steel needs special tools and slower speeds.

Flank wear makes cutting harder and can hurt your part.

Plastics are also used a lot in CNC machining. ABS is easy to machine. It is strong and lasts a long time. People use it for prototypes and finished parts. Polyoxymethylene, called POM or Delrin, is another easy plastic to machine. Many CNC shops use it.

When you machine plastics, you need sharp tools. You should use light cutting forces. If your tools are not sharp or you go too slow, ABS can stick to your cutters. Plastic chips can stick together and block the tool or coolant. This can make heat build up and make your cuts less accurate. Some plastics can bend if you do not clamp them well.

Use sharp tools and light forces for plastics.

Watch out for chip buildup and static electricity.

Clamp plastics well so they do not bend.

Tip: Clean up plastic chips often to keep your machine working well.

Composites like carbon fiber or fiberglass are hard to machine. These materials can change shape after cutting. This can make holes or pockets smaller than you want. Composites are rough on tools. Your tools can wear out fast. You may need to buy new tools more often, which costs more.

Composites make a lot of dust, which is bad for you and your machine.

You need special tools and ways to cut different composites.

Throwing away composite parts costs more because the materials are expensive.

Material Machinability is different for metals, plastics, and composites. You need to know these differences to pick the best material for your CNC project.

When you pick cutting tools for CNC, you must think about a few things. You need to know what material you are cutting. You should look at the shape and type of the part. You also need to check the machining conditions. Think about how smooth you want the part to be.

A good way to choose tools is to balance hardness and toughness. You can change cemented carbide by using different grain sizes. You can also add more or less cobalt binder. You need to watch out for thermal and chemical wear. Flank and crater wear show how heat moves in the tool at different speeds.

If you work with materials that are hard to machine, like Inconel or Hastelloy, you need special tools. The table below gives some examples:

Material | Machinability Rating (MR) |

|---|---|

M-308 | 0.05 |

Inconel 700 | 0.09 |

Hastelloy X | 0.09 |

Waspalloy | 0.12 |

The hardness of your material changes the best speed for cutting. Harder materials, like stainless steel, need slower speeds. This helps stop tools from wearing out and keeps heat low. Softer materials, like aluminum, let you use faster speeds. This makes your tools last longer and gives better results.

You want your parts to look nice and work well. Materials that are easy to machine help you get a smoother finish. Harder materials may need extra steps to look smooth. A smooth finish is important for moving parts. It helps lower friction and wear.

Smoother finishes help parts last longer.

Lower surface roughness is important for fast-moving parts.

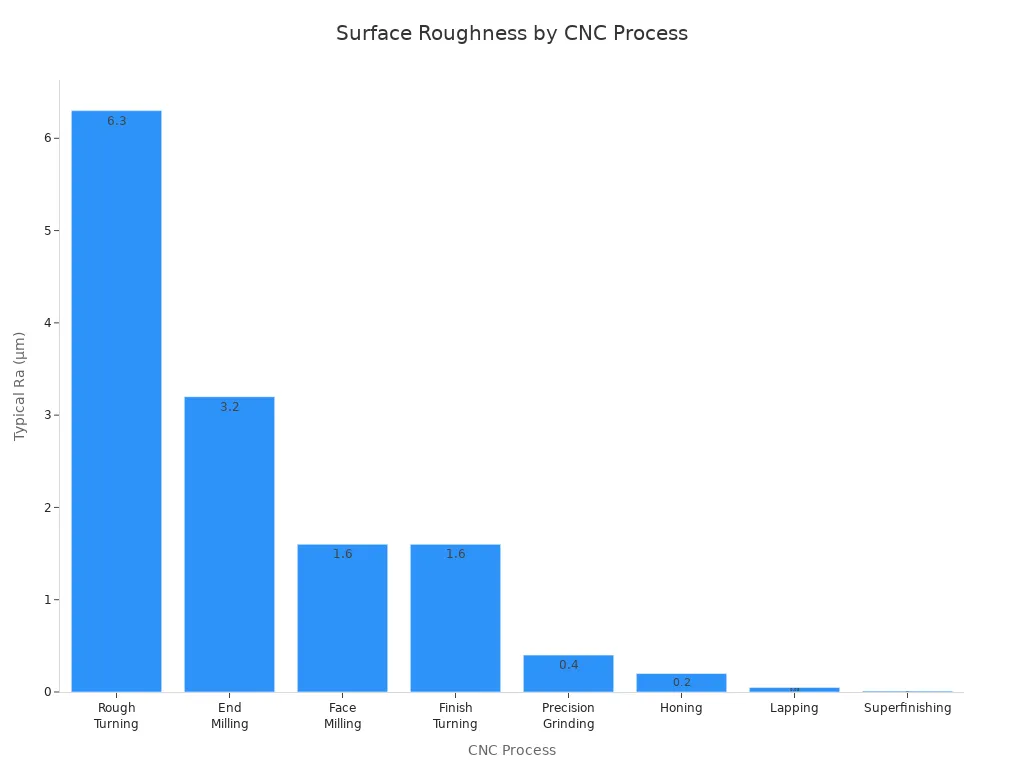

CNC Process | Typical Ra (µm) | Description | Typical Applications |

|---|---|---|---|

Finish Turning | 1.6–3.2 | Smooth surface | Shafts, bores |

Precision Grinding | 0.4–1.6 | High-accuracy surface | Bearings, bushings |

Lapping | 0.05–0.3 | Mirror-like surface | Valves, sealing surfaces |

Material Machinability changes how much your project costs. Easier-to-machine materials, like aluminum and some plastics, cost less to machine. Harder materials, like stainless steel or titanium, cost more. They take longer to machine and wear out tools faster.

Material | Machinability | Cost Impact |

|---|---|---|

Aluminum | High | Lower machining costs |

Stainless Steel | Low | Higher machining costs |

Titanium Alloy | Very Low | Highest machining costs |

Complex shapes and special tools can make costs go up.

Picking materials that are easier to machine can save money, especially if you make many parts.

For example, many shops use aluminum for light parts because it is cheap and easy to machine. Plastics like ABS are also used for test parts because they save time and money.

You want your CNC part to work well and last long. First, think about what your part will do. Ask if it needs to be strong or light. Check if it must handle heat. You should also look at your budget. Some materials cost more than others. Some are easy to machine. Others need special tools.

Here are things to think about when picking a material:

Think about what your part will be used for.

Check if you need strength or if weight matters.

Look at your budget and the price of each material.

Watch out for problems with machinability.

You can pick different materials for different needs:

Stainless steel is good if you need corrosion resistance.

Titanium is strong, light, and resists corrosion.

ABS plastic is a good balance of weight, strength, and cost.

Make sure your material can handle pressure and heavy loads. If your part rubs against other parts, pick one with good wear resistance. Some projects need materials that can stand up to hot or cold temperatures.

Tip: Try to balance what you want from your material with how much you want to spend. Check if the material is cost-effective and if you might waste a lot during machining.

Professionals look at many things before picking a material. The table below shows what they check:

Factor | Description |

|---|---|

Mechanical Properties | Materials are checked for strength, hardness, and ductility. |

Environmental Resistance | Think about how materials handle different conditions. |

Cost | See if using the material is affordable. |

Surface Finish | The finish after machining affects looks and how it works. |

Machinability ratings help you pick the best material for your CNC project. These ratings show how easy it is to machine a material. If a material has a high rating, you can cut it faster and use less energy. This helps you save money and finish your project sooner.

Machinability ratings let you compare different materials. Aluminum is easy to machine. You can make parts quickly and get a smooth finish. Stainless steel and titanium are harder to machine. You may need better tools and more time for these.

Machinability ratings help you balance cost and performance. If you choose a material with a higher rating, you can lower your production costs and work faster. Always match the rating to your project needs for the best results.

Material Machinability is very important in CNC work. You should look at machinability, strength, cost, and how well it works. To get good results, follow these steps:

Change the cutting speed and tool for each material.

Use normal hole sizes and thick walls to save time and help tools last longer.

Picking the right material lets you cut faster, spend less money, and make smoother parts.

Category | Example Materials | Best For |

|---|---|---|

Fast & Affordable | Aluminum 6061, Acetal | Prototypes, jigs, cheap parts |

Fast & Premium | PEEK, Titanium | Parts that need high performance |

Slow & Affordable | Stainless Steel 303/304 | Simple parts that resist rust |

Slow & Premium | Inconel, Tool Steels | Aerospace and tough environments |

Machinability shows how easy it is to cut a material with a CNC machine. If machinability is high, you can make parts faster. You also use less energy and your tools stay sharp longer.

You measure machinability by checking tool life and surface finish. You also look at cutting speed and how much power you use. Some materials have machinability ratings. These ratings help you see which materials are easier to machine.

Hard or tough materials make tools work harder. This makes more heat and friction. Tools wear out faster because of this. You might need special tools or slower speeds for these materials.

Yes, you can! Use sharp tools and the right cutting speed. Coolant helps too. Pick the best tool material for your job. Sometimes, you can change the material grade to make machining easier.

If you do not check machinability, you might break tools. You could waste time and spend more money. Your parts may not fit well or look smooth. Always check machinability before starting your CNC project.

Navigation

Navigation

Contact Us

Tel: +86 13417419143

E-mail: [email protected]

Add:

2nd Floor, Building 7, 156 High Tech Industrial Park, Fuyuan 1st Road, Zhancheng Community, Fuhai Street, Baoan District, Shenzhen City, China.