Jun.

17, 2025

Contents

Aluminum vs Stainless Steel: Which Material Fits Your CNC Project?

Aluminum vs Stainless Steel Comparison

When you face the Aluminum vs Stainless Steel choice for your CNC project, pick aluminum for light, cost-sensitive parts or stainless steel for maximum strength and corrosion resistance. Key factors include weight, strength, machinability, corrosion resistance, cost, and your application’s needs.

Aluminum alloys machine fast and weigh about 60% less than stainless steel, making them ideal for prototypes and electronics. Stainless steel costs up to three times more and takes longer to machine but offers superior durability and corrosion resistance.

Material Relative Cost Machinability Typical Uses Aluminum Baseline Excellent (100%) Prototypes, enclosures Stainless Steel 1.5-3x Moderate (40-50%) Medical, food-grade equipment Match these properties to your project for the best results.

When you compare strength, stainless steel stands out. It has a much higher hardness and can handle more stress before bending or breaking. For example, Stainless Steel 304 has a hardness of 210 HBW, while Aluminum 6061 only reaches 95 HBW. This means you should choose stainless steel if your CNC project needs to support heavy loads or resist wear over time. Aluminum is softer and more malleable, so it works well for parts that do not face high stress.

| Material | Hardness (HBW) | Strength Level |

|---|---|---|

| Aluminum 6061 | 95 | Moderate |

| Stainless Steel 304 | 210 | High |

Stainless steel keeps its strength even at high temperatures, making it a top pick for demanding environments.

Weight plays a big role in many CNC projects. Aluminum weighs about one-third as much as stainless steel. This makes it perfect for applications where you want to reduce weight, like in drones, robots, or automotive parts. Lighter parts can improve energy efficiency and make products easier to handle. Stainless steel, while strong, adds significant weight. You should use it when strength matters more than weight.

Aluminum: Lightweight, high strength-to-weight ratio

Stainless Steel: Heavy, best for stationary or load-bearing parts

Both aluminum and stainless steel resist corrosion, but they do so in different ways. Aluminum forms a stable oxide layer that protects it from further oxidation. Stainless steel uses a chromium-rich film that can heal itself if scratched. Scientific studies show that aluminum performs better in neutral or mildly acidic environments. Stainless steel excels in harsh, salty, or highly acidic conditions.

If your CNC project will face saltwater or chemicals, stainless steel offers better long-term protection. For indoor or less harsh settings, aluminum’s natural oxide layer is usually enough.

Research from journals like Corros. Sci. and technical reports from NASA highlight that alloying elements can change corrosion resistance. Some steels with added aluminum can even match or beat standard stainless steels in certain tests.

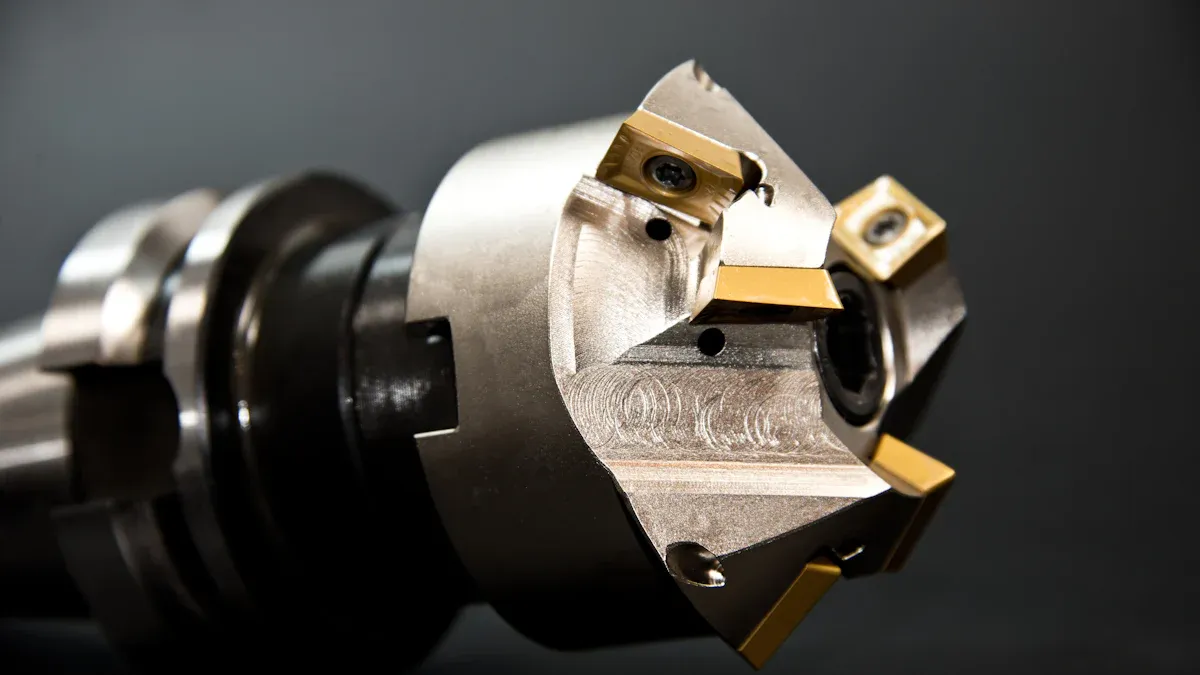

You will find aluminum much easier to machine than stainless steel. Its softness allows for faster cutting speeds, less tool wear, and shorter production cycles. For example, the material removal rate for Aluminum 6061 can reach 7.5 mm³/min, while Stainless Steel 304 only allows about 1.125 mm³/min. This means you can finish aluminum parts faster and with less effort.

Aluminum: Easy to cut, shape, and drill; ideal for rapid prototyping

Stainless Steel: Harder to machine, needs special tools, increases tool wear

Aluminum vs Stainless Steel in machinability: aluminum saves you time and money on most CNC jobs.

Cost often influences your material choice. Aluminum production uses a lot of energy, which can make it expensive. However, stainless steel usually costs more per part because it is harder to machine and takes longer to process. While aluminum has higher initial production costs, its recyclability and lower maintenance needs can save you money over the product’s life. Stainless steel, though more expensive upfront, may last longer in tough environments.

Think about both the upfront price and the long-term savings when you choose between aluminum and stainless steel.

Aluminum vs Stainless Steel shows big differences in conductivity. Aluminum has much higher electrical conductivity, making it the best choice for parts that need to carry electricity. It also has better thermal conductivity, which helps with heat dissipation during machining. Stainless steel, on the other hand, has lower electrical conductivity and, in some cases, better thermal conductivity for heat transfer applications.

| Material | Electrical Conductivity | Thermal Conductivity (W/m·K) |

|---|---|---|

| Aluminum 6061 | High | 205 |

| Stainless Steel 304 | Low | 16 |

Choose aluminum for electronic housings or heat sinks. Pick stainless steel for parts that need to stay strong at high temperatures.

When you need to create prototypes, aluminum often works best. You can machine it quickly and easily, which saves both time and money. Aluminum’s light weight makes it simple to handle and test. If your prototype does not need to handle heavy loads or harsh environments, aluminum is the smart choice. Stainless steel takes longer to machine and costs more, so you usually save it for final products that need extra strength or durability.

In aerospace and automotive projects, weight and strength matter a lot. Most modern aircraft use aluminum alloys for over 70% of their CNC components. You find aluminum in frames, wing structures, and wheels because it is light and strong. You can machine it into complex shapes with ease. Stainless steel comes into play when you need parts that must resist wear or handle high stress, like engine parts or fasteners. Both materials have a place, but aluminum dominates in lightweight applications.

| Material | Typical Use in Aerospace & Automotive |

|---|---|

| Aluminum Alloys | Frames, wings, wheels, engine blocks |

| Stainless Steel | High-stress parts, fasteners, wear-resistant |

You should choose stainless steel for most medical and food equipment. Grades like 304 and 316 resist corrosion and do not react with food or chemicals. Stainless steel meets strict safety rules and keeps your equipment safe for users. Aluminum works well for packaging, trays, and containers that need to be light and easy to sterilize. Both materials pass safety tests, but stainless steel offers better long-term durability and chemical resistance.

Tip: Stainless steel is the top pick for large storage tanks and processing machines in food and healthcare.

Outdoor and marine environments can be tough on materials. Stainless steel, especially grade 316, stands up to saltwater and harsh weather. It keeps its strength and resists rust, even in demanding conditions. Aluminum alloys like 5083 also resist saltwater and work well in marine parts that need to be light. For most outdoor or marine CNC projects, you should pick stainless steel for the best corrosion resistance, but aluminum can be a good choice if you need to save weight.

When you build structural parts, you need to balance strength, weight, and cost. Stainless steel gives you high hardness and durability. It resists corrosion and handles heavy loads. You should use it for parts that must last a long time or face tough conditions. Aluminum costs less and is easier to machine, but it can deform under heavy force. Use aluminum for lighter structures or when you need to keep weight down.

| Benchmark | Aluminum | Stainless Steel |

|---|---|---|

| Hardness | Lower | High |

| Durability | Moderate | Outstanding |

| Corrosion Resistance | Moderate | Excellent |

| Machinability | Easy | Moderate |

When you compare Aluminum vs Stainless Steel for CNC projects, always match the material to your project’s needs. Think about the environment, load, and how the part will be used.

Aluminum gives you many advantages when you work on CNC projects. You can machine it quickly and easily. The lightweight nature of aluminum makes it perfect for parts that need to move or reduce overall weight. You also benefit from good corrosion resistance because of its natural oxide layer. Aluminum offers strong thermal and electrical conductivity, which helps in electronics and heat sinks.

However, you may notice some drawbacks. Aluminum is softer than stainless steel, so it can deform under heavy loads. It does not match the strength or hardness of steel. You might face chip accumulation and thermal expansion during machining. You need to use proper coolants and check your tools often to avoid problems. Safety is important, so always wear protective gear and keep your workspace clean.

Tip: Choose aluminum for prototypes, lightweight frames, and parts where speed and cost matter most.

| Feature | Pros | Cons |

|---|---|---|

| Weight | Lightweight, easy to handle | Less suitable for heavy-duty applications |

| Machinability | High-speed cutting, less tool wear | Can clog tools if not managed |

| Corrosion Resistance | Good, resists rust in most environments | Not as strong as stainless steel in harsh settings |

| Cost | Cost-effective, widely available | May require more frequent replacement |

| Durability | Durable for many uses | Softer, lower lifespan under stress |

Stainless steel stands out when you need strength and durability. You get excellent corrosion resistance, especially with grades like 304 and 316. Stainless steel keeps its shape and strength even in extreme temperatures. It works well for medical, food, marine, and structural parts. You can also achieve fine surface finishes with the right tools.

You will face some challenges with stainless steel. It is heavier than aluminum, which can limit its use in weight-sensitive designs. Machining stainless steel takes more time and causes more tool wear. You need special tools and cooling systems to avoid work hardening. Stainless steel costs more, both for the material and the machining process.

Note: Stainless steel is your best choice for parts that must last a long time or face tough environments.

| Feature | Pros | Cons |

|---|---|---|

| Strength & Durability | Superior strength, long-lasting | Heavier, adds weight to assemblies |

| Corrosion Resistance | Excellent, even in harsh or salty conditions | Some grades are harder to machine |

| Machinability | Can achieve fine finishes | Increases tool wear, slower machining |

| Cost | Long-term value, less frequent replacement | Higher upfront and processing costs |

| Application Range | Ideal for demanding, high-stress uses | Not ideal for rapid prototyping |

When you compare Aluminum vs Stainless Steel, you see that each material fits different needs. Your choice depends on what matters most for your CNC project—weight, strength, cost, or durability.

When you choose between aluminum and stainless steel for your CNC project, you need to look at several important factors. Start by thinking about the strength your part needs. Stainless steel works well for heavy loads and high-stress jobs. Aluminum is lighter and fits projects where weight matters, like in drones or cars.

You should also consider the environment. Stainless steel resists rust in wet or salty places. Aluminum can corrode in saltwater but does fine indoors or in mild conditions. Machinability is another key point. Aluminum machines quickly and easily, which saves time and money. Stainless steel takes longer and wears out tools faster.

Cost plays a big role. Aluminum usually costs less to machine, but stainless steel lasts longer in tough settings. Think about the total cost, including maintenance and replacement. If your project needs to meet food or medical rules, stainless steel often meets those standards better.

Here is a quick table to help you compare:

| Factor | Aluminum | Stainless Steel |

|---|---|---|

| Weight | Light, easy to handle | Heavy, strong |

| Machinability | Fast, less tool wear | Slower, more tool wear |

| Corrosion Resistance | Good (indoors) | Excellent (all environments) |

| Cost | Lower machining cost | Higher upfront, lasts longer |

| Regulatory Compliance | Sometimes limited | Often required for food/medical |

Tip: Always match the material’s properties to your project’s needs for the best results.

You can follow a simple process to make your choice.

List your project’s needs, like strength, weight, and environment.

Check which material matches most of your needs.

Think about how easy it is to machine each material and how much it will cost.

Make sure the material meets any rules or standards for your industry.

Look at the part’s design. Aluminum lets you create finer details, while stainless steel works better for tough, simple shapes.

Experts suggest you also consider how the material will behave during machining. For example, aluminum allows faster cutting and more complex designs. Stainless steel needs slower speeds and special tools. If you need a special finish or coating, check if the material supports it.

Note: If you want a part that is light, easy to machine, and cost-effective, aluminum is often the best choice. If you need strength, durability, and top corrosion resistance, stainless steel is the way to go.

When you compare Aluminum vs Stainless Steel, always balance your project’s requirements with the properties of each material. This approach helps you get the best performance and value.

When you compare Aluminum vs Stainless Steel for CNC projects, you should match the material to your needs. Use aluminum for easy machining, low cost, and light weight. Pick stainless steel for high strength and top corrosion resistance. Here is a quick guide:

Need light, easy-to-machine parts? Choose aluminum.

Need strong, durable, or food-safe parts? Choose stainless steel.

| Material | Machinability | Strength | Corrosion Resistance | Cost |

|---|---|---|---|---|

| Aluminum | Excellent | Moderate | Low | Low |

| Stainless Steel | Low | High | Excellent | High |

For complex or high-stakes projects, talk to a CNC expert to get the best results.

You should use aluminum for most prototypes. It machines quickly and costs less. You can test your design faster and make changes easily. Stainless steel works better for final parts that need more strength.

You can use aluminum outdoors in mild environments. It forms a protective oxide layer. In salty or harsh weather, stainless steel lasts longer. For best results, pick stainless steel for marine or coastal projects.

Stainless steel resists rust because of its chromium content. You get excellent corrosion protection in most environments. Some grades, like 316, work well even in saltwater. Always choose the right grade for your needs.

Aluminum is much easier to machine. You can cut, drill, and shape it quickly. Stainless steel takes more time and wears out tools faster. For fast production, aluminum is the better choice.

You can use aluminum for some food trays and containers. Stainless steel is safer for most food and medical equipment. It meets strict health standards and resists chemicals better.

Navigation

Navigation

Contact Us

Tel: +86 13417419143

E-mail: [email protected]

Add:

2nd Floor, Building 7, 156 High Tech Industrial Park, Fuyuan 1st Road, Zhancheng Community, Fuhai Street, Baoan District, Shenzhen City, China.