Aug.

19, 2025

Contents

POM vs ABS: Which Plastic Works Best for Your Prototype?

Choosing the best plastic for your prototype often comes down to understanding the differences in POM vs ABS. Both materials offer unique advantages depending on your project’s requirements. To make the right choice, consider what matters most for your design.

List the key needs of your prototype and future parts.

Decide on the mechanical properties you require, such as strength or flexibility.

Consider the type of plastic and the manufacturing process you’ll use.

Evaluate factors like quantity, cost, size, and color options.

Select materials that ensure your prototype performs like the final product.

By focusing on these points, you’ll make a more informed decision when comparing POM vs ABS for your project.

When you look at POM vs ABS, you will notice each plastic is good at different things. You might pick POM if you want something strong and stiff. ABS is better if you need something that can bend and take a hit. The table below shows their main mechanical properties side by side:

Property | POM (Polyoxymethylene) | ABS (Acrylonitrile Butadiene Styrene) |

|---|---|---|

Tensile Strength | 55–80 MPa (higher) | Lower than POM |

Flexural Strength | 80–110 MPa (better) | Lower than POM |

Compressive Strength | 140–180 MPa | Generally lower |

Impact Resistance | High, but less than ABS | Superior, absorbs impacts well |

Hardness (Rockwell) | M85–M100 (good wear resistance) | Lower, more flexible |

Rigidity | High, stable shape | More flexible |

Easy to machine, keeps shape | More heat sensitive, can deform |

POM is great for parts that must stay in shape and hold heavy weight. ABS is good if you want a part that will not break when dropped.

Price and how they handle heat are also important. The next table lets you compare these things:

Property | POM (Polyoxymethylene) | ABS (Acrylonitrile Butadiene Styrene) |

|---|---|---|

Cost | Higher, premium engineering plastic | More affordable |

Machinability | Excellent, resists melting | Moderate, can melt with heat |

Melting Point | ~175°C (347°F) | 105–125°C (221–257°F) |

Heat Deflection Temp | 110°C at 0.46 MPa | 85–100°C at 0.46 MPa |

Flammability | Flammable, self-extinguishing | Flammable, self-extinguishing |

💡 Tip: If your prototype needs to handle more heat or heavy weight, POM might be best. If you want to save money and need something that can take a hit, ABS could be better.

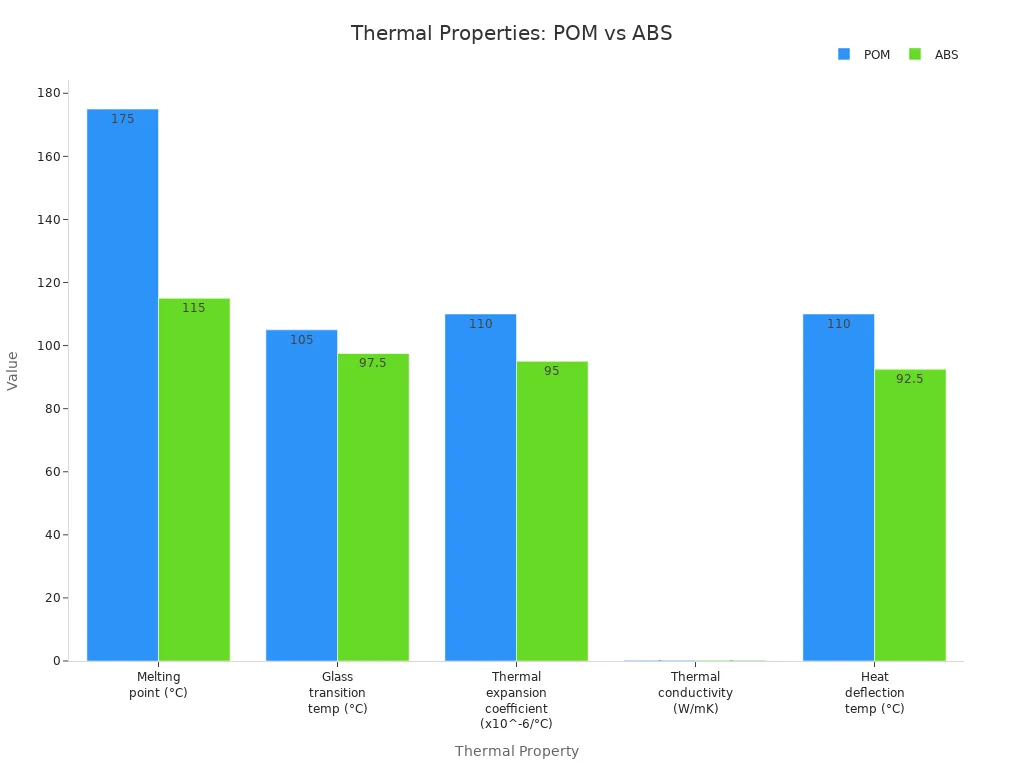

You can also check out this chart to see how they handle heat:

When you think about POM vs ABS, decide what is most important for your prototype. Use the tables and chart to help you pick.

POM is also called polyoxymethylene or acetal. This plastic is strong and stiff. Engineers pick POM when they need tough parts. It keeps its shape and does not wear out fast. You can find POM in gears and bushings. It is also used for parts that need to be very exact. POM works well with CNC machining. It makes smooth and accurate parts.

POM has a simple structure. It is a polymer made from formaldehyde. The repeating parts make strong bonds. This gives POM its toughness. POM does not soak up much water. It also resists many chemicals. Your parts stay stable even when wet.

POM is used when low friction and high precision are needed. It is not used much in 3D printing. But it is great for machined prototypes. If you want a part that lasts and works under stress, POM is a good pick.

ABS means acrylonitrile butadiene styrene. This plastic is made from three monomers:

Acrylonitrile helps ABS resist chemicals and heat.

Butadiene makes ABS tough and hard to break.

Styrene gives ABS its stiffness and makes it easy to shape.

ABS has been used for prototypes for a long time. Since the 1950s, ABS has been in cars, electronics, toys, and home items. It is tough and easy to machine. ABS is popular for 3D printing, especially with FDM. You can shape ABS and finish it by sanding or painting.

Now, ABS comes in many colors and textures. You can pick matte, marble, or neon styles. There are also eco-friendly and recycled ABS filaments. This helps the environment. ABS resists many acids, alkalis, and oils. But it does not do well with acetone or some solvents.

If you want a plastic that is strong, flexible, and not too expensive, ABS is a good choice for your prototype.

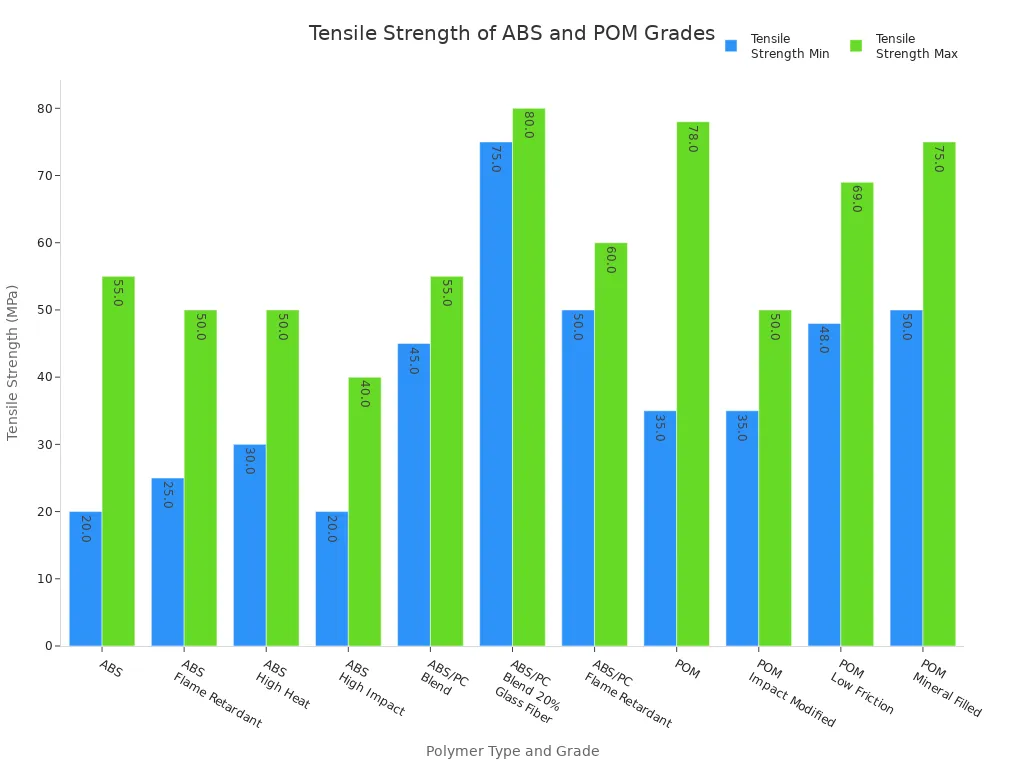

When you compare POM vs ABS, you see clear differences in their mechanical properties. POM stands out for its strength and stiffness. You often choose POM for gears, bushings, or parts that need to keep their shape under stress. ABS, on the other hand, offers more flexibility and impact resistance. This makes ABS a good choice for parts that might get dropped or bumped.

Here is a table showing the tensile strength ranges for different grades of POM and ABS, based on ASTM standards:

Polymer Type and Grade | Tensile Strength Range (MPa) |

|---|---|

ABS (Acrylonitrile Butadiene Styrene) | 20.0 – 55.0 |

ABS Flame Retardant | 25.0 – 50.0 |

ABS High Heat | 30.0 – 50.0 |

ABS High Impact | 20.0 – 40.0 |

ABS/PC Blend | 45.0 – 55.0 |

ABS/PC Blend 20% Glass Fiber | 75.0 – 80.0 |

ABS/PC Flame Retardant | 50.0 – 60.0 |

35.0 – 78.0 | |

POM Impact Modified | 35.0 – 50.0 |

POM Low Friction | 48.0 – 69.0 |

POM Mineral Filled | 50.0 – 75.0 |

You can also see these differences in the chart below:

🛠️ Tip: If your prototype needs to handle heavy loads or keep its shape, POM is often the better choice. If you want a part that can take a hit without breaking, ABS works well.

Thermal properties tell you how a plastic reacts to heat. POM vs ABS shows big differences here. POM can handle higher temperatures before it starts to deform. ABS softens at lower temperatures, so it may not work as well for hot environments.

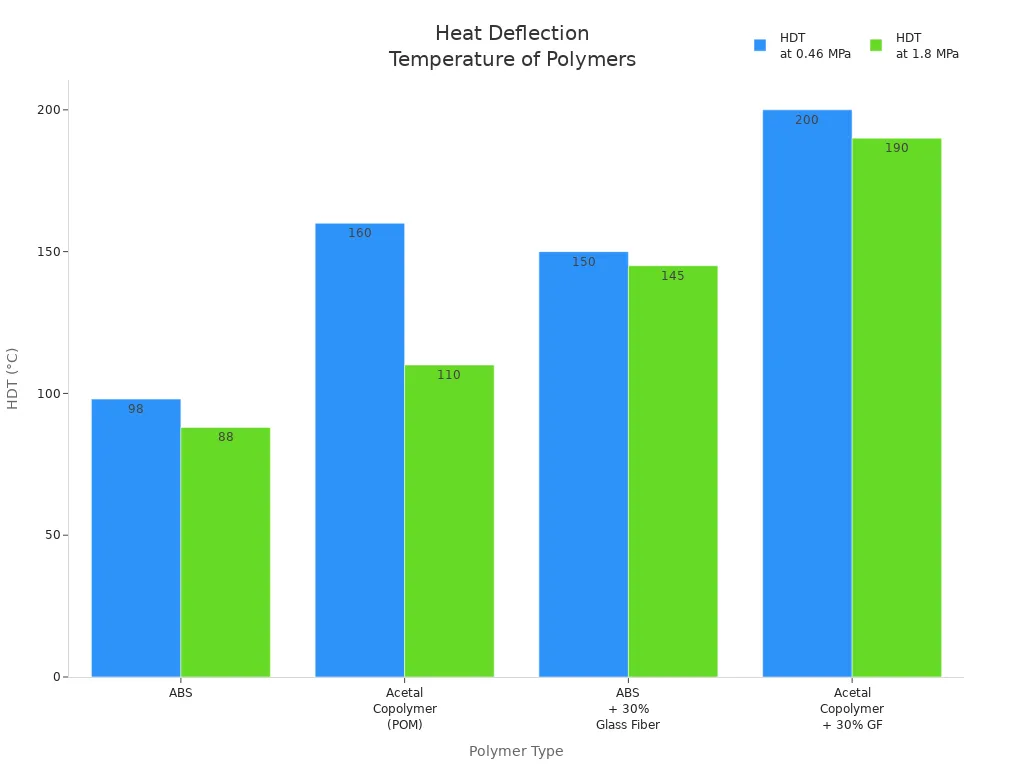

Here is a table comparing the heat deflection temperatures (HDT) for both plastics:

Polymer Type | HDT at 0.46 MPa (°C) | HDT at 1.8 MPa (°C) |

|---|---|---|

ABS | 98 | 88 |

Acetal Copolymer (POM) | 160 | 110 |

ABS + 30% Glass Fiber | 150 | 145 |

Acetal Copolymer + 30% GF | 200 | 190 |

You can see these values in the chart below:

POM HDT ranges from about 110°C to 175°C, depending on the grade and load.

ABS HDT ranges from about 85°C to 100°C at 0.46 MPa and 75°C to 90°C at 1.82 MPa.

ABS has a lower melting point and glass transition temperature than POM.

ABS deforms more under heat and load compared to POM.

🔥 Note: If your prototype will face high temperatures or need to keep its shape under heat, POM is usually the safer pick.

Chemical resistance is important if your prototype will face water, chemicals, or sunlight. POM vs ABS shows some key differences in this area.

ABS has moderate resistance to UV rays but can degrade without UV stabilizers.

Prolonged UV exposure causes yellowing, loss of gloss, and brittleness in ABS.

Untreated ABS loses strength under sunlight over time.

Humidity and chemical exposure can make ABS more likely to crack under stress.

POM (acetal) does not resist UV radiation well. Sunlight can make it brittle and cause surface damage.

POM shows excellent resistance to water and humidity. Even after long exposure to moisture, POM keeps its strength and shape.

POM copolymer grades handle high humidity better than homopolymer grades.

POM and ABS both have poor resistance to UV light if you do not add stabilizers. UV rays can cause the surface to become chalky, change color, and turn brittle. This damage mostly affects the surface but can lead to cracks and failure over time.

🌞 Tip: If your part will be outdoors or in sunlight, consider using UV-stabilized grades or coatings for both POM and ABS.

When you machine POM or ABS, you will notice some differences in how each plastic behaves. POM is known for its excellent machinability. You can cut it easily, and it keeps its shape well. This makes POM a top choice for CNC milling and turning. ABS is also easy to machine, but it can soften if you use too much heat.

Here is a table showing recommended machining parameters for ABS:

Parameter | ABS Recommended Value |

|---|---|

Spindle Speed | 2,000–6,000 rpm |

Cutting Speed | 200–400 m/min (milling) |

Feed Rate | 0.1–0.5 mm/rev |

Tool Type | Carbide tools, single/two flutes, TiN coated |

Cooling | Compressed air or mist |

🛠️ Tip: Use sharp tools and proper cooling to avoid melting ABS. For POM, you can expect smooth cuts and stable parts.

Surface finish matters for many prototypes. When you machine POM, you can achieve a polished look or a matte finish. Here is a quick guide:

Surface Finish | Typical Surface Roughness (Ra) | Notes |

|---|---|---|

As-Machined | 1.6 - 3.2 μm | Semi-smooth, visible tool marks |

Polished | 0.2 - 0.8 μm | Very smooth, good for sliding parts |

Bead Blasted | 1.6 - 3.2 μm | Matte, hides small imperfections |

You can 3D print both POM and ABS, but each material needs special settings. ABS is popular for 3D printing. It prints well with standard FDM printers. POM is harder to print because it can warp and needs careful temperature control.

Here is a table with typical 3D printing settings:

Parameter | POM | ABS |

|---|---|---|

Nozzle Temp | 210–230°C | 210–250°C |

Bed Temp | 100–130°C | 80–110°C |

Print Speed | 30 mm/s | 30 mm/s |

Enclosure | Required | Required |

Bed Surface | Glue/tape | Wood/glue stick/paper |

POM warps less than ABS, but both need a heated bed and an enclosed chamber. ABS releases more vapor, so you should print it in a well-ventilated area.

💡 Note: Slow printing and stable temperatures help prevent warping and layer separation.

Injection molding is a common way to make parts from POM and ABS. POM offers high strength and keeps its shape well during molding. You need to control mold temperature (80–120°C) and injection pressure (50–150 MPa) for the best results. This helps avoid defects and ensures smooth surfaces.

ABS usually releases from the mold easily. Its low friction and ability to form a thin surface layer help reduce sticking. Good mold design, proper draft angles, and using mold release agents like silicone can make the process smoother. These steps protect your parts and extend the life of your molds.

✅ Tip: Careful process control and the right materials help you get high-quality molded parts with both POM and ABS.

When you choose a plastic for your prototype, you need to think about material cost. POM and ABS have different price ranges. POM, also called acetal, usually costs more than ABS. The price of POM resin pellets often falls between $2.50 and $3.50 per pound. This price can change if the cost of raw materials goes up or down. When the base resin price rises, you will see the total cost of POM parts increase. This happens because the resin makes up a big part of the overall cost.

ABS is more affordable. You can often find ABS resin for less per pound than POM. This makes ABS a popular choice for projects where you want to save money. If you need to make many prototypes or large parts, ABS helps keep your budget under control.

💡 Tip: If you want a strong, high-performance part and cost is less of a concern, POM is a solid choice. If you need to watch your spending, ABS gives you good value.

Here is a quick comparison:

Material | Typical Price per Pound | Cost Trend |

|---|---|---|

POM | $2.50 – $3.50 | Sensitive to raw material price changes |

ABS | $1.50 – $2.00 | More stable, lower overall cost |

Material cost is only part of the story. You also need to consider processing cost. This includes the money you spend on machining, molding, or 3D printing your parts.

POM is easy to machine. You can cut it quickly and get a smooth finish. This can lower your machining costs, especially for complex parts. However, POM may need special tools or careful temperature control during molding, which can add to the expense.

ABS is also easy to process. It works well with 3D printing and injection molding. You can shape ABS at lower temperatures, which saves energy and reduces wear on your equipment. This can make ABS more cost-effective for both small and large runs.

🛠️ Note: If you want to keep processing costs low, ABS is often the better choice. For high-precision parts, POM may justify the extra expense with its excellent machinability and performance.

You want your prototype to look and feel right. Surface finish plays a big role in how your part appears and performs. ABS gives you many options for surface texture. You can choose from high-gloss, matte, or even dull finishes. These finishes come from different mold textures or post-processing steps.

Here is a table showing common surface finishes for ABS and POM:

Material | Common Surface Finishes | Typical Roughness (Ra) | Notes |

|---|---|---|---|

ABS | SPI A-3 (high polish), B-1 to B-3 (medium), C-1 to C-3 (low), D-1 to D-3 (dull), VDI 12, 15, 21, 24 | 0.05 µm – 3+ µm | Wide range, easy to texture |

POM | As machined, as molded | Varies (machined) | Smooth, standard CNC finish |

You can achieve a shiny, smooth look with ABS. You can also pick a rougher, matte feel. POM usually has a clean, machined surface. It feels smooth but not glossy. If you need a special texture, ABS gives you more choices.

🛠️ Tip: Choose your surface finish based on how you want your prototype to look and how it will be used.

Color matters for both looks and function. ABS stands out for its wide range of color choices. You can find ABS in almost any color, from bright reds to deep blues. You can even get special effects like marble or neon. This makes ABS a favorite for prototypes that need to match a brand or stand out.

POM comes in fewer colors. Most POM parts are white, black, or natural. Black POM offers more than just a dark color. It also gives better UV protection and thermal stability. When you use black POM, your parts resist fading and stay strong in sunlight. ABS, even with some UV resistance, can fade or crack if left outside for a long time. You can add coatings to ABS to help it last longer outdoors.

🌞 Note: If your prototype will spend time in the sun, black POM keeps its color and strength better than ABS. For indoor use or colorful designs, ABS gives you more options.

POM is also called acetal. It makes strong and exact parts. You pick POM when you want something tough that keeps its shape. Engineers use POM for gears and bushings. It works well for moving parts because it does not wear out fast. The surface is smooth, so parts slide easily.

Advantages of POM:

High strength and stiffness help parts stay in shape.

Great wear resistance means your prototype lasts longer.

Low friction surface lets parts move smoothly.

Good dimensional stability keeps measurements correct.

It resists water and many chemicals, so parts do not swell.

Disadvantages of POM:

Color choices are limited to black, white, or natural.

Not good for outdoor use unless you add UV protection.

Costs more than ABS.

Gears can break or bend if overloaded.

🛠️ Tip: Pick POM if your prototype needs to move, slide, or hold its shape under stress.

Material | Advantages | Disadvantages | Typical Applications |

|---|---|---|---|

POM | High strength, great wear resistance, low friction, stable size | Few colors, higher cost, needs UV protection outside | Gears, bushings, exact parts |

ABS is popular for prototypes because it is easy to shape and costs less. You choose ABS when you want a part that can take a hit and still work. Many products use ABS because it is strong, flexible, and cheap.

Advantages of ABS:

Low cost helps you save money, especially for big batches.

Easy to mold and process, so you make parts faster.

Good impact strength means parts survive drops and bumps.

Many colors and finishes let you design how you want.

Durable in many places, with good wear resistance.

Disadvantages of ABS:

Not as strong or stiff as POM, so it may bend.

Not good for high heat or tough outdoor use.

Not the best for parts that need to be clear.

💡 Note: If you want a colorful, tough, and cheap prototype, ABS gives you lots of choices.

Material | Advantages | Disadvantages | Typical Applications |

|---|---|---|---|

ABS | Low cost, easy to make, good impact strength, color variety | Lower strength, less heat resistance, not for clear parts | Electronics, cars, home products |

ABS prototypes can take hits and handle stress well. You can trust ABS for parts that need to last and get used every day. But if your part faces lots of friction or needs to be very exact, POM works better.

When you start a project, you want your prototype to look and work like the real thing. Both POM and ABS help you do this, but each plastic is good for different jobs. You often see POM and ABS used for quick prototypes and small batches. These plastics let you test your ideas before making lots of parts.

You can use POM for parts that need to be strong and exact. Gears, bushings, and moving parts are good examples. POM keeps its shape and slides easily, so your prototype lasts longer when you test it.

ABS is great if you want a tough and bendy part. You can make covers, cases, and toys with ABS. It can take hits and comes in many colors. If you need 10 or hundreds of parts, both POM and ABS work well for vacuum casting. You can also add color to match your design.

Huaruida Precision helps you pick the right plastic for your project. Their fast prototyping service lets you test and fix your designs quickly. If you only need a few parts, their low-volume and on-demand services give you speed and choices. Picking between POM and ABS changes how your prototype looks, feels, and works.

💡 Tip: Think about what your part needs to do. If it must move or handle stress, POM is a strong pick. If you want a colorful, impact-resistant part, ABS is a smart choice.

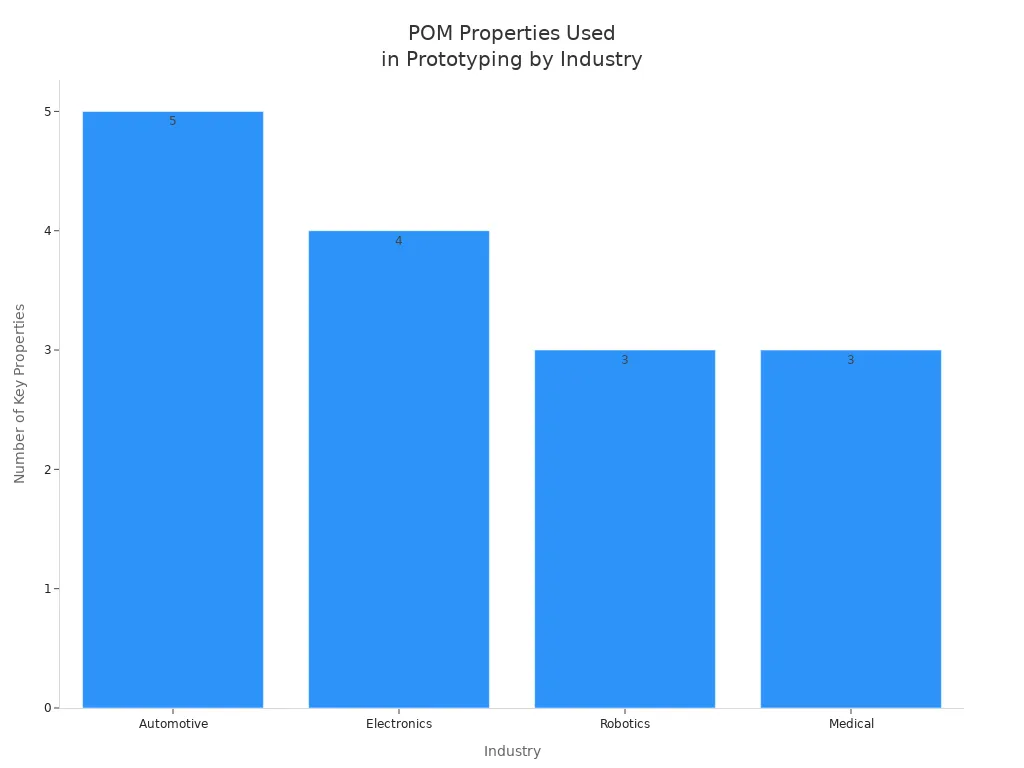

Many industries use POM and ABS for prototypes and small batches. You see these plastics in cars, electronics, robots, and medical devices. Each industry picks the plastic that fits its needs.

Here is a table showing how different industries use POM for prototypes:

Industry | POM Applications in Prototyping and Components | Key Properties Utilized |

|---|---|---|

Automotive | Gears, bearings, bushings, under-the-hood components, door handles | Dimensional stability, wear resistance, chemical resistance, low friction, mechanical strength |

Electronics | Connectors, buttons, sliders, switches | Dimensional accuracy, low friction, wear resistance, electrical insulation |

Robotics | Connectors, moving parts requiring precision and durability | Dimensional stability, low friction, wear resistance |

Medical | FDA-compliant equipment parts requiring chemical resistance and sterilization | Chemical resistance, dimensional stability, compliance with safety standards |

POM is popular for parts that need to be exact and last a long time. In cars, you might use POM for gears and bushings that work under stress. In electronics, POM helps make connectors and switches that must fit just right.

ABS is also used in these industries, especially when you need a part that can take a hit or needs a special color. For example, you might use ABS for dashboard covers in cars or for colorful cases in electronics.

Huaruida Precision works with clients in all these fields. Their team knows how to match the right plastic to your project. Whether you work in electronics, robotics, aerospace, medical, or cars, you can trust them to make good prototypes and parts. Their careful quality checks and advanced methods help you get the results you want.

🚗 Note: The right plastic makes a big difference. When you pick between POM and ABS, you decide how your prototype will work in real tests.

Use this checklist to help you decide if POM or ABS fits your prototype best. Go through each point and see which material matches your needs.

Strength: Do you need your part to hold heavy loads or keep its shape?

Choose POM for high strength and stiffness.

Impact Resistance: Will your part face drops or bumps?

Pick ABS for better impact resistance.

Machinability: Do you plan to use CNC machining for tight tolerances?

Select POM for smooth cuts and stable shapes.

3D Printing: Do you want to use FDM 3D printing?

ABS works well with most 3D printers.

Surface Finish: Do you want a glossy or textured look?

ABS offers more finish options.

Color Choices: Does your design need bright or custom colors?

ABS comes in many colors. POM is usually black or white.

Cost: Is your budget tight?

ABS costs less than POM.

Chemical and Water Resistance: Will your part face moisture or chemicals?

POM resists water and many chemicals better.

Outdoor Use: Will your part stay outside?

Use black POM or UV-stabilized ABS for better durability.

💡 Tip: Write down your top three needs. Match them to the checklist above to see which plastic fits best.

Follow this simple flowchart to make your choice:

Does your part need to be strong and stiff?

Yes → Go to 2

No → Go to 3

Will your part face water or chemicals?

Yes → Choose POM

No → Go to 4

Does your part need to survive drops or impacts?

Yes → Choose ABS

No → Go to 4

Is color or surface finish important?

Yes → Choose ABS

No → Choose POM

🛠️ Note: If you still feel unsure, reach out to a manufacturing partner like Huaruida Precision. Their experts can help you pick the right material for your project and guide you through prototyping and production.

When you look at POM and ABS, you notice they are different. POM is strong and keeps its shape well. ABS bends more and comes in many colors. The price and how each looks are not the same. What your project needs will help you pick the right plastic. Check the list and flowchart to help you decide. If you need help, you can ask Huaruida Precision for advice.

POM makes parts that are strong and exact.

ABS is good if you want parts that can take a hit and have color choices.

💡 Tip: Pick the material that fits what your prototype must do. This helps you get the best results.

POM gives you high strength and stiffness. ABS offers better impact resistance and more color choices. You pick POM for tough, precise parts. You choose ABS for flexible, colorful prototypes.

You can 3D print with both plastics. ABS works well with most FDM printers. POM needs careful temperature control and an enclosed chamber to avoid warping.

Black POM resists sunlight and heat better than ABS. If you want your part to last outside, pick black POM or use UV-stabilized ABS.

Yes, ABS costs less than POM. You save money with ABS, especially for large batches or colorful designs.

Write down what your part needs. If you want strength and precision, pick POM. If you want impact resistance and color, choose ABS. You can ask experts at Huaruida Precision for advice.

Navigation

Navigation

Contact Us

Tel: +86 13417419143

E-mail: [email protected]

Add:

2nd Floor, Building 7, 156 High Tech Industrial Park, Fuyuan 1st Road, Zhancheng Community, Fuhai Street, Baoan District, Shenzhen City, China.