Aug.

07, 2025

Contents

5-Axis Machined Aerospace Brackets Made from 6082-T6 Aluminum

You use 5-axis machined aerospace brackets for strong, light parts in planes. These brackets help hold and support key parts. When you use 5-axis machining with 6082-T6 aluminum, you get parts that are tough and do not rust easily. This teamwork lets you trust aerospace brackets to work well even when things get hard.

You use 5-axis machining to make parts with hard shapes. This technology lets the cutting tool move in five ways. You can shape parts from many angles. This helps you make brackets with curves and holes. Regular machines cannot do these tricky shapes.

Let’s look at how 3-axis and 5-axis machining are not the same:

Feature | 3-Axis Machining | 5-Axis Machining |

|---|---|---|

Movement | X, Y, Z (linear) | X, Y, Z (linear) + A, B (rotational) |

Part Complexity | Simple, flat, or 2.5D shapes | Complex, multi-sided, curved surfaces |

Tool Approach Angles | Limited | Multiple, from almost any direction |

Workpiece Reposition | Often needed | Rarely needed, automatic rotation |

Surface Finish | Basic | Smooth, precise, fewer tool marks |

5-axis machines can move in two more ways than 3-axis. This lets you reach more of the part without stopping. You do not need to move the part by hand. You save time and make fewer mistakes. You also get smoother and more detailed parts.

Tip: With 5-axis machining, you can make a part in one setup. You do not need to move it to another machine. This gives you better accuracy and faster work.

Aerospace parts need to be very exact. 5-axis machining helps you make parts with tiny errors. The machine can follow hard paths and keep the tool at the best angle. This stops shaking and tool damage.

You also get:

Consistent Quality: Each bracket is made the same as your design.

Better Fit: Parts go together with less fixing.

Less Waste: You use less material because you do not cut away as much.

You can trust 5-axis machining to make strong, light, and exact brackets for aerospace. This technology helps you meet the high needs of the industry.

If you need strong and light brackets, 6082-T6 aluminum is a good choice. This alloy is known for its strength and ability to fight corrosion. It is easy to machine, so you can make parts that fit well.

Here is a table with the main mechanical properties of 6082-T6 aluminum:

Property | Range (Min – Max) | Units |

|---|---|---|

Yield Strength | 240 – 280 | MPa |

Tensile Strength | 295 – 344 | MPa |

Elongation | 8 – 11.5 | % strain |

6082-T6 aluminum can take a lot of force before it bends or breaks. The elongation number shows it can stretch a little before snapping. This helps brackets handle shocks and heavy loads during flight.

Note: 6082-T6 aluminum does not rust easily. It can last a long time, even in harsh weather.

Aerospace needs materials that follow strict rules. 6082-T6 aluminum passes many important tests and standards. These show you can trust this alloy for important airplane parts.

6082-T6 aluminum meets standards like AMS-QQ-A-225/9 Alloy 6082 and BS HG30 6082 Wire.

The way it is made follows quality systems such as AS9100, OHSAS 18001, ISO14001, and ISO 9001.

It also has certifications for heat treatment and testing, including NADCAP HT, NADCAP NDT, and IATP16949.

These rules help make sure your brackets are safe and ready for use in planes.

When you pick 6082-T6 aluminum, you get a material that meets the tough needs of aerospace. You can trust its strength, quality, and history in the field.

You want your Aerospace Brackets to be strong but not heavy. 6082-T6 aluminum helps you get this mix. This alloy is strong for how light it is. You can use less metal and still hold up heavy things. Lighter brackets help make the whole plane weigh less. When planes weigh less, they use less fuel and cost less to fly. It is also easier to move and put in each bracket.

Tip: Lighter Aerospace Brackets help planes go farther and carry more stuff.

Aerospace Brackets must work in hard places. They face rain, snow, and salty air. 6082-T6 aluminum does not rust or corrode easily. This means your brackets last longer and do not need much fixing. You do not have to worry about them getting weak. The aluminum has a layer that keeps the surface safe. These brackets stay strong and keep their shape for many years.

You spend less money fixing things.

Your planes are safer to use.

You do not get sudden breaks from rust.

New planes need brackets with special shapes. Some brackets must fit in small spaces or hold things at odd angles. 5-axis machining lets you make Aerospace Brackets with tricky shapes. The machine can move the tool in many ways. You can make curves, holes, and small details all at once. This way, your brackets are smooth and fit just right.

Note: 5-axis machining lets you make brackets you could not make before.

When you use 6082-T6 aluminum and new machines, you get the best brackets. Your Aerospace Brackets are strong, light, and ready for hard jobs. You also follow the strict rules for airplane parts.

You start with a clear idea of what your Aerospace Brackets need to do. You use computer-aided design (CAD) software to draw the bracket. This software lets you see the bracket from every angle. You can check if it fits in the plane and if it will be strong enough. You also pick the right size and shape for each part. When you finish the design, you send the file to the machine shop.

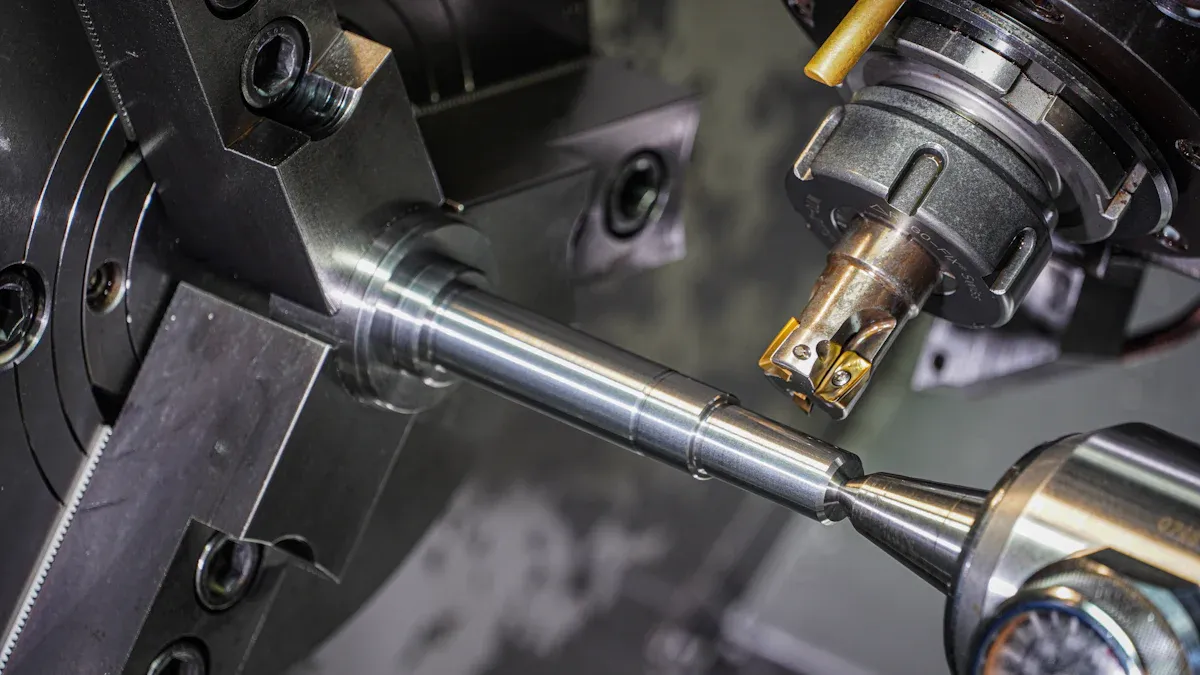

You use a 5-axis CNC milling machine to shape the bracket from a block of 6082-T6 aluminum. The machine reads your CAD file and follows the path you set. It moves the cutting tool in five directions. This lets you make curves, holes, and tricky shapes in one go. You do not need to stop and move the part by hand. The machine cuts away extra metal and leaves you with a smooth, finished bracket.

Here is a simple list of the steps:

Load the aluminum block into the machine.

Set up the CAD file and check the tool path.

Start the 5-axis milling process.

Remove the finished bracket from the machine.

Tip: 5-axis milling helps you make complex Aerospace Brackets faster and with fewer mistakes.

You check every bracket to make sure it meets strict rules. You use special tools to measure the size and shape. You look for cracks, rough spots, or other problems. If you find a mistake, you fix it before the bracket goes into a plane. Good quality control keeps your parts safe and ready for flight.

Quality checks help you trust your Aerospace Brackets in every mission.

You see 5-axis machined 6082-T6 aluminum brackets used in many parts of an airplane. These brackets help hold the plane together and keep it safe during flight. You find them in places where strength and low weight matter most.

You use these brackets to connect airframe parts.

They support fittings and joints that must handle heavy loads.

You find them in wing assemblies, landing gear, and control surfaces.

5-axis CNC machining lets you make brackets with complex shapes. You can create parts that fit tight spaces and odd angles. This process gives you high precision and smooth finishes. You do not need to move the part many times, so you make fewer mistakes. Tight tolerances help your brackets fit perfectly and keep the plane strong. When you use these brackets, you help the plane meet strict safety rules. You also lower the risk of problems during flight.

Tip: Precision in making these brackets helps keep every flight safe and reliable.

You also see these brackets in other fields. Many industries need strong, light, and precise parts. You find them in:

Automotive racing, where every ounce counts.

Robotics, where machines need exact movement.

Medical devices, which must be safe and reliable.

Marine equipment, which faces harsh weather.

You choose 5-axis machined aluminum brackets when you need parts that last and perform well. The same features that help in planes—strength, low weight, and resistance to corrosion—also help in cars, robots, and boats. You get parts that fit well and work right the first time.

When you pick 5-axis machining with 6082-T6 aluminum for Aerospace Brackets, you get lots of good things. This mix makes parts that are strong, light, and very exact. The table below explains why this alloy is great for planes:

Property | Value | Why It Matters |

|---|---|---|

Tensile Strength | ~410 MPa | Handles heavy loads |

Yield Strength | ~370 MPa | Resists bending and breaking |

Corrosion Resistance | High | Lasts longer in tough settings |

Machinability | Good | Makes complex shapes possible |

Weldability | Better | Joins parts safely |

You help keep planes safe and working well. You also help bring new ideas to aerospace engineering.

5-axis machining helps you make very exact parts. The machine can move in five ways. This lets you make hard shapes and smooth surfaces. You do not have to move the part yourself. This saves time and helps stop mistakes.

You pick 6082-T6 aluminum because it is both strong and light. It does not rust easily. You can shape it into detailed parts without trouble. This alloy helps brackets last longer and work well in tough places.

You use special tools to check every bracket. You look for cracks, rough spots, or mistakes. You fix any problems before using the bracket in a plane. Careful checks help you trust your parts.

Yes! You see these brackets in cars, robots, boats, and medical tools. You use them when you need strong, light, and exact parts. Their strength and rust resistance help in many jobs.

High strength but low weight

Great at fighting rust

Can make tricky shapes

Works well in tough places

Lasts a long time

Navigation

Navigation

Contact Us

Tel: +86 13417419143

E-mail: [email protected]

Add:

2nd Floor, Building 7, 156 High Tech Industrial Park, Fuyuan 1st Road, Zhancheng Community, Fuhai Street, Baoan District, Shenzhen City, China.