Aug.

07, 2025

Contents

CNC-Machined Parts for 304 Stainless Steel Camera Components: Turning and Milling for Precision

304 Stainless Steel in Cameras

CNC-Machined Parts for Cameras

Benefits of CNC-Machined Parts

When you want your camera to perform at its best, you need CNC-Machined Parts made from 304 stainless steel. CNC turning and milling help you get exact shapes and smooth surfaces. These methods let you reach tight tolerances and create strong, reliable parts. You can trust CNC technology to make custom components that fit your camera perfectly and last a long time.

If you pick 304 stainless steel for your camera, it will last in tough places. This alloy is strong and easy to work with. It does not get damaged easily. Here are some main benefits:

Corrosion Resistance: A layer forms on the outside. It keeps water and chemicals away from your parts. This helps your camera work in wet or hard places.

Thermal Stability: 304 stainless steel stays strong and keeps its shape up to 870°C. Your camera will work well even when it gets hot.

Toughness and Ductility: The material does not crack or dent easily. It can take hits, so your camera parts last longer.

Good Machinability: You can cut, drill, and shape this alloy well. This makes it simple and cheaper to make tricky camera parts.

Excellent Weldability: You can join pieces together. They do not lose strength or stop fighting rust.

Non-Magnetic and Formable: The austenitic structure keeps your parts non-magnetic. It also makes them easy to shape, which is good for camera builds.

Note: 304 stainless steel fights rust better than carbon steel or galvanized steel. That is why it is great for camera parts that get wet or touch chemicals.

You find 304 stainless steel in many camera parts. It keeps them safe and helps them work well. For example, some machine vision cameras use 304 stainless steel for the whole case. This gives you IP67 protection. Dust and water cannot get inside.

Common camera parts made from 304 stainless steel are:

Faceplates

Mounting plates

Mounting hardware

Hex drive mounting screws

These parts must be strong and work every time. 304 stainless steel stops rust and damage. It works even if you use your camera outside or in rough places.

Challenge / Factor | Description / Impact |

|---|---|

Poor surface finish | 304 stainless steel can look rough after you machine it. |

High power consumption | Machining this alloy uses more energy and wears out tools. |

Dimensional accuracy issues | How deep you cut changes how exact your parts are. |

Austenitic microstructure | This structure makes machining harder than with other stainless steels. |

You should think about these problems when you design and make your camera parts. If you use the right tools and settings, you can still get the quality your camera needs.

CNC turning is used to make round camera parts. The machine spins the 304 stainless steel piece. A cutting tool shapes it as it turns. You can make lens barrels, shafts, and threaded mounts this way. CNC turning helps you control the size and shape very well.

This process gives you high precision. Most camera parts can be made with tolerances as close as ±0.02 mm. This accuracy is important for parts that must fit together, like shafts and holes. If you need even tighter tolerances, you can get up to ±0.005 mm. But this can cost more. CNC-Machined Parts made by turning are strong and last a long time. That is why this method is good for small, detailed parts.

Here are some common tolerances for CNC turning:

Non-critical features: ±0.1 mm

Critical fits like shafts and holes: ±0.02 mm

Ultra-precise parts: ±0.01 mm or better

CNC turning works well with 304 stainless steel. This material does not rust and keeps its shape. Your camera parts will last longer. You also get the same results every time. This means every part matches your design.

Tip: CNC turning uses a computer to control the machine. This lowers mistakes and makes every part the same.

CNC milling is used to make custom shapes and flat surfaces. The cutting tool spins and moves across the metal. It removes material to make the part. You use milling for housings, faceplates, and optical mounts. This method lets you make slots, holes, and angled surfaces.

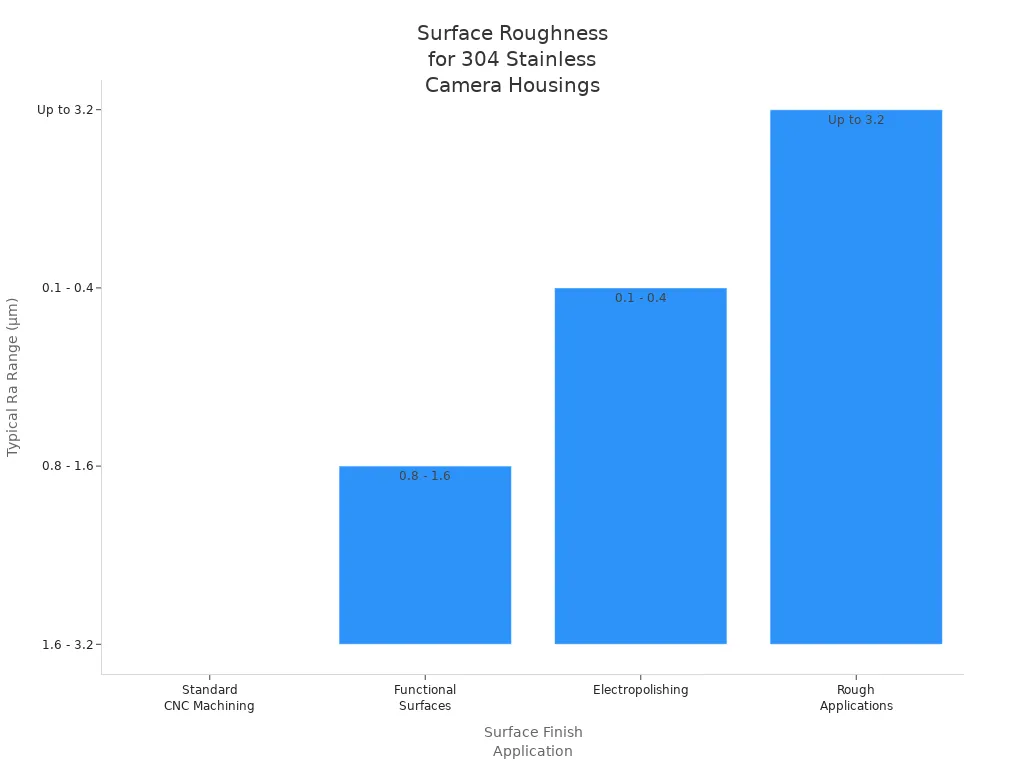

CNC milling can make smooth surfaces. Most camera housings made from 304 stainless steel have a surface roughness (Ra) around 1.6 μm or better. If you need a smoother finish, you can get Ra values as low as 0.8 μm. Here is a table with typical surface finishes:

Surface Finish Application | Typical Ra Range (μm) | Notes and Context |

|---|---|---|

Standard CNC Machining | 1.6 - 3.2 | Good for most stainless steel camera parts |

Functional Surfaces (Sealing) | 0.8 - 1.6 | Needed for tight fits and sealing |

Electropolishing (Post-process) | 0.1 - 0.4 | Used for shiny finishes, not common for camera housings |

Rough Applications | Up to 3.2 | For non-important surfaces |

CNC milling can also make parts with tricky shapes. You can add bevels, deep holes, slots, and notches. Other methods cannot do this. Multi-axis CNC machines help you make parts with many angles and features. This is important for lens mounts and filter rings. You can use CNC milling for many materials. But 304 stainless steel is a top choice because it is strong and does not rust.

Note: CNC milling can run all day and night. It does not need much watching. This helps you make more parts and saves money.

Some camera parts need both turning and milling. You might need a part that is round on one end and flat or has holes on the other. By using both processes, you can make complex CNC-Machined Parts in fewer steps.

A Mill-Turn machine can do both jobs. This saves time and makes parts more accurate. You do not have to move the part between machines. This stops alignment mistakes. It also cuts down setup time and waste. You get better size and surface finish. This is important for camera housings and parts with many features.

Here are some main benefits of using both turning and milling:

Faster production with less handling

Better accuracy and fewer mistakes

Can make complex shapes in one setup

Need fewer tools and fixtures

Easy to change designs and make custom parts

You can make a few parts or many without losing quality. CNC-Machined Parts made with both turning and milling meet high standards for cameras. You get strong, custom parts that help cameras work better.

When you make camera parts, you need every piece to fit just right. Tight tolerances mean that each part matches the design with almost no error. For 304 stainless steel camera components, you often see tolerances as small as ±0.01 mm. Some gears and small parts need even tighter control, with inside diameters held to about 0.001 inch (25 microns) and outside sizes kept within 0.002 to 0.003 inch (50 to 75 microns). These numbers show that the industry expects high precision for camera parts.

You can reach these tight tolerances by using advanced CNC machines. These machines follow your design exactly. They use computer controls to cut, shape, and finish each part. You also need to check the parts after making them. You can use special tools and machines to measure every detail:

Coordinate Measuring Machines (CMM) give you 3D measurements with very high accuracy.

Optical comparators let you check shapes and profiles.

Vision systems use cameras to measure small or delicate features.

Laser scanners collect lots of surface data quickly.

You should measure parts in a room with controlled temperature. This stops errors from heat or cold. Some shops use multisensor systems. These combine cameras, touch probes, and digital overlays. They help you check both small details and large areas without moving the part. You get fast, repeatable results. This makes sure your CNC-Machined Parts always meet the tight standards needed for cameras.

Tip: Always check your parts with the right tools. This helps you catch mistakes early and keep your camera parts working well.

The way a part looks and feels matters for cameras. Surface finish affects how parts fit together, how long they last, and how they look. You have many ways to finish 304 stainless steel camera parts. Each method gives a different texture and level of shine.

Here are some common surface finish options:

As-Machined Finish: You see tool marks, but the part keeps high precision.

Bead Blasting: This gives a smooth, matte surface by shooting tiny beads at the part.

Polishing: You buff the part until it shines like a mirror.

Brushed Finish: You get a straight, lined texture that looks modern and clean.

Electroplating: You add a thin metal layer for better corrosion resistance and a new look.

Passivation: You use chemicals to make a protective layer that stops rust.

Sandblasting: You remove dark spots or oxide layers with pressurized sand.

Pickling: You use acids to clean the surface and remove oxides.

Mechanical Polishing: You use machines to make the part very shiny.

Electrochemical Polishing: You use electricity and chemicals for a bright, smooth finish.

Chemical Oxidation: You create a colored or protective layer with chemicals.

Color Coating via Salt Immersion: You dip the part in special salts to add color.

Each finish changes how the part works and looks. For example:

A rough finish may cost less, but it can show scratches and wear faster.

Bead blasting gives a soft, even look that hides small marks.

Polishing makes the part shiny and smooth, which is good for parts you see or touch.

Passivation protects against rust without changing the look.

Electroplating adds both beauty and extra protection.

You should pick a finish based on what your camera needs. If you want parts that last longer and look great, choose a finish that adds both protection and style. Good surface finishes also help you spot defects like scratches or dents. This keeps your camera looking sharp and working well.

Note: The right surface finish helps your camera parts resist wear, fight rust, and look their best. It also makes sure every part fits and moves as it should.

When you machine 304 stainless steel for camera parts, you need to pick the right tools and settings. This helps you get smooth surfaces and tight tolerances. Here are some important steps you should follow:

Use carbide tools with high toughness and heat resistance. Tools coated with TiAlN or AlTiN last longer and reduce friction.

Choose positive rake angle inserts. These lower cutting forces and help chips break away cleanly.

Keep cutting speeds between 150-250 SFM. Lower speeds help control heat and protect your tools.

Set moderate feed rates. This avoids tool rubbing and helps remove chips.

Adjust the depth of cut so the tool stays engaged. Avoid shallow cuts that can cause work hardening.

Use high-pressure coolant systems. Direct coolant at the tool-chip area to flush chips and keep things cool.

Never pause or dwell mid-cut. This prevents work hardening and keeps your part smooth.

Pick machines with high rigidity. This reduces vibration and keeps your cuts accurate.

Clamp your workpiece tightly. This stops chatter and gives you a better surface finish.

Check your tools often for wear. Replace them as needed to keep quality high.

Tip: Always use sharp tools and keep your machine in good shape. This helps you avoid mistakes and get the best results.

You want every camera part to meet strict standards. Quality control makes sure your parts fit and work as they should. You can use many tools and checks during and after machining:

Calipers and micrometers measure outside and inside sizes with high accuracy.

Coordinate Measuring Machines (CMMs) check complex shapes and tight tolerances. Some CMMs use probes and cameras to inspect hard-to-reach features.

Surface roughness testers, like profilometers, check how smooth your part is.

Hardness testers make sure your material is strong enough.

Non-destructive tests, such as ultrasonic or X-ray, find hidden cracks or flaws.

Statistical Process Control (SPC) software tracks your process and spots trends.

Tool monitoring systems warn you when tools wear out.

Environmental sensors watch temperature and humidity to keep conditions steady.

Visual inspections with magnifiers or microscopes catch small defects.

Assembly tests check if parts fit together and work in the final camera.

Good records and traceability help you prove your parts meet all requirements.

Using CMMs gives you very accurate measurements. This helps you catch problems early and avoid costly mistakes. You can trust your camera parts to meet the highest standards every time.

You want your camera to work every time. CNC-Machined Parts help make this happen. These parts are made with high precision. They have tight tolerances. Camera mounts and sensor platforms stay steady and correct. Stabilization parts do not move out of place. Every part is made the same way. This means fewer problems and less time fixing things.

CNC machining makes sure your camera parts always match. You do not need to worry about parts not fitting.

In hard places like aerospace or defense, CNC-machined gimbal parts keep cameras steady.

Entertainment and robotics use these gimbals for smooth moves. This means fewer repairs.

Medical imaging uses these parts for clear, sharp pictures.

CNC machining can make parts with tolerances as close as ±0.0025 mm. Special finishes like anodizing or electropolishing help parts last longer. These finishes stop rust and wear. A study showed that CNC ball burnishing can make 304 stainless steel parts last three times longer. This means your camera parts will not break as often.

Tip: Using CNC-Machined Parts gives you strong and steady camera systems. They work well in many different jobs.

You might need camera parts for many uses. CNC machining lets you change each part to fit your needs. You can pick from many materials, shapes, and finishes. The process lets you make and test new designs fast. You can change things before making lots of parts. This helps you get the part you want.

CNC machining works for small or big orders. Small batches let you make changes quickly. Big orders give you the same quality every time. You can add logos, special coatings, or cool shapes. This is important for cameras in photos, planes, or hospitals.

Cost depends on what you use and how many you make. 304 stainless steel costs less than titanium. But it is harder to machine than aluminum. This can make it cost more because tools wear out faster. It also takes more time. For small batches, CNC machining may cost more than 3D printing. For big batches, molding can be cheaper. Still, CNC-Machined Parts give you the best mix of quality and custom choices.

Note: Always think about what you need and your budget. CNC machining gives you many ways to get the right camera part.

You can count on CNC-Machined Parts to make your camera work well. These parts help your camera have the right shape and smooth look. CNC turning and milling let you pick how fast you cut and which tool you use. If you choose 304 stainless steel and use the best steps, your camera parts will be strong and not rust.

Advanced machines and careful steps give you very exact parts and smooth surfaces.

You can make special designs and change them quickly to keep up with new camera ideas.

Using smart machines and tools helps you make parts faster and with fewer mistakes.

Picking CNC-Machined Parts lets you build cameras that last a long time and work great.

You get strong, rust-resistant parts with 304 stainless steel. This metal stands up to water and chemicals. It also keeps its shape well. You can trust it for camera parts that need to last.

CNC machines can make parts with tolerances as tight as ±0.005 mm. You get parts that fit together perfectly. This helps your camera work better and last longer.

Yes! You can pick different finishes like bead blasting, polishing, or brushing. You can also add logos or special coatings. This lets you match your camera’s style or brand.

CNC parts may cost more for small batches. You pay for high precision and custom options. For large orders, CNC machining can save money because you get fewer mistakes and less waste.

You use tools like calipers, CMMs, and surface testers. These tools measure size, shape, and smoothness. You also check how parts fit together. Good checks help you catch problems early.

Navigation

Navigation

Contact Us

Tel: +86 13417419143

E-mail: [email protected]

Add:

2nd Floor, Building 7, 156 High Tech Industrial Park, Fuyuan 1st Road, Zhancheng Community, Fuhai Street, Baoan District, Shenzhen City, China.