Oct.

21, 2025

Contents

CNC Machining Titanium vs. Steel: An Engineer's Guide

When you look at CNC Machining titanium and steel, you notice big differences in price, how easy they are to machine, and how they work. Titanium is strong for its weight and does not rust easily, but it costs more and wears out tools faster. Steel is easier to machine, keeps its shape better, and costs less. For a fast summary, see the table below:

Aspect | Titanium | Stainless Steel |

|---|---|---|

Cost | High | Lower |

Machinability | Challenging | Easier |

Performance | Lightweight, corrosion resistant | Durable, impact resistant |

Tolerance | Hard to maintain | More consistent |

There are many grades and types of titanium and steel in CNC Machining. Titanium has grades like Grade 1, Grade 2, Grade 5, and Grade 23. Each grade is good for different things. Steel comes in carbon steel, alloy steel, stainless steel, and tool steel. These types change how hard, strong, or rust-proof the steel is.

Grade | Composition | Key Properties | Applications |

|---|---|---|---|

Grade 1 | Commercially pure, low O₂ | Highest ductility | Chemical processing |

Grade 2 | Commercially pure, std O₂ | Balanced properties | Marine equipment |

Grade 5 | 6% Al, 4% V alloy | High strength, heat resistance | Aerospace, medical |

Grade 23 | Extra-low interstitial | Superior biocompatibility | Medical implants |

Carbon steel: Hardness and strength can be different.

Alloy steel: Has chromium or nickel to make it better.

Stainless steel: Has at least 10.5% chromium to stop rust.

Tool steel: Very tough, used to make tools.

Titanium is strong but not heavy. It gives you strong parts that do not weigh much. Titanium’s density is about 4.5 g/cm³. Steel is heavier with a density of 7.85 g/cm³. Steel can be stronger, but it weighs more. This is why titanium is used in planes and medical parts.

Material | Yield Strength (MPa) | Density (g/cm³) | Weight Comparison |

|---|---|---|---|

Titanium | 172 to 483 | ~4.57 | 43% lighter |

Stainless Steel | 170 to >790 | ~8 | Heavier |

Tip: Pick titanium if you want strong and light parts. Pick steel if you need high strength and weight is not a problem.

Titanium does not rust, even in salt water or strong chemicals. It lasts longer in tough places. Stainless steel also fights rust, but not as well as titanium in really harsh spots.

Material | Corrosion Resistance Rating | Impact on Longevity |

|---|---|---|

Titanium | Superior | Longer lifespan in harsh environments |

Stainless Steel | Good | Moderate lifespan |

Titanium alloys like Ti-6Al-4V stay strong and do not rust.

Stainless steel works in many places but can fail in very tough spots.

Titanium can bend more before breaking. Its Young’s modulus is about half of steel’s, so it is less stiff. Steel is stiffer and keeps its shape better. Use steel if you do not want the part to bend. Use titanium if you want it to bend a little and be lighter.

Property | Titanium (Ti-6Al-4V) | Stainless Steel |

|---|---|---|

Young’s Modulus | 114 GPa | ~200 GPa |

Flexibility | Higher | Lower |

Stiffness | Lower | Higher |

Note: Knowing these facts helps you choose the best material for your CNC Machining project.

Picking tools for CNC Machining titanium and steel is not the same. Titanium is hard to cut and gets very hot. It can react with cutting tools when it is hot. You should use carbide or coated tools for titanium. These tools handle heat and last longer. For steel, you can use high-speed steel or carbide tools. Steel does not need as many special coatings.

Titanium does not move heat away well. Heat stays at the tool tip and can hurt the tool.

Titanium can stick to the tool when hot. This can mess up the part’s surface.

Steel moves heat away better. Tools last longer with steel.

Tip: Always look at what the tool maker says before you start. The right tool saves you time and money.

Tools wear out faster with titanium. You see more chemical wear and diffusion. Titanium makes a layer called titanium carbide (TiC) on the tool. This layer can also hurt the tool. Steel does not wear out tools as fast. You can make more parts before changing tools.

Tool Material | Titanium | Steel |

|---|---|---|

Wear Mechanism | Diffusion, chemical wear | N/A |

Tool Protection Layer | TiC generated from titanium reaction | N/A |

Factor | Titanium | Steel |

|---|---|---|

Thermal Conductivity | Low | Higher |

Strength | High | Moderate |

Tool Wear Mechanisms | Adhesive, Abrasive, Diffusion | Less severe wear mechanisms |

Recommended Cutting Speed | 30-60 m/min | Higher than titanium |

Feed Rate Reduction | 20-40% compared to steel | N/A |

Depth of Cut | Limited to prevent tool damage | N/A |

Mechanism of Wear | Titanium | Steel |

|---|---|---|

Primary Wear Mechanism | Diffusion and dissolution | Less significant |

Influence of Cutting Conditions | Attrition and diffusion at higher rates | N/A |

Factor | Titanium | Steel |

|---|---|---|

Tool Selection | Requires careful attention | Standard practices |

Cutting Speed | Slower due to hardness | Faster |

Maintenance | More frequent due to wear | N/A |

Note: You will need to change tools more often with titanium. Plan for more maintenance to keep things running well.

You need different settings for titanium and steel. Titanium needs slower speeds and lower feed rates. This stops the tool from getting too hot or breaking. Steel can use faster speeds and higher feeds. This lets you finish parts faster.

For titanium:

Cutting Speed: 30 to 60 SFM (9 to 18 m/min)

Feed Rate: 0.002 to 0.005 IPR

Depth of Cut: 0.04 to 0.08 inches

For stainless steel:

Cutting Speed: 70 to 100 SFM (21 to 30 m/min)

Feed Rate: 0.004 to 0.008 IPR

Depth of Cut: 0.03 to 0.06 inches

Slower speeds for titanium mean it takes longer to make each part.

Faster speeds for steel help you finish jobs quicker.

Tip: Always change your CNC Machining settings for the material. This helps you get good results and keeps tools from breaking.

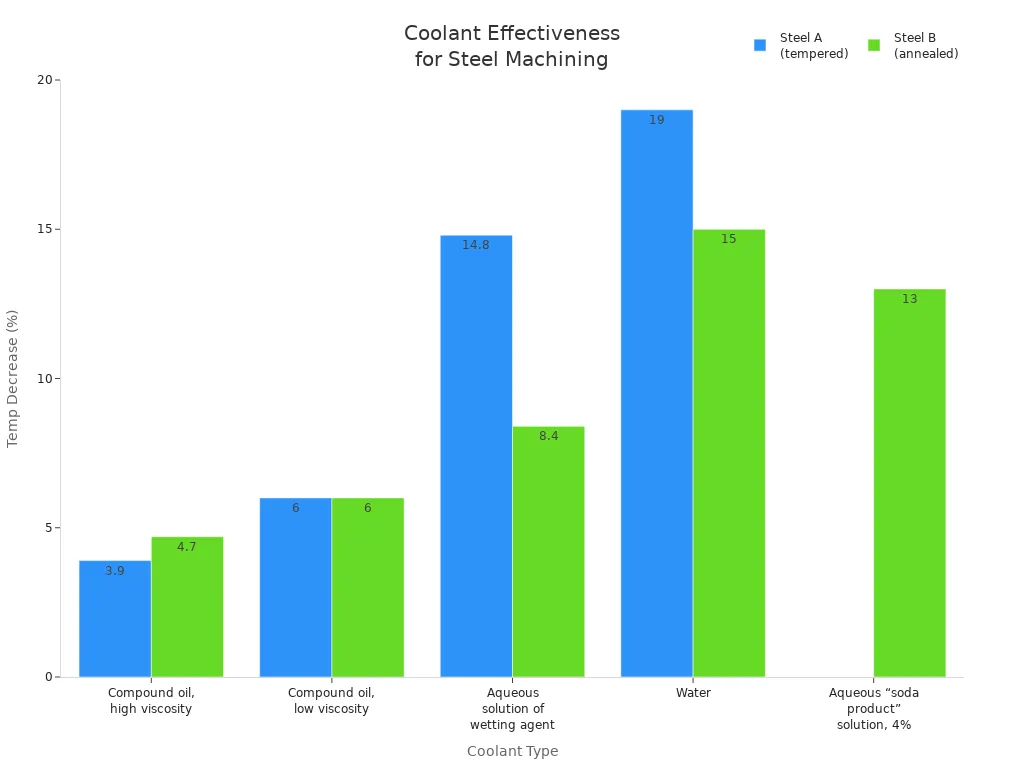

Coolant is very important in CNC Machining. Titanium gets hot fast, so you need a lot of flood coolant. This keeps the tool and part cool. It also stops rough edges and keeps the part smooth. Steel does not need as much coolant. But you should still use flood or mist coolant to clear chips and help the tool move.

Coolant Type | Specific Heat | Steel A (tempered) Temp Decrease % | Steel B (annealed) Temp Decrease % |

|---|---|---|---|

Air | 0.25 | N/A | N/A |

Compound oil, high viscosity | 0.489 | 3.9 | 4.7 |

Compound oil, low viscosity | 0.556 | 6 | 6 |

Aqueous solution of wetting agent | 0.872 | 14.8 | 8.4 |

Aqueous “soda product” solution, 4% | 0.923 | N/A | 13 |

Water | 1.00 | 19 | 15 |

For titanium, use lots of flood coolant to keep things cool and stop rough edges.

For steel, use flood or mist coolant to clear chips and help the tool work well.

Note: Using coolant the right way gives you better parts and helps your tools last longer.

When you turn titanium, you face more challenges than with steel. Titanium can work-harden if your tool stays in one spot too long. It does not move heat away well, so the cutting edge gets very hot. You often see long, stringy chips that make chip removal hard. Titanium’s elasticity can cause the part to bend under tool pressure, which leads to chatter.

Use sharp, heat-resistant carbide tools with special coatings like TiAlN.

Apply plenty of coolant to keep the tool and part cool.

Hold the workpiece tightly to stop vibration.

Choose lower RPMs and higher torque to handle the cutting forces.

Steel turning is easier. You can use standard tools and higher speeds. Chips break more easily, and heat spreads out better, so tools last longer.

Tip: Always check your setup before turning titanium. Stable workholding and the right tool make a big difference.

Milling titanium is harder than milling steel. You need to adjust your cutting angle and use more coolant to stop overheating. Titanium creates strong cutting forces and vibrations. If you do not plan your toolpath well, your tool might slip or even break. Trochoidal milling paths help keep the cutter engaged and reduce shock.

When you mill titanium, use rigid machines. Roll into the cut and keep your speed steady, especially in corners. This helps you avoid tool pull-out and keeps your part accurate.

Steel is more forgiving. You can use faster speeds and less coolant. The risk of tool breakage is lower, and you get smoother cuts.

Drilling titanium needs special care. Titanium work-hardens fast and does not let heat escape. Chips can clog the drill, and the metal can spring back after cutting. Use drills with higher point angles, split points, and polished flutes. Coolant-through drills help remove chips and keep things cool.

Use slower speeds (20-40 SFM for pure titanium) and higher feed rates.

Try peck drilling to clear chips and avoid tool dwell.

Specialized drills can improve tool life and hole quality by up to 300%.

Steel drilling is simpler. Standard drills work well, and you can use higher speeds. Chips clear out more easily, and holes stay accurate.

Note: For CNC Machining, always match your tools and settings to the material. This keeps your parts high quality and your tools in good shape.

When you machine titanium, the surface is often rougher than steel. Titanium keeps heat at the cutting edge. This heat can make the tool wear out fast. It can also leave marks on the part. Titanium makes long, stringy chips. If you do not remove these chips, they can scratch the part.

Steel usually gives a smoother finish. Steel moves heat away from the cutting area faster. This helps the tool last longer. The surface stays cleaner. Steel is stiffer, so the part does not bend much. You get less vibration and a more even surface.

Tip: If you want a shiny, smooth part, steel is easier to use. For titanium, use sharp tools and lots of coolant to help the finish.

You need to think about how close your part’s size is to your design. Titanium and steel act differently when you try to keep tight tolerances. Titanium can move or spring back after cutting. This is because it is not as stiff. It is harder to keep exact sizes with titanium.

Steel keeps its shape better. Its hardness and strength stop it from bending or warping. You can often get tighter tolerances with steel parts.

Here is a quick look at typical tolerances you can expect:

Material Category | Examples | Typical Tolerance (Linear Dimensions) | Tight Tolerance (Achievable with Process Control) |

|---|---|---|---|

Metals (Challenging) | Titanium, Inconel | ±0.1 mm (±.004″) | ±0.05 mm (±.002″) |

Several things affect how well you can hold tolerances:

Hardness & Strength: Harder materials like steel keep their shape better.

Thermal Conductivity: Materials that move heat away, like steel, do not expand as much.

Internal Stresses: Some metals have built-in stresses that can cause warping.

Toughness/Brittleness: Tough metals make long chips that can hurt the surface. Brittle ones may chip.

Note: Always check your part after machining. Measure it to make sure it meets your tolerance needs.

Titanium is used in many fields because it has special features. It is light and strong. It does not rust. These things make it great when weight and strength are important. You see titanium in airplanes and medical tools. It is also in sports gear. Titanium is good for chemical plants and the sea. This is because it does not corrode.

Here is a table that shows where titanium is used and why:

Application | Properties Supporting Use |

|---|---|

Aerospace | Lightweight, high strength, excellent corrosion resistance |

Medical | Biocompatibility, corrosion resistance |

Automotive | High strength, lightweight |

Chemical Processing | Corrosion resistance, high-temperature performance |

Marine | Corrosion resistance, lightweight |

Sports Equipment | Lightweight, high strength |

Tip: Pick titanium if you need a part that is light and lasts long. Titanium is also good if you want parts that do not react with the body or strong chemicals.

Steel is used a lot in CNC machining. You use steel when you want parts that are tough and strong. Steel is found in medical tools, cars, and planes. It is also in food factories. Stainless steel is liked because it does not rust. It is easy to keep clean. Steel is also used in the sea and energy fields.

Here is a table that shows where steel is used and why:

Industry | Primary Requirement | Common Stainless Steel Grades | Example Application |

|---|---|---|---|

Medical | Sterilizability, Biocompatibility | 316L, 420, 440C | Surgical Instruments, Implants |

Aerospace | High Strength-to-Weight Ratio | 17-4 PH, 15-5 PH | Engine Components, Landing Gear |

Automotive | Heat and Corrosion Resistance | 304, 409, 316 | Exhaust Systems, Sensor Housings |

You pick steel for these reasons: It can take heat and stress. It does not rust and stays clean. It lasts a long time, even in hard jobs.

Note: Pick steel if you need a part that is strong, safe, and easy to clean. Steel is also good if you want parts that can take high heat or heavy loads.

When you choose a material for CNC machining, cost matters a lot. Titanium costs much more than steel. You see this difference in the price per pound:

Grade 5 titanium: $40–$60 per pound

Steel: $1–$2.50 per pound

Titanium is much more expensive than many other metals, including steel.

If you need to keep your project budget low, steel gives you a big advantage. Titanium’s high price can add up fast, especially for large parts or high-volume production.

You also need to think about how long your cutting tools last. When you machine titanium, tools wear out quickly. Titanium does not move heat away from the cutting edge. About 60% of the heat stays in the tool. This makes the tool get hot and wear out faster. You will need to replace tools more often when working with titanium. This increases your costs for cutting tools and can slow down your work.

Steel is easier on your tools. More heat goes into the chips and away from the tool. Tools last longer, so you spend less money on replacements. You can run your machines longer without stopping to change tools.

Tip: If you want to save money on tools and reduce downtime, steel is a better choice.

Production speed changes based on the material you pick. Titanium takes longer to machine than steel. Titanium is harder, so you must use slower cutting speeds. The tool also wears out faster, which means more stops for tool changes. These factors slow down your whole process.

Steel lets you machine parts faster. You can use higher speeds and feeds. Your tools last longer, so you do not need to stop as often. This helps you finish jobs quicker and keep your costs down.

Factor | Titanium | Steel |

|---|---|---|

Material Cost | High | Low |

Tool Life | Short | Long |

Production Speed | Slow | Fast |

Note: Always consider these economic factors when you plan your CNC machining project. The right choice can save you time and money.

When you machine metal parts, you make a lot of waste. CNC machining cuts away material to shape each part. For stainless steel, you might throw away 30% to 50% as scrap. Titanium machining also makes a lot of waste. You can make less waste if you plan your toolpaths better. One company made 20% less titanium waste by changing how they cut. Some factories use near-net-shape blanks for steel. This helped a European car parts maker cut steel waste by one third.

Most scrap from CNC machining can be recycled. Steel and titanium are both easy to recycle. If you sort your scrap well, you can recycle up to 90%. Recycling saves money and helps the environment. You should always collect and sort scrap after each job. This makes recycling simple and works better.

Machining stainless steel can waste up to half the material.

Titanium machining also makes a lot of scrap.

Better toolpaths can cut titanium waste by 20%.

Near-net-shape blanks can lower steel waste by a third.

Good scrap management lets you recycle up to 90%.

Tip: You can help the environment by recycling scrap and using smart machining plans.

Machining titanium uses much more energy than steel. Titanium is harder to cut, so you need more power. You also use more energy to keep tools cool and sharp. Machining titanium parts with CNC uses four to six times more energy than metal additive manufacturing. All this extra energy means more carbon emissions. This is bad for the environment and makes your process less green.

Steel machining uses less energy. You can finish parts faster and use less power. Using less energy means fewer emissions and a smaller carbon footprint. If you want your shop to be greener, pick steel when you can.

Machining titanium needs almost ten times more energy than steel.

More energy use means more carbon emissions.

Steel machining is quicker and uses less power.

Using less energy helps protect the planet.

Note: You can help the earth by picking materials and machining ways that use less energy.

When you pick between titanium and steel, you must think about a few things. Each one has good and bad points. The table below shows how they compare:

Factor | Titanium | Stainless Steel |

|---|---|---|

Corrosion Resistance | Superior, ideal for marine use | Less resistant |

Conductivity | Less conductive | More conductive |

Strength | Higher strength-to-weight ratio | Lower strength-to-weight ratio |

Metal Cost | Generally more expensive | Generally less expensive |

Other Considerations | Weight, durability, machinability | Weight, durability, machinability |

Pick titanium if you need a part that will not rust. It is great for saltwater or strong chemicals. Titanium is best when you want parts that are strong but not heavy. Pick steel if you want a part that is tough and easy to make. Steel costs less and is good if you need it to carry heat or electricity.

Tip: Always choose the material that fits your project. Think about where you will use it, how much it weighs, and how much you can spend.

You can do better CNC machining if you follow some easy steps. These tips help you save time and keep your tools safe. They also help you make good parts:

Use peck drilling and ramping. These keep your tools cool and stop the metal from getting too hard.

Hold your workpiece tight. This stops shaking and keeps your part still.

Try high-speed machining. Use spindle speeds of at least 12,000 RPM to stop heat from building up.

Use lots of coolant on the cutting area. Coolant keeps things from getting too hot.

Pick special tool coatings for titanium. These coatings help your tools last longer and cut better.

Note: A good setup and the right steps help you get better results. Always check your machine and tools before you start.

You have to make a big choice between titanium and steel for CNC machining. The table below shows how they are different:

Aspect | Titanium | Steel |

|---|---|---|

Material Properties | Lightweight, strong, corrosion resistant | Durable, versatile, high strength |

Tool Selection | Needs carbide tools, special coatings | More tool options |

Machining Strategies | Slow speeds, strong cooling | Faster speeds, easier cooling |

Surface Finish | Needs careful control | Easier to achieve good finish |

Economic Considerations | Expensive, high tool wear | Cost-effective, easy to source |

Environmental Impact | Energy-intensive, recyclable | Lower impact, recyclable |

Titanium costs a lot more than steel. It needs careful machining. Steel is strong and saves you money. Pick the material that fits your project.

If you pick the wrong material, tools wear out faster and work slows down.

If you do not use the right tool shape, the machine can shake and parts may not be accurate.

If you use the wrong cutting settings, things can break.

If you do not control heat, tools and parts get too hot.

If you do not check tool wear, part quality goes down.

Tip: Think about how well the material works, how much it costs, and how easy it is to make. This helps you get the best results.

Titanium holds heat at the cutting edge. You see more tool wear and slower machining speeds. Steel moves heat away faster. You finish jobs quicker and change tools less often.

You need special carbide or coated tools for titanium. Standard high-speed steel tools work for steel. Using the wrong tool can cause breakage or poor part quality.

Titanium is rare and hard to process. You pay more for raw material and machining time. Steel is common and easier to shape. You save money on both material and labor.

Titanium resists corrosion much better than steel. You should pick titanium for marine or chemical use. Stainless steel works well but may fail in extreme conditions.

Navigation

Navigation

Contact Us

Tel: +86 13417419143

E-mail: [email protected]

Add:

2nd Floor, Building 7, 156 High Tech Industrial Park, Fuyuan 1st Road, Zhancheng Community, Fuhai Street, Baoan District, Shenzhen City, China.