Jul.

24, 2025

Contents

How to Choose the Right Stainless Steel Grade for Stamping

Stainless Steel Grade Selection

Choosing the right stainless steel grade is important. It affects how well your parts work and last. If you pick a grade like 304 or 316, you get strong corrosion resistance. These grades are also very durable. They work well in tough or harsh places. Grades like 409 can save you money. But they may not look as good or bend as easily. Think about corrosion resistance, strength, formability, cost, and fit for your use. Use a simple, step-by-step plan to match each property to your project.

Corrosion resistance is very important when picking stainless steel for stamping. If your parts will touch water, chemicals, or salt, you must think about rust and damage. Corrosion can happen in different ways. It can cause pitting, crevice corrosion, or stress corrosion cracking. These problems can make your parts break sooner or become unsafe.

| Corrosion Mechanism | Description | Relevant Conditions / Causes |

|---|---|---|

| Pitting Corrosion | Localized corrosion caused by exposure to chloride-containing environments. | Chloride presence; critical in ducts, piping, containment. |

| Crevice Corrosion | Localized attack in oxygen-depleted crevices, severity depends on crevice geometry. | Stagnant solutions with chloride build-up; occurs in nuts, washers, welds, deposits. |

| Bimetallic (Galvanic) Corrosion | Occurs when dissimilar metals contact in an electrolyte, accelerating corrosion of the less noble metal. | Contact with carbon steel bolts; influenced by area ratios, temperature, electrolyte. |

| Stress Corrosion Cracking (SCC) | Requires tensile stress and specific environment; uncommon in normal atmospheres. | Residual stresses from welding/bending; chloride-rich environments like marine or swimming pools. |

| General (Uniform) Corrosion | Much less severe in stainless steel; occurs at very low pH (<1.0). | Exposure to strong acids; chemical contact requires expert advice. |

| Intergranular Attack (Sensitisation and Weld Decay) | Chromium carbide precipitation at grain boundaries reduces corrosion resistance. | Prolonged heating (450-850°C); welding; mitigated by low carbon grades and modern steelmaking. |

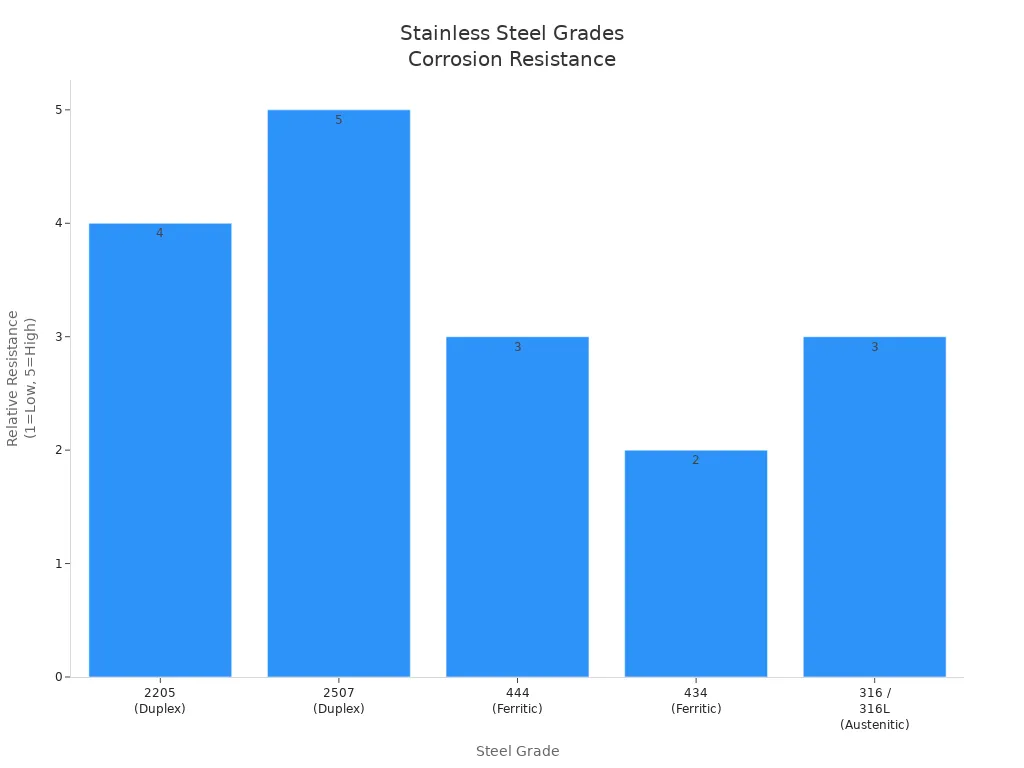

Pick a stainless steel grade that fits your environment’s corrosion risk. Grades like 316 and 316L are best for harsh places. These work well in marine or chemical areas. They stop pitting and crevice corrosion, which happen in salty or wet spots. Duplex grades like 2205 and 2507 are even stronger and resist corrosion better. Ferritic grades such as 444 and 434 also protect well, especially in hot or food processing places.

If you live in a dry area, you can use 304 or 316. In wet or polluted places, 316 is a better pick. The surface finish matters too. A smooth, shiny finish on 316 helps it last longer in salty air.

You should match the stainless steel grade to your job and location. Here is a quick guide:

| Stainless Steel Grade | Salt Spray Test Conditions | Corrosion Resistance Outcome |

|---|---|---|

| 316 | 3% salt spray, 96 hours | Passes test, superior corrosion resistance |

| 304 | 3% salt spray | Does not perform satisfactorily |

| 304 | 0.3% salt spray, up to 120 hours | May be acceptable under reduced salt concentration |

| 409 (similar to 430) | 0.3% salt spray, similar to 304 | Less corrosion resistant than 316 |

Use 316 for marine gear, chemical plants, or medical tools. It has molybdenum, which helps stop rust in tough places.

Pick 304 for kitchen items, food work, or things used at home. It is good for less harsh places but does not fight salt or chemicals as well as 316.

Choose 409 for car exhausts or places with some corrosion risk. It costs less but is not good for wet or salty spots.

Tip: Always think about where your part will be used and what kind of corrosion it might face. Tests like salt spray or soaking can help you compare grades before you decide.

Mechanical properties show how your stamped part acts under stress. You should check both strength and ductility before picking a stainless steel grade for stamping. These properties change how your part bends, stretches, or holds up when used.

If your part must hold heavy weight or fight wear, focus on strength and hardness. Some stainless steels are best for these needs. Martensitic grades like 440C and 420 get very hard after heat treatment. Precipitation-hardening grades like 17-4 PH give you high strength and also resist corrosion. You often see these grades in planes, chemical plants, and places with lots of wear.

| Stainless Steel Grade | Tensile Strength | Hardness (Rockwell C) | Typical Use |

|---|---|---|---|

| 17-4PH (H900) | ~203 ksi (1400 MPa) | ~44 | Aerospace, marine, chemical parts |

| 420 (Hardened) | N/A | 50+ | Cutting tools, surgical instruments |

| 440C (Heat treated) | ~110 ksi | 58-60 | Bearings, valves, high-wear parts |

Grades like 17-4 PH can be heat-treated and make strong, tough parts. Austenitic grades like 304 and 316 are not as hard but are easier to shape. You need to balance strength with how easy it is to form the metal.

Note: If strength goes up, formability often goes down. It can be harder to stamp very strong grades into tricky shapes.

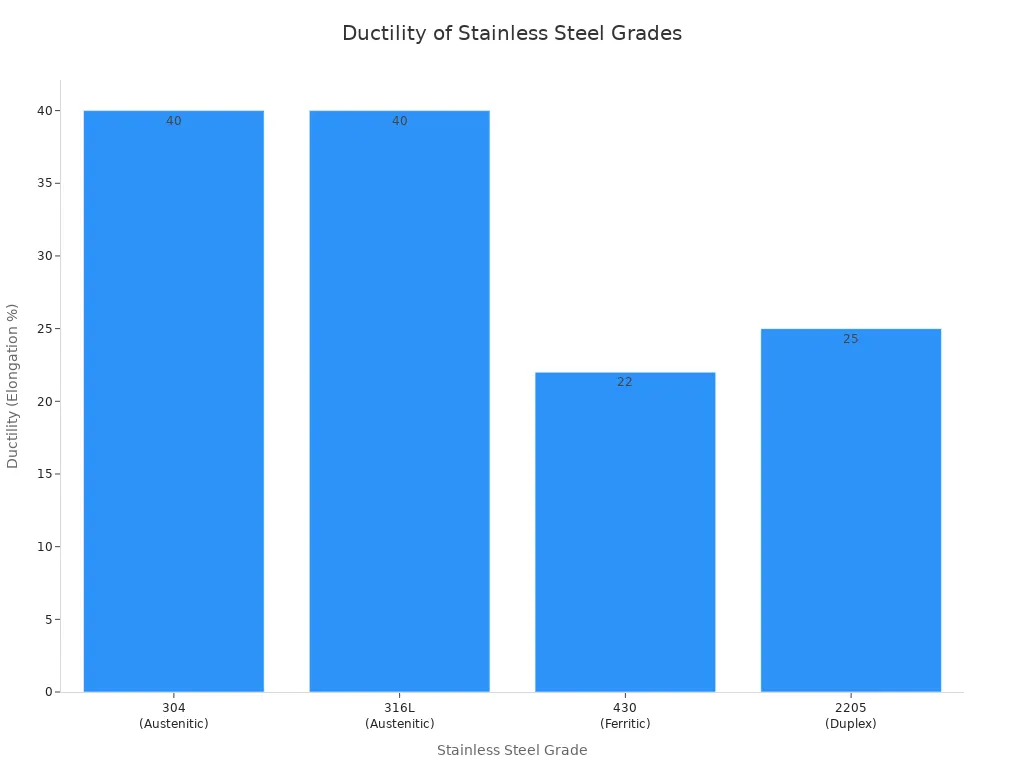

Ductility means a metal can stretch or bend before it breaks. Toughness means the metal can take hits without cracking. For stamping, you want high ductility and toughness so your part does not crack or split.

| Stainless Steel Grade | Ductility (Elongation %) | Description |

|---|---|---|

| 304 (Austenitic) | ~40% | Very high ductility, easy to stamp |

| 316L (Austenitic) | ~40% | High ductility, good for forming |

| 430 (Ferritic) | ~22% | Medium ductility, less flexible than 304/316L |

| 2205 (Duplex) | ~25% | Medium ductility, higher strength |

| Martensitic grades | Low | Not recommended for deep stamping |

Austenitic grades like 304 and 316L have the best ductility. These grades let you stamp deep or tricky shapes. Ferritic and duplex grades have medium ductility, so they work for simpler shapes. Martensitic grades are strong but can crack if you bend them too far.

Grade 302 is great for toughness and ductility. You can use it for springs, clips, and parts that need to bend.

Cold working 302 makes it harder, so it works even better for tough stamping jobs.

Tip: Always pick mechanical properties that fit your stamping job. If you need both strength and easy shaping, try austenitic grades for most uses. Use martensitic or precipitation-hardening grades only if you need extra strength and wear resistance.

If you want to stamp stainless steel, pick a grade that bends easily. It should not crack when you shape it. Austenitic grades like 304, 316, and 301 are best for this. These grades let you make deep and tricky shapes. People use them for kitchen sinks, pots, and medical tools.

| Stainless Steel Grade | Formability for Deep Drawing and Complex Stamping |

|---|---|

| 304 | Excellent; great for deep drawing |

| 316 | Very good; handles complex shapes well |

| 301 | High flexibility; ideal for tricky stamping |

| 430 | Good for simple shapes; less flexible than 304 |

| 304L, 316L | Similar to 304/316, with better weldability |

Formability is not just about the grade. The type of stainless steel and its chemical mix matter too. How hard or soft the steel is also changes how it bends. Soft, fully annealed steel bends better than hard steel. Ductility means the metal can stretch without breaking. If you need deep or thin shapes, pick a grade with high ductility and low work hardening.

Tip: Pick a stainless steel grade with high ductility for deep drawing. Grades like 305 have even more ductility and lower work hardening. This makes them great for tough stamping jobs.

Weldability means how easy it is to join stainless steel pieces. Austenitic grades like 304 and 316 are the easiest to weld. You can use many welding methods on them. They stay strong and resist rust after welding. Ferritic grades like 430 can be welded if you use the right filler. But they might lose some rust resistance. Martensitic grades like 420 are hard to weld. They can crack because they have a lot of carbon.

| Stainless Steel Grade | Weldability |

|---|---|

| Austenitic | Very High |

| Ferritic | Low |

| Martensitic | Low |

When you weld stainless steel, you might have problems:

Gas bubbles from dirty parts

Weak welds if the heat is too low

Cracks from stress or dirt

Warping from uneven heat

You can stop these problems by cleaning the parts well. Use the right welding method and control the heat. TIG welding is best for thin or neat welds. MIG welding is faster for thick parts. Always match your welding style and joint to the grade you use.

Note: Picking the right stainless steel grade helps you get strong, clean welds. It also keeps your parts looking good and lasting longer.

You must pick the right stainless steel grade for your stamping job. Different industries need different things. For example, cars, food factories, and hospitals all want special features. The table below helps you compare what matters most for each use:

| Criteria / Application | Automotive (e.g., 409, 430) | Food Processing (e.g., 304, 316) | Medical Devices (e.g., 316, 17-4 PH) |

|---|---|---|---|

| Corrosion Resistance | Good (suitable for exhaust systems, decorative) | Excellent (resistant to acids, hygienic surfaces) | Excellent (resistant to body fluids, sterilization) |

| Mechanical Properties | Medium strength and formability | High ductility and formability | High strength (especially precipitation-hardening grades) |

| Weldability | Moderate to low | High | Moderate to low (depends on grade) |

| Formability | Good | Excellent | Moderate |

| Heat Treatment Capability | Limited | Limited | Available (especially in PH grades for strength) |

| Hygienic / Biocompatibility | Not critical | Critical (smooth, easy to clean) | Critical (biocompatible, sterilizable) |

This table can help you choose the best grade for your needs. If you work with food, you need a grade that does not rust and is simple to clean. Grades like 304 and 316 are good for this. For cars, grades like 409 and 430 are cheaper and easy to shape. For medical tools, you need strong metal that is safe for the body. Grades like 316 and 17-4 PH are used a lot.

Austenitic grades like 304 and 316 are great for food and medical jobs. They do not rust and are easy to keep clean.

Ferritic grades such as 409 and 430 are used in cars. They are easy to shape and cost less.

Martensitic and precipitation-hardening grades, like 17-4 PH, are picked for medical tools that need to be strong and safe in the body.

Rules also help you decide which grade to use. For food and medical stamping, you must use grades that meet health and safety rules. These rules make sure your parts do not let germs grow and can handle strong cleaning. In airplanes, there are strict rules about what goes into the steel and how strong it must be. You have to follow these rules to keep people safe.

Tip: Always check if your project has special rules or standards. Picking the right grade keeps your parts safe and helps you avoid mistakes.

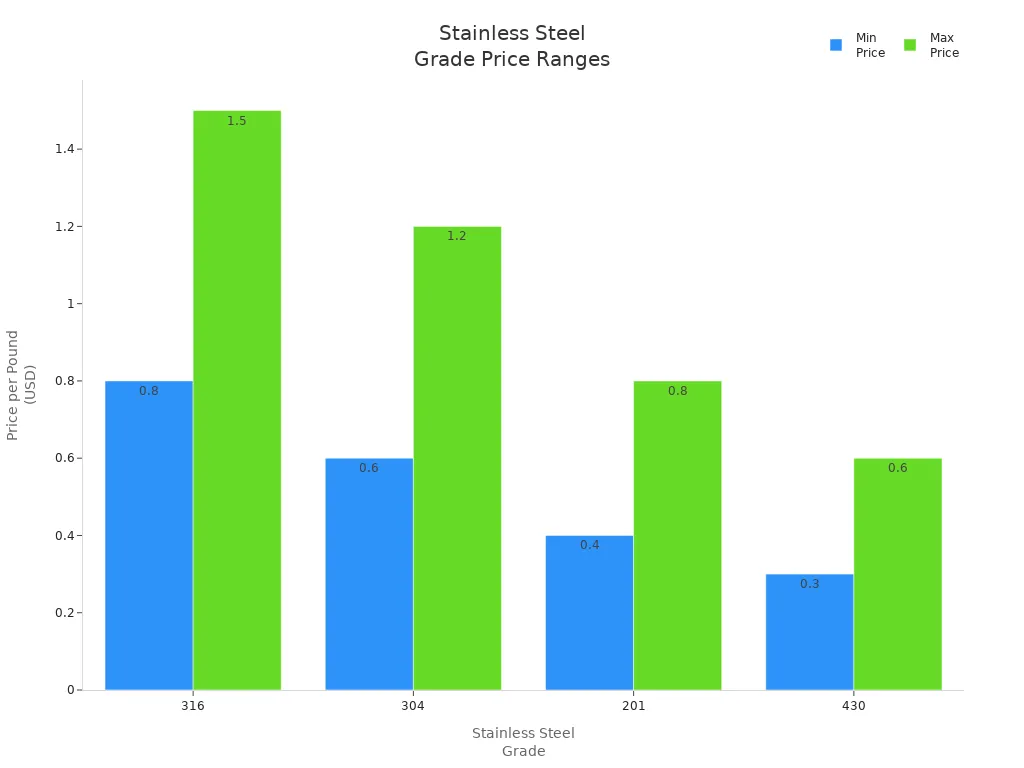

You should think about both price and how well the steel works. Some grades cost more because they have special metals inside. Others are cheaper but may not last as long in hard places. The table below shows how much some grades usually cost:

| Stainless Steel Grade | Relative Scrap Value | Typical Price Range (per pound) |

|---|---|---|

| 316 | Highest | $0.80 – $1.50 |

| 304 | High | $0.60 – $1.20 |

| 201 | Medium | $0.40 – $0.80 |

| 430 | Low | $0.30 – $0.60 |

Grades like 304 are easy to find and get fast. You can buy them from local sellers in just a few days. This helps you finish your stamping job quickly. Grades like 316L or 17-4 PH might take longer to get. They may also need special tools or heat, which adds time and money.

| Stainless Steel Grade | Procurement Lead Time | Machining Characteristics | Impact on Lead Time |

|---|---|---|---|

| 304 | Ships within days | Machines fast with standard tools | Fastest turnaround |

| 316L | 1-2 weeks | Slower machining, needs special tools | Longer lead time |

| 17-4 PH | 1-2 weeks extra | Needs heat treatment after machining | Longest lead time |

Steel prices can change fast. Grades with more nickel, like 316, cost more when nickel prices go up. Grades with less nickel, like 430 or 201, stay about the same price. If you have a big job, these price changes can affect your budget. Many companies make deals or keep extra steel to avoid running out or paying too much.

Pick 304 if you want a good mix of price, quality, and fast delivery.

Choose 201 or 430 for big jobs where saving money is most important and rust is not a big problem.

Use 316 or 17-4 PH only if you need the best rust protection or strength, and you can pay more and wait longer.

Note: Always ask your supplier about prices and how long it takes to get the steel. Planning ahead helps you avoid delays and extra costs.

You have to think about corrosion resistance, strength, how easy it is to shape, price, and if the grade fits your job. Stainless steel has chromium that helps stop rust. Strength and price decide how long your part lasts and how much you spend. If you forget about where your part will be used or pick the wrong grade, you might waste material and time.

For hard projects, ask suppliers or experts for help. Get samples and data to check if the steel bends and works well before you choose.

You will find 304 and 301 grades easiest to stamp. These grades bend well and do not crack. You can use them for deep drawing and complex shapes.

You can weld most grades, but austenitic types like 304 and 316 weld best. Martensitic grades may crack. Always clean your parts before welding for strong joints.

You can use a salt spray test. Place your stamped part in a salty mist and check for rust. Grades like 316 pass this test better than 304 or 409.

Stainless steel usually costs more because it contains nickel and chromium. You pay more for better rust resistance and longer life. Grades like 430 and 201 cost less than 316.

Ask your supplier for advice or request a sample. You can also check technical data sheets. Testing a small batch helps you avoid mistakes.

Navigation

Navigation

Contact Us

Tel: +86 13417419143

E-mail: [email protected]

Add:

2nd Floor, Building 7, 156 High Tech Industrial Park, Fuyuan 1st Road, Zhancheng Community, Fuhai Street, Baoan District, Shenzhen City, China.