Aug.

26, 2025

Contents

EDM Machining: Applications and Benefits in Modern Manufacturing

EDM Machining uses electrical sparks to shape metal parts. It makes parts with high accuracy. Companies in aerospace, automotive, medical, and electronics use this process. They need parts with tight tolerances and complex shapes. EDM Machining helps with hard materials like titanium and superalloys. Modern machines work fast and make detailed features. Other tools cannot match these details. Manufacturers can pick different EDM methods for their needs. This helps them work better and faster.

EDM Machining means Electrical Discharge Machining. It uses electrical sparks to take away metal from a workpiece. The workpiece must let electricity pass through it. A tool called an electrode gets very close to the workpiece. There is a tiny space between them. When electricity flows, sparks jump across this space. The sparks melt and turn small pieces of metal into vapor. A special liquid called dielectric fluid fills the space. This fluid cools the area and removes the melted metal.

There are three main kinds of EDM Machining:

Sinker EDM: Uses a shaped electrode to make 3D shapes like molds and dies.

Wire EDM: Uses a thin wire as the electrode to cut shapes, much like a band saw.

Hole Drilling EDM: Makes small, deep holes in hard metals.

Each kind uses a different electrode and way of working. All types use sparks and do not need the tool to touch the workpiece.

EDM Machining is very important in modern factories. It can shape hard metals like titanium and superalloys. Many industries use this process for parts with tight fits and tricky shapes. For example:

Aerospace companies use EDM to make turbine blades and engine parts.

Medical device makers use it for tools and implants.

Car and electronics companies use EDM for tiny, detailed parts.

EDM Machining can make shapes that other cutting tools cannot. It works well for small or fragile parts because it does not push or bend the metal. The process leaves no sharp edges and often needs little polishing. CNC-controlled EDM machines can follow exact paths, so they are very accurate.

Over the years, EDM Machining has gotten better. Computer controls and stronger materials have made it faster and more exact. Today, many factories use EDM Machining to make very precise parts.

EDM Machining takes away metal using electrical sparks. The tool does not touch the metal part. Sparks jump across a tiny gap and melt small bits of metal. The metal part and electrode sit in a special liquid called dielectric fluid. This fluid cools everything and cleans away melted metal. EDM Machining can shape hard metals and make very exact details because the tool never touches the part.

EDM Type | Principle | Electrode Type | Dielectric Fluid | Material Removal Mechanism | Key Benefits |

|---|---|---|---|---|---|

Wire EDM | Sparks happen between a moving wire and the metal part | Thin wire (brass/tungsten) | Deionized water | Melting and vaporizing small bits | Cuts are exact, shapes are complex, stress is low |

Sinker EDM | Sparks happen between a shaped electrode and the metal part | Shaped electrode (graphite/copper) | Oil or similar fluid | Melting and vaporizing small bits | Makes deep holes, complex shapes, works on hard metals |

Wire EDM uses a thin wire to cut metal. The wire moves through the metal part with help from computers. This way can cut tough metals like titanium and stainless steel. Wire EDM makes parts with very close fits, sometimes as close as ±0.001mm. It can make tricky shapes and tiny details that other machines cannot do. The wire does not wear out or hurt the part. Many companies use Wire EDM for parts that need to be very exact and delicate.

Sinker EDM is also called Ram EDM. It uses a shaped electrode to make 3D holes in metal. Both the electrode and metal part sit in oil or another special liquid. Sinker EDM is good for making molds and dies with deep or tricky shapes. It can work on hard metals like tool steel and Inconel. Sinker EDM is very exact, with fits as close as ±0.004mm. It does not hurt the part, so it is good for thin walls and fragile shapes. Huaruida Precision uses advanced Sinker EDM machines for tough jobs.

Hole Drilling EDM makes tiny, deep holes in hard metals. It uses a thin, spinning electrode to drill holes as small as 30 microns. Aerospace, car, and medical companies use this for things like turbine blades and fuel injectors. Hole Drilling EDM can make lots of parts and drill through metal up to 2 inches thick. Huaruida Precision offers this for fast samples and small batches, making sure the holes are exact and smooth.

Aerospace companies need parts that are very exact. These parts often have tricky shapes. EDM Machining helps makethings like turbine blades and engine parts. It works with strong metals such as titanium and Inconel. Wire EDM can cut sharp corners and hollow spots. Other machines cannot do this. EDM works for both small and big orders. Huaruida Precision uses new EDM machines to meet tough rules. Their team makes good parts fast, even when time is short.

Tip: EDM Machining lets machines work all night without stopping. This saves time and money for aerospace companies.

Medical device makers use EDM Machining for implants and tools. The process does not touch the metal, so it does not hurt it. Wire EDM can cut very hard metals like titanium and nickel alloys. This helps make strong and safe implants. Huaruida Precision can quickly make new medical device samples. Their checks make sure every part is safe and fits well.

Wire EDM helps make small, detailed parts for medical tools.

The process makes it easy to change or fix parts during testing.

Car factories use EDM Machining for engine parts, molds, and connectors. The process makes parts that fit tightly and feel smooth. EDM shapes hard metals with little bending. Huaruida Precision makes special molds and engine parts for cars and electric vehicles. Their fast service helps when parts are needed quickly.

EDM Machining helps make battery connectors and motor cores for electric cars.

The process works for both big and small orders.

Electronics companies need very tiny and detailed parts. EDM Machining, especially micro EDM, can make features as small as 20 microns. This helps make electrical contacts, fiber optic parts, and tiny holes. Huaruida Precision uses thin wire and hole drilling EDM for these small parts. Their team checks each part with special tools to make sure it is right.

EDM can shape hard or breakable materials used in electronics.

The process makes tiny holes and slots that other machines cannot.

Toolmakers use EDM Machining to make special tools from hard metals like steel and tungsten carbide. The process can cut deep shapes and sharp corners very exactly. EDM does not shake, so it avoids mistakes that happen with old milling machines. Huaruida Precision makes tricky molds and dies for many jobs. Their careful checks make sure every tool is just right.

EDM Machining makes shiny finishes, so less polishing is needed.

The process allows for machines to work by themselves for a long time.

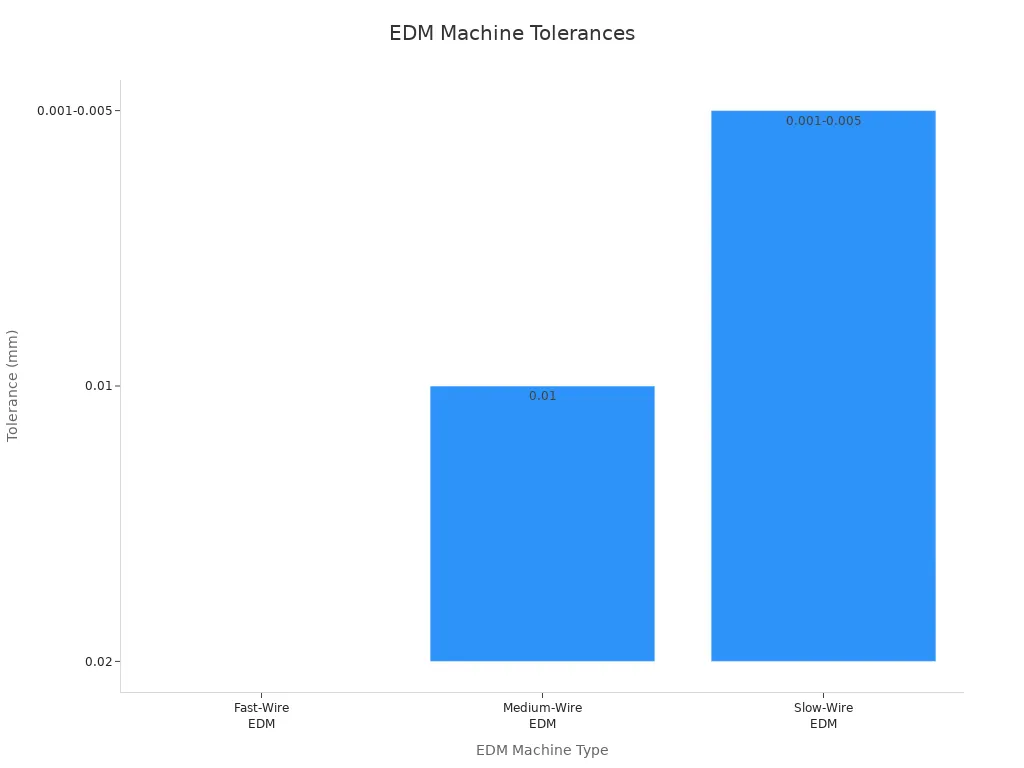

EDM Machining is known for being very exact. Wire EDM can make parts with tolerances from ±0.001mm to ±0.005mm. In real life, engineers have kept holes in turbine blades within 0.002mm. They also keep titanium alloy parts within ±0.003mm. This is better than what milling or laser cutting can do. The process uses sparks and special settings to keep mistakes small. Machine learning now helps watch and guess how accurate the process is. This makes EDM Machining even more trustworthy. Huaruida Precision checks quality and watches machines in real time. This helps them make sure every part is always very exact.

Tip: Cleaning filters and checking wires often helps keep parts accurate for a long time.

EDM Machining can work on hard and tough metals. It works with steel, titanium, tungsten carbide, Inconel, Hastelloy, aluminum, copper, brass, graphite, silver, gold, and Kovar. These metals are used in planes, medical tools, cars, and electronics. EDM Machining does not touch the metal, so it can make tricky shapes and drill tiny holes. For example, it makes smooth holes in turbine blades and medical tools. Huaruida Precision uses this to make parts from strong metals for hard jobs.

EDM Machining is great for hard metals that carry electricity.

It makes tiny shapes and details that other machines cannot do.

EDM Machining gives parts a very smooth finish. It does not leave lines or marks like other cutting tools. The process also keeps the metal strong near the cut. Wire EDM can make shiny, mirror-like surfaces as smooth as Ra 0.4μm. Many parts do not need more polishing after EDM Machining. Studies show that changing settings can make the finish even better, even on hard metals. Huaruida Precision uses many passes to make sure surfaces are smooth and high quality.

EDM Machining is fast for both small and big orders. The tools do not wear out quickly, so jobs cost less. Machines can run by themselves for a long time, which saves work and makes parts faster. Huaruida Precision helps with quick samples, small batches, and making parts when needed. Their flexible way of working helps customers get parts fast, even when they need them soon.

Tools last longer, so there is less stopping.

Machines can work all night or without a break.

EDM Machining has many benefits over old CNC machining. It can cut hard metals and make tricky shapes without pushing on the part. This means parts do not bend or break. EDM Machining makes tighter fits and smoother surfaces than milling or laser cutting. Old methods may have trouble with hard metals or tiny details, but EDM Machining does these jobs well. Huaruida Precision uses strict checks and new machines to make sure customers are happy and get good parts.

Feature | EDM Machining | Traditional CNC Machining |

|---|---|---|

Tool Wear | Minimal | Moderate to High |

Surface Finish | Superior, mirror-like | May need extra finishing |

Material Compatibility | Hard, conductive materials | Limited by tool hardness |

Tolerance | ±0.001mm to ±0.005mm | ±0.01mm or higher |

Complex Shapes | Excellent | Limited by tool geometry |

Note: EDM Machining is best for parts that need tight fits, smooth surfaces, and tricky shapes.

EDM Machining does have some limits. It only works on metals that carry electricity. It cannot cut plastics, ceramics, or composites. The process is slow at removing metal, so it is not good for making lots of big parts. For large jobs, factories often use EDM Machining with other cutting tools to save time.

Only works on metals that conduct electricity.

Slow cutting speed makes it less useful for mass production.

Factories today use new ways to make things better and faster. Wire cut EDM makes parts that are exact and smooth. These parts are used in planes, cars, and medical tools. Some examples are Mars Rover gears and tools for surgery. Experts say you should do these things for good results:

Check the part design early to see if EDM works.

Think about how smooth you want the part and how much it costs.

Get help from skilled engineers to make things better.

Companies like Huaruida Precision help people turn ideas into great parts. They work quickly and always give good service.

EDM Machining works on metals that carry electricity. Some common metals are steel, titanium, tungsten carbide, copper, and aluminum. EDM cannot cut things like plastics or ceramics. It also cannot cut materials that do not carry electricity.

EDM Machining can make parts with very close fits. Many parts are made with accuracy from ±0.001mm to ±0.005mm. This makes EDM good for jobs that need exact parts.

EDM Machining does not bend or push the metal. It uses sparks to shape the part. The part stays strong and keeps its shape. Most parts do not need much extra work after.

Tip: EDM Machining makes smooth surfaces and sharp edges.

EDM Machining can make tricky shapes and tiny details. It cuts sharp corners, deep holes, and thin walls. Many companies use EDM for parts that other machines cannot make.

Huaruida Precision works fast and checks quality closely. They use new machines and help with quick samples and small orders. Customers trust their team for good parts and expert help.

Navigation

Navigation

Contact Us

Tel: +86 13417419143

E-mail: [email protected]

Add:

2nd Floor, Building 7, 156 High Tech Industrial Park, Fuyuan 1st Road, Zhancheng Community, Fuhai Street, Baoan District, Shenzhen City, China.