Aug.

20, 2025

Contents

Precision Machining of Sand-Cast Iron Engine Components for Automotive Applications

Sand Casting in Automotive Engines

Automotive engineers use precision machining to make sand-cast iron engine parts better. Casting makes parts that are close to the right shape and saves money. But casting cannot make the parts smooth or exact enough for today’s engines. Gray and ductile iron are strong and last a long time, so they are used for important jobs. Precision machining makes the size, shape, and surface of the parts more exact. This helps the parts work well for a long time. Using both methods together saves time and money and makes better parts.

Sand casting is a main way to make engine parts. Engineers use it to make things like blocks and cylinder heads. This process helps make big parts with tricky shapes. Every step is important to make sure the part works well.

Pattern Creation: Technicians make a pattern that looks like the engine part. The pattern is a little bigger because metal gets smaller when it cools.

Mold Preparation: Workers put sand around the pattern to make a mold. They mix the sand with clay or chemicals to make it strong.

Core Making: Some parts need hollow spaces, like for coolant. Workers make sand cores and put them in the mold.

Assembly of Mold and Core: They put the mold pieces together and add the cores. The gating system helps the molten metal flow the right way.

Pouring the Molten Metal: Workers pour hot iron into the mold. They control the temperature and speed.

Solidification and Cooling: The metal cools and gets hard inside the sand mold. Cooling the right way helps the part stay strong.

Shakeout and Removal: When the part is cool, workers break the sand mold. They take out the casting and clean off the sand and cores.

Sand casting helps make engine parts with tricky shapes and exact sizes. This makes it great for cars.

Engineers pick different cast iron types for each engine part. The table below shows the most used cast irons for car engines:

Type of Cast Iron | Key Properties | Common Automotive Engine Applications |

|---|---|---|

Gray Iron | Easy to cast and machine; resists wear; medium strength; good at moving heat | Engine blocks, cylinder heads, brake rotors, exhaust manifolds, oil pans |

Ductile Iron | Stronger and bends more; resists hits and stress; easy to machine | High-performance engine parts, suspension parts, differential housings, transmission cases |

White Iron | Very hard and resists wear; does not bend much | Not used much in engines; used where wear is a big problem |

Gray iron is easy to machine and stops shaking, so it is good for engine blocks. Ductile iron is stronger and tougher, so it is good for parts that get hit or stressed. White iron is not used much in engines, but it is good when parts need to last a long time against wear.

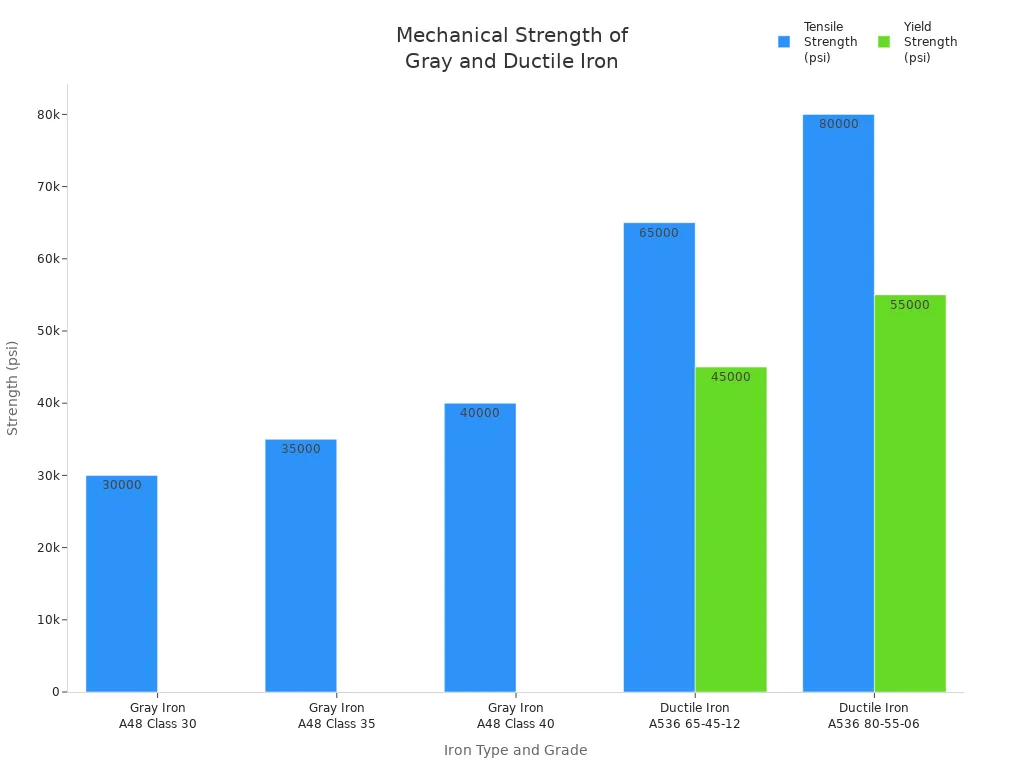

Sand-cast iron engine parts are very strong and last a long time. Automotive engineers pick gray and ductile iron because they can handle heavy loads. These materials also do not wear out quickly. Cast iron is dense, so it helps stop vibration and noise. This makes engines more stable and work better.

Iron Type | ASTM Grade | Tensile Strength (psi) | Yield Strength (psi) | Elongation (%) | Typical Automotive Uses |

|---|---|---|---|---|---|

Gray Iron | A48 Class 30 | 30,000 | N/A | N/A | Engine blocks, transmission housings |

Gray Iron | A48 Class 35 | 35,000 | N/A | N/A | Cylinder heads, brake drums, flywheels |

Gray Iron | A48 Class 40 | 40,000 | N/A | N/A | Machinery bases, brake rotors, engine parts |

Ductile Iron | A536 Grade 65-45-12 | 65,000 | 45,000 | 12 | Automotive components, housings, pump bodies |

Ductile Iron | A536 Grade 80-55-06 | 80,000 | 55,000 | 6 | Gears, axles, crankshafts, heavy-duty parts |

Cast iron works well even when it gets very hot. It keeps its strength and does not wear down fast. Cast iron is stronger and lasts longer than cast aluminum. That is why it is used for engine blocks and heavy-duty parts. Cast aluminum is lighter and does not rust easily. But it does not last as long as cast iron.

Sand-cast iron engine parts are strong and do not wear out fast. This makes them great for tough car jobs.

Sand casting helps save money when making engine parts. The first tools needed do not cost much, usually between $500 and $10,000. This makes sand casting good for making only a few parts or testing new designs.

Aspect | Sand Casting | Investment Casting | Centrifugal Casting |

|---|---|---|---|

Initial Tooling Cost | $500 - $10,000 (low tooling cost) | $5,000 - $50,000 (high tooling) | Often no tooling cost if dies exist |

Per-Part Cost | Lowest for simple geometries | Economical at volumes >100 parts | Best for cylindrical parts |

Production Volume | Most economical for 1-50 parts | More cost-effective at 100+ parts | Suitable if standard dies available |

Flexibility | High; easy pattern modification | Less flexible due to tooling cost | Limited to cylindrical shapes |

Material Compatibility | Virtually any alloy including cast iron | Limited by tooling and process | Mainly cylindrical ferrous parts |

Sand casting is flexible and easy to change. Makers can change sand molds to fit new designs or make tricky shapes. This helps them make new parts quickly. Sand casting works with many materials. Engineers can pick the best one for each engine part.

Sand casting lets makers change molds easily for new designs.

The process can make parts with tricky shapes inside, like engine blocks.

Low tool costs and quick work help companies keep up with what people want.

Sand casting is a cheap and flexible way to make strong engine parts for cars.

Precision machining is very important for sand-cast iron engine parts. Sand casting makes parts that are rough and not very exact. Most sand-cast parts can be off by about ±0.020 inches for every inch. This is not good enough for today’s engines. Engineers add extra material, usually 1.5 mm to 3 mm, to the castings. This extra material lets them finish the parts to the right size and shape.

Surface finish matters a lot too. Sand casting leaves the part with a rough feel. Engine parts need a smooth surface, with a roughness average (Ra) between 6.3 and 12.5 micrometers. A smooth surface helps lower friction and makes seals work better. It also helps the engine last longer. Castings have draft angles of 1° to 3°. These angles help workers take the part out of the mold without breaking it.

Surface Finish Category | Roughness Average (Ra) Range (µm) | Typical Application |

|---|---|---|

Fine | 6.3 to 12.5 | Automotive engine components |

Medium | 12.5 to 25 | Industrial machinery |

Rough | >25 | Construction parts |

Quality control tools help check if each part is made right. These tools include coordinate measuring machines (CMM), optical comparators, and go/no-go gauges. Precision machining makes the surface about 40% smoother. It also makes the size about 30% more exact. These changes mean fewer mistakes and better engine work.

Precision machining helps sand-cast iron engine parts fit tight spaces and have smooth surfaces. This is needed for engines to work well.

Engineers use different machining methods to make sand-cast iron engine parts better. Each method helps shape the part and make it more exact.

CNC Machining: Computer-controlled machines cut and shape parts very exactly. CNC machining gives the same good results every time, even for tricky parts.

Milling: Milling machines use spinning tools to cut away material. They make flat areas, slots, and special shapes. Milling is needed for making detailed parts.

Turning: Lathes spin the part while a cutter shapes it. Turning makes round surfaces and smooth finishes. This is important for shafts and holes.

Drilling: Drilling machines make holes for bolts, oil, and coolant. Engineers pick drill bits that make clean holes with few rough edges.

Grinding: Grinding uses rough wheels to take off tiny bits of material. This makes the surface very smooth and the size very exact, even more than cutting tools can.

All these machining methods turn rough sand-cast iron parts into finished engine parts. After machining, steps like grinding, polishing, and coating make the parts even better. Precision machining makes the parts look nicer and work better and last longer.

Using advanced machining, makers can create sand-cast iron engine parts that are very exact and smooth.

Machining sand-cast iron engine parts is not easy. The kind of cast iron changes how engineers shape and finish each part. Gray iron and ductile iron have different microstructures. This makes them act differently when machined.

Property | Gray Iron | Ductile Iron |

|---|---|---|

Graphite Structure | Flake | Spheroidal (nodular) |

Machinability | Excellent | Fair |

Vibration Damping | High | Low |

Strength | Moderate | High |

Typical Applications | Engine blocks, brake discs | Crankshafts, gears |

Gray iron has flakes of graphite inside. These flakes help break chips and act like oil during cutting. This makes cutting smoother and helps tools last longer. Gray iron also stops vibration well. This keeps engine blocks and brake discs the right size.

Ductile iron has round graphite because magnesium is added. This makes ductile iron stronger and able to bend more. But it is harder to machine because it is tougher. Ductile iron does not stop vibration as well as gray iron. Engineers need stronger tools and must change cutting speeds for ductile iron crankshafts and gears.

Gray iron is best for parts that need easy machining and less vibration. Ductile iron is picked for parts that need more strength and can take hits.

Sand casting can cause problems like porosity and inclusions in iron engine parts. Porosity happens when gas bubbles get trapped as the metal cools. Inclusions are bits of sand or other stuff stuck in the casting. These problems make the surface rough and the size less exact.

Sand-cast iron parts usually have more porosity and inclusions than investment-cast parts. Things like wet sand, how air moves through sand, and how good the melted metal is can change how many defects there are. Good ductile iron sand castings can keep porosity low, under 1-2%. Still, these problems mean extra machining is needed to get the right size and smoothness.

Molten iron touching the mold can change the surface. Engineers sometimes find layers of bad graphite and oxide scales on the outside. These layers can change how strong the part is and make machining harder. Careful planning and extra finishing steps help fix these problems and make the surface better.

Porosity and inclusions mean more machining is needed. Engineers use smart methods to fix these problems and make strong engine parts.

Machining sand-cast iron engine parts can wear out tools fast. Engineers use many ways to help tools last longer and work better.

Use finer or medium-angular sand grains and carbon-rich facing sand. This makes the casting skin smoother and lowers defects, so less machining is needed.

Lower mold compaction pressure. This stops metal from going into the wall too much, making cleaner castings and less tool wear.

Put mold-wash coatings on die cavities before pouring. This helps the first surface look better and means less finishing is needed.

Use multi-axis CNC machines for finishing. These machines remove material evenly and need less extra material.

Watch tool wear in real time by checking tool offsets and recalibrating often. This keeps machining exact and stops tools from wearing out too much.

Think about machine strength and vibration. Add a little more finishing material if needed. This stops tools from getting overloaded and wearing unevenly.

Use feedback and guessing methods to change machining settings based on past tool wear and machine actions.

Tool condition monitoring systems help make machining better. These systems give real-time updates on tool wear, so tools can be changed or fixed quickly. This helps tools last longer, stops surprise breakdowns, and keeps production steady.

Coolants like Pure-Cut® help keep cutting cool and smooth. They can make tools last two to five times longer and let machines cut faster. Cleaner machining with almost no liquid also means less extra work and less waste. Big car companies have cut cycle times by up to 60% by using better coolants.

Managing tool wear well helps precision machining, makes more parts faster, and lowers costs for car engine parts.

Automotive engineers use sand-cast iron for many engine parts. Engine blocks are the most common sand-cast iron part. Gray cast iron is tough and stops vibration. It also moves heat well. Ductile iron is stronger and can have thinner walls. This helps make the engine lighter. Compacted graphite iron (CGI) is now used in high-performance engines. CGI is strong and handles heat very well.

Precision machining changes these castings into good engine parts. Cylinder heads need flat surfaces and exact shapes. This helps coolant and oil move easily. Crankshafts need careful machining to lower vibration. This helps them spin smoothly. Gears need the right tooth shape and smooth surfaces. This helps power move well. Machining cylinder bores makes them round and smooth. This helps parts fit better and last longer.

Component Type | Material Type | Casting Technique | Description |

|---|---|---|---|

Engine Block | Grey Cast Iron | Sand Casting | Good thermal conductivity, machinability, and vibration damping. |

Engine Block | Ductile Cast Iron | Sand Casting | Higher strength and ductility; lighter blocks. |

Engine Block | Compacted Graphite Iron (CGI) | Sand Casting | Used for high-performance engines; better strength and thermal properties. |

Valve Guides | Grey Cast Iron | Sand Casting | Wear resistance and heat handling in internal combustion engines. |

Precision machining helps engine parts fit well and work the same every time.

Car makers use sand casting and precision machining for many engine parts. They make engine blocks, transmission housings, and steering gear housings from strong cast iron. This iron can take heat and hard hits. It is good for tough engine jobs. Makers pour hot cast iron into sand molds at 1250°C to 1350°C. When the metal cools, they break the sand to get the part.

Engine blocks and cases start a little bigger than needed. This lets them shrink and gives room for machining. Precision machining makes the size and surface just right. Some surfaces are made thicker so they can be machined to the right size. Brake drums, rear axle housings, and brackets are also made this way.

Sand casting is one of the oldest and most used ways to make big car parts.

Precision machining after casting makes parts strong and the right size.

Cast iron parts help engines work well and last a long time.

Top car companies use sand-cast iron and precision machining to make strong, exact engine parts that meet industry rules.

Car factories now use new technology to make sand-cast iron engine parts better. Many companies use 3D printing to make molds and cores fast. This helps them change designs quickly and make tricky shapes. It works for both test parts and making lots of parts. Engineered ceramic media, like alumina, help castings have smoother surfaces and keep their shape better. These materials also mean less extra machining is needed.

Modern binding systems, such as chemical and polymer-based binders, make molds stronger and more exact. Real-time sensors watch temperature, moisture, and how tight the sand is during casting. These sensors help keep the quality high and stop mistakes. Automation now does jobs like putting patterns in place, setting cores, and finishing parts. This makes results more exact and the same every time.

Quality assurance tools, like computer-aided design and non-destructive testing, help engineers find problems early. Predictive analytics and simulation software show how metal moves and cools. These tools help teams fix problems before they get expensive.

Key trends shaping the future include:

Additive manufacturing for tricky molds and faster test parts

High-performance iron alloys for stronger and tougher parts

Smart foundry technology and automation for more parts and safety

Environmental efforts, like using recycled materials and saving energy

Digital integration changes how engineers design and machine sand-cast iron engine parts. Computer-aided design (CAD) and computer-aided manufacturing (CAM) make casting more exact and faster. Hybrid ways, using 3D printing and automation together, help make tricky shapes with less work and more sameness.

Artificial intelligence and machine learning now guess where defects might happen and help improve casting steps. Real-time data from sensors lets teams change things quickly. Companies like SANDI Technology use advanced sand 3D printers to make big, detailed molds for engine blocks and heads. Automation in molding and core making lowers mistakes and makes parts faster.

Industry 4.0 brings real-time monitoring, AI-driven analytics, and smart manufacturing to foundries. These changes help make more good parts, waste less, and protect the environment. The future of sand-cast iron engine parts will use digital tools to make lighter, stronger, and better parts for cars.

Car makers make strong and affordable engine parts by using sand casting and precision machining together.

Sand casting lets them try new ideas fast and make parts with tricky shapes.

Precision machining makes sure parts are very exact and work well every time.

Choosing the right material and using both methods helps make better and greener engine parts.

Experts think new things like 3D printing, smart machines, and earth-friendly ways will change how engine parts are made in the future.

Machining makes sand-cast parts the right size and smooth. Sand casting alone cannot make parts exact enough for engines. Engines need tight tolerances and smooth surfaces to work well.

Gray iron is easy to machine and stops shaking. It handles heat and does not wear out fast. These things make it good for engine blocks that must last a long time.

Manufacturers use special coolants and strong coatings. They watch tools closely with real-time checks. They also pick the best speeds and tools for cutting. These steps help tools last longer and keep work exact.

Yes. Sand casting can make tricky shapes, even inside parts. Engineers design patterns and cores for these shapes. This way, they can make both simple and detailed engine parts.

Technicians use CMMs, go/no-go gauges, and surface testers. These tools check if parts are the right size and shape. Quality checks make sure every part meets car industry rules.

Navigation

Navigation

Contact Us

Tel: +86 13417419143

E-mail: [email protected]

Add:

2nd Floor, Building 7, 156 High Tech Industrial Park, Fuyuan 1st Road, Zhancheng Community, Fuhai Street, Baoan District, Shenzhen City, China.