Aug.

14, 2025

Contents

Custom 5-Axis CNC Machining of Aluminum Parts for Mining Machinery Applications

You need mining machines that work well in tough places. Custom 5-Axis CNC Machining of aluminum parts gives you better fits and special shapes. Standard ways cannot make these shapes. This new process helps your machines work longer. It also saves fuel and makes jobs faster.

When you use high-precision parts, your machines run better and last longer. Data shows that better parts can cut downtime in half. They also help save fuel. You get mining machines that are more reliable and work better every day.

You use machines to shape metal in many ways. 5-Axis CNC Machining gives you more control than old machines. The cutting tool moves in three straight lines: X, Y, and Z. It can also tilt and turn using two more axes called A and B. This helps you reach almost any angle you need. You can make deep holes, curved sides, and hard shapes in one go.

Tip: 5-Axis CNC Machining lets you make parts with fewer steps. You save time and do not make mistakes from moving parts between machines.

Here is a table that shows how 3-axis and 5-axis CNC machines are different:

Feature | 3-Axis CNC Machining | 5-Axis CNC Machining |

|---|---|---|

Axes of Movement | X, Y, Z | X, Y, Z + A, B (rotation) |

Tool Access | Flat surfaces, simple shapes | Complex shapes, multi-sided parts |

Setup Requirements | Many setups for complex parts | One setup for most parts |

Capabilities | Simple parts | Deep cavities, undercuts, intricate contours |

Precision & Finish | Good for simple parts | High precision, smooth finish on complex parts |

Programming | Easier | Needs skilled operators and advanced software |

Cost | Lower | Higher |

You can see that 5-Axis CNC Machining makes parts that 3-axis machines cannot. You get better results, which is important for mining machines that need strong and tricky aluminum parts.

Mining equipment must be tough and last a long time. 5-Axis CNC Machining helps you make aluminum parts with special shapes and tight fits. You can tilt and turn the tool, so you cut all sides of a part at once. You do not have to stop and move the part many times. This saves time and keeps the part correct.

Here are some ways 5-Axis CNC Machining helps you:

You make hard shapes by moving the tool in five ways.

You finish more sides of the part in one setup, so you work faster.

You get tighter fits, so your parts last longer and fit better.

You get smoother surfaces, so you do not need to polish as much.

You can design parts without worrying about what the machine can do.

You also use automation and real-time monitoring to get better results. Sensors watch the machine while it works. Software checks the tool path and changes it if needed. You use automatic tool changers and robots to switch parts and tools fast. This lowers mistakes and keeps your parts the same. You can run machines all night without stopping, so you make more parts.

Automation cuts down on hand work and mistakes.

Real-time monitoring helps you find problems early and fix them fast.

Predictive maintenance keeps your tools sharp and machines working.

Advanced controls let you change projects fast and handle hard designs.

Note: Shops using 5-Axis CNC Machining get better accuracy, longer tool life, and less extra work. You get parts that work better and last longer in tough mining jobs.

People pick aluminum for mining machines because it has special features. Aluminum is much lighter than steel. This makes machines easier to move. Lighter machines use less fuel and cost less to run. Aluminum makes a thin layer that stops rust. This keeps parts safe from water and chemicals. Your parts last longer, even in wet places.

Here is a table that shows how aluminum and steel are different in mining machines:

Aspect | Aluminum | Steel (including stainless steel) |

|---|---|---|

Weight | Much lighter; improves efficiency | Heavier; increases mass |

Strength | Good strength-to-weight ratio | Higher absolute strength |

Corrosion Resistance | Forms protective oxide layer | Rusts unless alloyed or coated |

Use in Mining | Best for weight and corrosion resistance | Best for heavy-duty strength |

You can choose from many types of aluminum for your needs. Some, like 6061 and 7075, are very strong. Others, like 5052 and 5083, fight rust very well. Grades such as 2011 and 6262 are easy to machine. This helps you get smooth and exact parts.

Tip: Picking the right aluminum type gives you the best mix of strength, weight, and lasting power for your mining machines.

Mining machines do hard work every day. Aluminum parts must hold heavy loads and shake a lot. They also face rain, sun, and cold. These parts need to be strong but not heavy. Aluminum is good because it is strong for its weight. It also does not rust from water, salt, or chemicals in mines.

Your machines work in very hot and very cold places. Aluminum parts stay strong and keep their shape in these temperatures. You can add special coatings, like anodizing, to make them last longer and fight rust even more.

You also need to think about how the parts are made. Parts must fit just right and have smooth surfaces. This helps machines work better and last longer. Picking the best alloy and using new machining, like 5-axis CNC, makes sure your parts are top quality. Checking and cleaning the parts often helps them work well, even in tough places.

You need mining machinery parts that fit perfectly and work every time. 5-Axis CNC Machining helps you reach very tight tolerances. This means your parts match the design exactly. You can get tolerances as close as ±0.005 mm for dimensions and ±0.01 mm for positions. These tight limits help your machines run smoothly and last longer.

Here is a table that shows typical tolerances you can achieve with CNC machining for aluminum parts:

Tolerance Type | Typical Range |

|---|---|

Dimensional Tolerance | ±0.005 mm |

Position Tolerance | ±0.01 mm |

Fit Tolerance | H7-h6 (standard fit) |

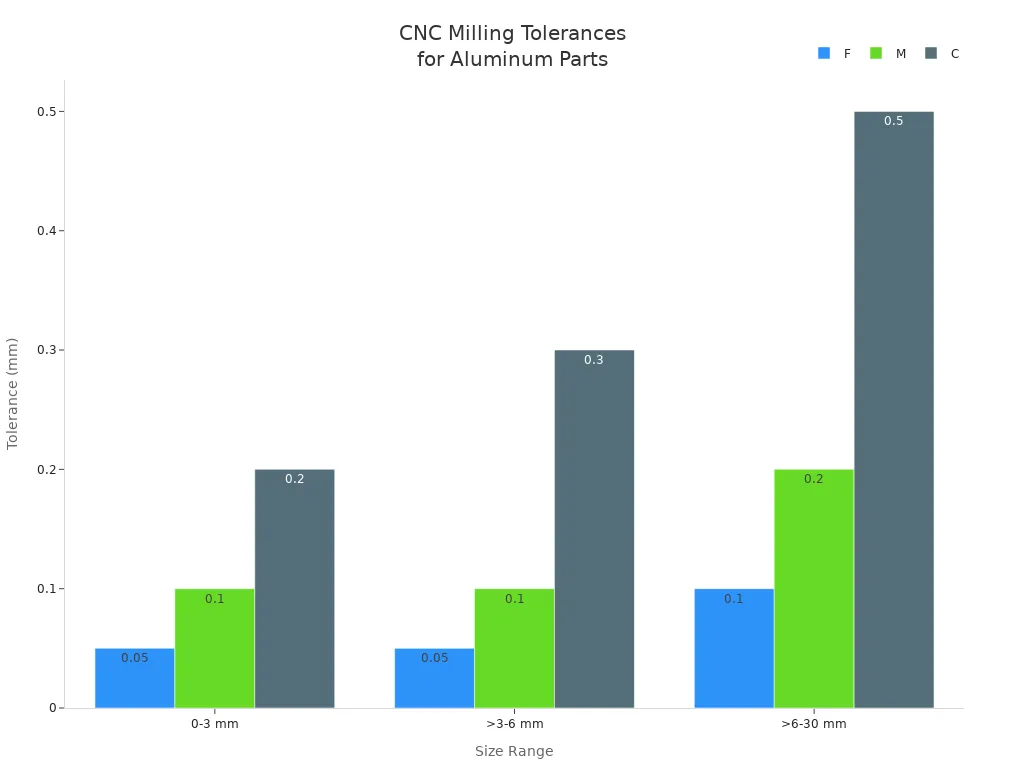

You can also see how tolerance classes change with part size:

Tolerance Class | 0-3 mm | >3-6 mm | >6-30 mm |

|---|---|---|---|

F | ±0.05 mm | ±0.05 mm | ±0.1 mm |

M | ±0.1 mm | ±0.1 mm | ±0.2 mm |

C | ±0.2 mm | ±0.3 mm | ±0.5 mm |

You get these results because the machine can move the tool in five directions. This lets you cut parts with high accuracy. When your parts fit better, your mining machines have fewer breakdowns and need less repair. You also get smoother surfaces, so your parts last longer in tough jobs.

Note: High-precision parts help your mining equipment work better and stay safe, even in hard conditions.

Mining machinery often needs parts with special shapes. You may need curved surfaces, deep holes, or tricky angles. 5-Axis CNC Machining lets you make these complex shapes in one setup. The machine can tilt and turn the tool, so you reach every side of the part.

You can make parts like blades, impellers, wheels, and shafts.

The machine cuts arcs, undercuts, and angles that are hard for other machines.

You finish the whole part in one go, so you do not need to move it.

You get the same high quality every time, even for big parts.

This technology helps you design better mining machines. You do not have to worry about what shapes the machine can make. You can focus on what works best for your job.

Tip: When you use 5-Axis CNC Machining, you can create parts up to 42 inches in diameter and 160 inches long. This is great for large mining equipment.

You save time and money when you use 5-Axis CNC Machining. The machine can cut from many angles without stopping. You do not need to move the part or set it up again. This means you finish parts faster and make fewer mistakes.

One setup does the job of many.

You lower the risk of errors from moving the part.

You cut down on downtime and keep your machines running.

You get more parts made in less time.

Because you do not need to stop and reset the machine, you also get better accuracy. The machine keeps the part in the same place, so every feature lines up just right. This helps your mining machines work better and last longer.

Callout: Faster setups mean you can respond quickly to new jobs or changes in design. You keep your mining operation moving forward.

You begin with a clear plan. You make a CAD model with all the details. This includes size, shape, and tolerances. You check if the design works for 5-axis machining. You look for ways to make cutting easier. You avoid thin walls. You add draft angles. You use big radii so the tool moves smoothly.

Here is how you turn your design into a finished aluminum part:

You send your CAD file and check for problems.

You study the design to see if it is easy to make.

You get a price and see how long it will take.

You use CAM software to make the best toolpaths.

You get the raw aluminum ready and mark it.

You set up the machine with the right tools.

You run the CNC machine and watch it as it works.

You check the part size with measuring tools.

You add surface treatments like anodizing or polishing.

You put the part together and check it again.

You pack the part with anti-corrosion steps and ship it.

Tip: Try advanced CAD/CAM simulation to stop tool crashes. It helps you make better cutting paths and fewer mistakes.

You want every part to meet strict rules. You keep the shop temperature steady to stop errors from heat. You check the machine’s level often and fix the feet to keep it stable. You use dial test indicators to measure runout and spot loose rotary axes.

You check and change machine settings to find the true center.

You use probing cycles and CAM software to line up the part for tight tolerances.

You park the machine table in a neutral spot when shutting down to keep it steady.

You watch for wear and looseness in axis parts to stop future problems.

Note: Regular checks and careful changes help your parts stay accurate and strong for tough mining jobs.

When you make aluminum parts, stresses can change their shape. Thin-walled parts often bend or twist after machining. These stresses can push or pull inside the metal. Machining puts these stresses into the part. You want your parts to stay straight and strong.

You can use different ways to lower these stresses:

Pneumatic hammer peening pushes stress into the surface. It can go as deep as 800 micrometers. You may see up to 37% less bending if you only cover some areas.

Deep cryogenic treatments help take away stress in aluminum. You cool the part to very cold temperatures. This works better than heat for nonferrous metals.

Tip: Use hammer peening only where you need it. Covering the whole part can fix too much and change the shape too much.

Tool wear is a big problem in 5-axis CNC machining. You want your tools to last longer and cut well. Many things can make tools wear out:

Cutting makes heat. Too much heat hurts your tools. Use the right fluid to cool the tool and part.

Chips from cutting can get stuck. If you cut them again, your tool wears out faster. Make sure chips leave the area fast.

Cutting speed and feed rate are important. Set them right to lower wear.

Pick the best tool type and coating. High-helix coated tools work well for aluminum.

Spread wear across the edge. Change toolpaths so one spot does not get all the stress.

Control machine runout and tool bending. This keeps wear even and stops damage.

Use good fixtures and set machining rules to lower shaking.

Note: Checking tools often and picking smart tools saves money and keeps parts correct.

You need skilled operators for good 5-axis CNC machining. Operators must know how to set up machines and pick the right tools. They change cutting rules and watch for tool wear and stress. They use advanced software to plan toolpaths and stop mistakes. Training helps operators learn new skills and keep up with new technology.

Skilled operators find problems early.

They change settings to make parts better.

They help your shop run safely and smoothly.

Callout: Train your team well. Skilled operators make mining machinery parts stronger and more reliable.

Picking the right 5-axis CNC machining partner helps you get good aluminum parts for mining machines. You want someone who knows what you need and can give you great results. Here are some things to think about:

Workpiece Specifications: Choose a shop with machines that fit your part size and weight. Make sure they can handle bigger parts if you need them later.

Material Expertise: Check if the partner knows about aluminum alloys. They should give you reports that show the material is good.

Technical Capabilities: See if they have real 5-axis machines and can do extra steps. They should be able to make parts with tight fits.

Quality Systems: Look for ISO 9001 certification and strong checks on parts.

Production Scalability: Make sure they can make both small and big orders without being slow.

CNC Controls and Automation: Pick shops with smart CNC systems and robots for better accuracy.

Supplier Reliability: Test their help, spare parts, and warranty rules.

Security: Ask if they use NDAs and keep your designs safe.

Tip: Always ask for a test cut with your material. This helps you see the quality before making lots of parts.

Good design makes parts easier to machine and stronger for mining. Use these ideas to help your parts work better:

Pick the best aluminum alloy for strength, easy cutting, or rust protection.

Make shapes simple and do not add extra details.

Put features together to use fewer parts and steps.

Add tabs or pins so parts fit together easily.

Set tolerances that are tight enough but not too costly.

Use finishes like anodizing or powder coating to protect parts.

Think about heat, shaking, and chemicals when you design.

Make a sample part first to find problems early.

Design Tip | Benefit |

|---|---|

Simplify geometry | Makes machining faster |

Combine features | Cuts down assembly cost |

Use self-locating features | Makes assembly easier |

Apply surface finishes | Helps parts last longer |

Many things change the price of custom 5-axis CNC machined aluminum parts. The material you pick matters—aluminum is cheap and easy to cut, so it saves money. Hard shapes and tight fits take more time and tools, so they cost more. Setup and tools cost extra, especially for special parts. Making more parts lowers the price for each one because you share the setup cost. For example, one part might cost $40, but if you order 100, each can cost less than $9.

Note: 5-axis machining costs more each hour, but it saves time and lowers mistakes for hard parts. Smart design and bigger orders help you save money and keep parts good.

Transmission systems help move power in mining machines. Custom aluminum parts made with 5-axis CNC machining make these systems better. You get gears, shafts, and housings that fit tightly and feel smooth. These parts can handle heavy work and do not wear out fast. Aluminum keeps the system light. This means your machines use less fuel and can move quicker.

You can make transmission parts with tricky shapes. The 5-axis CNC machine cuts deep grooves and curves in one go. You do not need to worry about parts not lining up or needing extra steps. Your transmission works well and lasts longer. These parts also fight rust, even in wet or salty mines.

Tip: Pick anodized aluminum for transmission housings. This finish makes the surface tougher and helps stop rust.

Transmission Part | Benefit of 5-Axis CNC Machining |

|---|---|

Gear | Exact teeth, smooth turning |

Shaft | Tight fits, strong support |

Housing | Light, fights rust |

Spare parts help keep mining machines working. Custom aluminum spare parts made by 5-axis CNC machining give you many good things. You get parts that fit right and work every time. The machine makes each part very exact, so you do not get pieces that do not match.

You can order parts for crushers, conveyors, or hydraulic systems. The CNC machine makes hard shapes and tight fits. Your spare parts last longer because aluminum stands up to heat, water, and wear. Anodizing makes the surface even harder and stops rust. You spend less time fixing machines and more time using them.

High precision and steady quality mean your machines work well.

Custom parts fit your equipment and stop failures.

Strong parts last in tough mining jobs.

Fewer breakdowns and less fixing means more work time.

Fast production keeps your machines running.

Note: Using CNC machined aluminum spare parts saves you money on repairs. You do not have to change parts as often, and you do not wait long for fixes.

You get lots of good things with 5-Axis CNC Machining for aluminum mining parts. You need fewer setups, so you make parts faster and more accurately. Aluminum is light and strong, so your parts last longer in tough places. You can make hard shapes and tight fits because the machine is very precise. Smooth surfaces and protection from rust help your parts stay strong.

You can do even better by working with skilled people, trying out designs first, and checking for quality certificates.

Next Steps for Mining Companies | Description |

|---|---|

Use prototyping services | Try out designs before making many parts |

Work with experts | Get solutions that fit your needs |

Check machining abilities | Make sure the shop can do your jobs |

Look for certifications | Find shops with ISO 9001 or similar |

You get more precise shapes and tighter fits. The machine moves in five directions. You finish parts faster and avoid mistakes. Your mining equipment works better and lasts longer.

You can choose 6061 for strength and easy cutting. 7075 gives you extra toughness. 5052 and 5083 resist rust. Pick the alloy that matches your job needs.

You use steady shop temperatures and regular machine checks. You measure parts with special tools. You watch for tool wear and fix problems early. This keeps your parts correct.

Yes, you can. Shops with 5-axis CNC machines make parts fast. You send your design. They check it and start production. You get your parts in less time.

You can use anodizing to make the surface tougher. Powder coating adds extra protection. These finishes help your parts fight rust and wear in harsh mining jobs.

Navigation

Navigation

Contact Us

Tel: +86 13417419143

E-mail: [email protected]

Add:

2nd Floor, Building 7, 156 High Tech Industrial Park, Fuyuan 1st Road, Zhancheng Community, Fuhai Street, Baoan District, Shenzhen City, China.