Jul.

03, 2025

Contents

Custom Online CNC Machining Services

Custom online CNC machining services help turn your ideas into real parts. These services use special machines to cut and shape metal or plastic. You upload your design and pick the material you want. The system shows you the price right away. Every step is checked to make sure it is correct. The machines work with design software to follow your plan. Sensors and barcodes help keep things accurate. Companies use cloud computing and big data to watch and improve the process. You get your parts fast and do not need to go to a factory.

Note: This market is growing very quickly. Experts think it could be worth $4.8 billion by 2033. More companies want custom, high-precision parts for things like planes, cars, and medical tools. Online platforms make it easy to order and track your parts. This helps save both time and money.

Many people use CNC machining services to get parts made. Engineers, procurement managers, and manufacturers use these platforms often. They work in places like car companies, airplane makers, electronics, healthcare, and architecture. Each group needs different things, like engine parts or medical tools.

Here is a simple look at who uses these services and why:

| Industry Sector | Professional Roles | Key Applications |

|---|---|---|

| Automotive | Engineers, Designers | Engine parts, chassis, interiors |

| Aerospace & Defense | Procurement Managers, Engineers | Aircraft parts, defense systems |

| Electronics | Designers, Engineers | Casings, connectors, circuit boards |

| Healthcare | Manufacturers, Engineers | Medical devices, surgical tools |

| Architectural | Architects, Designers | Custom elements, furniture |

| Mining | Manufacturers, Engineers | Specialized tools, components |

You can see that many people use these services for different reasons. More companies want custom parts and faster ways to make them. Digital tools and new technology help you get what you need, when you need it.

CNC Machining can make many different parts. There are two main ways to do this: milling and turning. Milling uses a spinning tool to cut away material from a block. You can make flat shapes, holes, and even 3D designs with it. Turning spins the part while a tool shapes it. This is best for round parts like shafts and bushings.

Here is a table that shows how milling and turning are different:

| Metric / Aspect | CNC Turning | CNC Milling |

|---|---|---|

| Surface Finish Quality | Surface roughness as fine as Ra 1–2 µm | Improved finish with ball-nose end mills; step-over control for 3D surfaces |

| Tolerance Capabilities | High precision for rotational parts | Tight tolerances around ±0.01 mm achievable |

| Production Throughput | High-speed automated bar feeders enable large runs with minimal manual intervention | Flexible multi-axis machining for complex parts; longer cycle times for simple shapes |

| Setup Complexity | Generally simpler setups for symmetrical parts; minimal setup time | More complex due to multi-face fixturing and multi-axis toolpaths |

| Automation Potential | Lights-out manufacturing with bar feeders, robotic arms, automatic part catchers | Pallet changers, modular fixtures, tool magazines, CAM software optimizations |

| Application Suitability | Ideal for cylindrical, tubular, or conical parts like shafts, pins, bushings | Best for flat surfaces, slots, holes, 3D contours, prismatic parts like housings and brackets |

| Hybrid Systems | Swiss-type lathes with live tooling combine turning and milling in one setup | Mill-turn centers combine both processes to reduce setups and improve efficiency |

You can use these methods to make one part or many. Most online services let you order any amount you want.

Tip: Mill-turn centers can do both milling and turning. This saves time and makes parts more accurate, especially for hard shapes.

CNC Machining works with many materials. You can pick metals, plastics, or composites for your project.

Metals:

Aluminum is light and does not rust. It is used in cars and planes.

Steel is strong and tough. It is good for building and machines.

Copper carries electricity well. It is used in electronics.

Titanium is strong but not heavy. It is used in planes and medical parts.

Brass is easy to cut and does not rust. It is used for fancy or detailed parts.

Plastics:

ABS is tough and used in many products.

Polycarbonate is strong and used in medical tools.

Nylon stands up to heat and chemicals. It is used in electronics and machines.

PVC and PEEK are cheap and easy to cut.

Composites:

Carbon fiber is strong and light. It is used in planes and sports gear.

Fiberglass is tough and used in cars and buildings.

You can choose the best material for your needs. Think about how strong, light, or cheap you want your part to be. Standards like ISO and ASTM help make sure the material is good. Some companies use recycled metals or plastics that break down to help the planet.

Note: Pick your material based on what your part must do. Think about strength, heat, and how you will use it.

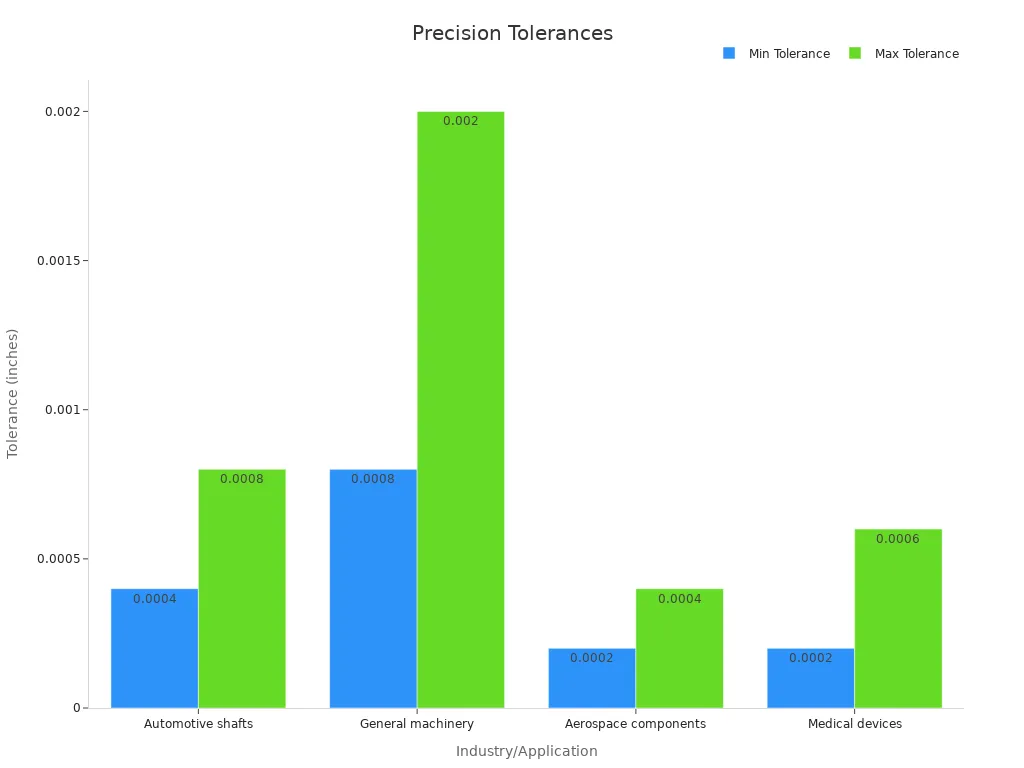

CNC Machining can make parts very exact. Tolerance means how close the part is to your design. Smaller tolerances mean more exact parts.

Here is a table that shows common tolerance ranges:

| Tolerance Range (inches) | Typical Application | Material Examples |

|---|---|---|

| ±0.001 | High-precision parts | Titanium, Stainless Steel |

| ±0.005 | General precision parts | Aluminum, Brass |

| ±0.010 | Large parts with less precision | Steel, Plastic |

Some jobs need very small tolerances. For example, car shafts often need tolerances between 0.0004 and 0.0008 inches. Parts for planes and medicine need even more control.

Most CNC Machining services can make parts as exact as ±0.0008 inches. This helps your parts fit and work right.

Tip: Smaller tolerances can cost more and take longer. Pick the right tolerance to save money and get the accuracy you need.

You can get a price for your part very fast. Most online platforms use smart programs to check your design. They give you a quote almost right away. If your part is simple, you might see a price in one minute. If your part is more complex, it usually takes less than five minutes. These programs look at your CAD file and check the size. They also pick the best way to make your part.

| Metric | Performance |

|---|---|

| Average Quote Time | Under 5 minutes |

| Simple Part Quote Time | About 1 minute |

| Quoting Accuracy | Around 99% |

| System Accessibility | Fully online, any computer |

You do not have to wait a long time for a quote. This speed helps you plan and make choices faster. About 78% of customers like getting answers quickly. Instant quotes help you trust the service because you see the price right away. Many companies say they make 15% more money with clear prices.

Tip: Instant quoting uses machine learning and expert knowledge. This gives you a fair price and lets you start your CNC Machining project sooner.

Uploading your design is simple and safe. You just drag and drop your CAD file on the website. The system checks your file and makes sure it works with the machines. Most platforms work with about 95% of CAD file types. You do not need to worry about file problems.

Your files are kept safe. The data is stored in secure buildings with guards all day and night.

All files use strong encryption when sent and stored.

Only people who need your file can open it.

The system checks your file for mistakes and helps you fix them before you order.

Here are some steps to help you get your file ready:

Clean your CAD file by removing extra parts and checking for mistakes.

Make sure your drawing uses the right units and layers.

Save your file in a common format and keep a backup.

Use the platform’s tools to check for errors before you upload.

Note: Secure file uploads keep your ideas safe. Only trusted teams can see your designs. This keeps your project safe from start to finish.

After you upload your file, the system gives you feedback. This is called Design for Manufacturability (DFM) feedback. It checks if your part is easy to make and shows any problems. You see tips right away, like making corners bigger or changing wall thickness.

| Case Study / Example | Description | Cost Savings / Impact |

|---|---|---|

| Machining Tool Corner Radii Redesign | Making corners bigger helped the machine work better and faster | 17% cost reduction |

| Automotive Industry | Removed extra steps like painting and sensor seats | Up to 0.26% savings on cylinder block |

| Consumer Electronics | Improved mold design and used less extra features | Lower material use and better reliability |

| General Principle | Early DFM feedback controls over 70% of part cost | Helps you save money before production |

DFM feedback helps you avoid mistakes that cost more money or make your part hard to make. Early feedback lets you fix problems before you pay to make the part. Many companies save up to 17% by using these tips.

Tip: Use DFM feedback to make your design better and cheaper. You can see problems early and fix them before you order.

You can also track your order online. The platform shows updates, photos, and inspection data as your part is made. Account managers and customer support help you with questions. Most orders arrive on time, and you can see the delivery date before you pay.

| Strategy Element | Focus Area | Impact on Ordering Efficiency and Business Performance |

|---|---|---|

| Intuitive Online Platform | Communication & order management | Up to 20% more repeat orders due to easy tracking |

| Transparent Pricing | Instant quotes | 15% profit boost with real-time pricing |

| Dedicated Account Management | Personalized support | 10% better profitability with tailored help |

Note: Real-time order tracking and fast support make everything easy. You always know where your part is and when it will arrive.

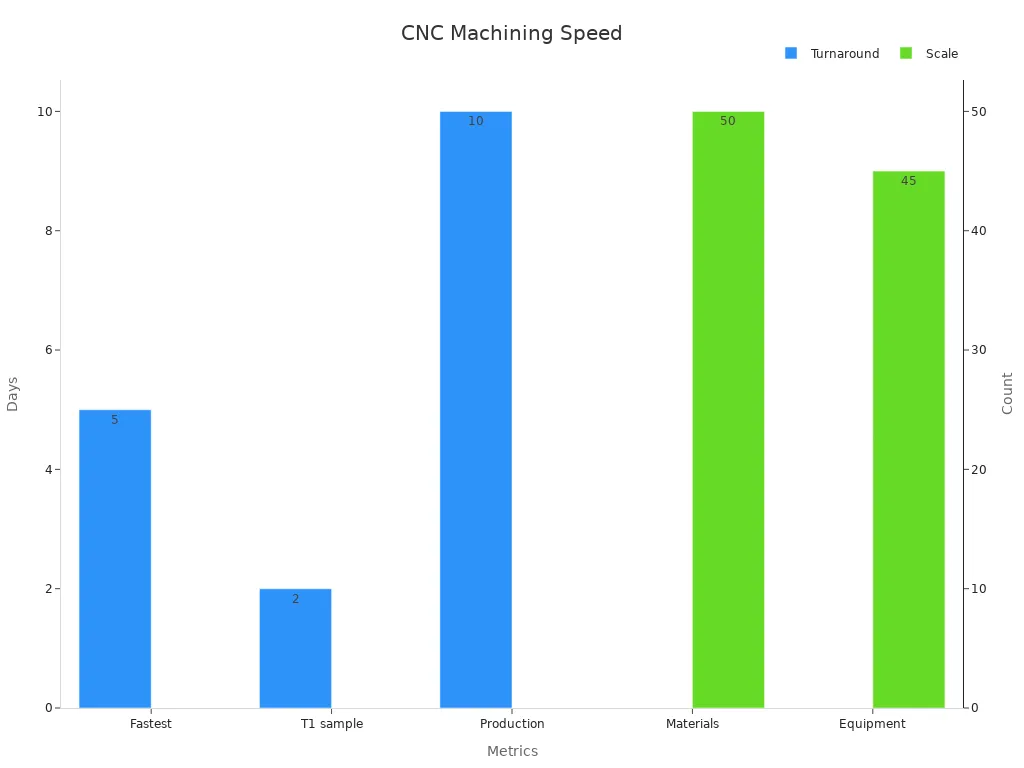

Custom online CNC Machining services help you get parts fast. Some companies can send parts in just one day. You get a price right away, so you can start making your part quickly. You do not have to wait for special molds or long setups. This helps you go from your idea to a real part very fast.

Here are some ways these services make things faster:

You get prices right away, so you can plan sooner.

Computers help program machines, which saves time and stops mistakes.

Checks during making keep things moving.

Smart plans match your job with the best machine.

Suppliers all over the world can start your job anywhere.

| Metric | Detail |

|---|---|

| Fastest delivery | Parts delivered in as fast as 5 days |

| Sample turnaround | T1 samples delivered in 2 days |

| Production parts | Delivered in 10 days |

| Materials offered | 50+ metals and plastics |

| Tolerance precision | Down to 0.01mm for critical components |

| Certification | ISO 9001:2015 certified |

| Equipment | 45 CNC machines covering many processes |

Tip: Getting parts fast helps you finish your work on time and beat others.

CNC Machining makes parts that are very exact. The machines use special tools to keep every part close to your design. Some parts are made with tolerances as small as ±0.001 inches. This is good for things like planes and medical tools.

Special tools check each part to make sure it is right.

Tests make sure every part is the same as the last one.

Computers watch for mistakes while making parts.

Machines are checked often to keep them working well.

Smart programs help the machines follow your design.

Note: Exact parts fit better and last longer. You get the right quality for your important jobs.

You can order just one part or many parts with CNC Machining. It works for new ideas, small groups, or big orders. You do not need special tools or long waits to start. This makes it easy to change your design or get more parts when you want.

You can make more or fewer parts when you need to.

No special molds means you save time and money.

You can pick from over 50 kinds of metals and plastics.

Some machines can make hard shapes.

Companies can use more machines or workers for big jobs.

| Performance Metric | Custom Online CNC Machining Service | Comparison Benchmark / Notes |

|---|---|---|

| Turnaround Time | As short as 1 day for certain parts | Enables rapid prototyping and urgent orders |

| Precision Tolerance | ±0.001" (±0.005mm) | Meets high-demand industry standards |

| Production Flexibility | One-off parts to >10,000 units | Supports prototyping and mass production |

| Material Range | 50+ industrial metals and plastics | Superior to 3D printing and injection molding |

Callout: Many online services also offer things like injection molding or laser cutting. This gives you more ways to finish your project.

Custom online CNC machining services let you get parts fast. The parts are made very accurately. You can pick from many materials. Many industries use these services and get big benefits:

| Industry | Key Outcome | Economic Impact |

|---|---|---|

| Aerospace | 25% cost reduction | 10% more market share |

| Automotive | 40% faster production | $2M in sales saved |

| Medical Devices | 30% longer tool lifespan | 20% market share increase |

| Technology | 98% prototype accuracy | 15% lower R&D costs |

| Marine | 50% longer part life | 20% less maintenance cost |

You can help your business grow with these tools. One CNC shop in Illinois used online tools to fill its schedule for six months. Try instant quoting now. It is simple to begin your next project.

You can get parts in as little as one day. Many services offer fast shipping options. The exact time depends on your design, material, and order size.

Most platforms accept common CAD files like STEP, IGES, and STL. You can check the website for a full list. Always save your file in a supported format before uploading.

You can order just one part. There is no minimum order requirement. This helps you test ideas or make prototypes without extra cost.

Your files stay safe with strong encryption and secure servers. Only trusted staff can see your designs. Many companies follow strict privacy rules to protect your ideas.

Navigation

Navigation

Contact Us

Tel: +86 13417419143

E-mail: [email protected]

Add:

2nd Floor, Building 7, 156 High Tech Industrial Park, Fuyuan 1st Road, Zhancheng Community, Fuhai Street, Baoan District, Shenzhen City, China.