May.

27, 2025

Contents

Which Material is Better for Drone Arms: Carbon Fiber or Aluminum

Material Properties Comparison

Application-Specific Recommendations

Choosing the best material for drone arms is important. Carbon fiber is popular because it is strong and light. It is 42% lighter than aluminum and 31% stiffer. Carbon fiber is also 60% stronger, with a tensile strength of 1600 kN·m/kg. Aluminum, in comparison, has a tensile strength of 500 kN·m/kg. These features make carbon fiber great for light and fast drones. But aluminum is still useful when cost and toughness matter more. Knowing these facts helps you pick the right material.

Carbon fiber is much lighter than aluminum. Its density is about 1.6 g/cm³, while aluminum's is 2.7 g/cm³. This makes carbon fiber 40-50% lighter than aluminum. Lighter materials help drones fly better and use less battery. They also make drones easier to control.

| Material | Density (g/cm³) | Weight Advantage (%) |

|---|---|---|

| Carbon Fiber | 1.6 | 40-50 |

| Aluminum | 2.7 | N/A |

If you want a faster and more agile drone, pick carbon fiber. Aluminum works fine if weight isn’t as important.

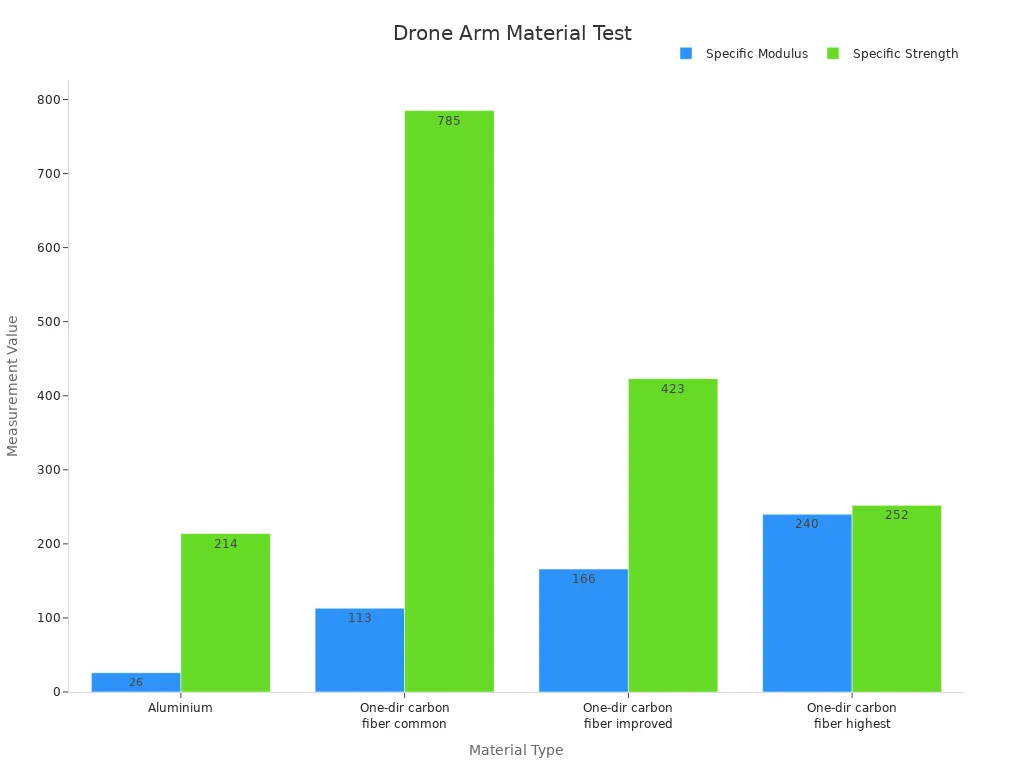

Drone arms need to be strong and stiff to handle stress. Carbon fiber is better than aluminum in both areas. Tests show carbon fiber is 2 to 5 times stiffer than aluminum. A carbon fiber part of the same thickness is 31% stiffer and 42% lighter than aluminum.

| Material Type | Stiffness against weight (Specific Modulus) | Resistance to damage (Specific Strength) |

|---|---|---|

| Aluminum | 26 | 214 |

| One-direction carbon fiber (common modulus) | 113 | 785 |

| One-direction carbon fiber (improved modulus) | 166 | 423 |

| One-direction carbon fiber (highest modulus) | 240 | 252 |

Carbon fiber’s strength and stiffness make it great for durable drones. Aluminum is less stiff but works well if cost or easy manufacturing matters more.

Thermal properties affect how drones perform in different temperatures. Aluminum spreads heat well, helping cool motors and electronics. This makes it good for drones in hot places or heavy use.

Carbon fiber doesn’t spread heat easily. This can be bad for cooling but helps in cold weather. It stays stable in changing temperatures, which is useful for high-altitude or cold-climate drones.

Think about where your drone will fly. If heat control is key, aluminum is better. For steady performance in cold, carbon fiber is the way to go.

Durability and fatigue resistance are important for drone arms. These features show how well materials handle stress and tough conditions.

Drone arms need to survive impacts, vibrations, and weather. Carbon fiber is very durable because it is strong and resists wear. It doesn’t rust, so it’s great for wet or chemical-filled areas. Aluminum, however, can rust unless coated. But it handles impacts well since it bends instead of breaking.

| Material | Rust Resistance | Impact Strength | Wear Strength |

|---|---|---|---|

| Carbon Fiber | Great | Medium | Great |

| Aluminum | Okay (if coated) | High | Okay |

If your drone will be in wet places, pick carbon fiber. For drones that might hit things often, aluminum is better.

Fatigue resistance shows how materials handle repeated stress. Carbon fiber is great because it doesn’t crack easily. This makes it good for drones with lots of movement or vibrations. Aluminum is strong but gets cracks over time from repeated use.

Tip: For drones used in tough jobs like deliveries, choose materials with high fatigue resistance.

Care: Carbon fiber needs less care since it resists rust and cracks. Aluminum needs checks and coatings to stay strong.

Lifespan: Drones with carbon fiber arms last longer in hard conditions. Aluminum arms may need replacing sooner in tough jobs.

Knowing about durability and fatigue resistance helps you choose wisely. Carbon fiber works best for most uses, but aluminum fits certain needs too.

Aluminum costs less than carbon fiber. This is especially true for large-scale production. Aluminum is common and easy to process, lowering its price. Carbon fiber costs more because making it is harder. But its higher price can be worth it. It improves drone flight and battery life.

Prices for both materials can change with the market. If you have a small budget or need many drones, aluminum is better. For high-performance drones needing strength and lightness, carbon fiber is worth the cost.

Making aluminum parts is simple and cheap. Aluminum can be shaped by casting, extruding, or machining. It is soft enough for fast and easy production.

Carbon fiber needs a harder process. Layers of carbon sheets are mixed with resin. Then, they are heated and pressed to harden. This needs special tools and skilled workers, raising costs. But the result is a strong, light, and durable material. It’s great for top-quality drones.

Aluminum is very easy to shape and cut. Regular tools can drill, cut, or form it. This makes making drone arms faster and easier.

Carbon fiber is harder to work with. Cutting it needs diamond-coated tools to avoid damage. The dust from cutting it can be harmful, so safety steps are needed. If you want easy production, aluminum is better. But if you need high performance and can handle the challenges, carbon fiber is a great choice.

When picking materials for consumer drones, think about cost and simplicity. These drones are often used for fun, like taking photos or learning to fly. Aluminum is a good choice because it’s cheap and easy to shape. This keeps the drone affordable. Also, aluminum is tough, which helps beginners who might crash often.

If you want a lighter drone that flies better, carbon fiber is a great option. It’s lighter, so the drone can fly longer and turn faster. This is perfect for hobbyists trying advanced flying tricks.

Tip: Beginners should start with aluminum arms. Later, upgrade to carbon fiber for better flying.

Industrial drones do hard jobs like mapping or inspecting buildings. They carry heavy loads and work in tough places. For these drones, strength and durability are key.

Carbon fiber is a top pick for industrial drones. It’s strong but light, so drones can carry more without losing flight power. It also lasts longer and handles wear well, making it great for harsh conditions.

Aluminum can work too, especially if you need to save money. It’s good at handling crashes and is easy to fix. But its heavier weight might shorten flight time, which could be a problem for some tasks.

Note: For tough industrial jobs, carbon fiber is worth the extra cost.

Professional drones are used for tasks like filming or research. These drones need to be stable, precise, and high-performing. For this, carbon fiber is usually the best material.

Carbon fiber is light, which helps the drone stay steady. This is important for smooth videos or clear photos. Its stiffness reduces vibrations, improving camera quality. Plus, it’s durable, so it’s reliable for important work.

Aluminum can still work in certain cases. For example, in hot places, aluminum helps cool the drone’s electronics. But its extra weight and lower stiffness make it less ideal for most professional uses.

Advice: For professional drones, choose carbon fiber for better results and dependability.

Picking between carbon fiber and aluminum depends on how the drone is used. Each task has different needs, so knowing them helps you decide.

For taking photos or videos, stability and accuracy are very important. Smooth footage and clear images need steady drones. Carbon fiber is great for this. It’s light, so drones can fly longer, which helps for long shots. It’s also stiff, reducing shakes and keeping cameras steady during tricky moves.

In hot places, aluminum might work better. It cools electronics by spreading heat well. But its heavier weight can shorten flight time and make drones less agile, which isn’t ideal for professional filming.

Tip: Use carbon fiber for stable drones and less vibration in photos.

Delivery drones carry heavy loads and need to stay efficient. Strength and toughness are key here. Carbon fiber is strong but light, letting drones carry more without slowing down. It also lasts longer and handles wear well, making it reliable for repeated use.

Aluminum is better at handling crashes. If your drones might hit things often, aluminum is a good choice. It’s also cheaper, which helps if you need many drones for deliveries.

Rescue drones work in tough places like bad weather or rough land. They need to be strong and dependable. Carbon fiber resists water and rust, making it great for wet or harsh areas. Its light weight also helps drones fly longer, which is useful in rescue missions.

Aluminum is easier to fix or change quickly. This makes it good for drones needing fast repairs during rescue work.

Racing drones need to be fast and easy to control. Carbon fiber is the best choice for this. It’s light, so drones move faster. Its stiffness helps with sharp turns and quick moves, giving racers an advantage.

Aluminum is heavier, so it’s not common in racing drones. But beginners might use it since it’s cheaper and tougher for practice.

Note: For racing, carbon fiber is almost always the better option.

Farm drones do jobs like checking crops or spraying fields. They need to cover big areas, so flying well is important. Carbon fiber is light and strong, helping drones fly longer and handle farm chemicals.

Aluminum might be better for drones needing frequent fixes or if cost matters more. It’s cheaper and easier to repair, making it good for farms with tight budgets.

Think about what your drone will do to pick the right material. Carbon fiber is great for light and strong drones. Aluminum works well for cheaper and tougher needs. Knowing these use cases helps you choose wisely.

Carbon fiber works well but harms the environment. Making it uses a lot of energy and releases harmful gases. These gases add to global warming. The main material, polyacrylonitrile (PAN), cannot be replaced easily. This makes carbon fiber less eco-friendly than other materials.

Some companies are trying to make carbon fiber greener. They are testing plant-based materials to lower its environmental harm. Recycling carbon fiber is another idea to reduce waste. But recycling is hard, costly, and not common yet.

If you care about the planet, think about carbon fiber’s downsides. Right now, it’s not as eco-friendly as aluminum.

Aluminum is one of the easiest materials to recycle. It can be reused many times without losing its quality. Recycling aluminum uses much less energy than making new aluminum. This makes it a better choice for the environment.

Recycling aluminum is simple. Old aluminum is collected, melted, and shaped into new items. This saves resources like bauxite, the ore used to make aluminum. Aluminum is also strong, so it can be reused many times before recycling.

If you want a greener option, aluminum is the better pick. Its ability to be recycled and reused makes it great for drone arms.

Picking between carbon fiber and aluminum depends on your drone's use. Carbon fiber is super strong and light, perfect for fast drones. Aluminum is tough and cheaper, good for drones that might crash. Think about what matters most—speed, cost, or eco-friendliness. Each material works best in certain situations. Knowing your drone's job will help you choose wisely.

Carbon fiber is very strong and light. It’s stiffer than aluminum, which helps drones fly better and turn faster. This makes it perfect for drones needing speed and accuracy.

Yes, aluminum is cheaper and tougher. It can handle crashes well, which is helpful for beginners learning to fly. It’s also easy to fix if damaged.

Recycling carbon fiber is hard because of how it’s made. Some companies are working on it, but it’s not common yet. Aluminum, however, is easy to recycle and reuse.

Aluminum is better for hot places. It spreads heat well, keeping motors and electronics cool. Carbon fiber doesn’t do this, so aluminum is the better pick for high heat.

If you want top performance, carbon fiber is worth it. It’s light and stiff, making drones fly more efficiently. But if you need something cheaper, aluminum is a solid and durable option.

Navigation

Navigation

Contact Us

Tel: +86 13417419143

E-mail: [email protected]

Add:

2nd Floor, Building 7, 156 High Tech Industrial Park, Fuyuan 1st Road, Zhancheng Community, Fuhai Street, Baoan District, Shenzhen City, China.