Jun.

19, 2025

Contents

CNC Supplier Secrets for Easy Small Batch Success

Working with a CNC Supplier for small batch production can feel simple when you know what to look for. You get real perks like cost savings, flexibility, and high quality. Take a look at how the numbers stack up:

| Parameter | Value | Description |

|---|---|---|

| Demand | 100 units/month | Monthly product demand |

| Setup Cost | $100/batch | Cost to set up per batch |

| Holding Cost | $5/unit/month | Cost to hold one unit in inventory |

| Optimal Batch Size | ~63 units | Balances setup and holding costs |

You save money by reducing inventory and only making what you need. Quality stays high with checks at every stage. Flexible processes like CNC machining help you adjust quickly. Picking the right supplier, keeping communication clear, and focusing on quality control make small batch CNC production accessible for you.

Before you start any CNC project, you need to know exactly what you want your parts to look like. Think about the size, shape, and features. You should write down the measurements and tolerances. For example, if you need a hole to be exactly 10mm wide, say so. Use drawings or 3D models to show your ideas.

Dimensional accuracy matters. Tools like micrometers and calipers help check if your parts match your specs.

Surface finish is important too. Some parts need to be smooth, while others can be rough.

Make sure you mention any special needs, like threads or tight corners.

Tip: Clear specs help your CNC supplier pick the right machines and tools. This keeps your parts consistent and high quality.

How many parts do you need? When do you need them? These questions shape your whole project. If you only need a few parts, your supplier can use rapid prototyping or small-batch runs. This saves time and money.

Shorter timelines work best with simple designs and clear communication.

Longer lead times can happen if your design is complex or needs lots of approvals.

Sharing your schedule helps your supplier plan and avoid delays.

Note: Regular updates and digital file sharing keep everyone on track and help you meet your deadlines.

Picking the right material is key. Each material has its own strengths. For example, aluminum is light and easy to machine. Stainless steel is strong and resists rust. Brass is great for electrical parts.

Think about what your part needs to do. Does it need to be strong, light, or resist heat?

Check if the material is easy to machine. Some metals take longer to cut.

Look at cost, availability, and how fast you can get the material.

Tip: Always ask your CNC supplier about the best material for your job. They know which ones work best for different shapes and uses.

Picking the right CNC Supplier can make or break your small batch project. You want a partner who understands your needs, uses the best technology, and keeps quality high. Let’s break down what to look for and how to ask the right questions.

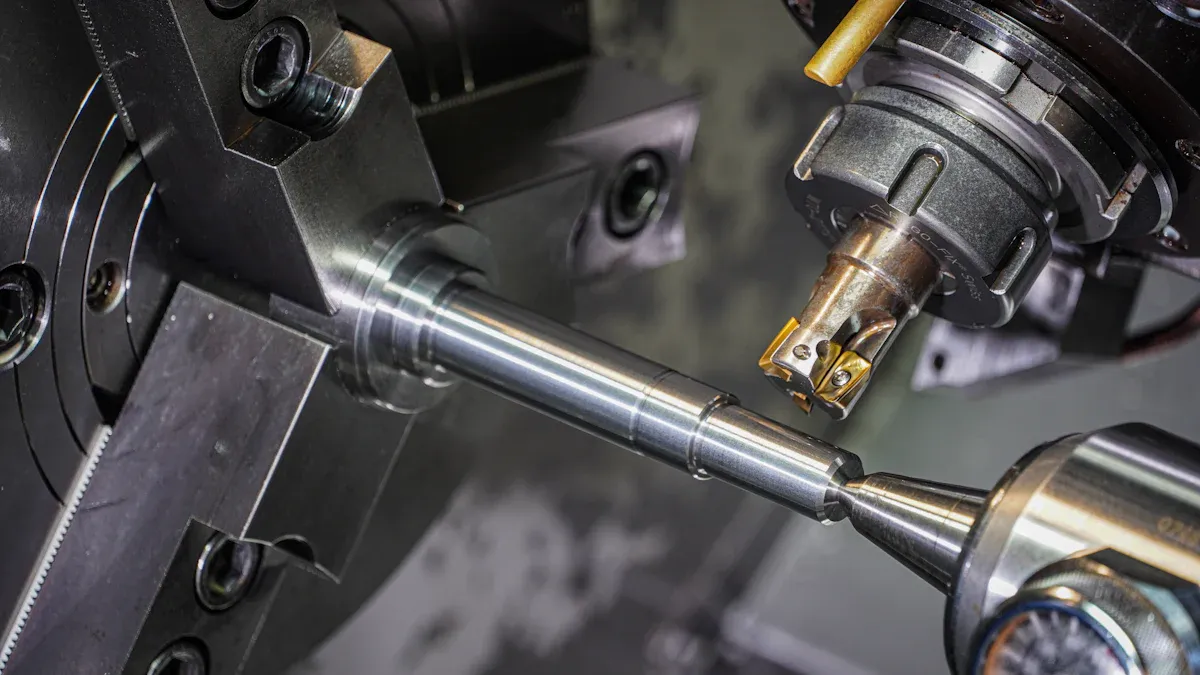

Start by checking the basics. Does the CNC Supplier have experience with your type of parts? Do they use advanced machines and up-to-date software? Suppliers with modern CNC technology can spot problems early and adjust quickly. For example, some shops use smart systems that watch for tool wear or vibration. These systems help catch mistakes before they turn into defects. You get better parts and fewer delays.

Look for suppliers with strong quality control. Certifications like ISO 9001, AS9100, or ISO 13485 show that a CNC Supplier follows strict rules for quality. These standards mean the shop checks every step, keeps good records, and always looks for ways to improve. Third-party audits help make sure they stick to these rules. You can trust a supplier with these badges.

Here’s a quick table to help you compare:

| Criteria | What to Look For | Why It Matters |

|---|---|---|

| Experience | Years in business, similar projects | Knows how to handle challenges |

| Technology | 5-axis machines, real-time monitoring | Better precision, fewer errors |

| Certifications | ISO 9001, AS9100, ISO 13485 | Proven quality and reliability |

| Quality Control | In-machine inspection, data tracking | Consistent results, less waste |

| Communication | Fast replies, clear updates | Fewer surprises, smoother work |

Tip: Always ask for proof of certifications and check if they have passed recent audits.

You want to know if a CNC Supplier can deliver what you need. Ask questions that dig into their process and attitude. Here are some you can use:

How do you handle design changes or last-minute updates?

What steps do you take to keep me updated on my order?

Can you show me examples of similar small batch projects?

What kind of machines and software do you use?

How do you check for quality at each stage?

What happens if there is a problem with my parts?

A good CNC Supplier will answer quickly and clearly. They should welcome your questions and offer solutions, not excuses. You can also ask for references or samples. Try a small test order to see how they work. If they respond fast, suggest improvements, and keep you in the loop, you know you’re in good hands.

Note: Visiting the shop or having a video call can help you see how they work and if they fit your style.

Not every CNC Supplier is ready for small batch jobs. You need someone who can switch gears fast and handle tight tolerances. Look for shops that talk about small batch work on their website or in their portfolio. Ask if they have made parts like yours before.

Some suppliers use advanced 5-axis machines and in-machine inspection tools. These help them hit tight specs and keep quality high, even for just a few parts. Real-time data collection and automatic adjustments mean fewer mistakes and less waste. Shops with this setup can handle complex shapes and quick changes.

You can find stories of suppliers who have helped customers with tricky small batch jobs. For example, one shop made medical parts with micron-level accuracy using smart machines and strict checks. Another supplier boosted their output by adding automation, cutting costs and speeding up delivery. These examples show that the right CNC Supplier can help you save money, get better parts, and finish faster.

Callout: A CNC Supplier with real small batch experience will offer design tips, suggest cost-saving changes, and work with you from start to finish.

Clear and ongoing communication with your CNC Supplier makes small batch projects run smoothly. When you share information the right way, you avoid mistakes, save time, and get better results. Let’s look at how you can make your communication process strong from the start.

You need to send technical files like CAD drawings, 3D models, or DXF files to your CNC Supplier. The way you share these files matters a lot. Cloud-based platforms and secure file-sharing tools help you send large files quickly and safely. These tools also keep your data organized and easy to find.

Use cloud storage with strong security, like Google Drive or Dropbox, to protect your designs.

Try digital collaboration platforms such as Slack or Microsoft Teams for real-time updates and file sharing.

Automated systems can check your files for errors before production starts, which cuts down on mistakes and delays.

Some CNC shops use networked machines and real-time data monitoring. This lets you and your supplier see updates as soon as they happen.

Tip: Always double-check your files before sending. Make sure you include the latest version and all the details your CNC Supplier needs.

Sharing files this way means everyone works from the same information. You get fewer errors, faster feedback, and a smoother project.

You want your CNC Supplier to know exactly what you expect. Start by sharing clear specs, deadlines, and any special requests. Use visual aids like CAD drawings or simulations to show what you mean. This helps your supplier understand your needs and reduces confusion.

Set up regular check-ins or meetings to talk about progress and solve problems early.

Keep a record of all changes, decisions, and feedback. This helps everyone stay on the same page.

Use automated notifications, like emails or messages, to get updates at key project steps.

Real-time tracking of machine status and production data gives you a clear view of what’s happening on the shop floor.

Note: When you set clear expectations, you help your CNC Supplier plan better and deliver on time.

Open feedback loops between you and your supplier make it easy to fix issues and improve the process. You build trust and get better results every time.

You might think one contact person is enough, but small batch CNC projects often need more. Orders can get complex, and you may need to talk to different people for quotes, technical questions, or delivery updates.

Multiple contact points help you manage orders, track progress, and solve problems faster.

Online CNC platforms let you talk to sales, engineers, and support teams all in one place.

Real-time machine data and project management tools keep everyone in the loop.

Regular communication with different team members helps you spot issues early and keep your project on track.

Callout: Don’t be afraid to ask your CNC Supplier who to contact for each part of your project. Knowing the right person saves time and keeps things moving.

Having several contact points means you always have someone to answer your questions. You get updates faster, solve problems quickly, and make sure your parts arrive on time.

You can save a lot of money and time by making smart design choices. Start by keeping your part shapes simple. Avoid deep cavities and thin walls because these features take longer to machine and can waste material. Use standard hole sizes and avoid super tight tolerances unless you really need them. When you pick materials, think about how easy they are to machine. For example, aluminum machines faster than titanium and costs less.

Use multipurpose tools and plan toolpaths for quick execution. This reduces machining time and tool wear.

Choose tolerances that match your part’s function. Don’t pay for extra precision if you don’t need it.

Try to minimize manual finishing steps. Design your parts so they come off the machine ready to use.

Tip: Talk to your supplier early. They can spot ways to simplify your design and cut costs before production starts.

Batch size has a big impact on your costs. If you make more parts at once, you spread setup and machine costs over more units. This means each part costs less. But if you make batches too small, you might pay more for setup and handling. There’s a sweet spot where you get the best price without making too many parts you don’t need.

A study shows that reducing batch size at first lowers your total costs because you wait less and hold less inventory. But if you go too small, costs start to rise again. Work with your supplier to find the right batch size for your project.

Bigger batches = lower cost per part

Too small batches = higher handling and setup costs

Getting a good quote means understanding all the costs. Setup, tooling, inspections, and even shipping can add up. Some suppliers use software to give fast, accurate quotes. This helps you compare options and avoid surprises.

| Cost Category | What It Covers | Why It Matters |

|---|---|---|

| Setup Costs | Machine prep, loading, tool changes | Directly affects unit price |

| Quality Costs | Inspections and testing | Ensures quality, adds expense |

| Tooling Costs | Endmills, inserts, consumables | Recurring, impacts per-part cost |

| Outside Services | Heat treating, coatings, shipping | Adds to total project cost |

| Engineering Costs | Design and fixture work | Can lower costs long-term |

Note: Ask your supplier for a detailed quote. Make sure you know what’s included so you can plan your budget with confidence.

You want to make sure your CNC parts are perfect before full production starts. That’s where sample approval comes in. Your supplier will send you a few finished parts, called production samples, for you to check. You look at these samples to see if they match your drawings, fit together, and meet your needs.

Here’s how the sample approval process usually works:

You get a Part Submission Warrant (PSW) that confirms the parts meet your specs.

You review design records and CAD files to check dimensions and materials.

You look at any engineering change documents if the design changed.

Your supplier shares a Design FMEA, which shows they checked for possible problems.

You see a process flow diagram and control plan, so you know how they keep quality high.

You check measurement system analysis results to make sure their tools are accurate.

You review capability studies, like CpK values above 1.33, to see if the process is stable.

You inspect the actual production samples.

You get material certifications to confirm the right materials were used.

Tip: Always ask for these documents. They help you trust that your parts will be right every time.

You want every part to meet your standards. That means checking parts at every step. Here’s a simple breakdown:

Raw Material Inspection: Your supplier checks the metal or plastic before machining starts.

First Article Inspection (FAI): The first part off the machine gets a full check for size, shape, and finish.

In-Process Inspection: The team checks parts during machining to catch mistakes early.

Final Inspection: Finished parts go through a full review, often with tools like CMMs for precise measurements.

Assembly and Fit-Up: Parts get tested together to make sure they fit and work as planned.

| Quality Step | What It Checks For |

|---|---|

| Dimensional Accuracy | Size and shape match your drawings |

| Material Hardness | Material is strong enough |

| Surface Finish | Smoothness and look of the part |

| Geometric Tolerances | Flatness, roundness, and straightness |

| Assembly and Fit | Parts fit together and work right |

Sometimes you need to change your design or fix a problem. Good CNC suppliers handle changes fast and keep quality high. They use smart machines and real-time data to adjust quickly. You might see them use AI or sensors to spot issues and fix them before they become big problems.

Automation and predictive analytics help them avoid downtime.

Smart sensors track machine health and keep everything running smoothly.

Teams work together and stay flexible, so changes don’t slow you down.

Callout: When your supplier uses these strategies, you get fewer defects, faster delivery, and better parts—even when things change.

You get better results when you give your CNC supplier clear feedback. Don’t wait until the end of a project to share your thoughts. Talk about what works and what needs fixing as soon as you notice it. This helps your supplier make quick changes and keeps your parts on track.

Many shops use smart systems to collect feedback. For example, they might use real-time process control or automated inspection tools. These systems spot problems early and send alerts right away. You can also ask your supplier for reports on quality checks and machine performance. When you both look at this data, you find ways to improve together.

Tip: Share your feedback often. It helps your supplier keep quality high and fix issues before they grow.

Planning your next CNC job gets easier when you and your supplier work as a team. Real-time data from machines shows you how things are running right now. This helps you spot trends and plan for what’s next. If a machine starts to wear out, sensors can warn you before it breaks. You avoid delays and keep your projects moving.

Cloud tools and online platforms let you and your supplier share updates fast. You both see inventory, schedules, and machine health in real time. This makes it simple to adjust plans or start new projects without missing a beat. Using up-to-date information means you make smart choices and avoid surprises.

Callout: When you and your supplier use real-time data, you plan better and finish projects on time.

Great support from your CNC supplier makes a big difference. You want fast answers when you have questions. Top suppliers pick up the phone in under two minutes and send parts within a day. If you need a technician, they try to arrive in 24 hours. Most machines get fixed and running again in about three days.

Look for suppliers who offer strong after-sales help. They should solve problems quickly and know their machines inside and out. Some suppliers cost more, but they deliver better support and faster fixes. Others may charge less but take longer to respond. Choose a supplier who values your time and keeps your shop running smoothly.

Note: Quick, expert support keeps your projects on track and builds trust for the long haul.

You now know how to work with a CNC Supplier for small batch success. Start by sharing clear specs and goals. Keep communication open and check quality at every step. Build a strong relationship with your supplier. These steps help you get great parts, save money, and finish projects on time. Stick with these tips and you will see your small batch CNC projects run smoother every time.

You should send 3D CAD models and 2D drawings. Include all measurements and notes. Double-check that you send the latest version. This helps your supplier make your parts right the first time.

Most suppliers finish small batches in 1–3 weeks. The exact time depends on your part’s design, material, and how busy the shop is. Ask your supplier for a timeline when you order.

Yes, you can! Tell your supplier as soon as possible. Quick changes work best before production starts. Some changes may cost extra or add time, so always check first.

Contact your supplier right away.

Share photos or samples of the problem.

Good suppliers will fix mistakes fast and help you get the right parts.

Navigation

Navigation

Contact Us

Tel: +86 13417419143

E-mail: [email protected]

Add:

2nd Floor, Building 7, 156 High Tech Industrial Park, Fuyuan 1st Road, Zhancheng Community, Fuhai Street, Baoan District, Shenzhen City, China.