Jun.

17, 2025

Contents

Tolerance Meaning in CNC Machining

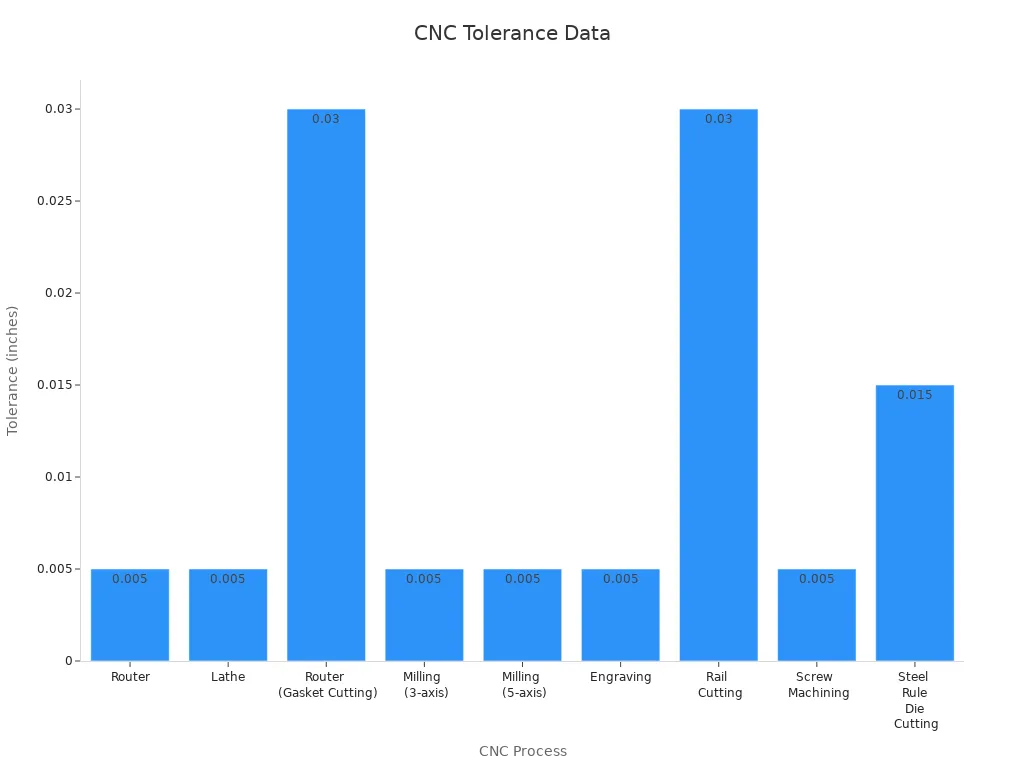

Tolerance Meaning in CNC machining refers to the allowed difference between a part’s actual size and its design value. For example, a shaft may need to measure 3.000 inches, but a tolerance of ±0.005 inches means the part can range from 2.995 to 3.005 inches and still work. Tight tolerances ensure parts fit and function properly, especially in fields like aerospace or automotive. Many CNC processes achieve tolerances as precise as ±0.005 inches, as shown in the chart below.

Tolerance Meaning in CNC machining describes the allowed difference between the actual size of a part and the size shown on the blueprint. This difference is called the allowable variance. Engineers use tolerance to show how much a part can be bigger or smaller than the target size and still work well. For example, if a drawing says a hole should be 3.000 ±0.002 inches, the hole can measure anywhere from 2.998 to 3.002 inches. The part will still meet the design needs.

Tolerance Meaning helps engineers and machinists understand how much "wiggle room" they have when making a part. It sets clear rules for what is acceptable and what is not.

Some important facts about tolerance in CNC machining include:

Regression models use ISO tolerance grades (IT grades) to set allowable variance.

The complexity of a part increases as the tolerance gets tighter. This is measured by comparing the size of the part to the tolerance.

Tighter tolerances slow down machining because the machine must cut more carefully.

Machining time depends on the number of features, the complexity, and the tolerance chosen.

Newer models use information theory and machine learning to predict how tolerance affects machining.

Tolerance Meaning is very important in CNC machining. It makes sure that parts fit together and work as planned. If the tolerance is too loose, parts may not fit or may fail during use. If the tolerance is too tight, making the part becomes harder and more expensive.

Manufacturers follow standards like ISO 2768 to control tolerance. These standards help:

Keep quality high and errors low.

Make sure parts from different places fit together.

Save time and money by reducing mistakes.

Tolerances appear on technical drawings as numbers with plus or minus signs. Engineers use different types of tolerances, such as bilateral, unilateral, and geometric tolerances. Geometric Dimensioning & Tolerancing (GD&T) is a special system that shows exactly how much a feature can move or change shape. For example, true position tolerance controls where a hole must be so that parts fit together during assembly.

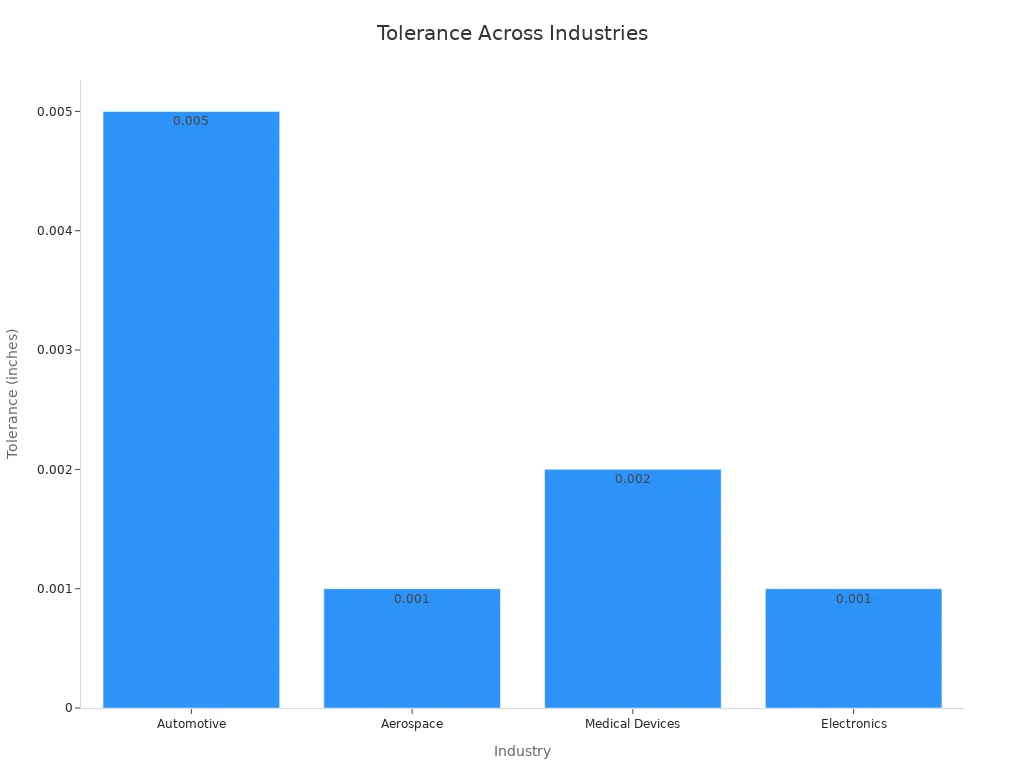

Research shows that many things affect tolerance, such as the material, the machine, the tool, and the process. Skilled workers, good machines, and regular checks help keep parts within the right tolerance. This is very important for industries like automotive, aerospace, medical devices, and electronics. The table below shows how different industries use tight tolerances to make sure parts work well:

| Industry | Component Type | Required Tolerance | Key Outcomes and Importance |

|---|---|---|---|

| Automotive | Engine parts (pistons, camshafts, cylinder heads) | ±0.005 in (typical), ±0.002 in (advanced) | Precise fit ensures compression, reduces friction and wear, improves engine efficiency and lifespan. Rigorous quality control (CMM inspections) ensures parts meet tolerance. |

| Aerospace | Turbine blades | ±0.001 in (typical), ±0.0005 in (advanced) | Tight tolerances critical for aerodynamic performance and structural integrity under extreme conditions. Use of 5-axis CNC, adaptive control, and real-time monitoring improves fuel efficiency and reduces maintenance. |

| Medical Devices | Orthopedic implants (hip, knee replacements) | ±0.002 in | Ensures perfect fit and function inside the human body. High-precision CNC milling and turning with laser scanning and CMM inspections guarantee safety and efficacy, improving patient outcomes. |

| Electronics | Printed Circuit Boards (PCBs) | ±0.001 in | Tight tolerances ensure precise component placement and reliable electrical connections, critical for device performance and durability (smartphones, laptops). Advanced CNC drilling and routing maintain these tolerances. |

Tolerance Meaning guides every step of CNC machining. It helps engineers choose the right process, tools, and checks to make sure each part works as it should.

CNC machining uses clear standards to set how much a part can differ from its design. Groups like ISO, ASME, and ANSI create these rules. Most shops follow ISO 2768 for general tolerances. This standard helps everyone understand what is acceptable.

A typical CNC process, such as milling or turning, often holds a tolerance of ±0.005 inches (±0.13 mm). High-precision work, like aerospace or medical parts, may need even tighter tolerances—sometimes as small as ±0.0025 mm. The right tolerance depends on the part’s size, use, and material.

Here is a table showing common tolerances for different CNC processes:

| CNC Process | Typical Tolerance Value |

|---|---|

| Milling (3-axis/5-axis) | ±0.13 mm (±0.005 inches) |

| Lathe | ±0.13 mm (±0.005 inches) |

| Router | ±0.13 mm (±0.005 inches) |

| Engraving | ±0.13 mm (±0.005 inches) |

| Screw Machining | ±0.13 mm (±0.005 inches) |

| Steel Rule Die Cutting | ±0.381 mm (±0.015 inches) |

| Rail Cutting | ±0.762 mm (±0.030 inches) |

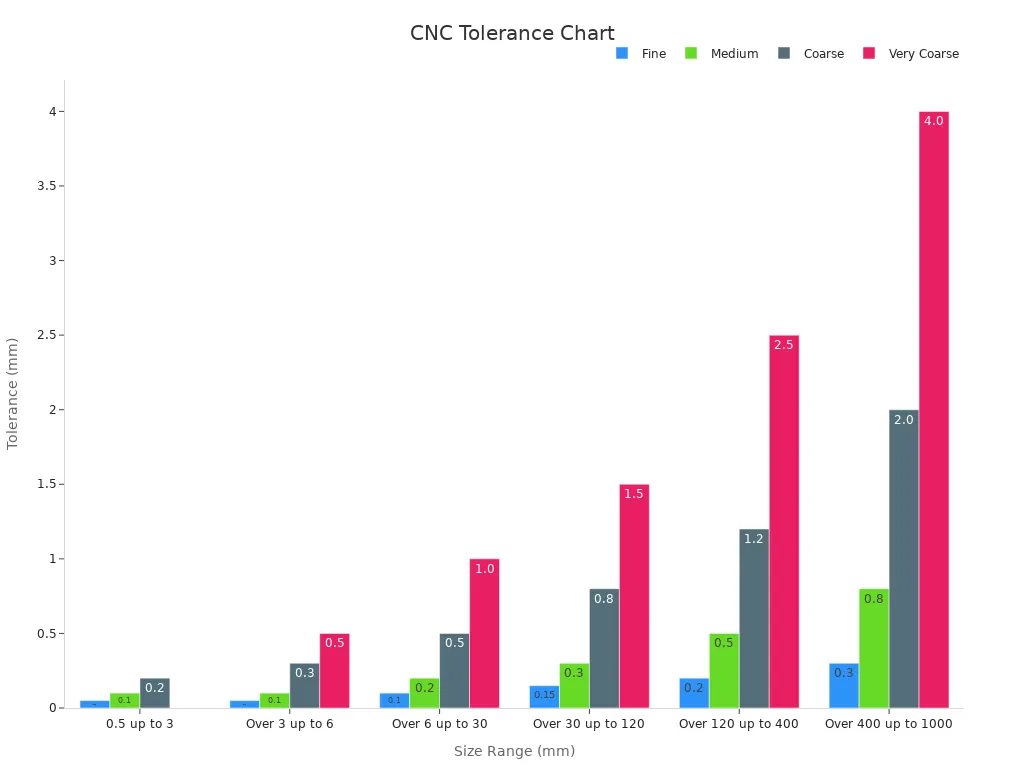

ISO 2768 also gives a range of tolerances based on part size and required finish. The table below shows how these values change:

| Size Range (mm) | Fine (f) | Medium (m) | Coarse (c) | Very Coarse (v) |

|---|---|---|---|---|

| 0.5 up to 3 | ±0.05 | ±0.1 | ±0.2 | N/A |

| Over 3 up to 6 | ±0.05 | ±0.1 | ±0.3 | ±0.5 |

| Over 6 up to 30 | ±0.1 | ±0.2 | ±0.5 | ±1.0 |

| Over 30 up to 120 | ±0.15 | ±0.3 | ±0.8 | ±1.5 |

| Over 120 up to 400 | ±0.2 | ±0.5 | ±1.2 | ±2.5 |

| Over 400 up to 1000 | ±0.3 | ±0.8 | ±2.0 | ±4.0 |

Engineers use special symbols and numbers to show tolerances on blueprints. This helps machinists know exactly what is needed. The most common ways to write tolerances include:

Plus/Minus (±): Shows how much a size can go above or below the target. Example: 10.00 ± 0.05 mm.

Limit Tolerance: Gives a range with two numbers. Example: 10.00 / 10.05 mm.

Unilateral Tolerance: Only allows change in one direction. Example: 10.00 +0.05/-0.00 mm.

Bilateral Tolerance: Allows change both ways, but not always the same amount. Example: 10.00 +0.03/-0.02 mm.

Geometric Dimensioning & Tolerancing (GD&T): Uses symbols to control shape, position, and orientation. Example: ⌀0.05 mm for true position.

A table below shows some common notations:

| Tolerance Type | Symbol / Notation | Typical Values |

|---|---|---|

| Linear Tolerance | ±X.XX mm (e.g., ±0.05 mm) | ±0.02 mm to ±0.1 mm |

| Angular Tolerance | ±X° (e.g., ±0.5°) | ±0.1° to ±1° |

| Limit Tolerance | X.XX / Y.YY | 10.00 / 10.05 mm |

| Unilateral Tolerance | X.XX +0.05/-0.00 mm | +0.02 / -0.00 mm |

| Bilateral Tolerance | X.XX ± 0.05 mm | ±0.01 mm to ±0.1 mm |

| Surface Finish | Ra X.XX µm | 0.2 µm – 3.2 µm |

| Fit Tolerance | H7/g6 | H7 (+0.015 / 0.000 mm) |

Tip: Always check the drawing legend for special symbols or notes. Standards like ISO and ASME Y14.5 make sure everyone understands the same symbols and rules.

Standard tolerances set the basic level of accuracy for most CNC machined parts. Many shops use a default value if the drawing does not specify a tolerance. For example, a common standard tolerance is ±0.125 mm (±0.005 inches). This value works well for most general parts and helps keep costs low. Industry standards like ANSI B4.1 and ISO 2768 define these values. When a part needs more precision, engineers may choose a tighter tolerance, such as ±0.025 mm (±0.001 inches).

Note: Over-tolerancing can make parts harder and more expensive to produce. Engineers should only use tight tolerances when truly needed.

Bilateral tolerances allow a part’s size to vary both above and below the target value. This type of tolerance can be symmetric or asymmetric. For example, a hole might be specified as 10.00 mm +0.05/-0.05 mm (symmetric) or 10.00 mm +0.03/-0.02 mm (asymmetric). Bilateral tolerances give machinists flexibility and help balance quality with manufacturing speed.

Bilateral tolerances appear often in CNC machining.

They help ensure parts fit together even if there is a small size difference.

Unilateral tolerances only allow variation in one direction—either above or below the target size, but not both. For example, a shaft might be 8.00 mm +0.00/-0.05 mm. This means the part can be smaller, but never larger than 8.00 mm. Unilateral tolerances are useful when one side of the limit is more critical for function or assembly.

Engineers use unilateral tolerances for features that must not exceed a certain size.

This type often appears with maximum material condition (MMC) in geometric tolerancing.

Limit tolerances show the smallest and largest acceptable sizes for a part. Instead of a plus or minus value, the drawing lists two numbers. For example, a slot might be 12.00 / 12.10 mm. The part must fall between these two limits. Limit tolerances make it easy for machinists to check if a part meets requirements.

| Tolerance Type | Example Notation | Typical Use Case |

|---|---|---|

| Limit | 12.00 / 12.10 mm | Slots, holes, fits |

Geometric Dimensioning and Tolerancing (GD&T) uses symbols and frames to control the shape, position, and orientation of features. GD&T goes beyond simple size limits. It tells machinists how much a feature can move, tilt, or change shape. The ASME Y14.5—2018 standard explains GD&T rules. Key concepts include datums, geometric controls, and feature control frames. GD&T helps ensure parts fit and function, even when shapes are complex.

Tip: GD&T controls like straightness, flatness, and true position are vital for high-precision CNC parts. They help engineers communicate exact design intent and improve quality.

Selecting the right tolerance in CNC machining depends on many factors. Engineers look at the part’s purpose, the material, the process, and the industry’s needs. The table below shows the main factors that influence tolerance selection:

| Factor Category | Description and Influence on CNC Tolerances |

|---|---|

| Industry-Specific Needs | Aerospace, medical devices, automotive, and electronics require very tight tolerances due to safety, performance, and miniaturization demands. |

| Material Properties | Different materials (e.g., aluminum vs. stainless steel) affect achievable tolerances due to hardness, machinability, and deformation tendencies. |

| Machining Processes | Milling, turning, drilling, and combinations thereof have inherent precision limits influencing tolerance selection. |

| Surface Finishes | Post-machining treatments (e.g., anodizing, sandblasting) can alter dimensions, requiring tolerance adjustments. |

| Cutting Tool Selection | Tool type, quality, and maintenance impact precision; worn tools increase tolerance variation. |

| Machinist Skills | Operator expertise affects ability to maintain tight tolerances through adjustments and process control. |

| Budget Considerations | Tighter tolerances increase costs due to more precise equipment, tooling, and inspection requirements; balancing cost and precision is critical. |

| Part Complexity | Complex parts with non-standard features or tight assembly fits require more stringent tolerance control. |

| Standards and Communication | Use of standards like ISO 2768 and clear communication of tolerance requirements to machining services ensures alignment and quality. |

Tighter tolerances often lead to higher costs because they need advanced machines, more tool changes, and extra inspections.

Material choice and part function play a big role in setting tolerances. Harder materials, like steel, allow for tighter tolerances because they resist deformation. Softer materials, such as plastics, may need looser tolerances due to their tendency to expand or contract. The function of the part also matters. Parts that must fit together or move smoothly, like bearings or gears, need very precise tolerances. Non-critical features can use wider tolerances to save time and money.

Tolerances depend on how the part will be used.

Critical features, such as mating surfaces, require tighter control.

Standards like ISO 286 and GD&T help engineers set the right fit.

Overly tight tolerances can raise costs without improving function.

Engineers often use tolerance analysis and prototypes to make sure the part works as needed.

Different industries set their own tolerance standards. Aerospace and medical device makers demand very tight tolerances for safety and performance. Automotive and electronics companies also need precision, but may allow slightly looser tolerances to control costs. Other sectors, like consumer goods, often accept wider tolerances if the part’s function allows it.

Safety and reliability drive tight tolerances in aerospace and medical fields.

Cost and efficiency may lead to looser tolerances in less critical applications.

Each industry balances risk, function, and budget when choosing tolerances.

Tight tolerances help prevent failures in safety-critical products.

The method used to make a part affects which tolerances are possible. High-speed CNC milling can achieve very fine tolerances and smooth surfaces, reducing the need for extra finishing. The accuracy of the CNC machine, the stability of the environment, and the skill of the machinist all matter. Measurement tools, like touch probes or coordinate measuring machines, help check if parts meet the required tolerances.

Machining parameters—such as spindle speed, feed rate, and tool type—also impact the final result. Optimizing these settings helps achieve the best balance between precision and cost. Companies often adjust tolerances based on what their machines and processes can reliably produce.

Choosing the right manufacturing method and process settings is key to meeting tolerance goals while keeping production efficient.

Tighter tolerances in CNC machining often lead to higher production costs. Manufacturers must use advanced machines and specialized tools, which cost more than standard equipment. Machining time increases because the process runs slower and may need extra finishing steps. Scrap rates also rise, as more parts fail to meet strict requirements. Inspection becomes more expensive, with skilled workers and high-tech devices like coordinate measuring machines (CMMs) needed to check each part. Traditional cost estimates use simple formulas, but modern methods rely on parametric models and machine learning to predict costs more accurately. These models consider factors like machining time, material use, and surface complexity. Studies show that even a small reduction in tolerance can lower manufacturing costs by up to 20%. Manufacturers should only use tight tolerances when necessary to avoid unnecessary expenses.

Tolerance directly affects the quality of CNC machined parts. When tolerances are too loose, parts may not fit together or work as intended. Tight tolerances help ensure that parts meet design goals and function properly. High-quality partsoften require precise tolerances, especially in industries like aerospace and medical devices. However, tighter tolerances do not always mean better quality if the part does not need them. Manufacturers must balance the need for precision with the cost and complexity of production. Using the right tolerance helps maintain product quality while keeping costs under control.

Inspection plays a key role in verifying that parts meet tolerance requirements. Drawings with clear GD&T callouts and specific tolerances guide the inspection process. Standards like ISO 2768 set general rules for size and location features. Inspectors use accurate measuring tools, such as CMMs, to check dimensions. These tools must be more precise than the tolerance being measured. Calibration and environmental control, like waiting for parts to reach room temperature, improve measurement accuracy. Advanced methods, such as laser alignment and ballbar tests, help check complex machines. The table below summarizes recommended inspection practices:

| Inspection Aspect | Recommendation or Tool |

|---|---|

| Standard Referenced | ISO 230-1, ISO 2768 |

| Measuring Instrument | CMM, high-accuracy lasers |

| Calibration | Regular, with calibration sheets |

| Environmental Control | Measure at 20°C for stability |

| Advanced Testing | Ballbar Trace for 5-axis machines |

Manufacturers can balance cost and quality by following expert strategies. Looser tolerances make machining easier, reduce waste, and lower inspection costs. Tighter tolerances should only be used when the part’s function demands it. Design for manufacturability (DFM) helps group tolerances and simplify operations. Using high-quality machines, optimizing toolpaths, and reducing setups also improve precision and save money. Simplifying part designs and controlling thermal effects further support tight tolerance goals. By applying these tips, manufacturers can achieve the right balance between cost and quality in CNC machining.

Tolerance Meaning in CNC machining shapes how parts fit, work, and last. Choosing the right tolerance helps control costs, improve quality, and ensure proper function. Experts highlight that tighter tolerances need better machines and more time, while material and process choices also affect results. Key points include:

Tolerance impacts cost, quality, and part function.

Standards like GD&T help balance precision and expense.

Careful selection leads to better products and fewer problems.

Readers can use this knowledge or talk with CNC experts for the best results.

Tolerance shows how much a part’s size can change from the design. For example, 10.00 ±0.05 mm means the part can be between 9.95 mm and 10.05 mm. This helps parts fit and work well.

Tighter tolerances need better machines, more careful work, and extra checks. This increases time and cost. Manufacturers use advanced tools and skilled workers to meet these strict limits.

Engineers look at the part’s use, material, and industry needs. They balance cost and function. For safety parts, they pick tighter tolerances. For simple parts, they use wider tolerances to save money.

If a part falls outside its tolerance, it may not fit or work as planned. Manufacturers often reject or rework these parts to avoid problems in the final product.

Navigation

Navigation

Contact Us

Tel: +86 13417419143

E-mail: [email protected]

Add:

2nd Floor, Building 7, 156 High Tech Industrial Park, Fuyuan 1st Road, Zhancheng Community, Fuhai Street, Baoan District, Shenzhen City, China.