Oct.

16, 2025

Contents

Climb Milling vs. Conventional Milling: Which is Right for Your Project?

Climb Milling vs. Conventional Milling

If you're trying to determine which method is best for your project, you'll find that most shops today prefer climb milling. This technique provides a smoother finish and exerts less stress on the tool. However, many machinists often get confused when deciding between climb milling vs. conventional milling. You might wonder if your machine’s backlash or the type of material you are working with plays a role in this decision. These factors are indeed very important. Always consider your machine, the material you are cutting, and the level of precision you require before making your choice.

Think about what material you are cutting before you pick a milling method. Some materials work better with one method than the other.

Climb milling is best for softer materials and when you want a nice finish.

Conventional milling is better for hard outer layers, like castings or forgings.

If you cut very hard surfaces, conventional milling keeps your tool safe and gives you more control.

Tip: Always look to see if your material has a tough outer layer. This can change which method is best.

The kind of machine you use matters a lot. Newer machines can handle climb milling because they control backlash. Older machines may not do this, so conventional milling is safer.

Milling Type | Characteristics | Advantages |

|---|---|---|

Conventional Milling | Chip width starts small and gets bigger. The tool rubs more at first. Chips fall in front of the cutter. Upward forces can lift the workpiece. | Stops backlash. Good for old machines and some materials. |

Climb Milling | Chip width starts big and gets smaller. Chips come off behind the cutter. Downward forces keep the workpiece down. | Best for new machines. Makes work faster and helps tools last longer. |

You want your parts to look smooth and nice. The milling method changes how the surface looks. Climb milling usually makes a cleaner and smoother finish. This is because the cutter slices the material better and chips move away from the cut.

Factor | Impact on Surface Finish Quality |

|---|---|

Tool Condition | Old tools can make rough surfaces. |

Machine Stability | Shaky machines leave marks on the part. |

Cutting Parameters | Wrong speed or feed can make the finish worse. |

Material Characteristics | Soft materials can smear if not cut right. Hard ones need careful control. |

Tool Coatings | Good coatings help the finish and tool life. |

Coolant/Lubrication | The right coolant makes a better finish. |

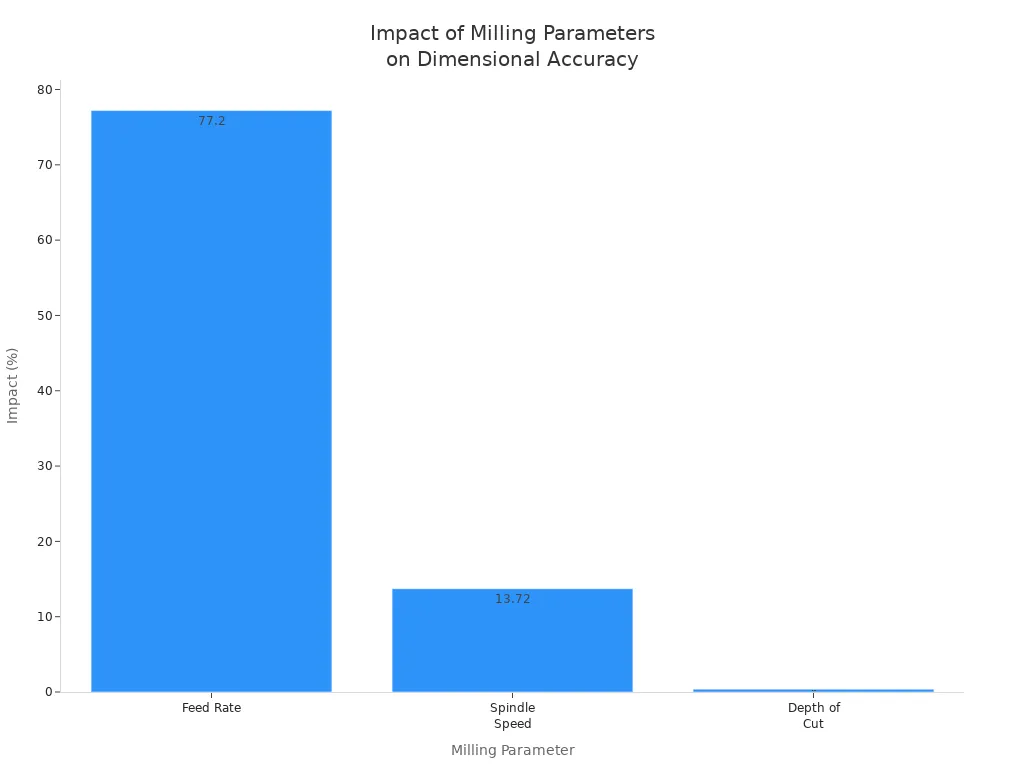

You want your parts to match your plans. The milling method and other things affect accuracy. Feed rate is the biggest thing that changes how close your part is to the plan. Spindle speed matters too, but not as much. Depth of cut changes accuracy the least.

Parameter | Effect on Dimensional Accuracy |

|---|---|

Feed Rate | Most important factor for accuracy (77.20%). |

Spindle Speed | Second most important factor (13.72%). |

Depth of Cut | Least important factor (0.38%). |

When you look at Climb Milling vs. Conventional Milling, always think about these key things. The best choice depends on your material, machine, finish, and accuracy needs.

Climb milling is also called down milling. In this method, the cutter moves the same way as the workpiece feed. The chip starts thick and gets thinner as the cutter goes forward. The cutting edge hits the workpiece at the top. Chips fall behind the cutter, so the area stays cleaner. This method pushes down on the workpiece. You do not need as much clamping. The cutter slices into the material more easily, so you use less power.

Here is a quick look at how climb milling works:

Aspect | Climb Milling (Down Milling) |

|---|---|

Chip Width | Starts at maximum and decreases |

Cutting Edge Interaction | Meets the workpiece at the top |

Chip Management | Chips are dropped behind the cutter |

Tool Wear | Less wear, up to 50% longer tool life |

Surface Finish | Improved due to less recutting |

Power Requirement | Requires less power |

Workholding | Simpler due to down force |

Climb milling has many good points. It gives you a smoother surface finish. Your cutting tools last longer because there is less rubbing and heat. You can also take away material faster. This helps you finish jobs more quickly.

Advantage | Description |

|---|---|

Better Surface Finishes | Climb milling produces smoother finishes on machined parts. |

Lower Tool Wear | This technique reduces the wear on cutting tools. |

Faster Material Removal Rates | Climb milling allows for quicker removal of material, enhancing productivity. |

💡 Tip: If you want to work faster and make your tools last longer, climb milling is often the best choice. This is true, especially if you use modern machines.

Climb milling does have some risks. You need a strong machine with little or no backlash. If your machine is old or has worn parts, the cutter can pull the workpiece into itself. This can break your tool or damage your part. Sometimes, the table may move suddenly if there is too much play. This can cause injury or flying debris.

Climb milling needs strong machines with almost no backlash.

On old machines with worn parts, the cutter can pull the workpiece in, which can break the tool or damage the part.

Climb milling can have backlash problems if cutter forces are high.

The table might get pulled into the cutter. If there is backlash, this can break the tool and cause injury from flying debris.

When you compare climb milling vs. conventional milling, always check your machine’s condition and safety before you choose.

Conventional milling is also called up milling. The cutter moves against the feed direction. The cutting edge starts at zero thickness. The chip gets thicker as the cutter moves forward. Chips start small and get bigger. The cutter pushes up on the workpiece. You must clamp the workpiece tightly. Chips fall in front of the cutter. You may need to clean them away often.

Here is a table that shows how conventional milling and climb milling are different:

Feature | Conventional Milling | Climb Milling |

|---|---|---|

Cutter Rotation | Same direction as feed (fighting the feed) | Opposite direction to feed (climbing) |

Chip Formation | Starts at zero width, increases | Starts at maximum width, decreases |

Surface Finish | Generally worse due to chip recutting | Better surface finish |

Tool Wear | More wear due to upward forces | Less wear due to downward forces |

Machine Requirements | Less powerful machines can be used | Requires more powerful machines |

Application | Preferred for rough surfaces | Preferred for smoother finishes |

There are good reasons to use conventional milling. It works with many materials like glass, metal, plastic, and wood. This method is safer for old or less accurate machines. The cutter pushes the workpiece down, so it stays in place. This helps stop chipping. You can use this method for hard materials or rough surfaces.

Works with glass, metal, plastic, and wood.

Good for older or less accurate machines.

Helps hold the workpiece and stops chipping.

Useful for hard materials and rough surfaces.

🛠️ Tip: If your machine has backlash or you cut tough materials, conventional milling gives you more control.

Conventional milling has some problems. The tool wears out faster because it rubs before cutting. The finish is rougher since chips can get stuck and cut again. Chips fall in front of the cutter. This means you need to clean more and your part could get damaged.

Tool wears out faster than with climb milling.

Surface finish is rougher because of chip recutting.

Chips fall in front and can get cut again.

When you look at Climb Milling vs. Conventional Milling, think about your machine, the material, and the finish you want. Both methods are useful in the shop.

You might ask how climb milling and conventional milling are different in a real shop. The table below shows the main differences between these two methods. It looks at surface finish, chip removal, tool life, and accuracy.

Feature | Climb Milling | Conventional Milling |

|---|---|---|

Surface Finish | Better surface finish because it cuts cleaner and shakes less. | Rougher finish from more rubbing and heat. You may need to polish more. |

Chip Removal | Chips move away from the cut. It removes chips fast and keeps the area clean. | Chips fall in front of the cutter. It does not remove chips as well. |

Tool Life | Tools last longer. There is less rubbing and lower cutting force. | Tools wear out faster. There is more rubbing and quicker wear. |

Dimensional Accuracy | Very accurate on strong, new machines. | More control on old machines or thin parts. |

Machine Requirement | Works best with new, strong machines that have little backlash. | Safer for old machines or those with backlash. |

Application | Good for most materials and smooth finishes. | Good for hard surfaces, thin walls, or rough cuts. |

📝 Note: Climb Milling vs. Conventional Milling is not only about speed. You should also think about your machine, the shape of your part, and the finish you want.

You need to pick the right milling method for your project. Here are some tips to help you choose:

Use climb milling when:

You have a new, strong machine with little or no backlash.

You want a smooth surface finish and tools that last longer.

You need to remove material quickly and keep the work area clean.

Your material is soft or medium-hard, and you want to stop burrs.

Use conventional milling when:

You use an old machine or one with a lot of backlash.

You need to cut thin-walled parts and want to stop the tool from bending.

You cut hard outer layers, like castings or forgings.

You use ceramic inserts in heat-resistant alloys.

Climb milling is usually chosen for most new projects. It gives a better surface finish, removes chips faster, and helps tools last longer. Many machinists pick climb milling for most jobs, especially when the machine and setup are good.

But conventional milling is still important in the shop. If you work with thin walls, use conventional milling for the last pass. This helps you keep accuracy and stops the part from bending. Old machines with backlash also work better with conventional milling because the cutting forces are steadier.

💡 Tip: For the best results, always match your milling method to your machine, material, and part design. Climb Milling vs. Conventional Milling is not the same for every project.

You need to pick the best milling method for your project. First, think about what you are making. Next, look at the material and your machine’s condition. Some projects work better with climb milling. Other projects need conventional milling.

Projects that benefit from climb milling include:

Aerospace parts need tight tolerances and smooth finishes.

Automotive components need speed and good surface quality.

Medical manufacturing needs precision for implants and tools.

Climb milling is good for these projects. It gives a cleaner finish and helps tools last longer. You also save time by removing material quickly.

Conventional milling fits other types of projects. Check the table below to see when you might use this method:

Project Type | Benefits |

|---|---|

Simple and single elements | You can finish faster if you have experience. |

Small-volume production | Good for small orders or when you need changes. |

Modifications of existing elements | You can repair or adjust parts more easily. |

If you do repairs or small batches, conventional milling gives more control. You can use it for hard surfaces or older machines.

Machine rigidity also matters. The table below shows how your machine’s strength affects your choice:

Milling Method | Effect of Machine Rigidity |

|---|---|

Climb Milling | Needs a strong, rigid setup to avoid backlash. |

Conventional Milling | Works with less rigidity but may lower finish quality. |

🛠️ Tip: Always check your machine before you start. If your machine feels loose or has backlash, use conventional milling for safety.

You can get better results by following easy tips. Avoid mistakes to keep your parts accurate and your tools safe.

Tips for better climb milling:

Use sharp tools with a positive rake angle. This lowers cutting resistance.

Set up your tools carefully. Make sure everything is tight and lined up.

Use higher feed rates. This helps reduce heat and gives a better finish.

Apply coolant or lubrication. This keeps your tool cool and helps it last longer.

Watch your process. Check for tool wear and make small changes as you go.

Extra tips for both methods:

Do not use climb milling with handheld routers. This is dangerous.

Use climb milling for small parts that need a perfect finish.

Avoid climb milling on the first pass if the material is rough or oxidized.

Try conventional milling if your stepover is more than half the cutter’s diameter.

Make sure older machines have a backlash eliminator and the right tool size.

Common mistakes to avoid:

Ignoring machine rigidity. Weak machines can cause chatter or tool breakage.

Using the wrong feed rate. Too slow can burn your tool, too fast can break it.

Forgetting to check tool sharpness. Dull tools ruin your finish and accuracy.

Skipping coolant. This causes heat buildup and shortens tool life.

💡 Note: Always match your milling method to your project’s needs. Think about the material, the finish you want, and your machine’s strength. Climb Milling vs. Conventional Milling is not a one-size-fits-all choice. You get the best results when you pick the right method for your job.

Climb milling is best for most new projects. Many experts say it makes smoother parts. It also helps tools last longer and work faster. Conventional milling is good for old machines or hard materials. Always look at your project and your machine before you pick.

Factor | Climb Milling | Conventional Milling |

|---|---|---|

Surface Finish | Smoother | Not as smooth |

Tool Life | Lasts longer | Wears out faster |

Machine Requirement | Needs strong, new | Works with older ones |

Tell us your milling stories or ask questions below. Your ideas help everyone learn!

Climb milling moves the cutter with the feed direction. Conventional milling moves the cutter against the feed. Climb milling makes a smoother finish. Conventional milling is better for older machines.

Climb milling works best on strong, modern machines. These machines have little backlash. Old machines may not control backlash well. This can break tools or give bad results.

Climb milling gives a smoother and cleaner surface. The cutter slices the material easily. You do not need to polish as much.

Pick conventional milling if your machine is old or has backlash. It works well for hard outer layers and thin walls. You get more control and stay safer.

Navigation

Navigation

Contact Us

Tel: +86 13417419143

E-mail: [email protected]

Add:

2nd Floor, Building 7, 156 High Tech Industrial Park, Fuyuan 1st Road, Zhancheng Community, Fuhai Street, Baoan District, Shenzhen City, China.