Sep.

23, 2025

Contents

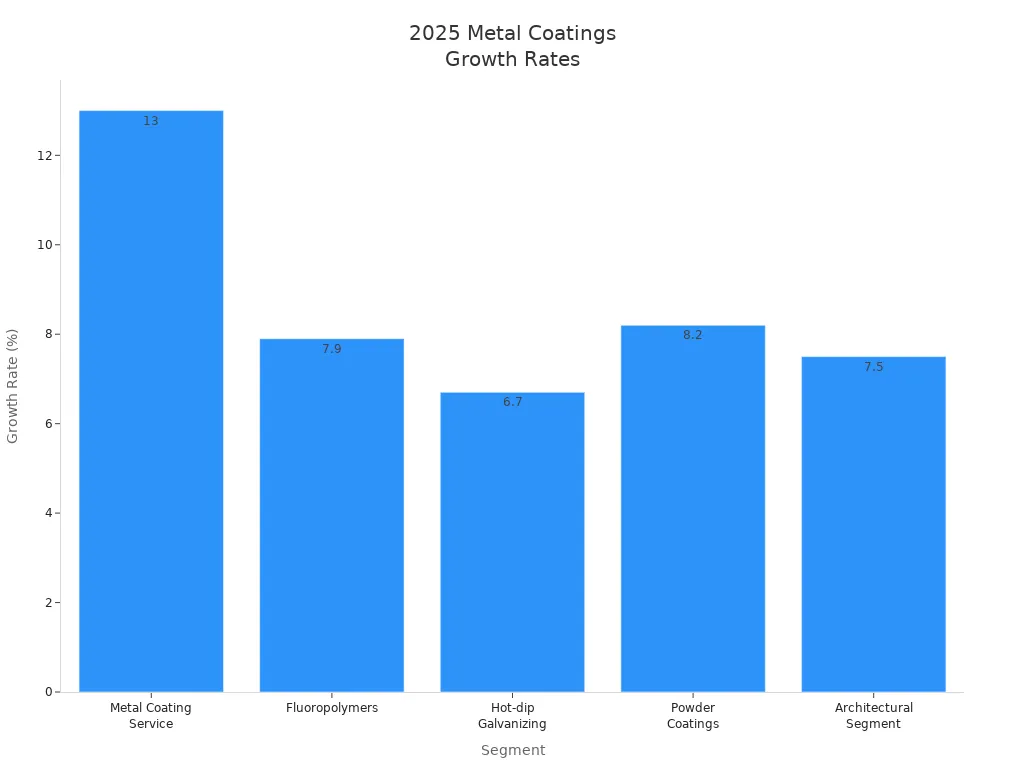

Exploring the Most Common Metal Coatings for 2025

You will notice new changes in Metal Coatings in 2025.

Eco-friendly and low-VOC coatings are getting popular.

Smart coatings can fix themselves when damaged.

Powder coating is used more often now.

Advanced corrosion-resistant coatings last longer.

Digital tools help watch the coating process.

Nano-coatings work well for very small details.

Metal coatings keep surfaces safe from rust and harm. The market is growing because of new ideas and strict rules. Solvent-borne coatings and epoxy resins are strong and last long.

You should pick the coating that fits your needs. Watch for new technology too.

You want metal things to last a long time. Metal coatings help stop rust and damage. They keep dirt and oil away from surfaces. Heavy machines like trains and cars use these coatings. Boats use them too. The coatings protect against oil and debris. They help stop chipping and scratching. Your machines stay strong when you use coatings. Some coatings help screws and bolts move easily. This makes them last longer.

Tip: Metal coatings can be liquid or powder. You can spray them on or dip things in them. Pick what works best for your project.

Here is a table that shows how metals do with coatings:

Metal | Corrosion Resistance | Surface Hardness | Longevity |

|---|---|---|---|

Stainless Steel | High | Moderate | Long-lasting |

Moderate | Low | Long-lasting | |

Copper | Moderate | High | Moderate |

Titanium | Very High | High | Very Long-lasting |

You do not have to pick between looks and strength. Metal coatings give you both at once. You can choose finishes that match your style. Some are smooth or shiny for cars and appliances. Coatings help products work better too. Some coatings resist heat. Others stop wear and tear. You can find coatings for almost any need.

The main types of metal coatings include:

Paint coatings like epoxy, polyurethane, acrylic, and alkyd.

Aluminum, nickel, titanium, and chrome coatings for extra protection.

Ceramic coatings for high heat.

Galvanization, powder coating, and anodizing for special uses.

You can pick the right coating. Your metal things will last longer and look nice.

Anodizing makes metals stronger and better looking. This process uses electricity to build a hard oxide layer on metal. Here is what happens: First, you put the metal in a special liquid. The metal becomes the positive side. Then, electricity flows through the liquid. Oxygen joins with the metal and forms a new layer.

You see anodizing used with these metals:

Aluminum

Titanium

Magnesium

Zinc

Niobium

Tantalum

Anodized coatings have many good points. The table below explains why people pick this method:

Benefit/Application | Description |

|---|---|

Corrosion Resistance | Anodizing makes a strong shield that stops rust, so it works well in tough places. |

Wear Resistance | The hard surface helps stop damage and makes parts last longer. |

Aesthetic Enhancement | You can get many colors and finishes, so it looks nice for electronics and home items. |

Applications in Industries | People use it in boats, planes, and buildings because it is tough and looks good. |

Tip: Anodizing is a good choice if you want both protection and color.

Galvanizing keeps metals safe by adding a zinc layer. You see this most with steel and iron. Here is how it works: First, clean the metal. Next, dip or coat it with zinc. Last, treat the surface to help it last longer.

The main metals for galvanizing are:

Steel

Iron

Other ferrous metals like cast steel, cast iron, malleable iron, hot-rolled steel, and cold-rolled steel

Galvanized coatings protect very well. Here are the top reasons to use them:

Corrosion resistance: The zinc keeps out water and air.

Durability: Galvanized steel handles bad weather and heavy use.

Cost-effectiveness: You save money because it needs less fixing.

You see galvanized metal in many places:

Beams, columns, and trusses

Roofs and walls

Fences and gates

Building frames

Road and bridge supports

Outdoor monuments

Note: Galvanizing is smart for outdoor things that need to last.

Electroplating uses electricity to cover metal with another metal. This can make things look better or work better. Here is how it works: Put the object in a liquid with metal ions. Electricity moves the metal onto the object and makes a new layer.

Common metals for electroplating are:

Zinc (for stopping rust)

Nickel (for strength and electricity flow)

Chrome (for a shiny look)

Electroplated coatings have many benefits:

More corrosion resistance: Stops water, chemicals, and heat from hurting it.

Better wear resistance: Parts last longer when rubbed.

Good conductivity: Needed for electronics and cars.

Harder surface: Stops dents and scratches.

Looks better: Makes things shiny and neat.

Cheaper protection: Costs less than using solid precious metals.

You find electroplated coatings on:

Car parts

Plane parts

Electronic connectors and circuit boards

Medical tools

Oil and gas equipment

Building metalwork

Tip: Electroplating is great if you want both good looks and strong parts.

Powder coating gives a strong, colorful finish without wet paint. There are three steps: First, clean the metal. Next, spray on dry powder. Last, heat the metal so the powder turns into a hard layer.

You can powder coat these metals:

Aluminum

Mild steel

Stainless steel

Galvanized steel

Cast iron

Powder coating has many good points:

Durability: It does not scratch, chip, or fade easily.

Versatility: You can pick from many colors and textures.

Efficiency: It is quick and does not waste much.

Environmental friendliness: It has no bad chemicals.

Cost-effectiveness: One coat covers a lot and saves money.

Easy maintenance: It is simple to keep clean.

You see powder-coated items in:

Outdoor furniture

Car parts

Factory machines

Farm equipment

Note: Powder coating is best for things that get rough use or stay outside.

Paint coating is a classic way to protect and decorate metal. You can use different ways to put on paint:

Method | Description | Advantages | Disadvantages |

|---|---|---|---|

E-Coating | Uses electricity to put on wet paint. Parts are dipped in paint. | Makes a tough finish, good for car undercoating. | Not good in sunlight, few color choices (mostly black or white). |

Spray Painting | Cheap and easy, uses air to spray paint. | Good for matching colors, works for small jobs. | Needs good prep, may not last as long as other ways. |

Powder Coating | Dry powder sprayed and baked for a hard layer. | Stops rust well, safe for the planet, lasts a long time. | Needs special tools, hard to remove, some sun limits. |

Paint coatings have many key benefits:

Stops damage from weather: Keeps out rust and corrosion.

Lowers repair costs: You do not need to fix or repaint often.

Makes things last longer: Metal stays strong for years.

Looks better and adds value: Keeps things clean and nice.

Safer and more reliable: Adds a safe layer for use.

You see paint coatings on:

Cars and trucks

Bridges and buildings

Appliances

Tools and machines

Tip: Paint coatings let you pick from many colors and styles.

Metal Coatings help protect, decorate, and make metal last longer. Each type has its own strengths, so you can choose what works best for you.

You want metal things to last a long time. Rust can ruin metal fast, especially near the sea or in factories. Coatings like anodizing add a thick layer that keeps out water and air. Plasma Electrolytic Oxidation (PEO) makes an even stronger shield. It stands up to chemicals and heat. These coatings help metal parts fight rust and work longer.

Anodizing makes aluminum harder to rust.

PEO uses plasma to build a tough shell.

Both work well outside, if the coating is at least 20μm thick.

Tip: Using a coating saves money because you fix things less often.

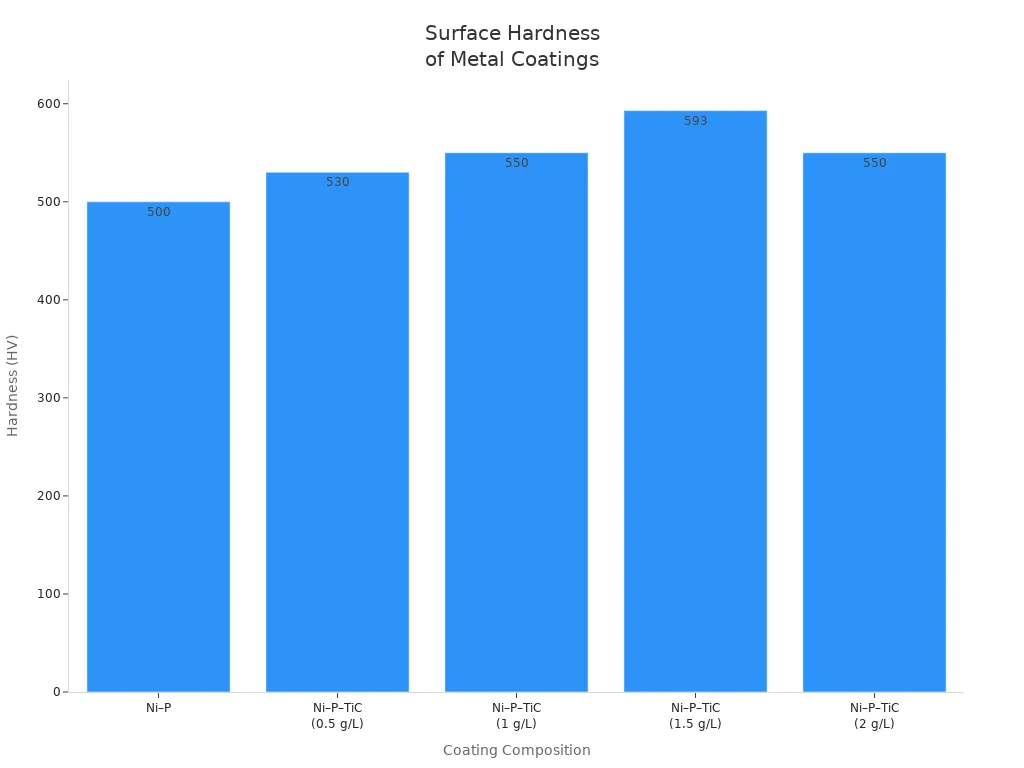

You need metal that does not scratch or wear out fast. Coatings can make metal much harder. Adding titanium carbide (TiC) to nickel-phosphorus (Ni–P) makes it up to 19% harder. Some coatings, like Al2O3/GO, make metal over 40% harder. Harder metal means your tools and machines last longer and work better.

Coating Composition | Hardness (HV) | Hardness Increase (%) |

|---|---|---|

Ni–P | ~500 HV | N/A |

Ni–P–TiC (0.5 g/L) | ~530 HV | 6% |

Ni–P–TiC (1 g/L) | ~550 HV | 10% |

Ni–P–TiC (1.5 g/L) | ~593 HV | 19% |

Ni–P–TiC (2 g/L) | ~550 HV | N/A |

You want metal things to last outside in any weather. Metal coatings protect from heat, wind, wet air, and rain. Zinc-rich coatings like ZRC Cold Galvanizing Compound keep metal safe from high heat and water. They also stop scratches from blowing sand and block rust from rain. This keeps bridges, fences, and outdoor machines working longer.

Environmental Factor | Impact on Metal Coatings | Protective Role of ZRC Cold Galvanizing Compound |

|---|---|---|

Extreme Heat | Makes rust happen faster | Stays strong in heat and wet air |

Wind | Scratches the surface | Stops tiny scratches |

Humidity | Makes rust worse | Works well in wet places |

Rainwater | Starts rust | Zinc keeps metal safe |

You want your things to look nice and stand out. Metal coatings let you add color, shine, or texture. You can match your brand or make a cool style. A good look can make your product worth more and help it sell better. In busy markets, a great finish helps people notice your product.

Coatings add color, shine, or special textures.

You can pick finishes for different looks.

Nice finishes can help you sell more and make your product special.

Note: Metal coatings protect and also make your products look better and worth more.

You will see more eco-friendly metal coatings soon. Companies want to help the environment. Many use water-based, powder, and high-solid coatings with low VOCs. These coatings help keep the air clean. They also follow strict rules about pollution. The automotive industry is leading this change. Big companies like BASF make new eco-friendly paints for cars and trucks.

Water-based coatings help lower air pollution.

Powder coatings do not make harmful fumes.

High-solid coatings use less solvent, so they are safer.

Companies change products to meet new standards.

Note: Tougher rules like the EU's REACH and VOC limits make companies pick safer and greener choices. This helps protect workers and the planet.

New technology will change metal coatings. These new ideas make coatings stronger and safer. They also last longer. Here is a table that shows some top technologies for 2025:

Technology Type | Description |

|---|---|

Nanotechnology-Based Coatings | Make metal harder and stop rust at a tiny level. |

Eco-Friendly Coatings | Use water-based and low-VOC finishes to help the environment. |

Self-Healing Materials | Fix small scratches or damage by themselves, so things last longer. |

Advanced Thermal Sprays | Help parts handle heat better in hot places. |

You will see these new coatings in many industries. Cars and buildings use them. They help things work better and follow new safety rules.

Smart coatings will be talked about more in 2025. These coatings can sense changes around them. They react to protect metal surfaces. Some smart coatings release special chemicals when rust starts. Others fix small cracks by themselves. This means you spend less time and money fixing things.

Smart coatings help you follow strict rules because they use safer materials. They also make products last longer and look nicer. You can trust smart coatings to keep metal safe, even in tough places.

Tip: Smart coatings are a good choice if you want less work and more protection for your metal things.

You get lots of good things from metal coatings. They protect metal from rust. They help surfaces stay strong for a long time. Coatings make things look nicer. They help electronics work better. You save money because you do not fix things as much.

To pick the best coating, do these steps. First, choose coil or extrusion application. Next, check if it works in bad weather. See if it bends and does not break. Make sure it does not get damaged easily. Check that the coating has all needed certifications.

Learning about new coating technology helps you stay safe. It helps you use less energy. Your products last longer, even in hard places.

You should choose galvanizing or powder coating for outdoor items. Both protect metal from rain, sun, and wind. Powder coating gives you more color choices. Galvanizing works well for fences and bridges.

You can paint over some coatings, like galvanized or anodized surfaces. Clean the surface first. Use a primer made for metal. This helps the paint stick better and last longer.

Most metal coatings last 10–20 years. Some, like anodizing or powder coating, can last even longer. The lifespan depends on the environment and how you care for the item.

Tip: Clean and check your coated metal often. This helps it last longer.

Eco-friendly coatings protect metal well. Many new products use water-based or powder formulas. These coatings meet strict rules and keep your items safe from rust and damage.

Coating Type | Eco-Friendly | Strong Protection |

|---|---|---|

Powder Coating | ✅ | ✅ |

Water-Based Paint | ✅ | ✅ |

Navigation

Navigation

Contact Us

Tel: +86 13417419143

E-mail: [email protected]

Add:

2nd Floor, Building 7, 156 High Tech Industrial Park, Fuyuan 1st Road, Zhancheng Community, Fuhai Street, Baoan District, Shenzhen City, China.