Jun.

26, 2025

Contents

Understanding CNC Surface Roughness for Better Machined Parts

Measuring and Specifying Roughness

Achieving Desired Surface Finish

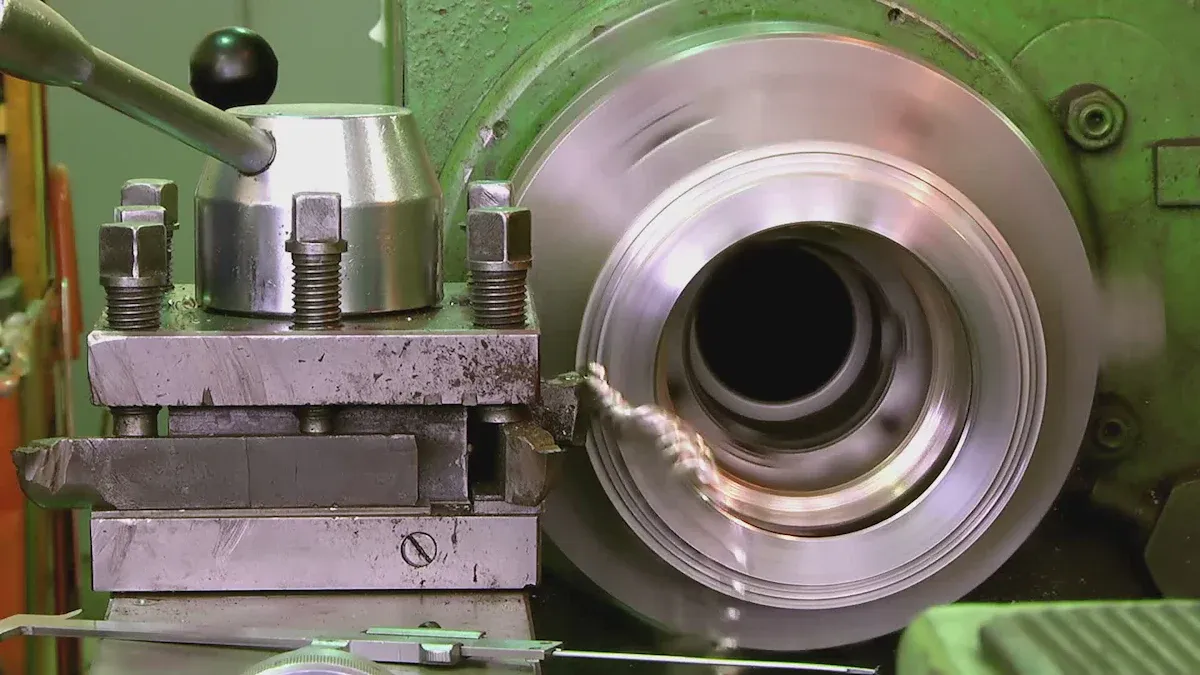

Imagine you need a smooth finish on a metal part for a machine. CNC Surface Roughness means the tiny bumps and dips left on a part after machining. This roughness changes how parts fit, look, and work. When you set things like feed rate and cutting speed, you can see up to 70% of surface finish changes. A better finish often lowers costs and makes parts last longer. You need to know how to measure and choose the right roughness for your parts.

Surface roughness means there are tiny hills and valleys on a part. These small bumps happen when the part is cut. CNC Surface Roughness shows these little height changes on the surface. People use special tools called profilometers to measure them. The most common way to talk about roughness is the Ra value. Ra stands for Roughness Average. Ra tells you the average height difference from the middle line over a certain length. There are other ways to measure roughness too. Rz shows the biggest height between the tallest peak and the lowest valley. RMS (Root Mean Square) is another way to look at the average height changes.

Researchers use careful machines and steps to get these numbers. They take measurements at different spots and then average them. They also remove any strange results to keep the numbers correct. Studies show that cutting speed, feed rate, and depth of cut all change roughness. If you cut faster, the surface is usually smoother. If you feed the tool faster, the surface gets rougher. The type of material matters too. Softer or less dense materials often have higher roughness because they have more pores.

Tip: Ra is the most common number used to check if a part meets industry rules. You will see it in micrometers (μm) or microinches.

CNC Surface Roughness is important for how parts fit, look, and work. Picking the right roughness helps your parts last longer and work better. A smoother surface can lower friction and wear. It can also stop cracks from starting, so parts do not break as easily.

| Surface Roughness (Ra) | Typical Application Contexts and Effects on Part Fit and Performance |

|---|---|

| 3.2 μm | Standard finish for parts under vibration or light load. Good fit and function, but visible tool marks remain. |

| 1.6 μm | Used for most machinery parts. Works well for slow-moving or lightly loaded surfaces. |

| 0.8 μm | Needed for high-stress parts like bearings or electronics. Gives close control and better durability. |

Different jobs need different surface finishes. Smoother finishes help bearings run quietly and last longer. Sometimes, making the surface better can make a tool last ten times longer. Smoother surfaces help parts fight fatigue and wear. This means they can take more stress before breaking. If you remove rough spots, a part can last over 35% longer.

Remember: Picking the right CNC Surface Roughness helps you balance cost, looks, and how well parts work. If the finish is too rough, parts may wear out fast or not fit right. If the finish is too smooth, you might spend more money than needed.

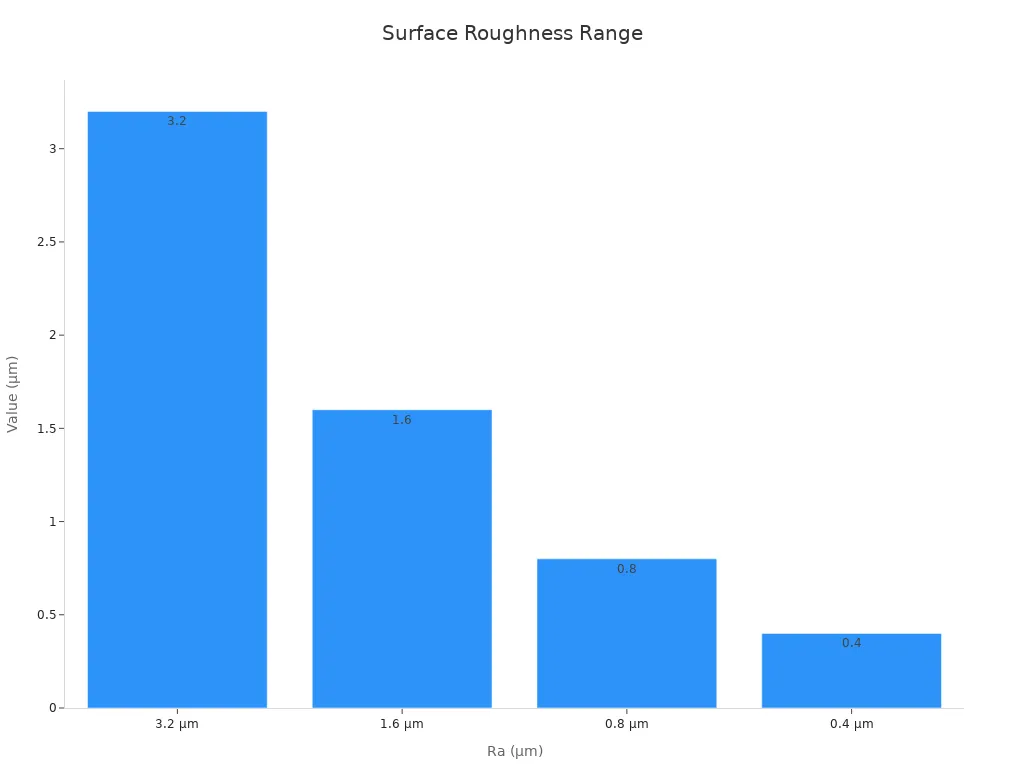

There are many surface roughness values in CNC machining. Ra is the main way to measure them. Most CNC parts have Ra between 0.1 and 6.3 micrometers (μm). Standard parts usually have an Ra of about 3.2 μm. If you want a smoother part, you can ask for more finishing. This can lower the Ra to 1.6, 0.8, or even 0.4 μm. Each smoother step takes more time and costs more money.

Here is a table that shows what Ra values mean and where they are used:

| Surface Roughness (Ra, μm) | Description | Typical Applications | Notes |

|---|---|---|---|

| > 6.3 | Very rough | Basic parts where finish does not matter | Milling or turning with no extra steps |

| 3.2 | Standard finish with cut marks you can see | Consumer parts, stressed parts, light load surfaces | Normal finish, no extra cost |

| 1.6 | Some cut marks still show | Tight fits, stressed parts, slow-moving surfaces | Adds about 2.5% cost for aluminum alloys |

| 0.8 | High quality, needs close control | Parts with stress spots, some bearings | Adds about 5% cost for aluminum alloys |

| 0.4 | Finest, best finish | High stress parts, fast spinning parts like bearings | Adds about 11-15% cost for aluminum alloys |

| < 0.4 | Ultra-smooth finish | Sealing surfaces, optical parts, fluid-contact parts | Made by grinding, lapping, or polishing |

You can also look at these values in a chart:

Ra values for CNC work often fall between 0.1 and 50 microinches. This covers most jobs, from rough cuts to very smooth finishes.

You need to pick the right roughness for the job. If the finish is too rough, the part may wear out fast or not fit well. If the finish is too smooth, it may cost too much. The best choice depends on how you use the part, how it should look, and your budget.

Here is a table that links Ra values to real uses:

| Ra Range (μm) | Surface Condition | Application Examples |

|---|---|---|

| 0.025–0.2 | Super Precision Polishing | Optical lenses, high-precision bearings |

| 0.2–0.8 | Precision Machining | Hydraulic valves, sealing surfaces, precision molds |

| 0.8–3.2 | Ordinary Machining | Gear teeth, shaft parts |

| 3.2–12.5 | Rough Machining | Non-mating surfaces, casting blanks |

For example, very smooth finishes (Ra less than 0.4 μm) are used in aerospace parts, fast bearings, and sealing surfaces. These parts need the smoothest surface to lower friction and wear. A standard finish (Ra 3.2 μm) works for most consumer products and machine parts that do not need a perfect surface.

Note: Smoother finishes cost more. For aluminum alloys, going from a 3.2 μm finish to a 0.4 μm finish can raise costs by up to 15%. Only ask for a very smooth finish if your part really needs it.

Sometimes, surface roughness changes how a part works in its place. For example, in offshore work, rougher surfaces can change how water moves around a part. This can change drag and how well it works. In dental work, studies show that enamel wear stays low when Ra is below 0.75 μm. If roughness is higher, wear goes up a lot.

CNC Surface Roughness is not just about looks. It changes how parts fit, move, and last. Picking the right roughness helps your parts work better and saves money.

You can change surface roughness by changing how you machine. Feed rate, cutting speed, and depth of cut are important. Feed rate changes roughness the most. If you make the feed rate higher, the surface gets rougher. Cutting speed is also important. When you cut faster, the surface is smoother. This is because fast cutting lowers tool shaking and stops built-up edge. Depth of cut matters less, but deeper cuts can still make the surface rougher.

You should check your tool often. If your tool is old or broken, it can leave marks. This makes the surface bumpy. Tool shaking can also change the surface and make lines you do not want. If you keep your tools sharp and steady, you get a better finish.

Here is a table that shows how each parameter changes surface roughness:

| Parameter | Influence on Surface Roughness | Notes |

|---|---|---|

| Feed Rate | Most significant | Higher feed rates make surfaces rougher. |

| Cutting Speed | Second most significant | Higher speeds improve finish by reducing vibration and built-up edge. |

| Depth of Cut | Less significant | Deeper cuts increase roughness. |

| Tool Condition | Indirectly considered | Worn tools and vibration can harm surface quality. |

The temperature of the part also changes the finish. When you cut faster, the part gets hotter. This can make the material softer and change how it cuts. If it gets too hot, the part can melt or smear. This makes the surface rougher.

Tip: Use the best speed, feed, and depth to get a good finish.

The material and tools you pick change surface roughness. Some materials, like PLA plastic, are stiff and give a smoother finish. Softer metals or plastics can look rougher after you machine them.

If you cut faster, the part can get hot and melt. This can make the surface uneven.

The way the tool moves and the direction you cut can change the surface look.

Slower cutting and flat build shapes usually give the smoothest finish.

Thicker walls and more fill in 3D-printed parts make the surface stronger and smoother.

Picking the right tool is important. A sharp tool that matches your material gives a better finish. If you use a dull or wrong tool, you may see scratches or bumps.

Remember: Picking the right material and tool helps your part look and work better.

There are a few ways to check surface roughness on parts. The profilometer is the most used tool. It has a small stylus that moves over the part’s surface. This stylus records all the bumps and dips it finds. Profilometers can measure Ra, Rz, and RMS values. They are accurate within about ±12% of the real value. These tools work best for Ra between 0.05 and 10.0 µm. They also work for Rz from 0.1 to 50 µm.

Other ways to measure include tape, depth micrometers, and optical checks. Depth micrometers can give results like the stylus and tape if you average the highest points. This matches ASTM rules and helps you get good data. Optical checks use light to scan the surface. They are fast and do not touch the part. But they may not be as good if the part is shiny or dark. Interferometry is another way that does not touch the part. It is very accurate but works best on very smooth surfaces.

Here is a table that shows how accurate and what range these tools have:

| Parameter | Value/Range |

|---|---|

| Accuracy | ±12% of actual value |

| Measuring Range (Ra) | 0.05 to 10.0 µm |

| Measuring Range (Rz) | 0.1 to 50 µm |

| Measuring Range (Rq) | 0.05 to 10.0 µm |

| Measuring Range (Rt) | 0.1 to 50 µm |

Tip: Always make sure your tool can measure the right range and is accurate before you check CNC Surface Roughness.

When you look at surface roughness numbers, you will see Ra, Rz, and RMS (Rq) a lot. Each one tells you something different about the part’s surface.

| Parameter | Definition | Typical Range (µm) | Application/Interpretation |

|---|---|---|---|

| Ra | Average height of peaks and valleys from the mean line | 0.1 - 6.3 | Used for general quality checks and looks |

| Rz | Height from the tallest peak to the deepest valley over five samples | 10 - 50 | Important for seals and moving parts |

| Rq (RMS) | Root mean square of profile height deviations | 0.05 - 50 | Used for optical parts and bearings |

You should always write the roughness you need on your drawings. For example, you might put "Ra 1.6 µm" next to a surface. This tells the machinist what finish you want. Standard tolerances, like ±0.1 mm, show how much the size can change. They also connect to what roughness you can get. If you need a very tight tolerance, you usually need a smoother surface.

Note: Picking the right way to measure and reading the results the right way helps you get the best part quality.

There are many ways to get the surface finish you want. Each way works differently and gives different results.

Mechanical Finishing

Grinding: A spinning wheel smooths the part’s surface. This can make the part very smooth, even down to 0.1 μm Ra.

Polishing and Buffing: Soft pads and fine grit make the part shiny and smooth.

Abrasive Blasting: Tiny particles hit the part to change its look. Glass bead blasting makes a smooth, dull surface. Aluminum oxide blasting is rougher and takes off more material. Plastic bead blasting is good for soft metals. Silicon carbide blasting is the roughest and works on tough jobs.

Chemical Finishing

Anodizing: This puts a strong layer on aluminum parts. It helps stop rust and makes the part last longer.

Electroplating and Chemical Etching: These add or take away thin layers. This changes how the part looks and works.

Electrochemical Finishing

Electropolishing: The part goes in acid and gets electricity. This removes tiny bumps and makes the part shiny. It also helps stop rust.

| Method | Pros | Cons | When to Use |

|---|---|---|---|

| Grinding/Polishing | Makes parts very smooth and exact | Takes time and skill | For shiny or precise parts |

| Abrasive Blasting | Works fast and covers big areas | Can make the part rough, less exact | For dull or textured surfaces |

| Anodizing/Electroplating | Protects and changes color | Needs special tools | For stopping rust or changing look |

| Electropolishing | Makes parts smooth and shiny, stops rust | Needs chemicals, best for metals | For clean or medical parts |

You can get smoother parts by following these tips:

Change cutting speed and feed rate to lower marks and heat.

Use sharp, hard tools and keep them in good shape.

Make sure your machine does not shake.

Use coolants to keep things from getting too hot.

Try polishing or grinding if you need a very smooth part.

Check your parts often with a profilometer to see if the finish is right.

Change spindle speeds or use special materials to stop shaking.

Tip: Always write the finish you want on your drawings. This helps everyone know what to do.

If you do not use dull tools or skip checks, your parts will turn out better. Keep your data and measurements clear and up to date. Watch out for strange results, and always check the whole part when looking at surface quality.

Knowing about CNC Surface Roughness helps you make strong parts. These parts can last longer and work better. You must think about how the part works, what it costs, and how it looks. Picking a smoother surface can help parts move with less rubbing. It also helps them wear out slower. But making a smooth surface costs more money. Sometimes, a rougher finish is best. It can help hold oil or give better grip. You should always follow the rules and use good steps to get the finish you need.

Smoother surfaces help parts work better but cost more.

Some parts need to be rough for special jobs.

Most drawings show the highest roughness allowed to keep quality good.

Tip: Always write down the roughness you want before you start machining.

Ra stands for Roughness Average. You use it to measure the average height of bumps and dips on a part’s surface. Most industries use Ra to check if a part meets quality standards.

You should think about how the part will work. Smoother surfaces help moving parts last longer. Rougher finishes cost less. Always match the roughness to the part’s job and your budget.

Yes, you can. You use finishing methods like grinding, polishing, or blasting to make the surface smoother. These steps help you reach the finish you need for your part.

Yes, it does. Smoother surfaces lower the risk of cracks and wear. This helps your parts last longer and work better, especially in high-stress jobs.

You use a profilometer or a surface tester. These tools move across the part and measure the bumps and dips. You then read the Ra or Rz value to see if the finish meets your needs.

Navigation

Navigation

Contact Us

Tel: +86 13417419143

E-mail: [email protected]

Add:

2nd Floor, Building 7, 156 High Tech Industrial Park, Fuyuan 1st Road, Zhancheng Community, Fuhai Street, Baoan District, Shenzhen City, China.