Aug.

20, 2025

Contents

Tungsten Steel 5-Axis CNC Machining for Durable Automotive Precision Components

You want car parts that work well and last long. Tungsten Steel 5-axis CNC machining gives you both things. Huaruida Precision uses smart machines and careful checks. This helps make parts you can count on. Picking good material and exact machining keeps your cars safe and working.

Strong materials like Tungsten Steel help make tough car parts. These parts are important for cars to work well.

5-axis CNC machining helps make parts with exact shapes. The machine moves in five ways. The cutting tool can reach the part from many sides. This lets it make smooth surfaces. It also keeps measurements very close. For example, 5-axis machines can be as exact as ±0.0005 inches (0.0127 mm). 3-axis machines are only exact to ±0.001 inches (0.025 mm). You save time because you do not need to move the part for every cut.

Here is a simple table to show how 5-axis CNC machining and 3-axis machining are different:

Aspect | 3-Axis CNC Machining | 5-Axis CNC Machining |

|---|---|---|

Axes Movement | Moves on X, Y, Z lines | Adds two turning axes for more angles |

Precision | ±0.001" (0.025 mm) | ±0.0005" (0.0127 mm) |

Complexity | Easier shapes, needs more setups | Hard shapes in one setup |

Automotive Use | Brackets, housings | Engine parts, special pieces |

The main steps for making car parts with 5-axis CNC machining are:

Make a CAD design and plan the tool path.

Get the material ready.

Do rough machining to shape the part.

Use precision machining for details.

Check and control the quality.

Finish the surface after machining.

Tungsten Steel helps car parts last longer and work better. It is strong and tough. Tungsten Steel has high tensile strength from 800 to 1200 MPa. Its hardness is 60-65 HRC. It stays strong even when it gets hot, up to 600°C. The density is 8.0 g/cm³. It does not wear out or get damaged by heat easily. These things make it great for hard jobs in cars, like engine parts and cutting tools.

Property Type | Key Properties and Values |

|---|---|

Mechanical | Tensile: 800-1200 MPa, Hardness: 60-65 HRC |

Physical | Density: 8.0 g/cm³, Melting Point: 2800°C |

Heat Resistance | Strong up to 600°C |

Chemical Composition | Tungsten, Chromium, Molybdenum, Vanadium |

Tip: If you pick Tungsten Steel for car parts, you get strong, tough, and heat-safe pieces.

You want car parts to last a long time. Tungsten Steel is very hard and strong. It does not wear out fast, even when it gets hot or parts rub together. Car makers use Tungsten Steel for engine parts, gears, and brakes. These parts keep working well, even when stressed.

Tungsten Steel stays strong when it gets hot. This matters for parts near engines or brakes.

It does not wear down as fast as most metals. You do not need to change parts often.

Tungsten carbide is a type of Tungsten Steel. It is almost twice as hard and dense as regular alloy steel. This helps it last longer and work better in tough jobs.

Car companies use Tungsten Steel for parts that take a lot of force. These include ball joints and transmission systems.

Tungsten Steel does not rust or get damaged by chemicals. Your parts stay strong in harsh places.

Note: In 2024, over 25% of tungsten industry money came from cars. This shows car makers trust Tungsten Steel for strong, long-lasting parts.

Here are some main reasons why Tungsten Steel is great for durability:

Very hard and tough

Great at resisting wear

Stays strong when hot

Handles heavy hits and loads

Not likely to crack or break

Car parts need to fit just right. Precision is important. Tungsten Steel works well with 5-axis CNC machining. This helps make parts with very tight tolerances. The parts match your design every time.

A study showed you can get tolerances as close as ±0.01 mm. This means your parts fit together well and work as they should.

Parameter / Aspect | Value / Description |

|---|---|

Setup tolerance | ±0.01 mm (ISO 230-1) |

Measurement systems | Digital Vernier Caliper, Coordinate Measuring Machine (CMM) |

Tooling | Tungsten carbide inserts with TiAlN coating |

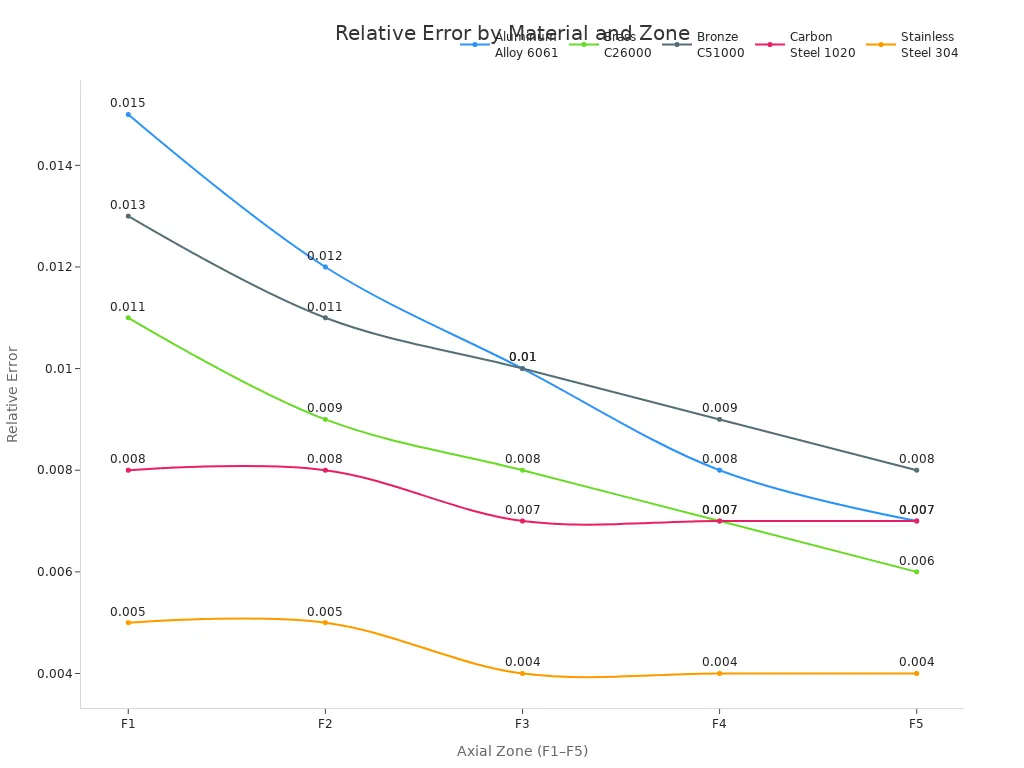

Relative error (CMM) for materials | As low as 0.004 mm |

These are the benefits of using Tungsten Steel for precision parts:

Parts are always high quality

Tight tolerances for a perfect fit

Less fixing or changing needed

Works better in fast or tough jobs

Tungsten Steel’s high wear resistance means tools and parts keep their shape. This helps you make accurate parts again and again.

You often need car parts with shapes that are not simple. Some parts have curves, holes at odd angles, or deep pockets. 5-axis CNC machining lets you make these complex shapes with ease. The machine moves the cutting tool in five directions at once. This means you can reach every side of a part without stopping to move it.

Traditional machines need you to stop and change the setup many times. Each time you move the part, you risk making a mistake. 5-axis CNC machining solves this problem. You can cut from all directions in one go. This reduces errors and saves time.

5-axis CNC machining lets you create parts like cylinder heads, engine blocks, and custom brackets. These parts often have undercuts, compound angles, and organic shapes. You cannot make these shapes with old methods.

You also get better accuracy. The machine keeps the part in the same place, so every cut lines up perfectly. You do not need extra fixtures or tools. This makes your parts more reliable and helps your car run better.

Here are some shapes you can make with 5-axis CNC machining:

Deep cavities and pockets

Angled holes and slots

Curved surfaces and organic forms

Undercuts and complex contours

You can even make one-piece parts that used to need assembly. This makes your parts stronger and lighter. In the car industry, this means better performance and safety.

You want your parts fast and with less waste. 5-axis CNC machining helps you do this. The machine finishes more work in one setup. You do not need to stop and move the part for each cut. This saves you time and reduces mistakes.

When you use 5-axis CNC machining, you also use your tools better. The cutting tool stays at the best angle. This keeps the tool sharp longer and gives your parts a smoother finish. You spend less money on new tools and get better results.

With 5-axis CNC machining, you can cut lead times and boost productivity. You finish jobs faster and keep your quality high.

Here is a table to show how 5-axis CNC machining improves efficiency:

Efficiency Factor | 3-Axis CNC Machining | 5-Axis CNC Machining |

|---|---|---|

Setups Needed | Multiple | Single |

Production Time | Longer | Shorter |

Tool Life | Shorter | Longer |

Surface Finish | Good | Excellent |

Error Risk | Higher | Lower |

You also get more parts done with the same number of workers. The machine does more of the hard work. This helps you meet tight deadlines and handle big orders.

If you need to make a prototype or a small batch, 5-axis CNC machining gives you flexibility. You can change designs quickly and still get high-quality parts. This is important when you want to test new ideas or respond to customer needs.

Tip: Use 5-axis CNC machining to save time, reduce waste, and get the best results for your automotive projects.

Car parts must be strong and work well. Huaruida Precision uses 5-axis CNC machining to help make these parts. This technology helps create many important car parts. Some examples are:

Engine blocks and cylinder heads

Transmission gears and shafts

Brake calipers and rotors

Battery tray frames for electric vehicles

Inverter housings and e-axle gears

You can get a prototype fast, sometimes in just three days. You do not have to buy a lot at once. There is no minimum order, so you order only what you need. Every part is checked to make sure it is good. You get parts that meet strict car rules.

Tip: On-demand production helps you react fast to changes. You can go from one prototype to many parts without waiting.

Tungsten Steel 5-axis CNC machining is used in many fields, not just cars. Huaruida Precision helps many industriesthat need strong and exact parts. Some of these industries are:

Aerospace (turbine blades, aircraft fuselages)

Medical devices (prosthetic limbs, dental implants, pacemakers)

Electronics and semiconductors

Electrical and power grid

Marine and construction

Robotics and automation

Food and beverage processing

Scientific and military applications

You get help from a company that can make hard shapes and keep tight sizes. Huaruida Precision uses smart machines and skilled workers for many jobs. You can trust them for one part or a big batch.

You want every part to be high quality. Huaruida Precision checks all parts very carefully. Skilled inspectors look at each piece before it leaves. No part goes out without approval from the inspection team. This 100% check helps you avoid problems in your work.

The company uses special machines to measure and test parts. Inspectors check size, shape, and how smooth the surface is. They use digital calipers and coordinate measuring machines (CMM). These tools help find tiny mistakes. You get parts that match your drawings and fit your needs.

Every part gets a full check before it is packed. You only get parts that are approved and reliable.

You need parts that work every time you use them. Huaruida Precision makes sure parts are reliable from start to finish. The team checks every step in making the parts. They use 5-axis precision machining for exact sizes and smooth surfaces. This careful work means your parts last longer and work better.

You can trust Huaruida Precision to make you happy. The company listens to your feedback and fixes problems fast. Many customers say they get well-packed, high-quality parts on time. You feel good knowing your parts will meet your needs.

Every order gets a 100% check

Quick answers to your questions

Focus on making parts last a long time

Tip: Pick a partner with strong quality checks to keep your projects safe and on track.

You might wonder how 5-axis CNC machining is different from old ways. Traditional machines can only move in a few directions. You have to stop and move the part for each new cut. This takes more time and can cause mistakes.

5-axis CNC machining makes things easier. You get:

Faster spindle speeds, usually from 15,000 to 50,000 RPM. Old machines run at 5,000 to 10,000 RPM.

Higher feed rates and smaller cuts. This helps tools last longer and saves time.

You can cut hard shapes in one setup. This saves time and lowers mistakes.

You get smoother surfaces, so you do not need extra polishing.

Parts come out with tight tolerances and smooth finishes. This means less fixing and lower costs.

5-axis CNC machining helps you finish jobs faster and better. You can make tricky car parts in less time and with fewer errors.

You have different choices for car parts. Tungsten steel is very hard and can take a lot of heat. Other materials might work for your needs too. Here is a simple table to compare them:

Property | Tungsten Steel | High-Speed Steel | Stainless Steel |

|---|---|---|---|

Hardness | Very high (HRA 89-92), stays hard up to 800-900°C | Medium (HRC 60-65), drops above 500-600°C | Lower than tungsten steel, changes by type |

Wear Resistance | Excellent | Good, but not as good as tungsten steel | Medium |

Heat Resistance | Best | Lower | Good |

Corrosion Resistance | Good | Medium | Best |

Machinability | Hard to machine, needs special tools | Easier, costs less | Easiest, can be used for many things |

Cost | High | Lower | Lower |

Typical Use | High-speed, exact engine parts | General car parts | Parts that need to fight rust |

Tungsten carbide is also used for cutting tools and tough parts. It is even harder than tungsten steel but can break more easily and is hard to machine. Stainless steel is good if you want to stop rust and save money. High-speed steel works well for normal parts that do not get very hot or worn out.

Pick your material based on what your part needs most. Think about hardness, heat, rust, or cost. Each material is good for different car parts.

You get strong and precise car parts when you choose Tungsten Steel and 5-axis CNC machining. This material stands up to heat and wear, so your components last longer. Advanced machining keeps every part accurate and ready for tough jobs. Huaruida Precision gives you reliable service and careful checks. You can trust your parts to work well and stay safe for years.

Tungsten steel gives you high strength and heat resistance. You get parts that last longer and work well under stress. This material helps your car stay safe and reliable.

You can make parts with curves, holes, and deep pockets. The machine moves in five directions. This lets you create shapes that older machines cannot handle.

Yes! You can order one part or a small batch. Huaruida Precision offers rapid prototyping and low-volume production. You only pay for what you need.

Every part goes through a 100% inspection. Skilled workers use special tools to check size, shape, and surface. You get parts that match your drawings and work as expected.

Navigation

Navigation

Contact Us

Tel: +86 13417419143

E-mail: [email protected]

Add:

2nd Floor, Building 7, 156 High Tech Industrial Park, Fuyuan 1st Road, Zhancheng Community, Fuhai Street, Baoan District, Shenzhen City, China.