May.

29, 2025

Contents

Why Robot Integrators Prefer Machined Parts Over Cast Components

Key Advantages of Machined Parts for Robot Integrators

Limitations of Cast Components in Robotics

Applications of Machined Parts in Robotic Systems

Why Precision and Durability Matter for Robot Integrators

The Role of Machined Parts in the Future of Robotics

When working with robots, accuracy and dependability are very important, especially for Robot Integrators.

Machined parts are extremely precise, with tolerances as small as ±0.0001 inches.

This helps robots work perfectly without mistakes.

These parts are also very strong, with 99.9% passing quality checks.

Unlike cast parts, machined parts are consistent and reliable.

Robot Integrators trust machined parts to create advanced and powerful systems.

Precision is vital for robots to work well. Machined parts are made with high accuracy and tight tolerances. Manufacturers use special tools, like Coordinate Measuring Machines (CMM), to check each part's shape. This ensures every piece matches exact measurements. CMM inspections follow ISO 10360 rules, making sure dimensions are correct. This level of detail allows robots to achieve very small tolerances in complex designs.

Quality control is improved with statistical process checks. These checks use measurement data to make production better. This ensures machined parts always match CAD designs. For you, this means robots work smoothly, with parts that fit perfectly.

Machined parts are strong and consistent, perfect for robots. CNC machining keeps all the material's strength intact. This makes parts tough enough for demanding robot tasks. For example, CNC machining achieves tolerances as tight as +/- 0.0002 mm, much better than 3D printing.

| Feature | CNC Machining | 3D Printing |

|---|---|---|

| Tolerance | +/- 0.0002 mm | 0.016 mm to 0.2 mm |

| Material Strength | 100% | 10-20% |

| Precision | 0.005 mm | Varies |

CNC machining creates parts that are both accurate and durable. This ensures robots work reliably, even in tough conditions.

CNC machining makes parts fit perfectly, which robots need.

It keeps material strength, making parts last longer.

Complex shapes are possible, improving robot designs.

Robots often need special parts. Machined parts can be customized for unique designs. Industries like automotive, aerospace, and medical devices benefit from this flexibility. For example, custom hydraulic fixtures in cars have cut cycle times by 40% and reduced labor. In aerospace, robotic systems with vision guidance have improved accuracy to 99.8%, speeding up production by 30%.

| Industry | Problem | Solution | Results |

|---|---|---|---|

| Automotive | Need precise hydraulic fixtures | Custom hydraulic fixtures for accuracy | 40% faster cycles, less labor, fewer defects |

| Aerospace | Manual handling caused tolerance issues | Robotic systems with vision guidance | 99.8% accuracy, 30% faster cycles |

| Medical Device Assembly | Slow production and errors | Fast robotic systems with automated tracking | 50% more capacity, no manual mistakes |

Custom solutions show how machined parts solve problems. Special designs improve robot efficiency and versatility. This helps robots handle different tasks easily, boosting productivity and reducing downtime.

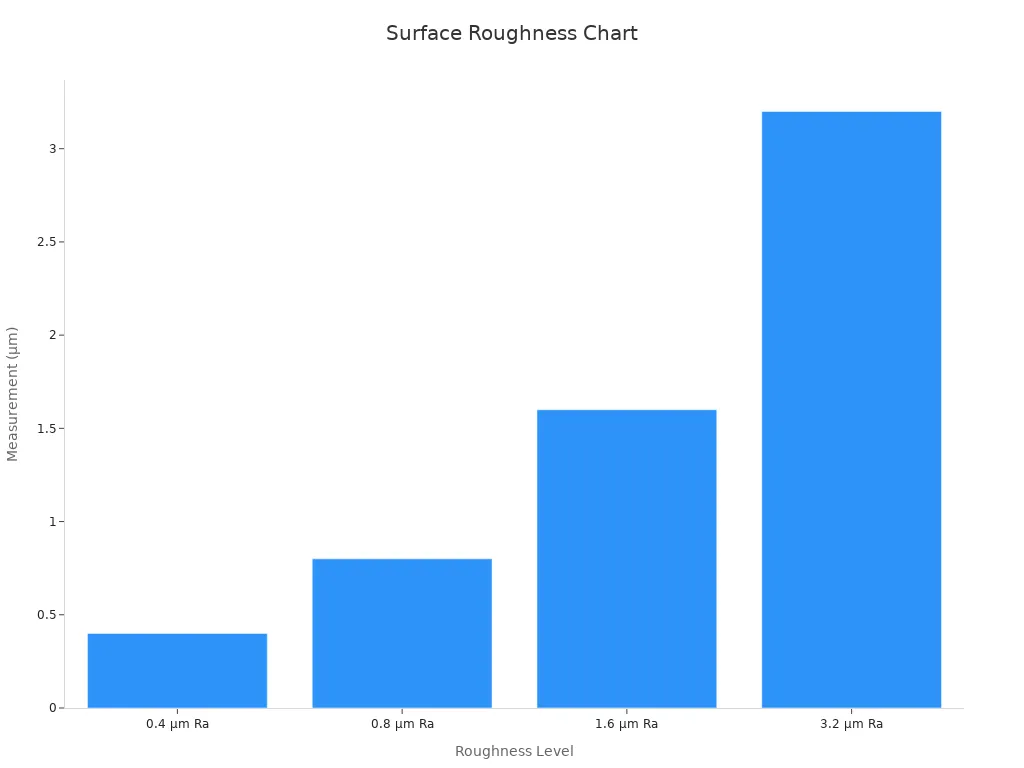

In robotics, surface finish quality is very important. It reduces friction, improves strength, and helps parts fit well. This makes robots work better and last longer.

Surface finishes are measured using tools like Ra and Rz. Ra shows how rough a surface is on average. Rz measures the height difference between the highest and lowest points. These tools check if machined parts meet quality needs. Special devices like profilometers help ensure smooth finishes.

Here’s a simple guide to roughness levels and uses:

| Roughness Level | Description | Application |

|---|---|---|

| 0.4 μm Ra | Very smooth, low friction, very strong | High-precision parts |

| 0.8 μm Ra | Good mix of cost and performance | Electronics, car parts |

| 1.6 μm Ra | Decent quality, lower cost | General machinery parts |

| 3.2 μm Ra | Works for less critical uses | Industrial components |

For precise robots, 0.4 μm Ra to 0.8 μm Ra is best. These finishes make parts fit perfectly and last longer.

Manufacturers use advanced methods to get these finishes. They check for flaws by looking and using profilometers. This ensures every part meets strict robotic standards.

For Robot Integrators, smooth finishes mean better robot performance. Smooth parts lower the chance of breaking, even under stress. Picking parts with great finishes ensures robots work well in tough jobs.

Tip: Spending more on smooth parts now saves money later. It lowers repair costs and reduces downtime.

In robotics, materials must be strong and reliable. Cast parts often have tiny holes, called porosity, inside them. These holes make the parts weaker and less dependable. Studies show porosity can lower flexibility by 80% in tough conditions. This means cast parts might break under pressure, risking your robot's performance.

CT scans can show how much porosity is in cast parts. These scans give a clear picture of the holes' size and shape. But even with these tools, casting can't fully fix these problems. Stress tests prove that porosity lowers strength, making cast parts unsuitable for precise and tough jobs.

On the other hand, machined parts are made from solid materials. This keeps them strong and reliable, even in hard tasks. Choosing machined parts removes the risks of porosity, giving your robots the strength they need.

Robots need precise parts to work well, but casting often lacks accuracy. Casting involves pouring melted material into molds, which can cause uneven shapes. Cooling and material flow issues make it hard to get exact sizes. Even small errors can misalign robot parts, causing wear and reducing efficiency.

CNC machining, however, is very precise. It uses advanced tools to shape parts with tolerances as tight as ±0.0002 mm. This ensures every piece fits perfectly, improving robot performance. Casting often needs extra work to match this precision, which adds time and cost.

Using cast parts may lead to frequent fixes and replacements, disrupting work. Machined parts solve this problem by meeting exact needs from the start.

Cast parts are less durable because their structure is inconsistent. They wear out faster and are weaker under stress. For example, cast aluminum has lower strength and fatigue resistance than machined aluminum. This makes cast parts fail sooner in tough jobs.

| Property | Cast Aluminum Parts | CNC Machined Parts |

|---|---|---|

| Tensile Strength | Weaker | Stronger |

| Internal Structure Consistency | Less stable | More stable |

| Fatigue Resistance | Lower | Higher |

| Resistance to Thermal Cycling | Better | Lower |

| Porosity Levels | Higher | Lower |

While cast parts handle heat changes better, they have more porosity and less strength. Machined parts are stronger and last longer, making them better for robots. By choosing machined parts, you avoid frequent repairs and ensure your robots perform well in tough conditions.

Note: Spending on strong, machined parts saves money over time. It reduces repairs and keeps robots running smoothly.

Using cast parts for robots may seem cheaper at first. But the extra steps to fix them can cost a lot. These steps take time and money, slowing down your projects.

Fixing cast parts needs many expensive steps. For example, Hot Isostatic Pressing (HIP) helps reduce porosity. This process costs $500 to $2,000 per part. It makes cast parts stronger but adds to the total cost. Also, machining cast parts for precision depends on how complex the job is. Surface finishing, which improves quality, can cost hundreds to thousands of dollars. Checking parts with tools like a CT scanner is very pricey, with equipment costing up to $1 million.

| Fixing Step | Cost Range |

|---|---|

| Hot Isostatic Pressing (HIP) | $500 to $2,000 |

| Machining | Depends on complexity |

| Surface Finishing | Hundreds to thousands |

| Metrology and Inspection | $1 million for CT scanner |

These costs show how expensive cast parts can be. Each step adds more expenses, making them less affordable. On the other hand, machined parts are made precise from the start. They don’t need extra fixes, saving money and time. This helps you finish projects faster.

Tip: Spending on machined parts early saves money later. They are reliable and don’t need costly fixes.

Choosing machined parts avoids the high costs of fixing cast parts. They are ready to use and help robots work better. Why choose less when you can have strong, precise parts right away?

End-effectors and grippers act like robot hands. They grab and move objects with care and strength. These tools are used in assembly, packaging, and moving materials. Machined parts make sure they work well under tough conditions. Their precise design and strong materials allow accurate movements and firm grips.

Here’s why machined parts matter for grippers:

Grasp strength shows how much weight they can hold.

Grasp cycle time measures how fast tasks get done.

Finger strength helps handle objects of different sizes.

Finger repeatability ensures they work the same every time.

Using machined parts makes robots faster and more accurate. They also reduce downtime and boost productivity.

Sensors help robots see and hear their surroundings. They guide robots by detecting changes around them. To work properly, sensors need strong and stable housings. Machined parts protect sensors from shaking, dust, and water.

For example, car and airplane industries use machined mounts to keep sensors steady. These mounts help sensors give accurate data, even in rough conditions. Choosing machined parts makes robots more reliable and prevents sensor problems.

Gears and bearings help robots move smoothly. They are key for robotic arms and moving vehicles. Machined gears, like planetary gearboxes, provide great power and accuracy. They are perfect for tasks needing exact and repeatable movements.

Strain wave gears are another example. They remove gaps in movement and improve accuracy. Their small size allows smaller motors, saving energy and improving efficiency. These gears are vital for modern robots that need to be precise and energy-saving.

By using machined gears and bearings, robots become more durable and precise. This lowers repair costs and improves how well they work.

Custom frames are the backbone of robotic systems. They give robots the strength and stability needed to work well. Machined components are strong and flexible, making them perfect for tough jobs.

Using machined frames adds advanced surface treatments like PVD and CVD. These treatments make parts last longer by reducing wear and friction. They also improve fatigue resistance, so robots handle repeated stress without breaking.

| Feature | Benefit |

|---|---|

| Surface Treatments | PVD and CVD reduce wear and friction, making parts last longer. |

| Fatigue Resistance | Better resistance to repeated stress keeps parts from failing. |

| Precision Machining | 5-axis CNC machining ensures exact sizes for stronger parts. |

| Tolerance Checks | CMM ensures tight tolerances of ±0.01mm for perfect alignment. |

5-axis CNC machining makes frames very precise. This accuracy ensures parts fit perfectly, lowering assembly mistakes. CMM tools check tolerances to make sure every piece matches the design.

Machined frames are also flexible. You can use lightweight aluminum for speed or strong steel for heavy tasks. This lets you build robots for any job, from factories to outdoor work.

Choosing machined frames helps robots work better and last longer. They cut down on repairs and save money over time.

Tip: Pick machined frames to keep your robots reliable and ahead of the competition.

Robots need to move exactly right every time. Whether building microchips or welding cars, their movements must be precise. Tools like encoders help track motor rotations accurately. This data helps robots know their position and move correctly every time.

Standards like ISO 9283 check how accurate and reliable robots are. These tests see if robots hit the right spot and return to it repeatedly. For example:

| Performance Criteria | What It Means |

|---|---|

| Accuracy | Checks if the robot reaches the correct position. |

| Repeatability | Tests if the robot can return to the same spot. |

Using machined parts helps robots meet these standards. This reduces mistakes and boosts productivity. Accurate robots waste less material and save money.

Robots often work in hot, dusty, or rough places. They need strong parts to handle these challenges. Machined parts, made from solid materials, last longer than cast ones. This strength keeps robots working well over time.

Strong parts also protect important systems like sensors. For example, tough sensor housings keep out dust, water, and vibrations. This helps sensors give accurate data, even in hard jobs. Choosing durable parts makes robots last longer and reduces costly repairs.

Every part in a robot affects how well it works. High-quality parts improve things like accuracy, speed, and power. Reliable robots break down less, saving time and money.

For example:

Accuracy keeps movements precise, improving product quality.

Speed and power make robots work smoothly and efficiently.

Reliability means fewer breakdowns and more work done.

Investing in machined parts makes robots better overall. This leads to fewer repairs, higher efficiency, and happier customers.

Tip: Choose precise and durable parts to build robots that last.

CNC machining is changing fast and helping robots improve. Combining CNC machines with robots makes production smoother and faster. Cobots, or helper robots, work safely with people and lower labor costs. These changes make factories more efficient.

AI and machine learning are making CNC machines smarter. They study patterns, improve processes, and boost accuracy. Hybrid manufacturing mixes CNC machining with 3D printing. This method is great for testing designs and saves materials while staying precise.

Smart factories are also transforming production. IoT-connected CNC machines track and adjust in real time. This increases productivity. As a Robot Integrator, you can use these tools to build better, faster systems.

Robotics is changing with customization and quick prototyping. Industries like healthcare and defense need unique solutions. 3D printing helps create custom parts quickly, cutting waste and saving time. This lets engineers adjust robot designs for specific jobs without starting over.

Virtual testing, called simulation prototyping, is becoming common. It checks designs in digital spaces to avoid risks and improve performance. This saves money and time by fixing problems before making real parts. Using these methods keeps you ahead in robotics.

Good machined parts are key to advancing robotics. CNC machining makes parts with exact sizes and tight tolerances. Robot tools, like end-effectors, depend on these parts to work in many ways. This flexibility means you don’t need new robots for every task.

Accurate and efficient parts drive innovation. They help create robots that are strong and adaptable. Choosing high-quality parts ensures your robots perform well, even in tough conditions.

Robot builders pick machined parts for their accuracy, strength, and flexibility. These features are key for making robots that work well in tough jobs. Unlike cast parts, machined parts are better for detailed designs and stay strong over time.

Here are some reasons why machined parts are great for robots:

| Feature | Why It Matters |

|---|---|

| Accuracy | Machined parts are more exact, perfect for advanced robots. |

| Strength | Strong parts make robots last longer and work harder. |

| Detailed Designs | They allow for complex shapes using advanced materials. |

| Faster Production | Automated machining speeds up making parts. |

| Better Performance | Robots need these parts for top-level tasks. |

As robots improve, the need for top-quality machined parts will grow. Choosing these parts keeps your robots advanced and working their best.

Machined parts are very precise, strong, and dependable. They meet tight size limits and keep material strength, helping robots work accurately and last longer. Cast parts often lack these features, making them less ideal for advanced robots.

At first, yes. But machined parts save money over time. They need fewer repairs, reduce downtime, and skip expensive fixing steps. Spending on quality early means better robot performance and lower upkeep costs later.

Yes! Machined parts are made from solid materials, so they’re strong and wear-resistant. They work well in extreme places like hot, heavy, or dusty environments. This keeps robots running even in hard jobs.

Machined parts are made with tight size limits and smooth surfaces. This ensures perfect fits and less friction, helping robots move precisely and repeat tasks correctly. Better accuracy leads to higher productivity and fewer mistakes.

Definitely! CNC machining lets you create unique shapes and sizes for your robots. This helps design robots for specific tasks, making them more efficient and flexible for different industries.

Tip: Pick machined parts for custom designs. They offer precision and dependability that standard parts can’t provide.

Navigation

Navigation

Contact Us

Tel: +86 13417419143

E-mail: [email protected]

Add:

2nd Floor, Building 7, 156 High Tech Industrial Park, Fuyuan 1st Road, Zhancheng Community, Fuhai Street, Baoan District, Shenzhen City, China.