May.

13, 2025

Contents

Collaborative Robot Parts: Why Customization is Key

The Challenges of Standard Collaborative Robot Parts

Why Customization Matters for Collaborative Robot Parts

Industry Applications of Customized Collaborative Robot Parts

Innovations Enabling Customization in Collaborative Robot Parts

How to Implement Customization for Collaborative Robot Parts

Every industry needs different things, and standard tools often don’t work. Customizing collaborative robot parts lets them fit your exact needs. This helps robots do tasks more accurately. Custom designs also make robots work well with your current systems. This not only saves time but also ensures that robots work reliably. Solving special problems with collaborative robot parts helps robots do their best and achieve better results.

Standard robot parts often can't handle unique tasks well. These parts are made for general use, not specific needs. For example, a robot arm with one type of gripper may fail to pick up items of different shapes or sizes. This makes it harder to improve workflows or meet special requirements.

In fields like healthcare or farming, precision and flexibility are very important. Without these, robots may need frequent changes or extra tools, causing delays and higher costs. Custom parts are necessary to help robots handle special tasks better.

Using standard parts can slow down robots and reduce their accuracy. These parts might not match your needs, leading to mistakes or slower work. For instance, a robot with basic software might take longer to finish tasks than one with custom programming.

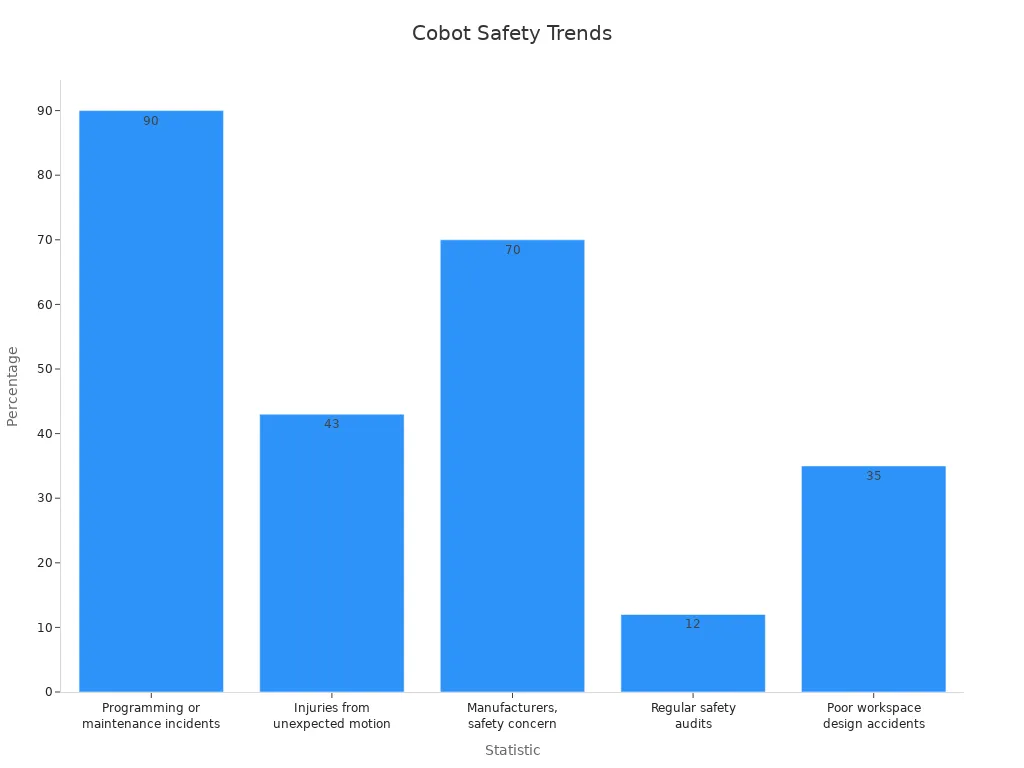

Studies show that 90% of programming issues come from standard designs. Also, 43% of injuries happen because robots move in unexpected ways, often due to poor customization. These problems lower productivity and can make robots unsafe.

| Problem Description | Percentage/Count |

|---|---|

| Issues during programming or maintenance | 90% |

| Injuries from unexpected robot movements | 43% |

| Manufacturers worried about cobot safety | 70% |

| Companies doing regular safety checks | 12% |

| Accidents caused by bad workspace design | 35% |

Standard robot parts may not work well with your current setup. You might face problems when trying to connect them to your systems. For example, a robot with a basic interface might not work smoothly with your software or machines. This can cause delays and require extra fixes.

Poor compatibility can also create safety risks. Data shows 70% of manufacturers worry about cobot safety, but only 12% do regular safety checks. Bad integration often causes these risks, as robots may act unpredictably in mismatched setups.

Custom parts solve these problems by fitting perfectly with your systems. This makes robots safer, faster, and more effective.

Customizing collaborative robot parts helps them work better and faster. When parts are made for specific tasks, robots can do tricky jobs. For example, a custom gripper can hold fragile items gently. A special sensor can notice small changes in heat or pressure. These upgrades make robots more accurate and dependable in places like hospitals and factories.

Custom software is also important for improving how robots work. Programming robots for certain tasks lowers mistakes and boosts efficiency. This makes sure robots do exactly what you need, whether building machines or helping in surgeries.

Tip: Using custom robot parts reduces errors and saves time by avoiding breakdowns.

Custom robot parts are great at handling different jobs. Modular designs let you swap parts, upgrade systems, or change tasks easily. This keeps robots useful as your needs change.

Easy repairs and maintenance keep robots running longer.

Affordable upgrades make systems last without big changes.

Robots can switch tasks, like welding and assembling in factories.

You can add new features when needed.

Robots work well in tough conditions, like extreme heat or rough surfaces.

In factories, modular robot arms can switch between welding and assembly.

In healthcare, custom tools help robots give precise care to patients.

Self-driving vehicles use modular parts to handle different tasks.

Inspection robots change parts to work in various environments.

Research robots use modular designs to test ideas quickly.

Customizing robot parts makes them flexible and ready for the future.

Real-life examples show how customization works. NASA’s Perseverance rover, built for Mars, shows how custom designs handle tough conditions. Aigen’s solar-powered farm robots do jobs like weeding and checking soil efficiently.

In farming, Carbon Robotics made the LaserWeeder, which uses AI to tell crops from weeds. Verdant Robotics focuses on planting and managing crops with precision. Tortuga AgTech runs 150 robots for harvesting crops.

The construction robot market is growing fast. It was worth $168 million in 2022 and could reach $774 million by 2032. These examples prove that custom robot parts lead to amazing results in many industries.

Note: Customization not only improves how robots work but also helps them solve hard problems in different areas.

In factories, custom robot parts help improve speed and accuracy. Special robots can do tasks like welding, assembling, or packing better. For example, a custom gripper can hold fragile parts without breaking them. This ensures products are made correctly.

Custom robots also solve worker shortages by doing hard-to-fill jobs. They adjust to your needs, saving money and boosting efficiency. Duo Global Technologies used a flexible cobot to stay competitive. Regular robots were too costly and stiff for small businesses, but custom ones helped them succeed.

Using custom parts makes work smoother, reduces mistakes, and speeds up production.

In healthcare, custom robot parts improve surgeries and patient care. Robots with special tools make surgeries safer and more precise. For instance, a custom robotic arm can hold tools steady, helping doctors focus on tough tasks.

These robots also assist in patient care. Custom sensors can check vital signs or help with therapy. Their flexibility makes them useful in hospitals and clinics. As robotics grow, healthcare will see more creative ways to use them.

Custom robot parts make farming tasks like planting and picking easier. Robots designed for certain crops can tell when fruits are ripe or plant seeds perfectly. This cuts waste and boosts harvests.

For example, Carbon Robotics made the LaserWeeder, which uses AI to spot weeds. These robots save time and work well in tough conditions like uneven fields or bad weather.

Custom robots also help with farm labor shortages. They handle hard or boring tasks, letting farmers focus on other work. Tailored robots make farming more productive and eco-friendly.

Customized collaborative robot parts are changing how warehouses and deliveries work. These special solutions solve problems like wasted time, busy seasons, and handling inventory better.

In warehouses, robots with custom tools can manage different packages. They handle fragile or heavy items safely and quickly. Modular robot arms can switch tasks, like sorting or packing, without big system changes.

Custom software is also very helpful. It programs robots to pick items faster and avoid crowded areas. For example, retail centers using wave optimization cut picker travel by 65-70%. They also reduced aisle visits by 60%. eCommerce centers saw 50% less congestion and processed 30% more items per hour.

| Example | Problem | Fix | Outcome |

|---|---|---|---|

| Retail Center | Pickers walking too far | Better pick paths | 65-70% less travel distance |

| eCommerce Warehouse | Crowded aisles during busy times | Spread out fast-moving items | 50% less congestion |

| Multi-channel Retail | Slow inventory blocking space | Moved unused inventory | 81.8% fewer aisle visits |

Big companies like Amazon and Ocado show how customization works. Amazon uses over 200,000 robots to speed up packing. Ocado’s robots fill orders quickly and accurately. Cainiao cut worker tasks by 70% with robot automation.

Using customized collaborative robot parts makes work faster and cheaper. It also helps businesses stay ready for future needs.

Tip: Custom robots boost productivity and reduce mistakes in busy places.

AI and machine learning are changing how robot parts are designed. These tools study data to create solutions for specific needs. For example, Autodesk's Dreamcatcher software makes many design choices using machine learning. This lets designers focus on creative ideas instead of repeating tasks.

AI improves designs by thinking about size, weight, and how parts work. It can also use data from smart devices to make future designs better. The Hack Rod project is a real example where sensor data helped improve designs. These tools make creating robot parts faster and smarter.

Machine learning also helps robots learn new tasks quickly. This makes them more useful in places like factories, where speed and accuracy matter.

Tip: Adding AI to your design process saves time and makes better robot parts.

Modular designs make robot parts easier to change and use. Each module works alone, so you can adjust setups as needed. For example, you can swap springs based on how much weight they need to hold. Springs with different stiffness can be used for specific jobs.

| Feature Description | Key Benefit |

|---|---|

| Quick spring replacement | Works in different environments |

| Independent module operation | Makes setup changes simple |

| Pre-set stiffness options | Matches tasks easily |

This design lets robots do many types of jobs. Modular parts are also easy to fix, saving time and money. Instead of replacing whole systems, you just change the needed part.

New materials make robot parts stronger and more efficient. Special alloys and composites resist damage and work well in tough conditions. Composites are light but strong, helping robots move faster and use less energy.

Materials like synthetic rubber and ABS plastic balance strength and flexibility. Rubber helps robots grip better on rough surfaces. These materials also make robot parts last longer and need less fixing.

Picking the right materials helps robots work better and last longer, even in hard environments.

Note: Using advanced materials makes robots stronger and more efficient.

To customize, first understand what your robots need. Check the tasks they do and find where standard parts fail. For example, if your robot isn’t precise, it might need special sensors or grippers.

Look at how your work flows. Find delays or problems caused by robots not matching the job. Think about the environment they work in. Tough places, like very hot or uneven areas, may need stronger materials or flexible designs.

Make a list of problems. Include things like task difficulty, needed accuracy, and how well robots fit with your systems. This helps you focus on fixing the most important issues.

Tip: Knowing your challenges helps you pick the best customizations for your robots.

Experts can help make robots fit your needs. They know how to combine hardware, software, and sensors to work smoothly. This makes robots reliable and efficient.

Specialists also follow industry rules like ROS and ROS2. These systems make robots flexible and ready for updates. Experts design robots to match your work, improving speed and cutting downtime.

| Feature | Benefit |

|---|---|

| Expert System Design | Combines parts for smooth and reliable robot performance. |

| Knowledge of Industry Rules | Uses ROS and ROS2 for easy upgrades and better adaptability. |

| Custom Solutions | Matches robots to your tasks, boosting efficiency and reducing delays. |

| Growth-Friendly Designs | Builds robots that can handle more work as your business grows. |

| Ongoing Support | Keeps robots working well and adjusts them as your needs change. |

Experts also make robots ready to grow with your business. They design systems that can handle more work and automation later. Long-term help keeps robots running well as your needs change.

Testing makes sure your custom robot parts work right. Try them in real situations and see how they handle different jobs.

Find where changes are needed. For example, if a gripper doesn’t work well with certain items, its design might need fixing. Testing lets you improve robots for better results.

Use feedback from workers and test data to make changes. This helps robots adjust to your needs and work reliably.

Note: Testing and improving regularly keeps your robots working their best.

Investing in customized collaborative robot parts means checking ROI and future gains. ROI shows if your spending helps your business grow.

You can use different metrics to see how custom robots help. These include:

| Metric | Description |

|---|---|

| Labor Cost Savings | Robots lower the need for workers, saving money. |

| Increased Production Output | Robots work nonstop, making more products faster. |

| Reduced Downtime | Robots cut delays and need less fixing time. |

| Faster Throughput | Robots speed up tasks like packing and shipping. |

| Improved Quality Control | Robots make fewer mistakes, improving product quality. |

| Enhanced Customer Satisfaction | Better products make customers trust your business more. |

Tracking these metrics shows how robots save time and money. For example, faster work and fewer delays mean higher productivity and profits.

Custom robots give lasting benefits that help your business grow:

Reduced Ergonomic Risks: Robots do hard tasks, keeping workers safe from injuries.

Employee Morale and Retention: Robots let workers focus on creative jobs, making them happier.

Flexibility and Scalability: Custom robots can change tasks and grow with your business.

Enhanced Customer Perception: Customers like businesses that use smart technology for better products.

These benefits make your business more efficient and show you're ready for the future.

Follow these steps to get the most from your investment:

List how robots will help your workplace, like saving time or money.

Rank each benefit by how much it improves your work.

If your score is 50% or higher, think about long-term gains, not just savings.

This method helps you decide where robots add the most value.

Tip: Check your metrics often to see progress and improve your plan.

By focusing on ROI and future benefits, custom collaborative robot parts help your business grow and stay ahead of competitors.

Changing robot parts to fit your needs makes them work better. It helps solve special problems and boosts efficiency in many industries. Custom parts improve how robots perform and connect with your systems. This makes robots more dependable and ready for future tasks. Spending on custom solutions keeps robots useful as technology changes quickly.

Collaborative robot parts are pieces that help robots work with people. These include arms, grippers, sensors, and software. They make robots safe and efficient in shared spaces.

Customization helps robots match your needs perfectly. Special parts improve accuracy, flexibility, and fit with your systems. This boosts performance and cuts downtime.

Custom parts make robots safer by fixing specific risks. For example, special sensors can spot obstacles, and custom software keeps movements steady to avoid accidents.

Navigation

Navigation

Contact Us

Tel: +86 13417419143

E-mail: [email protected]

Add:

2nd Floor, Building 7, 156 High Tech Industrial Park, Fuyuan 1st Road, Zhancheng Community, Fuhai Street, Baoan District, Shenzhen City, China.