Jun.

24, 2025

Contents

Rapid Prototyping for an Industrial Housing

Rapid Prototyping in Industrial Housing

Rapid prototyping is changing how people build industrial housing. It lets designers and builders make real models fast and easily. This technology uses 3D printing and in-house prototyping. It gives many clear benefits:

Companies can lower design and building costs by up to 50%.

Build times go from six months to three, and costs are cut in half.

North America is ahead in using this. Automation, smart manufacturing, and sustainability help drive this change.

Many teams now finish projects on time. They also make better quality work. They can react faster when things change.

Rapid prototyping is now a big part of building industrial housing. Teams use digital models to make real prototypes fast. This helps designers and engineers test ideas and find problems early. They can fix things before making the final product. This way, the work is better and there are fewer risks in design and building.

Rapid prototyping is used in many ways for industrial housing. Designers make small models of buildings to see how they look and work. Engineers test parts like wall panels, joints, and modular units with prototypes. This helps teams pick the best options for strength, safety, and comfort.

In real projects, rapid prototyping has helped social housing and sanitation in Kenya and Zambia. Teams made modular toilet units for refugee camps. They changed designs quickly after getting feedback from users. This made hygiene and use better. In Zambia, rapid prototyping made the time from idea to finished product 60% shorter. These stories show how this method gives better, faster, and more accepted housing, even in tough places.

Architects use rapid prototyping to make detailed building models. They start with sketches, then make computer models, and finally real prototypes. This lets them test ideas, improve designs, and show others their plans. It saves time and money compared to old ways of making models.

Note: Rapid prototyping with 3D printing can cut development time from months to days. For example, the ESP-Flasher project made over 140 prototypes with resin-based 3D printing. This let them improve and test every day.

| Market Segment | 2023 Market Size (USD Billion) | 2032 Market Size (USD Billion) | CAGR (2025-2034) |

|---|---|---|---|

| Additive Manufacturing | 3.0 | 8.0 | N/A |

| 3D Printing | 3.5 | 9.0 | N/A |

| Conventional & Rapid Prototyping Market | 15.49 (2024) | 45.64 (2034) | 11.41% |

These numbers show that more companies use rapid prototyping to make products faster and cheaper.

Many important technologies help rapid prototyping in industrial housing. 3D printing is the most important one. Companies like Apis Cor and HuaShang Tengda built homes in just 24 hours. They used only 40% of the materials needed for old building methods. These new ways lower costs and make homes cheaper.

Other technologies are also important:

AI and robotics do boring or dangerous jobs, so building is safer and faster.

AI tools help designers fix mistakes and make better plans, which saves money.

Augmented reality and AI-powered training help workers learn new skills fast.

Building Information Modeling (BIM) links all these tools, so teams can share data and work together at the same time.

Tip: Interdisciplinary teams, like those in the 3D4VA project at Virginia Tech, use these technologies to make new ways to build affordable housing.

These new ideas help fix big problems in industrial housing, like high costs, not enough workers, and harm to the environment. They help people build better homes faster and for less money.

Speed is a big advantage in building industrial housing. Teams can turn digital models into real prototypes in just days. Before, this took months. This fast process helps companies finish work on time. They can also react quickly when things change.

The table below shows how building speed has improved:

| Metric | Evidence of Improvement | Quantified Benefit |

|---|---|---|

| Construction Speed | 3D printed houses built faster than traditional | Project timelines reduced by 20-50% |

| Building Time Reduction | Focus on machine uptime and timeline optimization | 40% reduction in building times |

| Time-to-Market (SMEs) | Faster prototyping accelerates market readiness | 50% faster time-to-market |

Many companies now finish projects sooner than planned. They give homes to people and communities faster. This speed lets them do more projects each year. It also helps them get more work done.

Saving money is very important for new building methods. Automation and in-house prototyping lower labor and material costs. PrintNest Homes saves over 35% for each unit they build. Small and medium companies with in-house systems save up to 35% on development.

| Metric | Evidence of Improvement | Quantified Benefit |

|---|---|---|

| Cost Savings | Automation reduces labor and material expenses | Construction costs lowered by 20-30% |

| Cost Savings per Unit | PrintNest Homes reports cost savings per unit | Over 35% cost savings per unit built |

| Development Costs (SMEs) | In-house prototyping reduces development costs | Up to 35% reduction in development costs |

Rapid prototyping helps stop expensive mistakes. Early tests and feedback keep teams from redoing work. Companies use their money better and can offer cheaper homes.

Design flexibility is much better with new prototyping tools. Teams can make and test many ideas quickly. They use CAD software and 3D printing for complex shapes and detailed models. This helps designers find problems early and fix them fast.

Designers try out different layouts, materials, and features. They get feedback from users and make changes right away. This flexibility leads to better and more creative homes. Teams can follow new trends and meet client needs faster.

Note: Rapid prototyping makes it easier to change designs and respond to feedback or market needs.

Early validation helps teams find mistakes before they get big. Rapid prototyping lets teams make, test, and improve prototypes quickly. They get feedback from users, other team members, and automated tools. This helps avoid costly errors and lessens the need to redo work.

Teams find and fix mistakes early.

Feedback from users and peers makes products better.

Repeating the process brings steady improvement.

Projects finish faster.

The "Fail Fast, Learn Faster" idea helps teams adapt quickly.

Fast feedback lowers mistakes and improves quality.

Early validation means better homes and fewer problems during building. Teams can give better results with less risk.

Many companies have trouble using rapid prototyping in industrial housing. Big 3D printers cost a lot, so small businesses cannot always buy them. There are not enough skilled workers to run these new machines. Teams need people who know how to use both the machines and digital design tools. The technology changes often, so workers must keep learning new things.

Advanced 3D printers are expensive and slow down mass production.

Not enough skilled workers makes it hard to use new technology.

3D printing keeps changing, so teams must learn all the time.

Problems in the supply chain can make it hard to get materials.

Issues with accuracy and surface finish can lower prototype quality.

Note: Even with these problems, rapid prototyping still helps teams work faster and save materials.

Picking the right material is still a big problem in rapid prototyping. Some materials do not work well with 3D printing. Concrete and composites can make it hard to change designs or make strong prototypes. Some materials need extra work after printing, which takes more time and money. Teams also have trouble with color choices and the quality of 3D models.

Not many materials work for 3D printing.

Accuracy and surface finish can be hard to get right.

Metals and composites need more steps after printing.

Few color choices make prototypes look less real.

Bad input data can hurt the final results.

Teams must pick materials carefully to avoid mistakes and make sure prototypes fit the project.

Adding rapid prototyping to old ways of working is not easy. Companies must buy new machines and software, which costs a lot. Teams often need to change how they design and build things. There are not enough rules for testing and checking quality, so results can be different each time. Security and ownership of digital files can also be a problem when using cloud tools.

New machines and software cost a lot of money.

Workers need training and must learn new ways to design.

Not enough rules for checking quality.

Digital files can have security and ownership risks.

Many companies say it is hard to add rapid prototyping to their work.

Tip: Companies can make this easier by using simple software, training workers, and making clear rules for data safety and ownership.

The prototyping process in industrial housing has clear steps. Each step builds on the one before it. Teams start with ideas and end with tested models. In-house prototyping gives teams feedback faster. This helps them find and fix mistakes early.

Design begins with setting goals and thinking of ideas. Teams use sketches and drawings to plan the project. They use timelines and diagrams to track their work. This helps them see progress and compare choices.

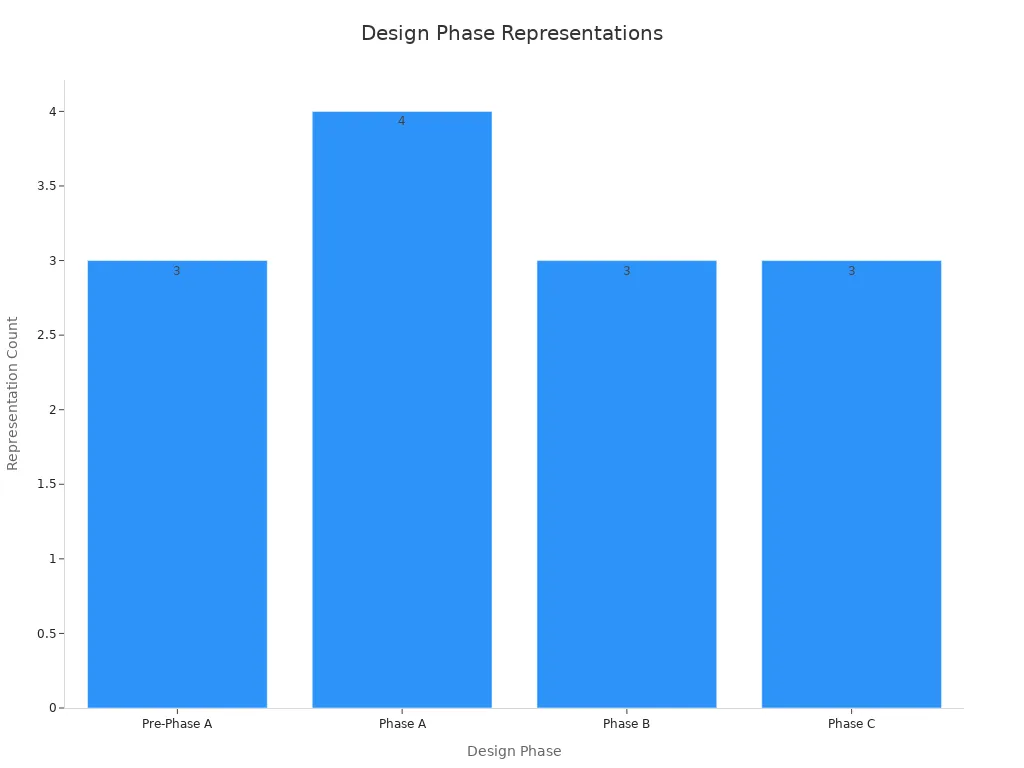

| Design Phase | Description | Key Tools |

|---|---|---|

| Pre-Phase A | Think of ideas, set goals | Sketches, product hierarchies |

| Phase A | Make concepts and needs | Functional diagrams, trade studies |

| Phase B | Make first design | Architectural designs, V&V planning |

| Phase C | Finish design, get ready to build | Detailed layouts, BOMs |

Teams turn sketches into 3D models on computers. Special tools help make these models detailed and correct. Projects like ESP-Flasher and Elephant Belay Device show this works well. Printer resolution, material, and how the model sits all matter. These things help make models more accurate and faster.

Fabrication means making real parts from digital models. Teams use 3D printers and other machines for this. They check designs and plan how to build them. Each step is checked for quality. Machines are watched to catch problems early.

| Step | Description |

|---|---|

| Drawings Received | Check 3D files, pick materials and finish |

| Design Review & DFM | Look for problems with building |

| In-process Checks | Watch machines, make first samples |

| Final Checks | Check samples, make sure they meet needs |

Testing checks if the prototype works as planned. Teams do tests and ask users for feedback. They check if it is easy to use and works right. Tools like CMMs and profile projectors measure how close it is to the plan. Real-time data helps teams fix problems fast.

Iteration means making changes and testing again. Teams look at results and change the design. They test again to see if it is better. Each time, mistakes go down as the prototype gets better. This keeps going until the prototype is just right.

Tip: Rapid prototyping lets teams learn quickly, fix mistakes early, and get better results with less risk.

Picking the right technology is very important for rapid prototyping. Teams usually start with simple models like sketches or wireframes. These help them test ideas fast. Later, they use 3D printing or CNC machining for stronger models. The material used is important at every step. Teams try different materials to check strength, look, and how things work. Digital simulations and virtual tests show how designs will work. This saves time and cuts down on waste. Teams should change designs after testing to stop expensive mistakes. Teams track things like how fast they finish designs, how often they get it right the first time, how happy customers are, and how much money they spend. Many teams start with small projects and use digital tools to watch progress and handle risks.

Tip: Teams should check their work often and keep good records. This helps them make better choices and build better prototypes.

Good teamwork helps projects turn out better. Teams use shared online spaces to keep files and plans together. This makes it easy for everyone to find what they need. It also helps people give feedback quickly. Using agile methods and clear steps helps teams work well together. Teams that work together well can train new people faster. They also make fewer mistakes when handing off work. New features get finished faster.

| Metric Category | Measurement Example | Collaboration Benefit |

|---|---|---|

| Process Efficiency | Cycle time from concept to delivery | Faster project completion |

| Quality Outcomes | First-time acceptance rates | Fewer defects and rework |

| Team Health | Collaboration satisfaction ratings | Higher team morale and trust |

Teams that use these ways often have half as many handoff problems. They also see customer happiness go up by 40%.

Quality control makes sure prototypes meet project needs. Teams check design files to make sure they are right. They set up machines to lower mistakes. Teams test and get feedback often to find problems early. Digital tests and real-time data help teams spot issues before making real models. Teams also make clear rules for records and reviews. This leads to more first-time approvals and fewer fixes later. Checking work often and finding problems early keeps projects on track and makes results better.

Note: Using digital tools and strong review steps helps teams make good, reliable prototypes every time.

Rapid prototyping helps many industries make better products. Teams test ideas quickly and get feedback to improve. The table below shows how projects used rapid prototyping to meet their goals:

| Project Type | Success Story / Outcome | Measurable Outcome / Lesson |

|---|---|---|

| Mobile App Startup | They checked user engagement during testing. This led to a good launch. | Better usability and user engagement helped the product succeed. |

| Fashion Retailer | They changed store layout after looking at sales data from prototypes. | Sales data showed problems. The layout was fixed before opening, saving money. |

| Wearable Fitness Tracker | User feedback made the tracker more comfortable. | The team made the tracker easier to wear by focusing on comfort. |

| Hardware Prototype | Early changes stopped the device from being hard to use. | Fast changes and asking for feedback made the product easier for people. |

| Gaming Console Prototype | They removed a hard-to-use gesture control after users had trouble. | Learning from mistakes helped make the controls better. |

| Smart Home Device Prototype | They balanced new ideas with what works after fixing connection issues. | The team learned to mix new features with things that work in real life. |

| Furniture Design Prototype | Using costly materials made the team worry about price. | Picking the right materials helps save money and makes better designs. |

These stories show rapid prototyping helps teams launch faster and save money. Teams learn fast and avoid big mistakes.

Teams learned important lessons from rapid prototyping:

After each project, look at what worked and what did not.

Keep a list of failures so future teams do not repeat them.

Set goals to learn from mistakes and track how fast teams test ideas.

Try small tests first to see if ideas work before making big changes.

Meet often to talk about feedback and improve as a group.

Rapid prototyping helps teams spot problems early and fix them fast. This saves time and money. Teams can test ideas in weeks, not months. They use feedback from users and experts to make better choices. By using both expert advice and data, teams decide faster and feel more sure. This way also helps teams solve hard problems and feel less unsure. Rapid prototyping helps teams be creative and get better results for everyone.

Many companies want to try rapid prototyping but are unsure how. First, they should learn what the technology does and how it helps. Teams should begin with small, easy projects. Desktop 3D printers are good for learning and practice. These printers let teams learn without spending a lot of money.

The 3D printing market is growing fast. New machines and materials come out often.

Desktop 3D printers are now used in schools and small businesses. This makes it easier for more people to try the technology.

Some small companies worry about high costs or not having enough skills. Training and clear guides can help them get started.

Prototyping is used in industries like cars, planes, and healthcare. These fields show how rapid prototyping can make work faster and better.

Tip: Teams can go to trade shows or join online groups to learn from others. Sharing what you know helps everyone do better.

Companies should also look at how they design things now. They can find steps that take too long or cost too much. Rapid prototyping can make these steps faster and easier. Teams should set clear goals and check their progress. This helps them see if the new tools are working well.

When teams feel ready, they can use rapid prototyping for more things. Many companies go from making one prototype to making many parts at once. This shows they trust the technology more.

Surveys show more companies now print over 10 parts at once. Some even print more than 1,000 parts.

Large 3D printers let teams build bigger things, like walls or rooms.

New materials with special features help teams with different needs.

Automation and better finishing, like vapor smoothing, make it easier to handle more parts.

AI tools help check quality and improve designs, making things run smoother.

A team can work with partners who know about design or making things. This help lets them avoid mistakes and grow faster. They should also spend time on training. When more people learn about design for additive manufacturing, teams make fewer mistakes.

| Scaling Step | Key Action | Benefit |

|---|---|---|

| Batch Production | Print many parts at once | Saves time and work |

| Large-Format Builds | Use bigger printers for housing | Makes new projects possible |

| Automation | Add robots or smart tools | Less manual work needed |

| AI Integration | Use AI for checks and design | Better quality and speed |

Rapid prototyping changes quickly. Companies must keep learning to stay ahead. They should watch for new trends, like AI and new materials. Mergers and partnerships help companies grow and share ideas.

The market has many mergers and companies joining together. This helps them get stronger and learn more.

New materials and smarter machines come out often. Teams must keep up to use the best tools.

More people are learning about design for additive manufacturing. Skilled workers help companies do better.

Other ways, like injection molding and CNC machining, are still important. Teams should know when to use each one.

Note: Companies that train workers and buy new tools often lead the market. They can change faster and make better products.

Teams should check their process often. They can have regular meetings to talk about new ideas or problems. By sharing lessons and tracking results, they keep getting better. This helps them stay ahead and give better housing solutions.

Rapid prototyping has changed how people build industrial housing. It makes building faster, cheaper, and brings new ideas. Reports say 3D printed homes can be built 75% quicker. They also need less money for workers. The Iowa Innovative Housing Project shows how digital tools help teams work better. Automation helps people learn new skills for their jobs.

The US prefabricated housing market could be worth over $60 billion. This growth comes from building off-site, saving money, and making flexible designs.

Teams keep learning and changing to stay ahead as technology and the market change.

Rapid prototyping uses computers and machines to make real models. Teams can try out ideas and see if parts fit together. They fix designs before building the real thing. This saves time and helps stop mistakes.

3D printing builds parts one layer at a time from a computer file. Teams can make tricky shapes and test new ideas fast. This way, they use less material and finish projects sooner.

Teams use plastics, concrete, and composites for different jobs. Plastics are good for small models. Concrete and composites are better for big, strong parts. Teams pick what works best for each project.

Yes, small companies can use rapid prototyping too. Many start with desktop 3D printers because they cost less. These help teams learn and practice. Training and easy projects help teams get better before using bigger machines.

Teams sometimes forget to test early or pick the wrong material. They might not check for mistakes in their designs. Checking work and getting feedback helps teams do better and fix problems.

Tip: Teams should write down each step and look at feedback often. This helps them find mistakes early.

Navigation

Navigation

Contact Us

Tel: +86 13417419143

E-mail: [email protected]

Add:

2nd Floor, Building 7, 156 High Tech Industrial Park, Fuyuan 1st Road, Zhancheng Community, Fuhai Street, Baoan District, Shenzhen City, China.