Jul.

17, 2025

Contents

POM vs PTFE: Which Is Better for Precision Insulating Parts?

Temperature & Chemical Resistance

When deciding between POM vs PTFE for precision insulating parts, PTFE generally offers superior electrical insulation, especially in high-voltage environments. However, the best choice depends on your specific project requirements. You should consider factors such as dielectric strength, mechanical strength, thermal stability, chemical resistance, and dimensional stability.

Dielectric strength prevents electricity from breaking through.

Mechanical strength and stiffness ensure parts remain strong and precise.

Thermal and chemical resistance protect parts from heat and harsh chemicals.

Dimensional stability helps parts maintain their shape and size.

Choosing the right material means balancing these properties based on your application when comparing POM vs PTFE.

The table below shows how POM and PTFE are different. It looks at important things for precision insulating parts.

| Property | POM (Polyoxymethylene) | PTFE (Polytetrafluoroethylene) |

|---|---|---|

| Mechanical Strength | High strength and stiffness | Low strength, soft, elastic |

| Wear Resistance | Excellent | Low |

| Friction | Low | Very low |

| Temperature Resistance | Up to 100-120°C | Up to 260°C |

| Chemical Resistance | Moderate | Excellent |

| Machinability | Excellent | Difficult, soft and gummy |

| Dimensional Stability | High | Low, prone to creep |

| Cost | Lower | Higher |

| Dielectric Properties | Good | Excellent |

Tip: When you look at POM vs PTFE, think about what your project needs most. Some parts need to be strong. Other parts need the best insulation or chemical resistance.

POM and PTFE both have good and bad points for precision insulating parts.

POM Strengths:

Strong and stiff

Wears down slowly

Easy to shape with tight sizes

Keeps its shape well

Costs less

POM Weaknesses:

Can’t handle high heat

Only okay with chemicals

Not as good at insulation as PTFE

PTFE Strengths:

Great with chemicals

Slides very easily

Insulates electricity very well

Handles high heat

PTFE Weaknesses:

Not very strong, can bend out of shape

Hard to shape exactly right

Costs more money

Loses its shape under pressure

Choosing POM or PTFE depends on what your part needs. POM is good if you want strong, exact, and cheaper parts. PTFE is better if you need great insulation, chemical resistance, or easy sliding, even if it is soft or costs more.

Dielectric properties tell us how well a material stops electricity. PTFE is one of the best plastics for electrical insulation. It has a dielectric strength from 60 to 100 kV per millimeter. This means PTFE can block strong electric fields without breaking. PTFE can also handle voltages up to 22,000 volts all the time. Many engineers pick PTFE for high-frequency and high-voltage parts because it works so well.

POM is also an insulator, but not as good as PTFE. The dielectric constant shows how much energy a material can store. A lower dielectric constant means better insulation. The table below shows the dielectric constants for POM and PTFE:

| Polymer Type | Dielectric Constant Range | Frequency Dependence and Explanation |

|---|---|---|

| POM (Polyoxymethylene) | ~3.00 to 4.70 | Higher dielectric constant because of polarity; values change with frequency and type. Dielectric constant goes down as frequency goes up. |

| PTFE (Polytetrafluoroethylene) | ~2.10 to 3.00 | Lower dielectric constant since it is non-polar; not much affected by frequency changes; usually lower than POM. |

Note: PTFE has a lower dielectric constant and is non-polar. This makes it more stable and reliable for electrical insulation, even when frequency changes.

POM has a higher dielectric constant because it is polar. This makes POM more sensitive to moisture and temperature changes. PTFE is non-polar, so it keeps its insulating power even if conditions change.

High-voltage places need materials that do not break down easily. PTFE works very well in these places. It can handle up to 300 volts in many uses. POM can only handle up to 220 volts.

| Material | Maximum Voltage Rating (Volts) |

|---|---|

| POM (Polyoxymethylene) | Up to 220 V |

| PTFE (Polytetrafluoroethylene) | Up to 300 V |

PTFE has a higher voltage rating and strong dielectric strength. This makes it the best choice for high-voltage insulating parts. PTFE also resists arc damage better than POM. Engineers use PTFE in power supplies, transformers, and important electronics where safety matters.

⚡ Tip: If you need the best electrical insulation and high-voltage safety, PTFE is usually better than POM.

POM and PTFE have different mechanical strengths. POM is very stiff and tough. It can handle strong forces without bending. POM’s tensile strength is between 62 and 70 MPa. Its flexural modulus is from 2,600 to 2,880 MPa. These numbers show POM is hard to break or bend. PTFE has a higher tensile strength at 130 MPa. Its flexural modulus is 7,600 MPa. But PTFE feels softer and more stretchy when used. It does not keep its shape as well as POM.

| Material Type | Tensile Strength (MPa) | Flexural Modulus (MPa) |

|---|---|---|

| Homopolymerized POM | 70 | 2,880 |

| Copolymerized POM | 62 | 2,600 |

| PTFE | 130 | 7,600 |

POM’s high crystallinity makes it tough and long-lasting. It can take hits and shakes without cracking. This is why POM is good for gears and moving parts. PTFE is strong in some ways but not as tough as POM. PTFE is better when you need low friction or chemical resistance.

Tip: Pick POM if your part needs to stay strong and stiff under heavy loads.

Precision parts need to keep their shape over time. POM is great at holding its shape. It does not soak up much water. It also does not change size much with heat. This helps POM parts stay the right size even if it gets hot or wet. POM does not bend or sag after a long time.

POM keeps its shape when you cut or use it.

It stands up to wear, hits, and bending in wet or dry places.

POM-C works even better in damp or basic settings.

PTFE can also keep its shape, especially special types like Fluorosint™ 207. This type does not swell or shrink much in steam. But regular PTFE bends more under heat and pressure. POM’s structure and low water absorption make it best for parts that need to be exact for a long time.

🛠️ Note: Use POM if you need parts to keep their shape and size for many years.

Heat tolerance matters for insulating parts. PTFE can handle very hot and very cold temperatures. It works from -200°C up to 260°C. This makes PTFE a good pick for parts in freezing or hot places. The table below shows how much heat each material can take:

| Material | Operating Temperature Range (°C) | Melting Point (°C) | Maximum Continuous Use Temperature (°C) |

|---|---|---|---|

| PTFE | -200 to +260 | 327 | 260 |

| POM | -40 to +100 | ~175 | ~100 |

POM can only take heat up to about 100°C. It melts at a lower temperature than PTFE. This means POM is not good for very hot places. PTFE keeps working even when the temperature changes fast. But PTFE can get weaker if it gets hot and cools down many times. It might crack or lose strength after lots of heating and cooling. POM, especially when mixed with other stuff, stays strong outside and in sunlight. This helps POM keep its shape and strength when the weather changes.

🔥 Tip: If your part needs to handle high or changing heat, PTFE is usually safer.

PTFE almost never reacts with chemicals. It does not get damaged by strong acids, bases, or solvents. This makes PTFE great for tough chemical places. POM can handle fuels, oils, and weak acids. But strong acids or bases can break POM down. Even a little chlorine or hot water can hurt POM. The table below shows how each material handles chemicals:

| Property | PTFE (Polytetrafluoroethylene) | POM (Polyoxymethylene) |

|---|---|---|

| Chemical Resistance | Outstanding; inert to almost all chemicals | Good to fuels, alcohols, weak acids; poor with strong acids/bases |

| Hydrolysis/Oxidation | Excellent; resists hydrolysis and oxidation | Poor; degrades with acids, bases, chlorine, hot water |

POM can crack, change color, or get weaker if it touches harsh chemicals or things like chlorine. PTFE has strong bonds that help it stay safe in almost any chemical place. If you need a part for strong acids, bases, or things that cause rust, PTFE is the best choice.

🧪 Note: Pick PTFE for parts that must resist strong chemicals or work in wet, harsh places.

POM and PTFE act very differently when you machine them. POM, also called Delrin, is simple to cut and shape. It works well with CNC machines and gives a nice, smooth surface. POM keeps its size and shape while you work on it. Tools do not wear out fast, so they last longer. PTFE, or Teflon, feels soft and sticky. It can bend or change shape when you cut it. PTFE needs sharp tools, slow speeds, and careful holding to avoid mistakes. PTFE usually has a rougher surface than POM.

POM is simple to machine and gives a smooth finish.

PTFE is harder to machine and can bend.

Both do not wear out tools much, but PTFE needs more care.

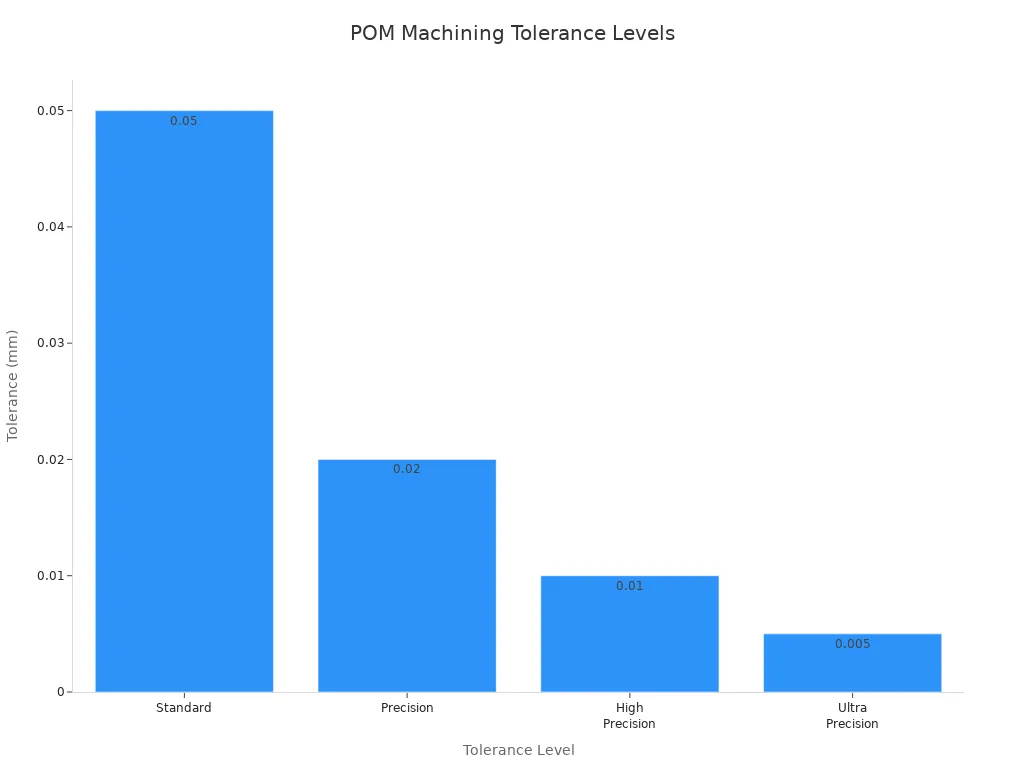

Machinists can make very exact parts with POM. The table below shows the usual tolerances for POM:

| Tolerance Level | Typical Tolerance Range | Example Applications | Key Considerations |

|---|---|---|---|

| Standard | ±0.05mm to ±0.02mm | General parts, non-critical dims | Most economical, suitable for most uses |

| Precision | ±0.02mm to ±0.01mm | Gears, bearings, precision parts | Requires careful setup and tooling |

| High Precision | ±0.01mm to ±0.005mm | Medical devices, precision tools | Needs temperature control and specialized equipment |

| Ultra Precision | Below ±0.005mm | Optical components, calibration | Very challenging, may need post-machining stabilization |

POM can reach very tight tolerances, like ±0.02mm, even on tricky parts. Machinists use sharp tools, keep things cool, and let parts rest after cutting to keep them steady. PTFE does not have exact tolerance numbers, but it is harder to keep sizes tight because it bends and moves when you machine it.

🛠️ Tip: If you need parts with exact sizes and smooth surfaces, POM is usually the best pick.

POM and PTFE also have different prices. POM costs less than PTFE. The table below shows the average material and processing costs:

| Material | Average Material Cost | Processing Cost Information |

|---|---|---|

| POM | $2.50 - $3.50 per pound | Processing costs are 5-15% lower than nylon due to faster cycle times and less tool wear |

| PTFE | $8.3 - $8.7 per kg | Detailed processing costs not explicitly provided |

POM’s lower price and easy machining make it a smart choice for big projects or when you need to save money. PTFE costs more to buy and takes longer to machine. This higher price comes from the material and the extra care needed when working with it.

💡 Note: If you want to save money, POM is cheaper for both material and machining. PTFE is only worth the extra cost if you really need its special features.

POM is used in many fields because it is strong and stable. It also insulates electricity well. Companies use POM for many precision insulating parts.

Automotive Industry: POM is used for gears, bearings, and fuel system parts. It is also in door handles and window regulators. These parts must last a long time and move easily.

Electronics and Electrical Components: POM is made into connectors, switches, and other insulating parts. It helps stop electricity from leaking and keeps devices safe.

Industrial Machinery: POM is found in conveyor belts, pump parts, seals, and gears. Its low friction and wear resistance help machines work longer.

Consumer Goods: POM is used in snap-fit assemblies, zippers, fasteners, and sports gear. These items need to be tough and easy to make.

Food and Beverage Industry: POM parts are safe for food processing machines.

| Industry | Common Applications of POM in Precision Insulating Parts and Components |

|---|---|

| Automotive | Gears, bearings, fuel system components, door handles, window regulators |

| Aerospace | Control mechanisms, hinges, interior parts |

| Electronics | Connectors, switches, insulating housings |

| Industrial Machinery | Conveyor belts, pump components, seals, precision gears |

| Consumer Goods | Snap-fit assemblies, fasteners, sports equipment |

| Medical Devices | Precision parts needing biocompatibility and stability |

POM gives strong electrical insulation and high dielectric strength. It keeps its shape in many conditions. POM also resists water and chemicals, so it lasts a long time.

PTFE is chosen when the job needs the best insulation and chemical resistance. Many companies use PTFE for these reasons.

Electronics and semiconductors use PTFE in capacitors and circuit boards. It is also used as coatings for wires and cables.

The chemical industry uses PTFE for reactors, storage tanks, and lab tools. PTFE does not react with most chemicals.

Mechanical engineers use PTFE for bearings, gears, seals, and gaskets. PTFE helps reduce friction and wear.

Medical fields use PTFE in implants, tubes, catheters, and surgical tools. PTFE does not react with body fluids.

PTFE is also used in food processing, power plants, and outdoor gear. It is non-stick and stands up to weather.

PTFE has excellent dielectric strength and works in very hot or cold places. It resists fire, water, and sunlight. Its low friction helps moving parts last longer.

When engineers compare POM vs PTFE, they look at many things.

| Factor | POM (Polyoxymethylene) | PTFE (Polytetrafluoroethylene) |

|---|---|---|

| Mechanical Strength | High tensile strength and impact resistance | Lower mechanical strength |

| Wear Resistance | High wear resistance | Lower wear resistance |

| Friction | Low friction | Extremely low friction |

| Chemical Resistance | Moderate | Excellent chemical resistance |

| Thermal Stability | Good across wide temperature range | Very high, melting point above 327°C |

| Dimensional Stability | High, maintains precise dimensions under load | Lower dimensional stability |

| Cost-effectiveness | More cost-effective, suitable for high-volume parts | Generally more expensive |

| Typical Applications | Automotive gears, bushings, fuel system components, industrial machinery parts | Applications requiring superior chemical resistance and very low friction |

POM is best when you need strength, wear resistance, and a lower price. PTFE is better for jobs needing top chemical resistance, very low friction, or high heat tolerance. Industry rules and certifications also help decide, especially for food, medical, or electronics parts.

📝 Tip: Always pick the material that fits your job best. For high-voltage or harsh chemical places, PTFE is often better. For strong, stable, and cheaper parts, POM is usually the best choice.

New research shows POM is stronger than PTFE. POM also lasts longer and keeps its shape better. This makes POM the best pick for most precision insulating parts. PTFE is the right choice if you need strong chemical resistance or very low friction. The table below can help you choose:

| Choose POM for... | Choose PTFE for... |

|---|---|

| High strength and stability | Harsh chemical environments |

| Tight tolerances and durability | Very low friction needs |

| Cost-effective solutions | Applications above 100°C |

Engineers should think about what their project needs. They should talk to material experts and check with suppliers. This helps them pick the best material between POM and PTFE.

PTFE has a lower dielectric constant and higher dielectric strength. This means PTFE blocks electricity better than POM. PTFE also stays stable when the temperature or frequency changes.

PTFE works in temperatures up to 260°C. POM only works up to about 100°C. PTFE is the better choice for hot environments.

Yes. POM machines easily and keeps its shape during cutting. PTFE feels soft and can bend or move when machined. Machinists prefer POM for tight tolerances.

POM usually costs less than PTFE. POM is cheaper to buy and easier to machine. PTFE costs more because of its special properties and harder processing.

Navigation

Navigation

Contact Us

Tel: +86 13417419143

E-mail: [email protected]

Add:

2nd Floor, Building 7, 156 High Tech Industrial Park, Fuyuan 1st Road, Zhancheng Community, Fuhai Street, Baoan District, Shenzhen City, China.