Jul.

08, 2025

Contents

Why POM Delrin is Popular in CNC Machining

You see that POM Delrin is special in CNC machining. It gives you a good mix of strength, easy cutting, stability, and saving money. When you pick this material, you get strong parts. These parts have a tensile strength of about 10,000 psi. They also do not soak up much water. This means your parts last longer and stay exact.

Here’s how POM Delrin compares:

Metric POM Delrin Nylon 66 Advantage Tensile Strength 10,000 psi 8,500 psi 18% higher Moisture Absorption 0.2% 2.8% 93% lower Machining Time 14 min 22 min 36% faster

You also save money because POM Delrin lets you cut parts faster. You make less waste when you use it.

You will notice that POM Delrin stands out for its free-cutting properties. When you use this material, you can cut it at high speeds, often between 250 and 400 meters per minute. This speed helps you finish jobs faster. The crystalline structure of POM Delrin gives you a smooth and steady cut. You do not need to worry about the material chipping or breaking during machining. Carbide-tipped tools with sharp angles work well with this plastic. You can also use hard-steel tools without much wear.

Tip: Drying the material and using coolants can help you get even better results and keep your tools in good shape.

You can keep tight tolerances with POM Delrin. This means your parts will fit together just as you planned. The low friction and low moisture absorption help you avoid swelling or warping. You get reliable results every time.

POM Delrin enables high precision manufacturing with reduced cycle times.

You will see less tool wear, which means your machines last longer.

The low friction coefficient and high wear resistance make machining easier.

Chemical resistance lets you use POM Delrin in tough environments.

When you machine POM Delrin, you get parts with smooth, glossy surfaces. You do not need to spend extra time sanding or polishing. The material forms small, manageable chips that do not clog your tools. This keeps your workspace clean and safe. You can achieve a fine finish even on complex shapes.

Machining trials show that POM Delrin gives you consistent surface quality. You can trust that each part will look and feel the same. This is important when you need professional-looking products or parts that must slide or fit together smoothly.

You need strong and stiff materials for CNC parts that face heavy loads. POM Delrin gives you this strength. It has a tensile strength between 9,000 and 11,000 psi. This means your parts can handle big forces without bending or breaking. The crystalline structure of this plastic keeps it stable, even when you use it for a long time. You can trust it to keep its shape under pressure.

POM Delrin also resists impacts well. It can take sudden hits without cracking. For example, the Izod impact strength reaches up to 6.8 ft-lb/in (unnotched). This makes it a good choice for parts that move fast or face shocks. You can use it in places where temperature changes often. It works from -40°C to 90°C, so your parts stay strong in many settings.

You will see this material in gears, bushings, and bearings. These parts need to stay stiff and exact. POM Delrin helps you make parts that last and work well, even in tough jobs.

When you use moving parts, you want them to last. POM Delrin stands out for its wear resistance. It keeps working, even when parts rub together every day. The table below shows why it works so well in gears and bearings:

| Property / Feature | Description / Value | Why It Matters for Wear Resistance |

|---|---|---|

| Rockwell Hardness | R118 - R125 | Hard surface lowers wear |

| Tensile Strength | ~70 MPa | Handles heavy loads |

| Flexural Modulus | ~2800 MPa | Keeps shape under stress |

| Coefficient of Friction | < 0.2 | Less friction means less heat and wear |

| Self-lubricating Fibers | Present | Needs less oil, reduces wear |

| Dimensional Stability | High | Keeps size and shape over time |

| Moisture Absorption | Very low | Stops swelling and keeps fit tight |

You will find POM Delrin in automotive gears, conveyor rollers, and bushings. It resists fuels and oils, so it works well in engines and machines. Its self-lubricating nature means you spend less time on maintenance. Your parts keep running smoothly, even after many cycles.

You want your CNC parts to stay the right size and shape. POM Delrin helps with this. It keeps its shape during and after machining. This means it does not bend, swell, or shrink much. Your parts will fit together as you planned.

Here are some ways to keep parts the right size with POM Delrin:

Pick good, modified grades to stop cracking or bending.

Use sharp tools and make many small cuts to control heat.

Lower stress by choosing the right material and using even cuts.

Change how you hold the part, like using soft pads or vacuum, to stop squeezing.

Make small cuts again and again to handle the material’s stretch and keep it straight.

You can check your finished parts with a coordinate measuring machine. This helps you see if the size is right. You can also test the parts in real life to see if they work well and keep their shape.

| Property | Value/Range | Why It Matters |

|---|---|---|

| Ultimate Tensile Strength | 60–89.6 MPa | Stops stretching and bending |

| Young’s Modulus | 2.5–4 GPa | Shows how stiff and strong it is |

| Coefficient of Thermal Expansion | 75.7–202 × 10⁻⁶ /°C | Controls size changes from heat |

| Maximum Use Temperature | 76.9–96.9°C | Handles normal machining heat |

Tip: Try a few test runs with your material. This helps you find problems with shape or size before making lots of parts.

You want parts that do not change shape when wet. POM Delrin does not soak up much water. It keeps its size and strength in damp places. This makes it a good pick for outdoor or wet jobs.

| Property | Value |

|---|---|

| Water Absorption (%) | 1.4 |

Because it does not take in much water, your CNC parts stay the right size. You do not have to worry about warping or loose fits from moisture. This helps your products last longer and work better in many places.

You can use POM Delrin for many CNC machined parts. This material works well in places where you need strength, smooth movement, and exact sizes. Here are some common uses:

Automotive gears and bushings: These parts need to last a long time and move smoothly.

Bearings and rollers: You want low friction and high wear resistance for these parts.

Medical device components: POM Delrin gives you precision and is safe for many medical uses.

Electrical insulators and connectors: The material does not conduct electricity, so it keeps circuits safe.

Consumer electronics: You find it in moving parts and housings that need to stay strong and stable.

Sporting goods: It works well in parts that need to handle impact and keep their shape.

Note: You can machine POM Delrin using milling, turning, drilling, and sawing. The material forms small chips and does not clog your tools. You get clean, accurate parts with less effort.

You also have choices between different grades. POM C is good for general parts, while POM H handles higher temperatures. This flexibility lets you pick the right type for your project.

When you choose a material for CNC machining, you want to know how it stacks up against others. POM Delrin stands out for its balance of strength, stability, and easy machining.

| Property/Aspect | Delrin (POM-H) | POM-C | Nylon (PA6/PA66) | PEEK |

|---|---|---|---|---|

| Tensile Strength | ~70 MPa | ~65 MPa | Higher than Delrin | Superior to Delrin |

| Hardness (Rockwell M) | 94 | 90 | N/A | N/A |

| Melting Point | 175°C | 165°C | N/A | Higher than Delrin |

| Chemical Resistance | Excellent | Very Good | Good | Superior |

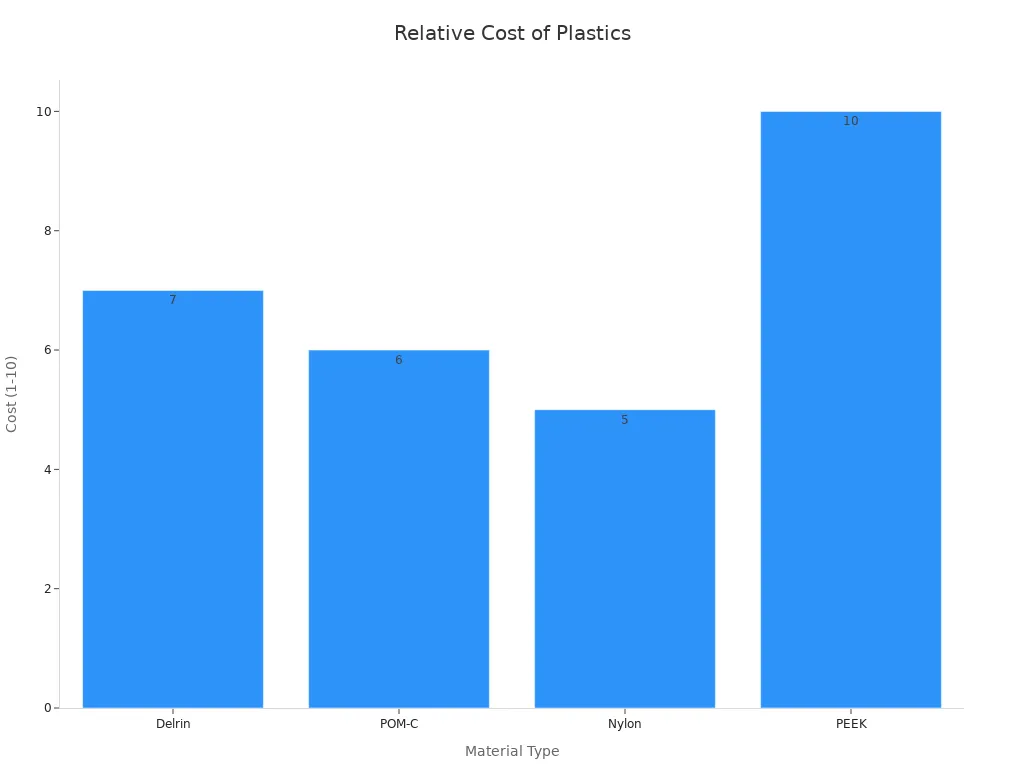

| Cost (Relative 1-10) | 7 | 6 | 5 | 10 |

You will notice that POM Delrin is lighter than metals like steel or aluminum. It does not rust, so you do not need to worry about corrosion. Metals give you higher strength and better heat flow, but they are harder to machine and cost more to process. Delrin lets you make parts faster and with less tool wear.

Compared to Nylon, POM Delrin keeps its shape better and does not soak up much water. Nylon can bend more and takes in moisture, which can change the size of your parts. PEEK gives you the best heat and chemical resistance, but it costs much more. You might pick PEEK for very tough jobs, but for most uses, Delrin gives you the best mix of price and performance.

Tip: If you need parts that slide, fit tightly, or work in wet places, POM Delrin is a smart choice. You get smooth finishes, strong parts, and less trouble with swelling or warping.

You can see how the cost of these materials compares in the chart below:

POM Delrin also gives you natural lubricity and electrical insulation. This means you can use it in moving parts and electrical devices without extra coatings or treatments. You get reliable, long-lasting parts for many industries, from cars to electronics.

You want to save money when you pick a material. POM Delrin helps you do this. Delrin might cost more at first than some plastics. But you save money in other ways. Delrin is easier and faster to cut. It does not wear down tools quickly. This means you spend less on new tools. Parts made from Delrin last longer. You do not need to replace them as often.

Here is a quick comparison:

| Aspect | Acetal (POM) | Delrin |

|---|---|---|

| Initial Cost | Lower | Higher |

| Machinability | Standard machining techniques | Superior machinability, faster cutting speeds |

| Durability | Moderate wear resistance | Exceptional wear resistance |

| Processing Costs | Higher due to machining time | Lower due to ease of machining |

Even though Delrin costs more at the start, you save later. You spend less fixing, replacing, or waiting for parts. This helps you keep your total costs down.

You want your CNC shop to work well and fast. POM Delrin helps you reach this goal. You can cut Delrin 5-10% faster than regular POM. This means you finish jobs sooner. You can take on more work. You also make less waste. One study showed scrap dropped from 7% to under 2% after switching from glass-filled nylon to POM. Less waste saves you money and uses materials better.

Here are some key benefits you get with POM Delrin:

You can cut faster, up to 20-30% more than some plastics.

Tools last longer, so you buy fewer new ones.

You throw away less material, so you save more.

Jobs finish faster, so you deliver sooner.

You get paid sooner, which helps your cash flow.

Tip: Pick the right grade and plan your work. This can help you save even more.

You can count on POM Delrin for strong, steady parts. It keeps your costs low and your shop running well.

There are lots of reasons to pick POM Delrin for CNC machining. This material is easy to cut and makes strong parts. It helps your parts keep their shape. You can make parts with exact sizes and smooth surfaces.

You save money, especially on small or medium jobs.

Using POM Delrin in CNC machining helps you make test parts fast and get the same results each time.

You do not have to spend a lot on tools and can make detailed shapes.

When you know your material, you can make better parts. You also get the best results from your CNC work.

You get better machinability and higher strength with POM Delrin. Delrin gives you smoother finishes and tighter tolerances. You also see less tool wear and faster cutting speeds. This helps you save time and money.

Yes, you can use certain grades of POM Delrin for food and medical parts. Look for FDA or NSF-approved grades. Always check the certification before you start your project.

No, you do not need special tools. Standard carbide or high-speed steel tools work well. You get the best results with sharp tools and proper cooling.

POM Delrin resists water and weather. It does not swell or warp in wet places. You can use it for outdoor parts or in damp areas without worry.

Yes, you can recycle POM Delrin. Many shops collect and reuse scrap. Always check local recycling rules before you send material for processing.

Navigation

Navigation

Contact Us

Tel: +86 13417419143

E-mail: [email protected]

Add:

2nd Floor, Building 7, 156 High Tech Industrial Park, Fuyuan 1st Road, Zhancheng Community, Fuhai Street, Baoan District, Shenzhen City, China.