May.

07, 2025

Contents

Case Study: Solving Heat Dissipation Challenges for a Drone Client

Understanding the Drone Client

Heat Dissipation Challenges in Drones

Objectives for Thermal Management

Solutions to Heat Dissipation Challenges

Key Takeaways from the Case Study

Drones face unique challenges when they are in operation. One significant issue is the heat dissipation challenges they encounter. Excessive heat can damage components, reduce performance, and lead to failures. Addressing heat dissipation challenges is crucial for ensuring that drones operate safely and efficiently, even in demanding environments. For those who design or utilize drones, understanding how to manage heat is essential. Overcoming these challenges not only extends the lifespan of drones but also enhances their performance. Additionally, it paves the way for innovative and advanced drone concepts in the future.

To know the client’s challenges, look at their drone systems. These drones are built for tough tasks, needing accuracy and dependability. They have advanced tools like thermal cameras, GPS, and live data sharing. Each drone gets regular check-ups and follows a strict schedule to work its best.

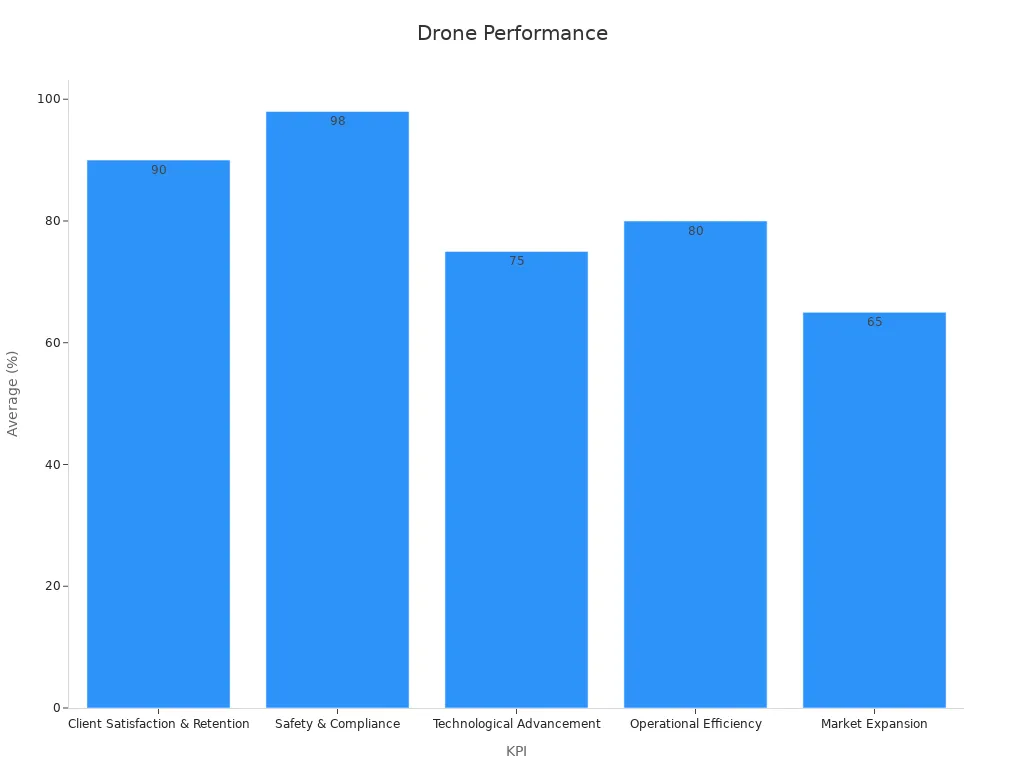

The client tracks key goals like safety, efficiency, and new ideas. For instance, their safety rate is an impressive 98%, and efficiency is 80%. Below is a table showing important numbers:

| KPI | What It Measures | Average |

|---|---|---|

| Safety & Compliance | Following safety rules and quick response to issues | 98% |

| Operational Efficiency | Flight performance, fuel use, and fleet management | 80% |

| Technological Advancement | Using new tech and investing in research | 75% |

These numbers show the client’s dedication to keeping their drones top-notch.

The client’s drones are used in many tough jobs. They help with wildfire tracking, emergency aid, and city safety. For example, during wildfires, drones with heat cameras watch fire movement and strength. This live info helps firefighters plan better and act faster.

In emergencies, drones are like first responders. They give aerial views, find missing people, and bring supplies. They also help with crime scenes, crowd control, and tsunami evacuations. These uses show how drones solve problems in many ways.

By knowing how the client uses drones, you see their unique needs. These needs make it clear why strong heat control is vital for safe and reliable missions.

Drones often struggle with heat because of their small size. Their compact design leaves little room for cooling systems. This makes it hard to control heat. Powerful parts like motors and processors create a lot of heat. When these parts run for a long time, heat builds up fast.

Batteries are another reason for heat issues. Most drones use lithium-ion batteries, which get hot when charging or working hard. If the battery is used for too long, it can overheat. Poor ventilation in the drone’s design can trap heat, making the problem worse.

Too much heat can make drones work poorly. Overheated parts may slow down or stop to avoid damage. This is called thermal throttling, and it makes drones slower and less responsive. Heat can also mess up sensors, causing errors in tasks like mapping.

Heat also lowers reliability. It wears out important parts like batteries and circuits faster. Overheating often leads to sudden failures, crashes, or interrupted missions. For drones used in emergencies, these problems are very serious.

The environment affects how drones handle heat. Hot places, like deserts, make cooling harder. In one test, drones in 42°C heat for four hours showed better performance when they had higher hydration (specific heat capacity).

Humidity also matters. High humidity can hurt cooling, while low humidity and heat can damage batteries. For example, during LiDAR surveys, flying on clear, low-humidity days helps sensors work better and reduces heat issues.

How drones are used also adds to heat problems. Long flights or carrying heavy loads make motors and batteries work harder. This creates more heat. In hot weather, this can cause overheating and slow performance. Knowing these factors helps plan safer and better flights.

Fixing heat issues needs clear goals to stay on track. Stopping overheating is the main focus. Too much heat breaks parts and stops drones from working. Cutting overheating by 50% makes drones last longer and work better. This helps drones stay reliable in tough situations.

To do this, improve how drones handle heat. Use special materials that cool down fast. Build drones with better airflow to keep heat away. These fixes solve current problems and help make drones better in the future.

Here’s the main goal:

| Goal | What It Means |

|---|---|

| Stop overheating | Lower overheating by 50% to protect parts and improve reliability. |

This goal shows why fixing heat problems is so important. Keeping drones reliable means they can handle tough jobs without slowing down.

Good heat control makes drones work better and last longer. When heat is managed, motors run smoothly, sensors give correct data, and batteries stay charged. This lets drones finish tasks without stopping.

Making parts last longer is also key. Heat wears out parts faster. Fixing heat problems slows this down. Drones last longer, need fewer repairs, and save money. For example, drones with better cooling can fly farther and carry heavier loads without overheating.

Think about the environment too. Drones built to handle heat work well in hot places or humid weather. This makes them useful for jobs like wildfire tracking or rescue missions.

By focusing on better performance and longer life, drones become more valuable. These upgrades help drones work better now and prepare them for future improvements in technology.

Special materials can help drones handle heat better. These materials soak up and release heat quickly, keeping parts cool. For example, engineers use things like graphite sheets or phase-change materials. These are light and perfect for drones, where weight matters a lot.

In one example, a drone's body was tested for heat problems. The test showed that some parts were overheating. By adding special thermal materials, the team fixed the cooling issue. This change made the drone work better and stopped future overheating. Also, drones with heat cameras can find hot spots in machines. This helps avoid problems like fires or costly repairs.

Picking the right materials keeps drones working well, even in tough conditions. These materials not only fix heat problems now but also prepare drones for harder tasks later.

Good cooling systems are key to controlling heat in drones. These systems remove heat from important parts to keep them stable. For example, liquid cooling or tiny fans can be added to drones. These systems may be more complex but make drones more reliable.

Data shows how cooling systems help. For instance:

| Metric | With Cooling Systems | Without Cooling Systems |

|---|---|---|

| Warranty Length | 3-5 years | 1-2 years |

| Maintenance Cost Savings | $120-$180 per flight hour | None |

| Reliability Rate | 98% uptime | 82% uptime |

One company said their cooling systems helped drones succeed 98% of the time in hot areas. This proves that good cooling systems help drones work well, even in extreme heat. Adding these systems lowers repair costs, extends warranties, and boosts reliability.

Changing drone designs can also solve heat problems. By moving parts around, you can improve airflow and reduce heat. For example, keeping hot parts away from sensitive ones stops overheating. Adding vents or using sleek designs helps cool drones naturally.

Long flights or heavy loads make drones hotter. Better designs can handle this extra heat. For example, drones used in wildfires or emergencies need better cooling to work longer. These design changes fix heat issues now and make drones ready for future challenges.

Improving designs makes drones more efficient and dependable. They can handle more jobs and work better in different situations.

Testing heat solutions is very important for drones. It ensures drones can handle heat in real-life situations. This involves trying different conditions and seeing how well the heat systems work.

Engineers use tests to check if heat solutions work. These tests copy what drones face during their jobs. Here are some common tests:

Temperature Control Tests: These check if drones keep safe temperatures while working. Engineers watch parts like motors, batteries, and processors.

Stress Tests: Drones are pushed hard, like flying long or carrying heavy loads. This shows how heat systems handle tough conditions.

Failure Tests: Engineers create problems, like broken pumps or less cooling fluid. This helps find weak spots in the system.

Tip: Testing in tough conditions finds hidden problems. It makes drones more reliable in hard jobs.

The tests give useful details about heat systems. Below is a table of key results:

| Test Type | Main Results |

|---|---|

| Hot Legs Temperature Control | Max temperature stayed at 40 °C; extra heat removed by steam generators. |

| Low Water Level Test | Showed heat issues when water level dropped in cooling system. |

| Pump Stop Test | Stopping pumps caused small temperature changes, making it hard to spot problems visually. |

These results show why strong heat systems are needed. For example, keeping the temperature at 40 °C protects parts. But the low water test showed risks when cooling resources run out. Fixing these issues makes drones safer.

Validation checks if heat systems work in real-world conditions. Drones must be tested in hot weather, humid places, or long flights. This proves the systems can handle real missions.

By testing and checking heat systems, drones become safer and last longer. These steps make sure drones work well, even in tough situations.

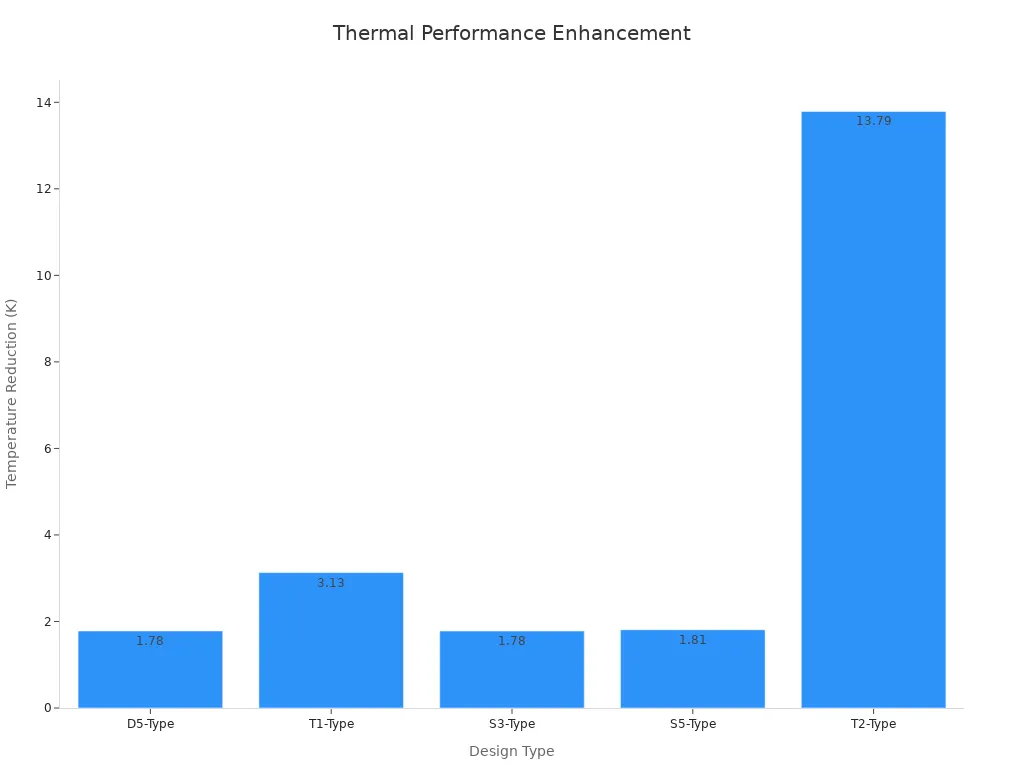

The new heat management methods made drones handle heat better. Using advanced materials and smarter designs, drones stayed cooler during use. For example, the T2-Type design lowered the temperature by 13.79 K, showing great cooling power. Below is a table comparing how different designs manage heat:

| Design Type | Max Temperature (K) | Temp Drop (K) | Pump Power (W) | Pressure Drop (Pa) |

|---|---|---|---|---|

| S9-Type | 331.16 | - | 0.0841 | N/A |

| D5-Type | 331.26 | 1.78 | N/A | N/A |

| T1-Type | 332.38 | 3.13 | N/A | N/A |

| Z-Type | 334.51 | N/A | N/A | N/A |

| S3-Type | 333.44 | 1.78 | N/A | N/A |

| S5-Type | 333.45 | 1.81 | N/A | N/A |

| T2-Type | 339.35 | 13.79 | N/A | N/A |

These results prove that the new designs keep drones cool. This helps them work well, even in tough conditions.

The better heat control also made drones more reliable and efficient. Keeping parts cool stops them from breaking. For example, lightweight cooling materials save energy and reduce weight. This makes drones use less power while staying cool. The table below shows key improvements:

| Aspect | Improvement | Description |

|---|---|---|

| Heat Management | Better Reliability | Parts stay cool, lowering the chance of breaking. |

| Passive Cooling | Higher Efficiency | Light materials save power while keeping drones cool. |

| Battery Protection | Longer Battery Life | Foam carriers keep batteries cool and safe from damage. |

These upgrades let drones fly longer without stopping. This makes them great for jobs like wildfire tracking or rescue missions.

The heat solutions also help drones last longer. Materials like thermal silicone pads and thermal gels keep heat under control in tough places. These materials protect important parts like sensors and motors, helping drones work in extreme conditions. Below is a summary of their benefits:

| Material | Advantages | Applications |

|---|---|---|

| Thermal Silicone Pads | - Moves heat quickly to keep parts cool. | - Cools sensors and processors. |

| - Soft and flexible for steady performance. | - Helps motors and drive systems. | |

| - Works well in extreme weather. | - Protects high-tech parts. | |

| Thermal Gels | - Moves heat efficiently to keep parts safe. | - Fills gaps between tight parts. |

| - Spreads heat evenly for better cooling. | - Keeps heat balanced in motors, FPGAs, and GPUs. | |

| - Stays strong in different environments. | - Used in advanced electronics. |

Using these materials helps drones last longer and need fewer repairs. They also prepare drones for future upgrades. These changes improve today’s drones and open doors for better designs later.

This study shows why managing heat in drones is crucial. Overheating can harm parts, slow performance, and shorten a drone's life. Fixing these problems makes drones more reliable and efficient.

One important lesson is using advanced materials and cooling systems. Materials like thermal silicone pads and gels remove heat quickly. This protects delicate parts from damage. Testing is also very important. By copying real-world conditions, weak spots can be found and fixed.

Another lesson is improving drone designs. Changing layouts to allow better airflow helps reduce heat. Separating hot parts from others also lowers overheating risks. These changes solve current problems and prepare drones for harder tasks.

Tip: Always test your heat solutions to ensure they work in real-life situations.

New ideas in heat control are shaping drone designs. Smaller, smarter thermal cameras are being made using AI and machine learning. These cameras are lighter, cheaper, and more efficient. This makes drones better and more capable.

Future drones will likely include these new technologies. They will be smaller, lighter, and cost less. These changes will improve performance and save money. The global market for thermal drones is expected to grow because of these advancements.

Custom heat solutions greatly improve how drones work. Here’s how they help:

Redesigned circuit boards save energy, letting drones fly longer.

Better processors reduce delays, making drones faster and smarter.

Heat control cuts overheating by 50%, protecting parts and making them last longer.

Custom solutions help drones meet specific needs. By solving unique problems, drones become more useful and dependable for different tasks.

Managing heat in drones is key to keeping them safe and working well. Special thermal fixes make drones more reliable and able to do more. For instance, drones with smart thermal imaging can spot hot areas and see better in smoky places. New battery designs let drones fly longer, helping firefighters watch fires more closely.

| Advancements | Benefits |

|---|---|

| Thermal Imaging | Helps drones see through smoke and understand the situation better. |

| Battery Innovations | Lets drones fly longer to cover more ground during firefighting. |

Improving thermal management will help create drones that perform great in tough jobs.

Drones get hot because of their small size and strong parts. Motors and lithium-ion batteries make a lot of heat, especially during long flights or heavy jobs. If the drone has poor airflow, heat gets trapped inside, making it worse.

Using special materials like thermal silicone pads can help. Adding small fans or liquid cooling systems also keeps drones cooler. Changing the drone’s design to improve airflow reduces the chance of overheating.

Testing shows if heat fixes work in real-life situations. It finds weak spots in cooling systems and checks if they can handle tough jobs like long flights or hot weather.

Tip: Test drones in the same conditions they will be used in to make sure they work well.

Better heat control makes drones last longer and work better. It stops parts from breaking and lets drones fly longer without stopping. This is great for important jobs like watching wildfires or finding missing people.

Yes, drones with the right heat fixes can handle hot or humid places. Materials like thermal gels and smart designs protect parts, keeping drones steady even in hard conditions.

Note: Take care of drones and check them often to keep them working well in tough environments.

Navigation

Navigation

Contact Us

Tel: +86 13417419143

E-mail: [email protected]

Add:

2nd Floor, Building 7, 156 High Tech Industrial Park, Fuyuan 1st Road, Zhancheng Community, Fuhai Street, Baoan District, Shenzhen City, China.