Apr.

29, 2025

Contents

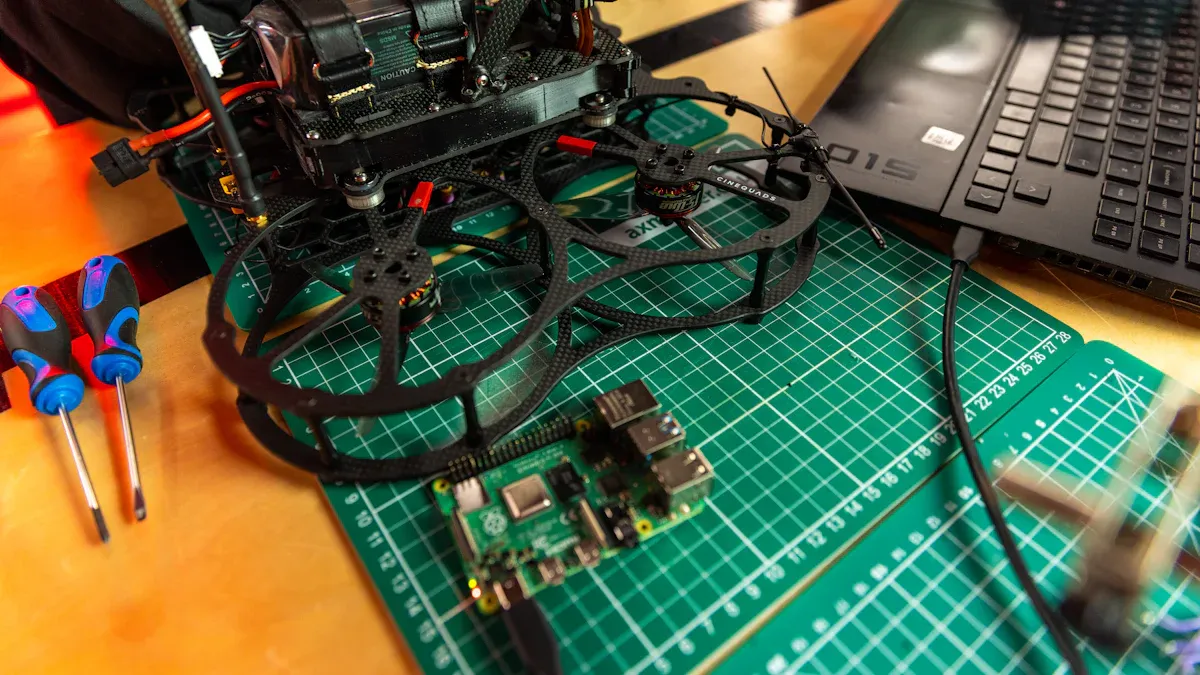

Designing Lightweight Parts for Drones: A Guide to Precision CNC Machining

Why Lightweight Parts Matter for Drones

Precision CNC Machining for Lightweight Parts

Choosing Materials for Lightweight Drone Parts

Techniques for Designing Lightweight Parts

Real-World Examples of Lightweight CNC-Machined Drone Parts

Lightweight parts are very important for better drone performance. A lighter drone can fly longer, carry more weight, and move faster. For example, the Skyfront Perimeter 8 drone can fly for 3 hours. This is much longer than most drones that fly 15-20 minutes. This improvement helps finish two-day tasks in just one day.

CNC machining helps make these lightweight parts possible. Using materials like magnesium or special aluminum makes the components lighter but still strong. For example, a racing drone uses a custom aluminum gearbox. Careful machining removes extra material while ensuring the parts remain strong.

Lightweight parts help drones fly better and move easier. A lighter drone reacts faster to controls, making it more agile. A study on a squirrel-inspired drone shows this well. Its wings adjust to forces, improving how it flies. This helps it turn quickly and stay steady in tough conditions. Research by Somashekar and Vinod also proves this. Lightweight drones handle sharp angles better. They stay in control during tricky moves, showing less weight improves movement.

Lighter drones use less power, so batteries last longer. A lighter drone needs less energy to stay in the air. Studies say reducing weight can cut drone weight by 12%. This means batteries can last 12% longer per charge. Longer battery life helps drones fly more without extra power. This is useful for jobs like taking photos or delivering items, where long flights are needed.

Lightweight parts let drones carry more without breaking. The design and materials keep the frame strong but light. Fixed-wing drones, for example, support heavier loads better. Motor setups also help by spreading weight evenly, keeping the drone stable. Below is a table showing what affects carrying weight and strength:

| Factor | How It Affects Carrying Weight and Strength |

|---|---|

| Frame design | Stronger frames hold more weight; fixed-wing drones are better for heavy loads. |

| Motor setup | More motors share the load, making it stable and able to carry more. |

| Thrust | Bigger rotors and better body design increase lifting ability. |

| Battery size | Larger batteries give more power and longer flight time. |

| Balance | Where the weight is placed changes stability and how well it flies. |

By designing lightweight parts, drones can carry more while staying strong and steady.

CNC machining makes sure drone parts are made exactly right. These machines can work with tiny tolerances, as small as a few microns. This means the parts fit perfectly and help drones perform better. Tools like Coordinate Measuring Machines (CMM) and Non-Destructive Testing (NDT) check the size and strength of each part. These checks make sure the parts are not only light but also strong and dependable.

Here’s a simple table showing how accuracy is checked:

| Quality Control Measure | What It Does |

|---|---|

| Precision and Tolerances | Ensures parts fit perfectly by working with tiny tolerances. |

| Testing and Inspection | Uses tools like CMM and NDT to check size and strength. |

| Certifications and Standards | Follows rules like AS9100 and ISO 9001 for safety and quality. |

By following these steps, CNC machining makes lightweight parts that are strong and meet drone needs.

CNC machining doesn’t just focus on accuracy; it also saves materials. Picking the right material and using pieces close to the needed size reduces waste. This makes the final product light and efficient.

Here are ways to save materials:

High-tech cutting tools reduce leftover material.

Automated systems save energy and improve work speed.

Using recycled materials lowers the need for new resources.

Lean manufacturing also helps by cutting out extra steps and improving workflows. This reduces waste and makes CNC machining a smart choice for making lightweight parts.

| Practice | How It Helps |

|---|---|

| Material choice | Picking the right material reduces waste and ensures good results. |

| Choosing dimensions carefully | Using stock close to the final size means less material is removed. |

| Clustering and nesting | Grouping parts together saves material and reduces waste. |

CNC technology allows for creative and detailed designs. It can make complex, lightweight parts that traditional methods can’t. Multi-axis machining helps create tricky shapes, making drone parts stronger and more efficient.

Here’s how different technologies help with design:

| Technology | How It Helps |

|---|---|

| Flexible Manufacturing Systems | Handles both small and large batches of parts efficiently. |

| Computer Integrated Manufacturing | Combines management and tech to use resources wisely. |

| Distributed Numerical Control | Simplifies processes and lets multiple machines work smoothly. |

| STEP-NC Technology | Offers smart control and clear task displays for better designs. |

With these tools, CNC machining makes it easy to design lightweight parts. Whether you need thin walls, hollow shapes, or detailed patterns, CNC technology helps create strong and functional drone components.

Picking the right material is key for making drone parts. Carbon fiber, aluminum alloys, and plastics are popular for lightweight designs. Carbon fiber is very strong and stiff, great for frames and arms. Aluminum alloys like 6061 and 7075 are strong, resist rust, and are easy to shape. These are used for motor mounts and brackets. Plastics such as ABS and polycarbonate are flexible and tough, perfect for casings and housings.

The aerospace field uses these materials to boost performance and save energy. Lighter drones need less power, making them more efficient. While these materials may cost more at first, they save money over time by cutting energy and repair costs.

Strength-to-weight ratio is vital when picking drone materials. Carbon fiber is the strongest, with a tensile strength of 3.5 to 7.0 GPa and a modulus of 220 to 320 GPa. Aluminum alloys are less strong but still good, with a tensile strength of 0.2 to 0.6 GPa and a modulus near 70 GPa. Plastics are lighter but weaker, so they work best for non-structural parts.

| Material | Tensile Strength (GPa) | Modulus (GPa) | Elongation (%) |

|---|---|---|---|

| Carbon Fiber | 3.5 - 7.0 | 220 - 320 | 1.5 - 2.8 |

| Steel | 0.4 - 2.5 | ~200 | ~15 |

| Aluminum Alloys | 0.2 - 0.6 | ~70 | ~8 |

Knowing these numbers helps you pick materials that balance strength and weight for drones.

CNC machining works well with many lightweight materials. Metals like aluminum and titanium are strong and easy to machine. Plastics like ABS and polycarbonate are light and flexible, great for creative designs. Advanced materials like carbon fiber need special methods but perform the best.

Aluminum Alloys: Easy to shape and used for strong parts.

Plastics: Light and flexible, good for parts that don’t carry weight.

Magnesium Alloys: Very light metals, ideal for cutting weight in gearboxes.

CNC machining shapes these materials precisely, making lightweight parts that fit drone needs.

Hollow shapes and thin walls help make drone parts lighter. Removing extra material keeps parts light but still strong. For example, hollow arms on a drone frame weigh less but stay sturdy. Thin walls in covers or cases lower weight while protecting the inside parts.

CNC machining can carve out hollow spaces with great accuracy. This method spreads the remaining material evenly to avoid weak areas. Thin walls need careful planning to stop bending during machining. Advanced tools like multi-axis CNC machines help balance lightness and strength.

Tip: Focus on low-stress areas when designing hollow parts. This keeps the drone strong while cutting down on weight.

Topology optimization is a smart way to design lighter parts. It uses software to study forces on a part and removes material where stress is low. This makes parts both strong and lightweight.

Some examples show how well this works:

Researchers improved the DJI F450 quadcopter frame using special design software.

They aimed to cut the frame's weight by 10% without losing strength.

Simulated flight tests compared the original frame to four new designs.

The lighter frames handled stress well and kept performance steady.

Using topology optimization, you can design parts that fit their job perfectly. This method lowers weight and boosts drone performance.

Advanced CAD software is key for creating lightweight parts. These tools let you plan, test, and improve designs before making them. Features like generative design and FEA show where material can be removed safely.

With CAD software, you can try different shapes and layouts. For instance, lattice designs spread weight evenly while staying light. You can also test real-world conditions, like flight forces, to ensure your designs work well.

Note: Tools like SolidWorks and Autodesk Fusion 360 have features for lightweight design. They make it easier to create parts ready for CNC machining.

Racing drones need to be fast and easy to control. Lightweight parts are key to making this happen. CNC machining helps create exact parts like hollow frames and thin motor mounts. These parts lower weight but stay strong. Aluminum alloy frames are often used because they are light and tough. Multi-axis CNC machines make detailed designs that improve how air moves around the drone, making it faster.

Tip: Focus on cutting weight in less important areas like frame edges. This boosts speed while keeping the drone strong.

Delivery drones must carry heavy loads but stay efficient. Lightweight parts let them carry more without using too much power. CNC-machined parts like carbon fiber arms and magnesium alloy gearboxes make drones lighter. This helps them lift heavier items. For example, companies like Amazon use lightweight frames for long-distance deliveries. CNC machining ensures these parts are strong and last a long time while staying light.

Callout: CNC machining helps delivery drones carry more and use less energy, making them great for business use.

Recreational drones work better with lightweight parts. Lighter drones need less power, so they can fly longer. Materials like carbon fiber and ABS plastic make this possible without losing strength.

Lighter drones use less energy to stay in the air.

The energy needed depends on how heavy the drone is.

Carbon fiber lowers weight but stays strong.

CNC machining makes lightweight parts that help drones fly longer. This means you can take more photos or enjoy longer flights. Lightweight designs make flying more fun and useful.

Making drones with lightweight parts makes them work better and faster. These parts help drones fly longer, move quicker, and carry more weight. They also use less energy, which saves power. By picking the right materials, using smart designs, and CNC machining, you can make strong and useful parts.

Here’s a simple table showing how materials help drones:

| Material | Benefits |

|---|---|

| Aluminum | A cheap and strong option for building drones. |

| Composites | Light, strong, and long-lasting materials for drone parts. |

| Plastics | Easy to shape and great for detailed designs. |

Using these ideas helps drones perform their best while staying strong and efficient.

Carbon fiber is very strong and super light. Aluminum alloys are great for strong parts, while plastics like ABS work well for parts that don’t carry weight. Pick materials based on your drone’s job and the need for strength and lightness.

Yes, CNC machining is great for making tricky shapes. Multi-axis machines can create hollow parts, thin walls, and detailed patterns with accuracy. This makes it easy to design lightweight parts that fit your drone’s needs.

Lighter drones use less power, so batteries last longer. They also move faster and are easier to control. Less weight lets drones carry more without losing strength or balance.

CNC machining reduces waste and makes exact parts, cutting down on mistakes. It may cost more at first, but the strong and efficient parts save money over time.

Advanced CAD tools like SolidWorks and Autodesk Fusion 360 are helpful. They let you plan designs, save material, and test ideas before making the parts.

Navigation

Navigation

Contact Us

Tel: +86 13417419143

E-mail: [email protected]

Add:

2nd Floor, Building 7, 156 High Tech Industrial Park, Fuyuan 1st Road, Zhancheng Community, Fuhai Street, Baoan District, Shenzhen City, China.