Aug.

26, 2025

Contents

CNC Turning for Precision Machining

CNC Turning uses machines run by computers to shape metal parts very accurately. You use this process when you need exact parts for things like planes, hospitals, or cars. Huaruida Precision gives advanced manufacturing services and follows strict inspection rules. You get help from their skill, strong quality checks, and promise to make customers happy.

CNC Turning helps you make metal or plastic parts very exact. A lathe spins the part fast. The cutting tool moves and cuts away extra material. The computer tells the machine what to do each time. This makes every part look the same.

The part spins on a spindle and is held tight by a chuck.

The cutting tool sits on a turret and moves to cut the part.

You set up the part, pick the tool, and use CAD or CAM to program the machine.

The part spins, and the tool moves in straight lines on the X and Z axes.

CNC Turning is good for making round parts like shafts, bushings, and bolts.

Tip: You can make shapes like steps or tapers by changing how the tool moves.

CNC Turning is used when parts must be very exact in size and shape. The machines are advanced and need careful planning to work well. Many things help you get tight tolerances and smooth surfaces.

Factor | Description |

|---|---|

Machine Capability | CNC machines are very accurate, strong, and make the same part every time. |

Tooling and Inserts | Using sharp, good tools helps you get the right size and a smooth finish. |

Fixturing and Clamping | Holding the part tight stops shaking and keeps it in place. |

Cutting Parameters | Changing speed, feed, and depth helps control heat and tool wear, which makes parts more exact. |

Environmental Control | Keeping the temperature and vibration steady stops mistakes from happening. |

Quality Control | Checking parts with measuring tools makes sure they meet all the rules. |

CNC Turning gives you the same, high-quality parts every time. The process lowers mistakes and helps you trust every part you make.

It is important to know the main parts of a CNC turning system. Each part helps the machine work well and make the same part every time.

Spindle: This part spins the workpiece very fast. The cutting tool shapes the part while it spins.

Chuck with Jaws: This holds your part tight. Three-jaw chucks are best for round parts. Four-jaw chucks help with square or odd shapes.

Cutting Tools: These tools cut away extra material. They are made from carbide. The turret holds the tools and can switch them fast.

Control Unit: This is the brain of the machine. It reads the program and gives orders to each part.

Drive System: Motors and screws move the cutting tool. This helps the tool move with great accuracy.

Tooling System: This includes tool holders and tool changers. It lets you swap tools quickly and correctly.

Work Holding Device: This keeps your part steady. It helps the machine cut more accurately.

Coolant System: This sprays coolant to keep things cool. It also removes chips and protects the tool and part.

Axis System: This lets the cutting tool move in different ways. It usually moves along the X and Z axes.

Huaruida Precision uses modern CNC lathes with all these parts. You get very exact parts, quick tool changes, and results you can trust.

The CNC turning process has clear steps from start to finish. Here is how it goes:

Design & Engineering: First, you make a 3D CAD model of your part. This digital drawing shows every size and shape.

CAD to CAM Conversion: Next, you move the CAD model into CAM software. Here, you plan how the machine will cut the part.

Toolpath Generation: The software makes the path for the cutting tool. It sets the speed and depth for each cut.

G-code Generation: The toolpath turns into G-code. The CNC machine reads this code.

Simulation: You run a test on the computer. This helps you find mistakes or crashes before making the part.

Program Transfer: You send the G-code to the CNC lathe.

Machine Setup: You put in the raw material and the right tools. You set the starting point for the machine.

Program Execution: The CNC lathe follows the program. It spins the part and moves the tool to cut the shape.

Quality Control: After cutting, you check the part with measuring tools. This makes sure it matches the design.

Finishing & Surface Treatment: You may polish, coat, or treat the part. This can make it look better or work better.

Digital designs and CAD software help you get great results. You can spot and fix problems before making the part. This saves time and cuts down on waste.

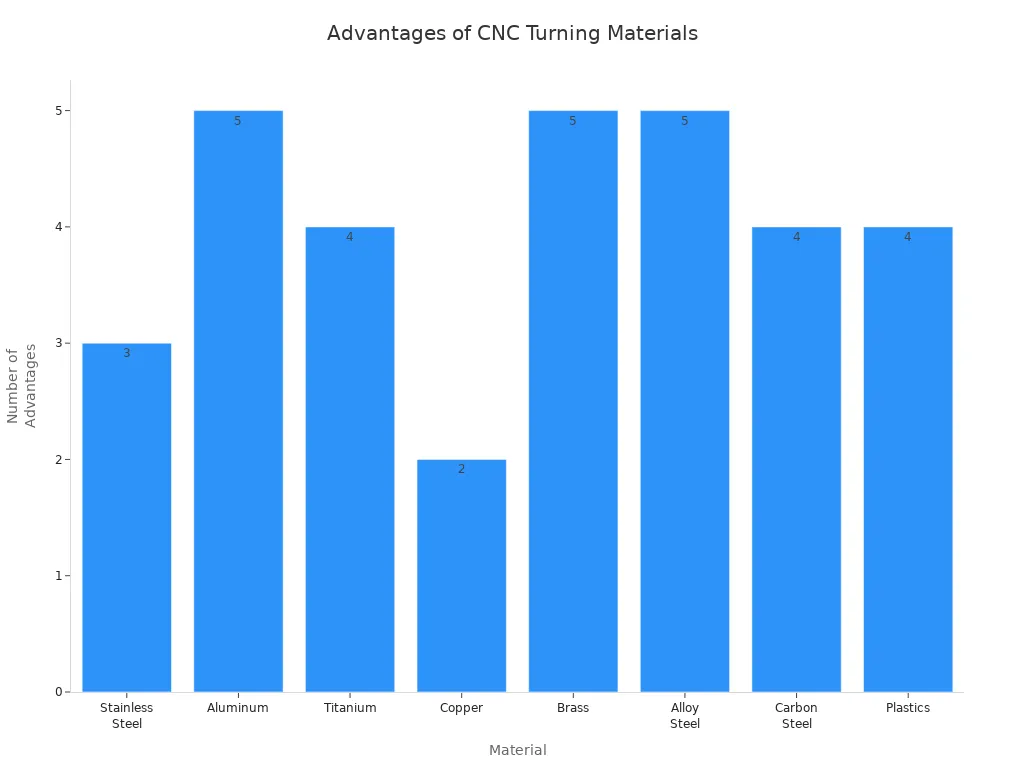

You can pick from many materials for CNC turning. Each one has its own good points. Huaruida Precision works with metals like tungsten steel, stainless steel, and aluminum. They also use plastics. This means you can choose the best material for your job.

Material | Advantages | Typical Applications |

|---|---|---|

Stainless Steel | Strong, reliable, resists rust and corrosion | Shafts, gears, bolts, aerospace, medical |

Aluminum | Lightweight, easy to machine, resists corrosion, conducts heat and electricity | Aerospace, automotive, medical, consumer products |

Titanium | Tough, light, resists corrosion, safe for the body | Medical implants, aerospace, military |

Copper | Excellent conductor of heat and electricity | Electrical parts, wiring, marine hardware |

Brass | Durable, easy to machine, resists corrosion, conducts electricity | Plumbing, electrical, medical |

Alloy Steel | Strong at high temperatures, resists corrosion, weldable | Industrial, automotive, appliances |

Carbon Steel | Affordable, strong, easy to machine | Shafts, pins, sprockets |

Plastics | Lightweight, resists chemicals, insulates electricity, resists moisture | Bearings, lab equipment, electrical, medical |

Huaruida Precision checks every part before packing. You always get parts that fit your needs, no matter what material you pick.

You use CNC Turning when you need parts that are always the same. The computer tells the cutting tools what to do. This makes sure each part has the right size and shape. This is very important for things like planes and cars. Even small mistakes can cause big trouble.

CNC Turning uses computer control to make parts very exact.

New machines make fewer mistakes and work faster.

You get smooth parts with tight tolerances, better than by hand.

You check how exact the parts are by measuring them many times. Repeatability means the machine keeps making the same part over and over. You use charts to watch for changes and catch problems early. You must check and adjust the machine often. First article inspection checks everything before making lots of parts. You can use CMMs to measure tiny details up to 0.001 mm. Vision systems look at the surface and sort parts fast. You keep parts very close to the right size, under ±0.005 mm, by watching heat, tool wear, and machine strength. You get better by finding problems, training workers, and using new technology.

You can trust your parts every time. This helps your customers trust you and helps your business grow.

CNC Turning lets you work fast and change jobs easily. You can go from making one part to making many without new machines. Automation and computer control help you make parts quickly and correctly. This is better than doing it by hand.

Using the same setups and tools saves time and keeps things the same.

Smart programming makes the tools move faster and saves time.

Machines can check parts while working, so you fix mistakes right away.

You can change jobs fast because the machines are programmable.

You can make many different parts in small amounts, which is good for custom work.

CNC Turning is also good for the environment. You use less material because the machine cuts very exactly. Energy-saving features use less power and save money. Automation means fewer mistakes and less waste. You can pick recycled or earth-friendly materials and handle waste better. This helps the planet.

You save time, money, and resources. You also give your customers the custom, high-quality parts they want.

CNC turning is used in many industries. These industries need parts that are exact and reliable. Huaruida Precision helps companies in aerospace, medical, and automotive. They also work with electronics and robotics. CNC turning is found in oil and gas, marine, and defense. It is used in biotechnology and sporting goods. Space technology and chemical processing use CNC turning too. Jewelry, water treatment, and HVAC need CNC-turned parts. Construction and agriculture use these parts as well. Consumer goods, railways, mining, and optics also need CNC turning.

Aerospace: You need shafts, fasteners, and bushings for engines.

Medical: You use implants, surgical tools, and MRI parts for safety.

Automotive: You get gears, wheel hubs, and engine parts for cars.

Electronics: You need small parts for circuit boards and heat sinks.

Robotics: You use gears, frames, and boards for smart machines.

Huaruida Precision gives you flexible ways to order parts. You can get prototypes to test new ideas. You can order small batches for research. You can ask for parts when you need them for new jobs.

CNC turning makes many kinds of parts you use daily. Most parts are round or shaped like a cylinder. They must be very accurate and strong. You find these parts in planes and medical tools.

Sector | Common CNC Turning Parts | Key Characteristics |

|---|---|---|

Aerospace | Shafts, threaded parts, fasteners, pins, bushings | Round, very exact, reliable |

Medical | Implants, surgical tools, MRI parts | Detailed, custom, very accurate |

Automotive | Crankshaft journals, gears, wheel hubs | Very exact, smooth finish, strong |

Electronics | Circuit board cases, heat sinks, RF shields | Small, tight fit, conducts electricity |

Robotics | Robot frames, gears, actuator parts | Custom shapes, strong, repeatable |

You can ask for prototypes to check if parts fit and work. You can order small amounts for special jobs or quick fixes. Huaruida Precision uses advanced CNC turning to make the part you want. You get your part fast and do not pay extra.

Using CNC-turned parts helps you stay ahead. You save time and waste less. Your products work better and last longer.

You sometimes have to pick between CNC Turning and CNC Milling. Each one works in its own way. They are good for different shapes and jobs. The table below shows how they are not the same:

Aspect | CNC Turning | CNC Milling |

|---|---|---|

Movement | Workpiece spins; tool does not move | Tool spins and moves; workpiece stays still |

Tool Type | One-point cutting tool | Many-point cutting tool |

Suitable Shapes | Round or cone-shaped parts | Flat, odd, or tricky shapes |

Cutting Nature | Cuts all the time | Cuts on and off |

Production Speed | Quicker for round parts | Slower but can do harder shapes |

Cost Efficiency | Cheaper for spinning parts | Costs more for tricky shapes |

Complexity of Parts | Easier, round shapes | Harder, many sides and angles |

Typical Applications | Shafts, tubes, bolts, pulleys | Engine parts, covers, tools, fancy mechanisms |

CNC Turning is best for round or tube-like parts. CNC Milling is better for flat or strange shapes. Turning is faster and costs less for easy shapes. Milling helps you make parts with more details.

Tip: You can use both turning and milling if your part needs round and flat areas.

Pick CNC Turning if your part must be round or shaped like a tube. This is good for things like shafts, rods, and tubes. You get very exact sizes for the width and length. CNC Turning can make big round parts, up to 1.5 meters wide and 4 meters long. It keeps the size close to ±0.05 mm.

Turning is used a lot for cars, trucks, and oil and gas parts. It works well with tough metals like stainless steel and cast iron. These metals can change shape when hot. You can also add threads or smooth the surface with turning.

Use turning for:

Shafts and rollers

Bushings and pins

Tubes and rods

Bolts and pulleys

If your part is round and needs to be very exact, CNC Turning is the best choice. You save time and money and still get great quality.

You can run into problems when using precision turning machines. These problems can make your parts less accurate or lower their quality. Here are some issues you might see:

Tools get dull after a while. Dull tools make rough parts and bad surfaces.

Some materials are hard or break easily. This makes them tough to machine.

Heat from cutting can make parts change size.

It is hard to keep tight tolerances if the setup is wrong.

Picking the wrong tool or settings can make the surface look bad.

If you make a programming mistake, the machine may move wrong. This wastes material and can be unsafe.

Machines can shake or get too hot if parts are old or not cared for.

If workers do not know enough, they can make mistakes or break the machine.

Dust, big changes in temperature, wet air, or power spikes can hurt how the machine works.

Power problems can make parts wrong or stop the machine.

Tip: Watch for rough cuts, leaks, worn bearings, or feeding issues. These signs mean your machine needs fixing.

You can fix these problems by using smart steps and good habits:

Set the right speed and feed to help tools last longer. For many materials, use speeds from 4000 to 8000 RPM.

Cut in small steps to keep parts smooth and the right size.

Pick tools with special coatings like carbide or DLC. These help tools last and cut better.

Use coolants or air to keep things cool and stop parts from growing.

Use sharp tools and chip breakers to stop burrs and bent parts.

Try new ways to clean up edges, like ultrasonic deburring, for smoother parts.

After cutting, polish or coat parts to make them stronger and smoother.

Use machines that watch tool wear so you can fix problems early.

Change or fix tools before they make bad parts.

Use special holders or soft jaws to keep parts still and stop bending.

Teach workers well and keep machines in good shape to avoid mistakes.

Note: Good planning, the right tools, and regular checks help your machines work well and keep your parts correct.

Machining technology changes quickly every year. New software and machines help you work faster and smarter. You can use advanced CAD/CAM programs to design, test, and check parts before cutting. This helps you avoid mistakes and saves time.

ZW3D lets you model parts and use automation to work better.

FeatureCAM finds holes and pockets, then makes toolpaths with smart rules.

CATIA helps with multi-axis machining and checks for crashes, so hard parts are easier.

VERICUT shows machining in 3D, finds errors, and makes G-code better.

New machine features help you even more. Live tooling with C- and Y-axis machining lets you make hard shapes in one setup. Automatic tool inspection stops the machine to check inserts, so tools last longer and parts look better. Powerful CAD integration opens almost any file, so programming is faster. Accelerated Finishing™ and 3D tooling support help you finish parts quickly and do tough jobs.

Technological Advancement | Description | Benefit |

|---|---|---|

Intelligent ID and OD Roughing | Roughs castings to a boundary | Makes work faster and more exact |

Live Tooling with C- and Y-axis | Uses more axes for hard machining | Lets you do many moves at once |

Tool Inspection | Checks inserts while working | Makes tools last and parts better |

Powerful CAD Integration | Opens any CAD file for modeling | Cuts mistakes and saves time |

Accelerated Finishing™ | Uses new profile tools | Speeds up finishing and boosts work |

3D Tooling Support | Handles tough 3D machining jobs | Lets you do more types of work |

Toolpath Verification | Checks toolpaths are right | Stops mistakes and waste |

Dynamic Motion™ | Removes material fast and cuts cycle times | Makes work quicker and tools last longer |

You can see real results. For example, 3D-Machine, Inc. made hoist drums 83% faster by using custom thread toolpaths. They cut hours from 40 to just 7.

You will see more changes as automation and artificial intelligence grow. AI looks at real-time data and tells you how to change your machining process. Machine learning helps your machines learn from old jobs and get better. AI can guess when you need repairs, so you do not lose time.

AI and automation work together to do hard jobs and stop mistakes.

Robots learn new jobs and help when there are not enough workers.

Predictive maintenance keeps machines working longer and saves money.

Data analytics show you ways to make parts better and faster.

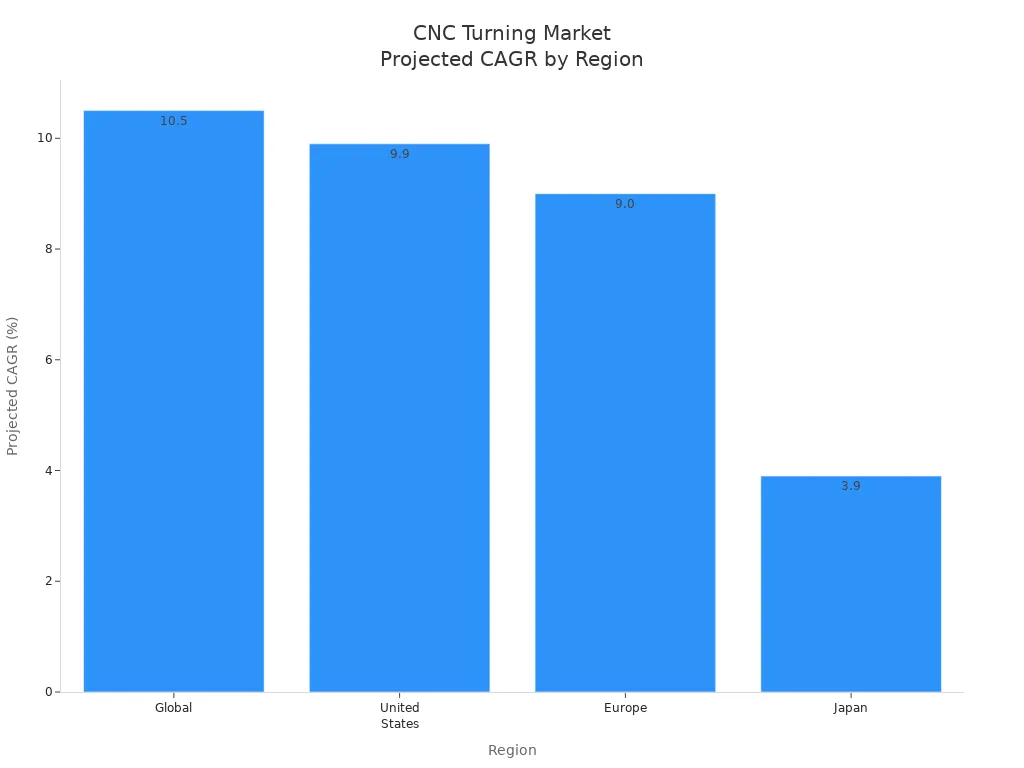

Productivity may go up by 40% by 2035 as these technologies spread. The market for advanced machining keeps growing. The chart below shows how fast CNC turning will grow in different places:

Region | Projected CAGR (2025-2034) |

|---|---|

Global | 10.5% |

United States | 9.9% |

Europe | 9.0% |

Japan | 3.9% |

You stay ahead by using new technology and smart automation. The future brings smarter machines, better parts, and faster delivery for your business.

You get many good things when you pick precision machining. This process gives you very accurate parts, makes them quickly, and can change to fit your needs.

Advantage | Description | Example Use |

|---|---|---|

High Precision | Makes each part very exact | Aerospace, medical devices |

Efficiency | Quick to set up and make parts | Automotive, electronics |

Flexibility | Easy to change programs for new jobs | Multi-industry |

Safety | Machines work by themselves to keep people safe | General manufacturing |

Quality Control | Checks make sure parts look and work great | Medical, aerospace |

You get special parts that are smooth and the right size.

Huaruida Precision uses top machines and careful checks so every part is just right.

Their team helps you fix hard problems and gives you parts you can trust.

They keep making things better and checking quality so your parts work well, even in tough jobs.

Talk to Huaruida Precision if you want help with your next project and want it done right.

CNC turning uses computers to control the machine. This makes parts very exact and the same every time. Manual turning is done by hand. It is slower and not as exact. CNC turning is better for making tricky parts fast and with good quality.

You think about how the part will be used. You also look at how strong it needs to be and where it will go. Stainless steel does not rust. Aluminum is light. Huaruida Precision can help you pick the best material for your job.

Yes, you can make special parts. You send your idea or drawing to the team. They use CAD software to design your part. You get the shape, size, and finish you want.

Huaruida Precision checks each part with special tools. Every part is looked at before it ships. This makes sure your parts are made right and work well.

Industry | Example Parts |

|---|---|

Aerospace | Shafts, bushings |

Medical | Implants, tools |

Automotive | Gears, hubs |

Electronics | Connectors, cases |

Robotics | Frames, gears |

Many industries use CNC-turned parts. These parts are needed when things must be exact and work well.

Navigation

Navigation

Contact Us

Tel: +86 13417419143

E-mail: [email protected]

Add:

2nd Floor, Building 7, 156 High Tech Industrial Park, Fuyuan 1st Road, Zhancheng Community, Fuhai Street, Baoan District, Shenzhen City, China.