Aug.

14, 2025

Contents

Thin-Walled 304 Stainless Steel Tubes: CNC Turning for Professional Camera Systems

Thin-Walled 304 Stainless Steel Tubes

Thin-Walled 304 Stainless Steel Tubes are great for camera systems. They are strong and light. This is important for cameras. Precision is very important for cameras to work well. CNC turning makes parts very exact. The parts can be made within ±0.005 mm. This helps protect the lenses. It also helps line up the parts just right. Good manufacturing and careful checks make sure cameras last a long time. Picking the right materials and steps helps cameras work well and stay stable.

Thin-Walled 304 Stainless Steel Tubes are used in many fields. Some examples are aerospace, medical, and camera systems. People use them because 304 stainless steel is strong and flexible. It also does not rust easily. This steel has about 18% chromium and 8% nickel. These parts help the tubes fight rust and stay tough in different places.

304 stainless steel can handle a lot of force. Its tensile strength is between 520 and 750 MPa. The yield strength is about 215 MPa. Heat does not make it stronger. Cold working makes it tougher. This helps make thin-walled tubes that are strong and bendable. The austenitic structure lets the tubes bend without breaking. The density is 7,900 kg/m³, so the tubes are light.

Huaruida Precision uses these features to make seamless and welded redrawn tubes. Their tubes have thin walls and work well for tough jobs.

Property | Value/Description |

|---|---|

Tensile Strength | 520–750 MPa |

Yield Strength | ~215 MPa |

Hardness | Brinell 201, Rockwell B92 |

Ductility | High, allows forming into thin-walled tubes |

Corrosion Resistance | Excellent in many environments |

Strengthening Method | Cold working |

Thin-Walled 304 Stainless Steel Tubes help engineers and camera makers. Wall thickness is important for how the tube works. Thinner walls make tubes lighter. This is good for things you need to carry, like cameras. The tubes are still strong enough to protect inside parts.

Thin walls make tubes strong and light at the same time.

New ways of making tubes keep them strong, even when thin.

Picking the right wall thickness helps balance strength and weight.

Thin-walled tubes can handle pressure and stress in camera systems.

Huaruida Precision makes tubes with exact wall thickness and size. Their skill makes sure every tube is strong and works well.

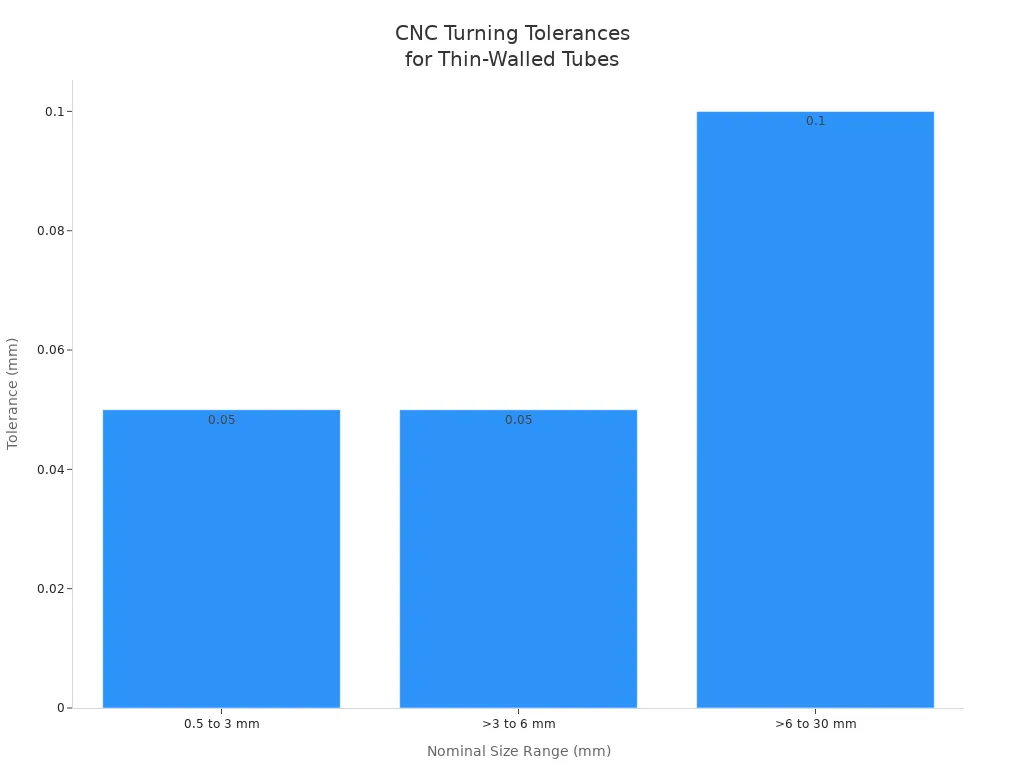

CNC turning uses computers to control machines. These machines shape thin-walled 304 stainless steel tubes very accurately. The machines follow set instructions. They move the cutting tools carefully. Engineers use CNC turning to make camera parts fit just right. This process keeps the tube walls even. It also stops mistakes that could hurt how cameras work. The chart below shows how CNC turning can make different sizes with tight tolerances.

Parameter | Achievable Tolerance / Surface Finish | Relevance to Camera Components |

|---|---|---|

Bore concentricity | 0.01 mm TIR | Prevents optical errors |

Flatness (reference face) | ≤ 0.005 mm across 100 mm | Supports mirror bonding |

Surface roughness | ~0.4 µm Ra | Smooth for mechanical parts |

Nickel plating thickness | 0.005–0.010 mm uniform layer | Protects against corrosion |

Huaruida Precision uses strong CNC machines. These machines have sturdy frames and balanced tool holders. This helps stop shaking and keeps each tube exact. Automation lets them make many parts that are all the same.

Camera systems need smooth parts to fit and work well. CNC turning can make surfaces very smooth, down to 0.4 µm Ra. This is good for camera parts that need to be precise. Normal machining makes surfaces rougher, about 3.2 µm Ra. Extra steps can make the surface even smoother. Huaruida Precision checks every part before it is packed. Their team looks for problems and only picks the best tubes. This careful checking makes sure every tube meets high standards.

CNC turning lets engineers add special shapes to tubes for cameras. Machines can make grooves, slots, steps, and threads very accurately. Some advanced ways include:

Using mandrels to keep tubes round and stop bending.

Doing rough cuts in stages with cooling to protect thin walls.

Using lasers to help make steady cuts.

Using special jigs made by 3D printing to support thin walls.

Checking for leftover stress and using heat to relax the metal.

Using laser peening and hydroforming to fix shapes.

Doing micro-turning for tiny shapes and tight fits.

Huaruida Precision uses these methods to make custom tubes for new camera systems. Their careful checks and new technology help make strong, high-quality parts every time.

Professional cameras need strong parts to hold everything together. Engineers use Thin-Walled 304 Stainless Steel Tubes for frames inside cameras. These tubes help keep lenses and sensors in place. The tubes do not bend or twist much. This keeps the camera steady outside or in a studio. Huaruida Precision makes tubes that fit well and stay straight. Their team checks each tube to make sure it is good. Cameras with these tubes last a long time.

Note: Strong tubes keep camera parts safe from bumps and drops.

Camera makers want parts that are not heavy. Thin walls in the tubes make cameras lighter. People can carry cameras longer without getting tired. Lighter cameras are easier to move and set up. Huaruida Precision picks the right thickness for each tube. Their engineers test sizes to find the best mix of weight and strength. Many cameras use these tubes to stay light. This helps photographers and filmmakers work faster.

Lighter tubes make cameras easier to use.

Thin walls give more space inside the camera.

Good design lowers weight but keeps strength.

Cameras need to last through lots of use. Stainless steel does not rust or get damaged by water. Tubes made from 304 stainless steel last a long time. Huaruida Precision uses CNC turning to make smooth tube surfaces. Smooth tubes help stop dirt and water from sticking. Their tubes work well even in rain or dust. Many companies trust Huaruida Precision for camera parts. Their skill with optical tools and electronics helps them make strong tubes.

Feature | Benefit for Camera Systems |

|---|---|

Corrosion resistance | Works well outdoors |

High strength | Protects sensitive components |

Smooth finish | Reduces wear and tear |

Custom sizing | Fits many camera designs |

Tip: Strong tubes help cameras work well for many years.

Reliability is very important for professional cameras. Thin-Walled 304 Stainless Steel Tubes work well in tough places. These tubes do not rust because they have a chromium oxide layer. This layer helps cameras work outside, near the sea, or around chemicals. The tubes stay strong and keep their shape in hot or cold weather. Many camera makers use these tubes because they last long and need little care.

Industry rules say these tubes are good for precise camera parts. Certifications like ISO 13485, RoHS, and REACH show that makers follow safety and quality rules. Custom services include cutting, bending, and laser welding. These steps help make camera parts fit tightly and have smooth edges. Each batch comes with a material certificate, so buyers can trust the product.

Note: Good tubes protect camera parts and help keep pictures clear.

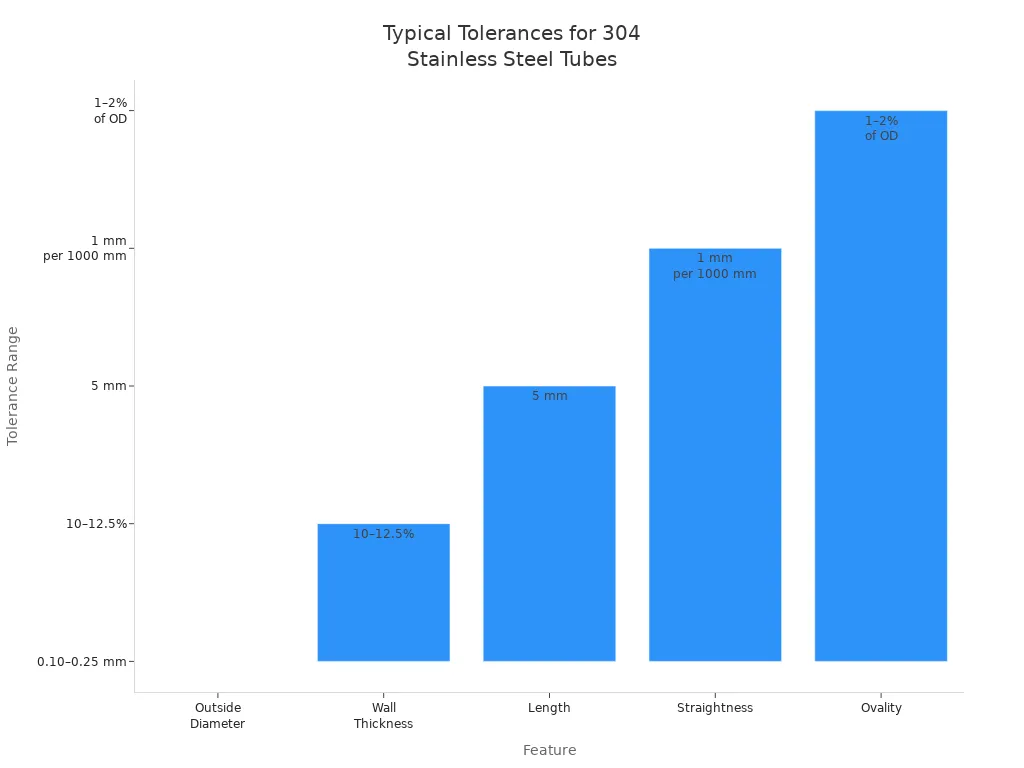

The chart below shows how these tubes meet tight size rules for camera parts:

Camera designers sometimes pick other materials like aluminum or titanium. Each material has good and bad points. The table below shows how 304 stainless steel and aluminum compare:

Property/Aspect | 304 Stainless Steel | Aluminum (e.g., 6061, 5xxx series) |

|---|---|---|

Corrosion Resistance | Excellent; robust in marine, chemical, and industrial environments | Good; anodizing helps, but less resistant in salt or harsh chemicals |

Toughness (Impact Energy) | High (75–100 J) | Lower (10–25 J depending on alloy) |

Service Temperature Range | –196 °C to +800 °C; strong up to ~500–600 °C | –200 °C to +150 °C; weakens above ~150 °C |

Longevity in Harsh Environments | Superior; often maintenance-free | Needs more maintenance and recoating |

Weight | Heavier | Lighter |

Application in Camera Context | Best for durability and corrosion resistance | Good for lightweight needs, but less durable |

Titanium is used in some fancy camera systems. It is strong and light, but costs more and is harder to shape. Aluminum is lighter and easy to work with, but does not last as long in wet places.

Thin-Walled 304 Stainless Steel Tubes are strong, do not rust, and last a long time. They follow strict rules like ASTM A554 and DIN 2391. These rules make sure the tubes are the right size and shape. This helps every tube fit and work well in cameras.

Standard | Region/Scope | Key Notes |

|---|---|---|

ASTM A554 | US / Global (decorative/structural) | Defines mechanical properties and tolerances for welded stainless steel tubing |

EN 10296-2 | Europe (mechanical use) | Sets tolerances and delivery conditions for welded stainless steel tubes |

JIS G3446 | Japan (mechanical/automotive) | Used in automotive and mechanical parts |

DIN 2391 | Germany (precision tubing) | Covers seamless precision tubing, including thin wall applications |

Tip: Picking the best tube material helps cameras work better and need fewer repairs.

Industry experts say these tubes and CNC turning help cameras in many ways:

The tubes do not rust and are very strong, so cameras last longer.

The tubes are light, so cameras are easy to hold and work well.

Smooth and exact shapes help cameras work better and take good pictures.

The tubes last a long time and do not need much fixing, which is good for the environment.

The tubes look nice and make cameras look better.

People who buy camera parts like these tubes because they are not too expensive, work well, and can be trusted. Working with skilled companies like Huaruida Precision helps get the best results.

304 stainless steel resists rust and stays strong. It bends without breaking. This makes it a safe choice for camera tubes. Many engineers trust it for its long life and toughness.

CNC turning shapes tubes with high accuracy. Machines follow exact plans. This process gives each part a smooth finish and the right size. Camera makers get parts that fit and work well.

Yes! Huaruida Precision offers custom tube sizes and shapes. Their team works with clients to match special needs for camera systems. They check every tube for quality before shipping.

Thin-walled 304 stainless steel tubes handle bumps and weather. They protect camera parts from rain, dust, and drops. Many outdoor cameras use these tubes for safety and long life.

Navigation

Navigation

Contact Us

Tel: +86 13417419143

E-mail: [email protected]

Add:

2nd Floor, Building 7, 156 High Tech Industrial Park, Fuyuan 1st Road, Zhancheng Community, Fuhai Street, Baoan District, Shenzhen City, China.