Jul.

10, 2025

Contents

Choosing the Right Aluminum Alloy for CNC: 2024 vs 6061 vs 7075

Choosing the Right Aluminum Alloy

The strength requirements, including yield and tensile strength.

The corrosion resistance needed based on the environment.

The ease of machining, which affects tool life and surface finish.

The overall cost, including both material and machining expenses.

Any special properties your project demands.

Refer to the comparison table below to help you in choosing the right aluminum alloy for your project.

When you pick the Right Aluminum Alloy for your CNC project, it helps to see how each one works. The table below shows how 2024, 6061, and 7075 compare on important things:

| Property / Alloy | 2024 | 6061 | 7075 |

|---|---|---|---|

| Tensile Strength | 400–500 MPa (58–72 ksi) | ~310 MPa (45 ksi) | 572–638 MPa (83–92 ksi) |

| Yield Strength | 275–325 MPa (40–47 ksi) | ~276 MPa (40 ksi) | 503–572 MPa (73–83 ksi) |

| Elongation | 10–15% | ~12% | 5–11% |

| Machinability | Good | Excellent | Fair |

| Corrosion Resistance | Moderate (needs coating) | Excellent | Fair to Moderate (needs coating) |

| Cost | Moderate | Low | High |

| Typical Applications | Aircraft skins, structural parts | Automotive, marine, general fabrication | Aerospace, high-stress parts, defense |

Tip: Use this table to quickly check which Aluminum Alloy fits your CNC job.

You want to make a smart choice for your CNC project. Look at these main things when picking the Right Aluminum Alloy:

Strength Requirements

If your part needs to be very strong, 7075 is the best. 2024 is also strong and good for planes. 6061 is fine for most jobs that do not need super high strength.

Machinability

6061 is the easiest to machine. It is simple to cut and shape, so you save time and tools last longer. 2024 is also good but can crack if you are not careful. 7075 is harder to machine and can wear out tools faster.

Corrosion Resistance

If your part will get wet or be outside, 6061 is best. 2024 and 7075 need a special coating to stop rust if used outdoors or in water.

Cost

6061 usually costs the least. 2024 costs more because it is stronger. 7075 is the most expensive since it is the strongest.

Application Fit

Pick the alloy that matches your project:

6061 works for cars, boats, and most other uses.

2024 is good for airplane skins and strong parts.

7075 is best for tough airplane and defense parts.

Processing Considerations

Think about how the alloy acts during CNC machining. 6061 lets you cut faster and gives a nice finish. 7075 needs slower speeds and more cooling to keep tools safe.

Note: Always pick your alloy based on what your project needs for strength, rust protection, and machining. If you are not sure, ask your CNC supplier or an engineer.

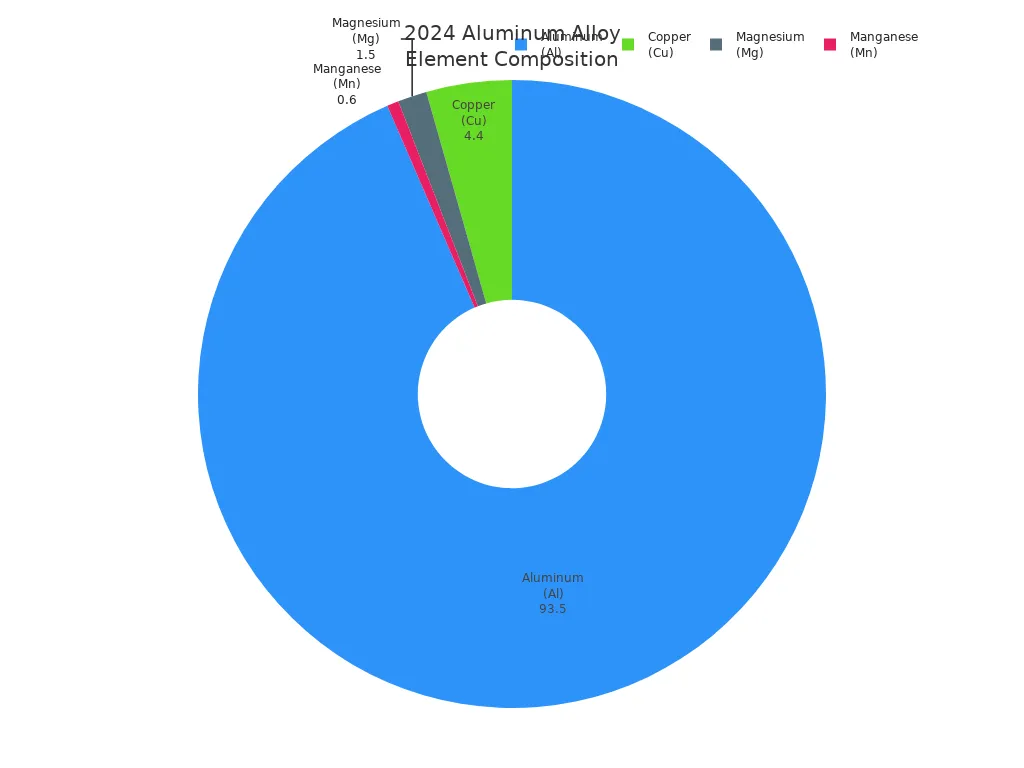

2024 aluminum is known for being strong and easy to machine. People use this alloy in many tough CNC projects. It is made from aluminum, copper, magnesium, and manganese. The copper makes it stronger but also means it can rust more easily.

| Element | Typical Content (%) |

|---|---|

| Aluminum (Al) | About 93.5% |

| Copper (Cu) | Around 4.4% |

| Magnesium (Mg) | Approximately 1.5% |

| Manganese (Mn) | About 0.6% |

2024 aluminum has a density of about 2.77 g/cm³. This is a little heavier than pure aluminum. It is still light but much stronger.

It has an ultimate tensile strength of about 470 MPa. The yield strength is close to 325 MPa. This alloy can handle lots of stress over and over again.

2024 aluminum has many good points for CNC machining. But it also has some things you need to watch out for.

| Advantages | Disadvantages |

|---|---|

| High strength-to-weight ratio | Lower corrosion resistance (needs coating) |

| Good machinability | Limited weldability |

| Heat treatable for better properties | Limited formability |

| High fatigue strength | Susceptible to stress corrosion cracking |

| Precise, smooth CNC finishes | Needs careful machining to avoid damage |

Tip: Always add a protective coating if your part will get wet or be in a rough place.

Pick 2024 aluminum when you need parts that are strong and can take a lot of use. This alloy is best for:

✈️ Aerospace: Brackets, body panels, landing gear parts

🚗 Automotive: Engine blocks, transmission cases, frames, suspension parts

💻 Electronics: Computer cases, phone frames, heat sinks

🏗️ Construction: Window frames, door frames, siding

🏠 Consumer Goods: Appliance housings, furniture, sports gear

2024 aluminum is great for parts that must be strong, light, and last a long time. If your part will be in tough places, make sure to add a protective finish.

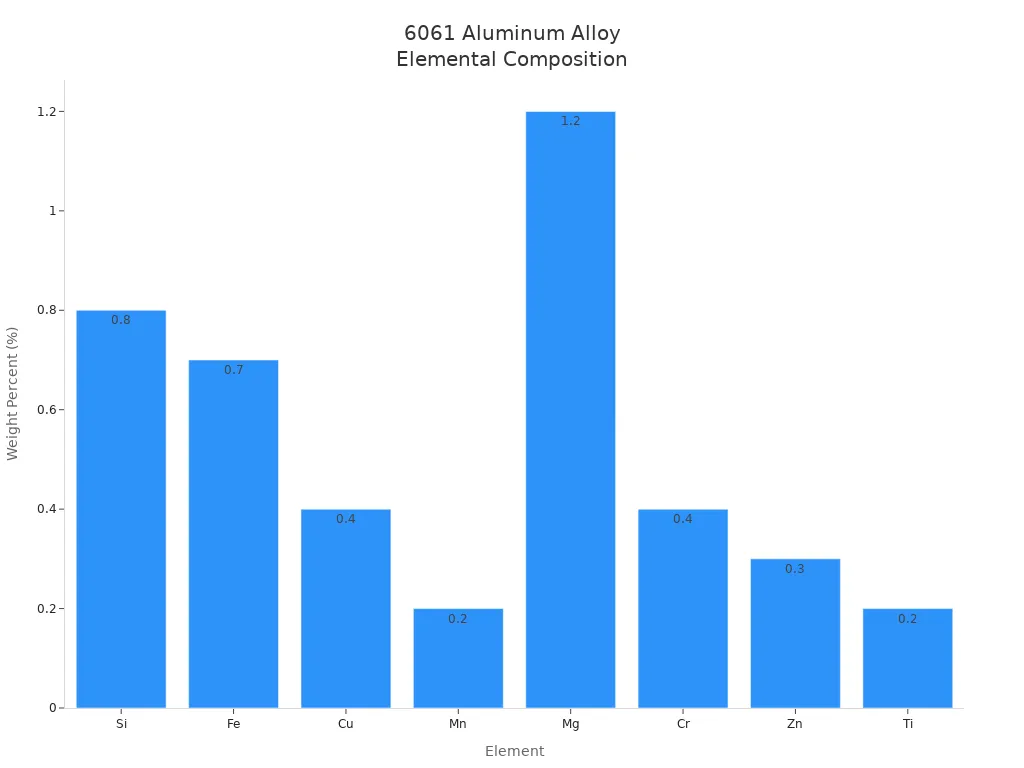

6061 aluminum is a very popular choice for CNC machining. It gives you a good mix of strength, rust resistance, and easy machining. This alloy has about 97.9% aluminum. It also has 1.0% magnesium, 0.6% silicon, 0.28% copper, and 0.2% chromium. These elements make the metal light, with a density of 2.7 g/cm³. Silicon and magnesium help make it stronger and easier to cut. Copper and chromium make it tougher.

| Element | Aluminum | Magnesium | Silicon | Copper | Chromium | Others |

|---|---|---|---|---|---|---|

| wt. % | 97.9 | 1.0 | 0.6 | 0.28 | 0.2 | Trace |

6061 aluminum also has tiny amounts of iron, manganese, zinc, and titanium. These small parts help improve its features. Because of its mix, you can use this alloy in many places.

6061 aluminum gives you many good things for CNC work. It is easy to use and works well for lots of jobs.

| Strengths | Weaknesses |

|---|---|

| Excellent machinability | Lower strength than 2024 or 7075 |

| High corrosion resistance | Not ideal for heavy-load aerospace parts |

| Good weldability | Can lose strength near welds |

| Affordable and widely available | Not as hard as some other alloys |

| Consistent surface finish after machining | May deform under extreme stress |

Tip: Pick 6061 if you want a metal that is easy to machine and does not rust. It is great for outdoor or marine parts.

6061 aluminum can be used for many CNC jobs. Its flexibility makes it a favorite in many fields.

🚗 Automotive: Frames, wheels, engine parts, and brackets

🛥️ Marine: Boat fittings, hulls, and hardware

🏗️ Construction: Structural components, railings, and platforms

🏠 Consumer Products: Bicycle frames, furniture, electronics housings

⚙️ General Fabrication: Fixtures, jigs, and custom machine parts

6061 aluminum is best when you need strength, rust resistance, and easy cutting. It gives you steady results for most CNC jobs and does not cost too much.

7075 aluminum is one of the strongest types you can use for CNC machining. It gives you high strength but does not weigh much. The density is about 2.81 g/cm³. This is just a little heavier than other aluminum alloys. But it is much stronger.

This alloy has a special mix of elements. These elements give it its strong features. Here is what is inside 7075 aluminum:

| Element | Composition Range (%) |

|---|---|

| Silicon (Si) | ≤ 0.40 |

| Iron (Fe) | ≤ 0.50 |

| Copper (Cu) | 1.2 - 2.0 |

| Manganese (Mn) | ≤ 0.30 |

| Magnesium (Mg) | 2.1 - 2.9 |

| Chromium (Cr) | 0.18 - 0.28 |

| Zinc (Zn) | 5.1 - 6.1 |

| Titanium (Ti) | ≤ 0.20 |

| Other Elements | ≤ 0.05 (each), ≤ 0.15 (total) |

| Aluminum (Al) | Remainder |

Zinc and magnesium are big parts of this alloy. They help make 7075 aluminum very strong and hard. Copper also adds strength. But copper can make it rust more easily.

7075 aluminum is one of the strongest aluminum alloys you can pick. It is great for parts that need to hold heavy weight or take lots of force.

Strengths:

Very high tensile and yield strength

Good at handling repeated stress

Light for how strong it is

Can get even better with heat treatment

Weaknesses:

Rusts easier than 6061 (needs a coating)

Harder to machine (tools wear out faster)

Not good for welding

Costs more than other alloys

Note: Always add a protective finish if your part will get wet or be in tough places. This helps stop rust and keeps your part strong.

Pick 7075 aluminum when your CNC part must be super strong and last a long time. This alloy is best for jobs where breaking is not allowed.

✈️ Aerospace: Wings, body frames, and landing gear

🏍️ Motorsports: High-performance parts, suspension, and wheels

🛡️ Defense: Military equipment, gun parts, and armor plates

🚴 Sporting Goods: Bike frames, climbing gear, and top sports gear

7075 aluminum is perfect for important parts that must stay strong under big stress. If you want the best strength for the weight, this alloy is a great choice.

When you look at 2024 and 6061, you see they are different. 2024 is much stronger than 6061. It is best for parts that need to handle a lot of stress. 6061 is not as strong, but it works for most jobs. 2024 is harder to cut and can wear out tools faster. 6061 is easy to cut and shape. It does not wear out tools as much. 2024 can rust if you do not add a coating. 6061 does not rust easily and is good for outdoor use. 2024 costs more because it is stronger. 6061 is cheaper and good for saving money. 2024 is used in planes and cars that need to be tough. 6061 is used for car frames, boat parts, and things people use every day. 2024 is hard to weld, so people use other ways to join it. 6061 is easy to weld and great for making things with welded parts.

Pick 2024 if you need the most strength and want your part to last under stress. Pick 6061 if you want something easy to cut, that does not rust, and costs less.

Key Points:

2024 is stronger, but you must protect it from rust.

6061 is easier to cut and weld.

Most CNC jobs use 6061 unless you need extra strength.

Both 6061 and 7075 work well for CNC, but they are not the same. 6061 is strong enough for most parts. 7075 is much stronger and is used for parts that must not break. 6061 is very easy to cut and finish. 7075 is harder to cut and can wear out tools quickly. 6061 does not rust and is good for outside or near water. 7075 can rust, so it needs a coating if used outside. 6061 is cheap and easy to find. 7075 costs a lot more because it is so strong. 6061 is used for cars, boats, and things people use every day. 7075 is used for planes, defense, and racing parts. 6061 is easy to weld. 7075 is not good for welding.

Use 7075 if your part must hold a lot of weight or stress. For most other jobs, 6061 is better because it is cheaper and easier to use.

Key Points:

7075 is the strongest, but it costs more and is harder to cut.

6061 is easier to use and does not rust as much.

7075 is best for planes and defense. 6061 is best for most other parts.

2024 and 7075 are both strong, but they are not the same. 7075 is one of the strongest aluminum alloys. 2024 is also strong and can handle stress over and over. 2024 is easier to cut than 7075, but not as easy as 6061. 7075 is harder to cut and wears out tools fast. Both 2024 and 7075 can rust, so they need a coating if used outside. 2024 costs less than 7075, but it is still not cheap. 7075 costs the most because it is so strong. 2024 is used for plane skins and car parts that need to be strong. 7075 is used for planes, defense, and racing parts that must not break. Both are hard to weld, so welding is not a good choice.

Pick 7075 if you need the most strength and can pay more and work with harder cutting. Pick 2024 if you want strong parts but need to save money.

Key Points:

7075 is the strongest, but it is hard to cut and costs more.

2024 is strong and easier to cut than 7075.

Both need coatings to stop rust if used outside.

7075 is best for important plane or defense parts. 2024 is good for strong parts that do not need the top strength.

When you pick the Right Aluminum Alloy for your CNC job, always match what the alloy can do to what your part needs. This way, you get the best results and save money.

If you want to compare 2024, 6061, and 7075 aluminum, this table helps. It shows the main features for CNC machining. You can use it to pick the right alloy fast.

| Feature | 2024 Aluminum | 6061 Aluminum | 7075 Aluminum |

|---|---|---|---|

| Strength | High | Medium | Very High |

| Machinability | Good | Excellent | Fair |

| Corrosion Resistance | Moderate (needs coating) | Excellent | Fair (needs coating) |

| Weldability | Poor | Excellent | Poor |

| Cost | Moderate | Low | High |

| Best For | Aircraft, auto, strong parts | General, marine, consumer | Aerospace, defense, racing |

| Surface Finish | Smooth | Smooth | Good |

| Fatigue Resistance | High | Medium | Very High |

Tip:

Pick 6061 if you want easy cutting and welding. Choose 7075 if you need the most strength. If you want good strength and a lower price, use 2024.

Quick Checklist:

🛠️ Want easy cutting? Pick 6061.

✈️ Need the most strength? Pick 7075.

💰 Want strength but need to save money? Pick 2024.

This table helps you match your project to the best alloy. Always think about what you need for strength, rust protection, and price before you choose. If you are not sure, ask your CNC supplier or an engineer for help.

When you need to pick the Right Aluminum Alloy for your CNC project, follow these easy steps. This checklist helps you make good choices and skip mistakes:

| Checklist Item | Description |

|---|---|

| Alloy Grade | Choose the aluminum alloy (6061, 7075, 2024, etc.) that fits your needs for strength, machinability, and use. |

| Mechanical Properties | Look at tensile strength, fatigue resistance, and temper (like T6 or T73) for your part. |

| Corrosion Resistance | Make sure the alloy can handle where it will be used. 6061 or 6082 are good for outside or near water. |

| Machinability | Pick an alloy that works well with your machines. 6061 is easier to machine than 7075. |

| Weldability | If you need to weld, pick an alloy that welds well. 2024 and 7075 do not weld easily. |

| Dimensional Stability | For parts that must be exact, look at alloys like MIC-6 or 5080 to stop bending. |

| Heat Treatment & Temper | Pick the right temper for more strength and rust protection. |

| Application Suitability | Match the alloy to what you are making, like planes, electronics, or tools. |

| Anodizing Options | Think about anodizing to help stop rust and make the surface harder. |

| Cost and Availability | Make sure the alloy fits your budget and is easy to get. |

Tip: Go through each checklist item before you buy your material. This helps you avoid mistakes and makes sure your part will work right.

Common Mistakes to Avoid:

Not thinking about how soft aluminum is, which can make parts bend.

Forgetting that tools can still wear out, even though aluminum is softer than steel.

Picking an alloy without checking if it matches your strength and cost needs.

Not changing machine settings for the alloy you pick.

Not balancing quality and price or missing out on new machine ideas.

Frequently Asked Questions:

Which alloy grade is best for my project?

How do I stop tool wear and control chips?

Which alloy has the best strength for its weight?

How do I keep parts from rusting in tough places?

What extra steps, like anodizing, should I use?

How do I make sure my parts are very exact for planes or medical use?

Picking the Right Aluminum Alloy is easier when you use this checklist and answer these questions. You will do better if you match the alloy’s features to what your project needs.

Picking the best alloy depends on what your project needs. Look at the table below to see which alloy works best for each CNC job:

| Aluminum Alloy | Key Properties | Ideal CNC Machining Use Cases |

|---|---|---|

| 2024 | High strength | Aircraft parts needing strength |

| 6061 | Versatile, corrosion resistant | Automotive, structural, outdoor parts |

| 7075 | Superior strength, fatigue resistance | Aerospace, military, high-performance gear |

Think about how you will use the part, how strong it must be, how easy it is to machine, and how much it costs. Check the summary table and checklist before you pick an aluminum alloy. If you are not sure, ask a CNC supplier or an engineer for help.

You should start with 6061 aluminum. It machines easily, costs less, and resists corrosion. You will find it forgiving if you make mistakes. Many shops use it for training and prototyping.

You can weld 6061 aluminum with good results. 2024 and 7075 do not weld well. These alloys crack or lose strength after welding. Always check the alloy’s weldability before you start.

Apply anodizing or a protective coating.

Store parts in dry areas.

Avoid contact with harsh chemicals.

You should always protect these alloys if you use them outdoors or in wet places.

6061 aluminum gives you the smoothest and most consistent surface finish. 2024 also finishes well but may need extra care. 7075 can show tool marks if you do not use sharp tools and proper speeds.

You should choose 7075 only if your part needs maximum strength and fatigue resistance. For most jobs, 6061 or 2024 will meet your needs at a lower cost.

Navigation

Navigation

Contact Us

Tel: +86 13417419143

E-mail: [email protected]

Add:

2nd Floor, Building 7, 156 High Tech Industrial Park, Fuyuan 1st Road, Zhancheng Community, Fuhai Street, Baoan District, Shenzhen City, China.