Jun.

19, 2025

Contents

Anodizing vs Sandblasting: Which Surface Treatment Should You Choose?

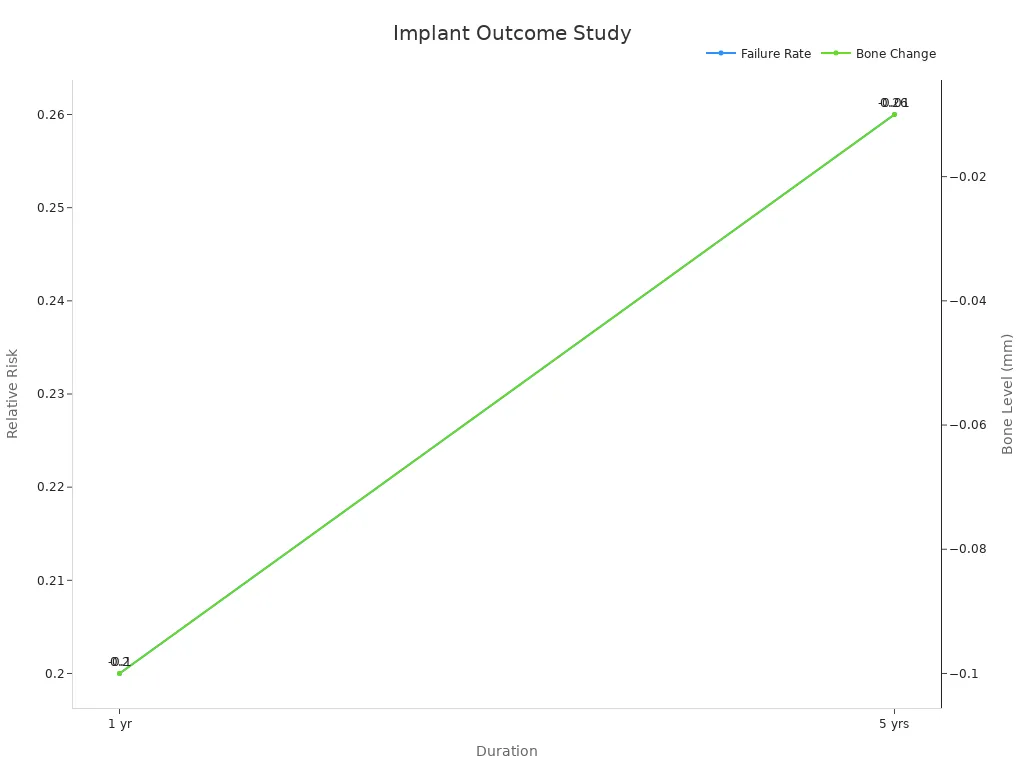

When you compare Anodizing vs Sandblasting, your choice depends on your needs. Anodizing works best if you want strong corrosion resistance and a colorful, decorative finish. Sandblasting gives you a matte texture and prepares surfaces for coatings or painting. Recent studies show sandblasting can lower failure rates for implants, but anodizing offers the highest bond strength and surface durability.

Think about your goals—do you need a smooth look, extra strength, or lower costs? This guide will help you choose the right method.

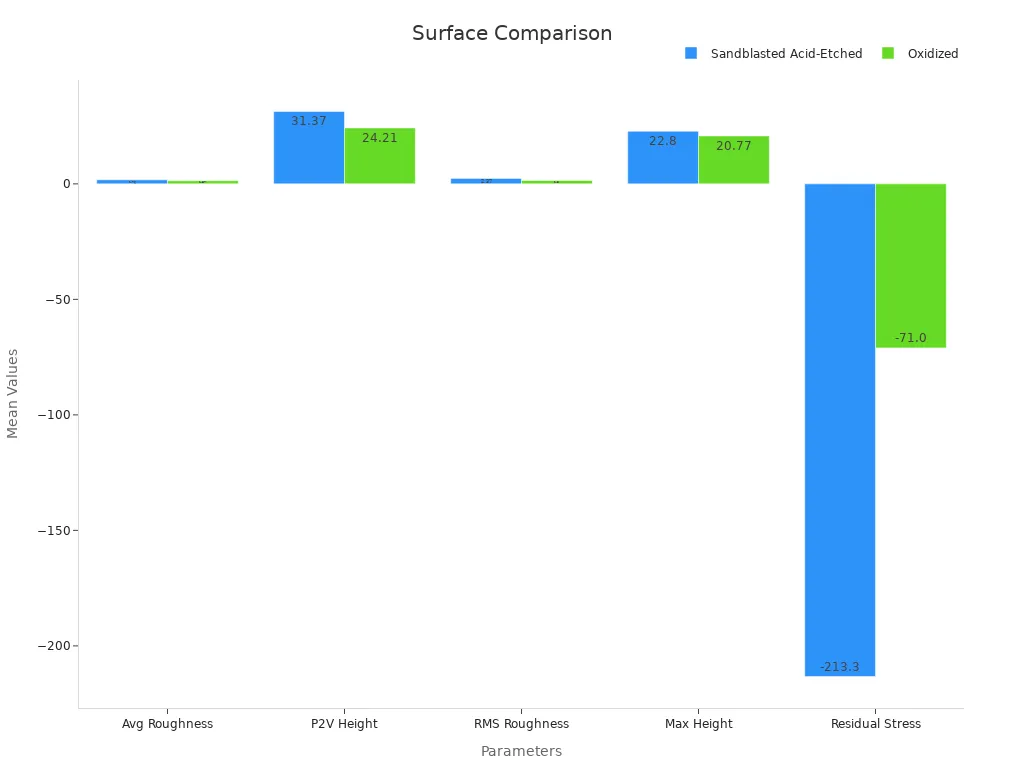

You may wonder how anodizing and sandblasting stack up side by side. The table below shows how each method changes the surface of metals like titanium and aluminum. Sandblasting creates a rougher, more textured surface. Anodizing forms a smoother, protective layer.

| Parameter | Sandblasted Acid-Etched (SA) | Oxidized (OS) | Significance (p-value) |

|---|---|---|---|

| Average Roughness (Ra, μm) | 1.76 ± 0.21 | 1.37 ± 0.11 | 0.0008 |

| Peak-to-Valley Height (Rt, μm) | 31.37 ± 2.30 | 24.21 ± 2.89 | 0.0002 |

| Root Mean Square Roughness (Rq, μm) | 2.37 ± 0.12 | 1.50 ± 0.13 | 0.0003 |

| Maximum Height (Rz, μm) | 22.80 ± 3.30 | 20.77 ± 4.00 | 0.0001 |

| Residual Stress (MPa) | -213.3 ± 3.6 | -71.0 ± 5.1 | 0.0001 |

Sandblasting increases the surface area and roughness. Anodizing, on the other hand, gives a more uniform and protective finish. When you combine both, you can improve the look and durability of aluminum products.

Sandblasting uses high-speed particles to clean and roughen the surface. You often see this in aluminum casting to remove rust, old coatings, or imperfections.

Anodizing is an electrochemical process. It creates a porous layer on aluminum that can hold dyes for color and adds corrosion resistance.

Sandblasting changes the surface topography but does not affect the metal’s nano-structure or how it attracts water.

Anodizing focuses on coating quality and follows strict standards, such as MIL-PRF-8625F, to ensure a strong, even finish.

Tip: If you want a colorful, decorative finish with strong protection, choose anodizing. If you need to prepare a surface for painting or want a matte texture, sandblasting works best.

Market research shows that sandblasting is key in many industries for cleaning and prepping surfaces. Anodizing is popular for its ability to add color and protect aluminum from corrosion. When you combine both, you get better aesthetics and longer-lasting products.

Anodizing uses electricity and chemicals to change the surface of aluminum. You start by cleaning the metal to remove dirt and natural oxides. Next, you place the aluminum in a tank filled with sulfuric acid. The aluminum connects to the positive side of a power supply, making it the anode. When you turn on the electricity, oxygen ions from the acid react with the aluminum. This reaction forms a thick layer of aluminum oxide on the surface. The layer has two parts: a thin, hard barrier close to the metal and a porous outer layer. You can add color by putting dyes into the pores. Sealing the layer with hot water or chemicals makes it even more resistant to corrosion. Careful control of temperature, acid strength, and electricity helps you get the right thickness and hardness.

Anodizing gives you several important advantages:

You get strong corrosion resistance, which protects aluminum from rust and weather.

The surface becomes much harder, making it more scratch-resistant.

You can choose different finishes, from matte to glossy, and add bright colors.

The process improves how well paint or glue sticks to the metal.

Research shows that special anodizing methods, like phosphoric sulfuric acid anodizing, make the surface even tougher and more durable. When you add extra treatments, you can boost hardness and wear resistance even more.

Tip: Anodized aluminum often lasts longer and looks better than untreated metal.

Anodizing does have some drawbacks. You need very clean surfaces before you start. The process takes time and careful control. It usually costs more than simple surface treatments like sandblasting. Not all metals work well with anodizing; aluminum is the best choice. If you use poor-quality alloys or skip cleaning steps, you may get uneven finishes or weak protection.

You can use anodizing in many industries. The table below shows which type works best for different needs:

| Anodizing Type | Description | Best Use Scenarios |

|---|---|---|

| Type I (Chromic Acid) | Thin, flexible coating | Aircraft parts needing both corrosion resistance and flexibility |

| Type II (Sulfuric Acid) | Standard anodizing | General corrosion protection, paint prep, and better adhesion |

| Type III (Hard Anodize) | Thick, hard, wear-resistant coating | Firearm parts, gears, valves, and sliding or high-wear surfaces |

You should pick the type that matches your project’s needs, such as flexibility, corrosion protection, or extra hardness.

You use sandblasting, also called abrasive blasting, to clean or prepare metal surfaces. The process works by shooting abrasive particles, such as sand, steel grit, or glass beads, at high speed onto the surface. You control the outcome by adjusting the type of media, particle size, blast velocity, angle, and exposure time. Most sandblasting systems use compressed air, but some use mechanical wheels or even water for wet blasting. Wet blasting helps reduce dust and gives a gentler finish. You need to follow safety rules because the process creates dust and flying debris. Wearing goggles, respirators, and using containment systems keeps you safe and protects the environment.

Industry standards help you choose the right level of cleaning:

| Standard Name | Description |

|---|---|

| SSPC-SP5/NACE No. 1 (White metal) | Removes all rust, mill scale, and contaminants, leaving a bright surface. |

| SSPC-SP10/NACE No. 2 (Near-white) | Removes most rust and mill scale for high corrosion protection. |

| SSPC-SP6/NACE No. 3 (Commercial) | Removes most loose rust and mill scale; some staining may remain. |

| SSPC-SP7/NACE No. 4 (Brush-off) | Removes loose rust and mill scale; some staining and tightly adhered contaminants remain. |

Sandblasting gives you several key advantages:

You can quickly remove stubborn rust, old paint, and surface impurities.

The process creates a uniform matte or satin finish, which is ideal if you want a non-reflective look.

You can choose different abrasive media to get the finish you want. For example, steel grit gives a smooth surface, while glass beads leave a soft, matte texture.

Sandblasting works well for large areas and tight deadlines.

Wet sandblasting reduces dust and residue, making it safer and cleaner for sensitive surfaces.

Tip: Sandblasting is often the first step before painting, coating, or anodizing. It helps new layers stick better.

Sandblasting does not provide strong corrosion resistance by itself. The process cleans and roughens the surface, but it does not add a protective layer. Studies show that sandblasted metals can resist corrosion better in some alkaline environments, especially after extra treatments like autoclaving. However, in acidic or neutral conditions, sandblasted surfaces may corrode faster if left unprotected. The finish is usually duller than anodized or polished surfaces. You must also use safety equipment to protect yourself from dust and debris.

You will find sandblasting in many industries, from automotive to heavy machinery. It works best when you need to clean, prepare, or texture metal surfaces. The table below shows how different sandblasted finishes fit various industrial needs:

| Surface Finish Type | Reflectivity Category | Sandblasting Example | Industrial Application Scenario |

|---|---|---|---|

| Coarse Sandblasted Metals | Diffuse | Coarse sandblasted aluminum, steel | Bin picking, simple scenes without strong reflections |

| Fine Sandblasted Metals | Semi-Specular | Fine sandblasted aluminum, steel | Machine tending, scenes with moderate reflections |

You should use sandblasting when you want to remove coatings, achieve a matte finish, or prepare a surface for further treatment. It is not the best choice if you need long-term corrosion protection unless you add another protective layer afterward.

When you look at the results of anodizing vs sandblasting, you will notice clear differences in how each finish looks. Anodizing gives aluminum a smooth, even surface. You can choose from many colors, from bright silver to deep blue or red. The finish can be glossy or matte, depending on your needs. This makes anodized parts popular for products where appearance matters, like electronics, bicycles, and car trim.

Sandblasting creates a rough, matte texture. The surface looks dull and feels gritty. You will not get bright colors or a shiny finish from sandblasting alone. Instead, you get a surface that hides scratches and fingerprints. Many people use sandblasting when they want a non-reflective look or need to prepare metal for painting or coating.

Tip: If you want a colorful, decorative finish, choose anodizing. If you prefer a soft, non-glossy look, sandblasting works better.

You need to think about how long each treatment will last. Anodizing vs sandblasting shows big differences in durability. Anodizing forms a hard oxide layer on aluminum. This layer protects against rust, scratches, and wear. It also helps paint and glue stick better. When you add a primer after anodizing, you get even more protection. The primer blocks water and stops the oxide layer from breaking down.

The table below compares how much strength each treatment keeps after aging:

| Surface Treatment | Retained Strength After Accelerated Aging | Retained Strength After 1 Year Natural Weathering | Durability Mechanism / Notes |

|---|---|---|---|

| Sandblasting (SB) | ~90% | N/A | Durability depends on surface porosity and wettability; mechanical pre-treatment effectiveness varies |

| Phosphoric Acid Anodizing (PAA) | ~60% | N/A | Lower retention due to humidity penetration into fine pores; aluminum oxide hydration degrades adhesion |

| PAA + Primer (PAA-P) | N/A | >80% | Best performance; primer reduces humidity penetration, improves chemical bonding and adhesion |

Sandblasting does not add a protective layer. It only cleans and roughens the surface. This means sandblasted parts can rust or wear out faster if you do not add another coating. In some cases, sandblasting helps paint or glue stick better, but it does not protect metal by itself.

You will see that anodizing, especially with a primer, gives the best long-term protection. Sandblasting works well as a first step before other coatings.

You should compare the cost of anodizing vs sandblasting before you choose. Sandblasting usually costs less. The process is fast and does not need special chemicals or electricity. You can use sandblasting for large parts or when you need to clean many items quickly.

Anodizing costs more. The process takes longer and needs careful control of chemicals and electricity. You also need to clean the metal very well before you start. If you want special colors or a thick, hard layer, the price goes up. However, anodizing can save money in the long run because it protects parts from rust and wear, so you replace them less often.

Note: For simple cleaning or surface prep, sandblasting is the budget choice. For long-lasting protection and color, anodizing is worth the extra cost.

You will find anodizing vs sandblasting used in many industries, but each method fits different needs. Anodizing is common in products that need to look good and last a long time. Car makers use anodizing for trim and body panels, especially in electric and lightweight vehicles. Electronics companies use anodized aluminum for cases and parts that need both color and protection. Bike makers choose anodizing for frames and parts that face rain and dirt.

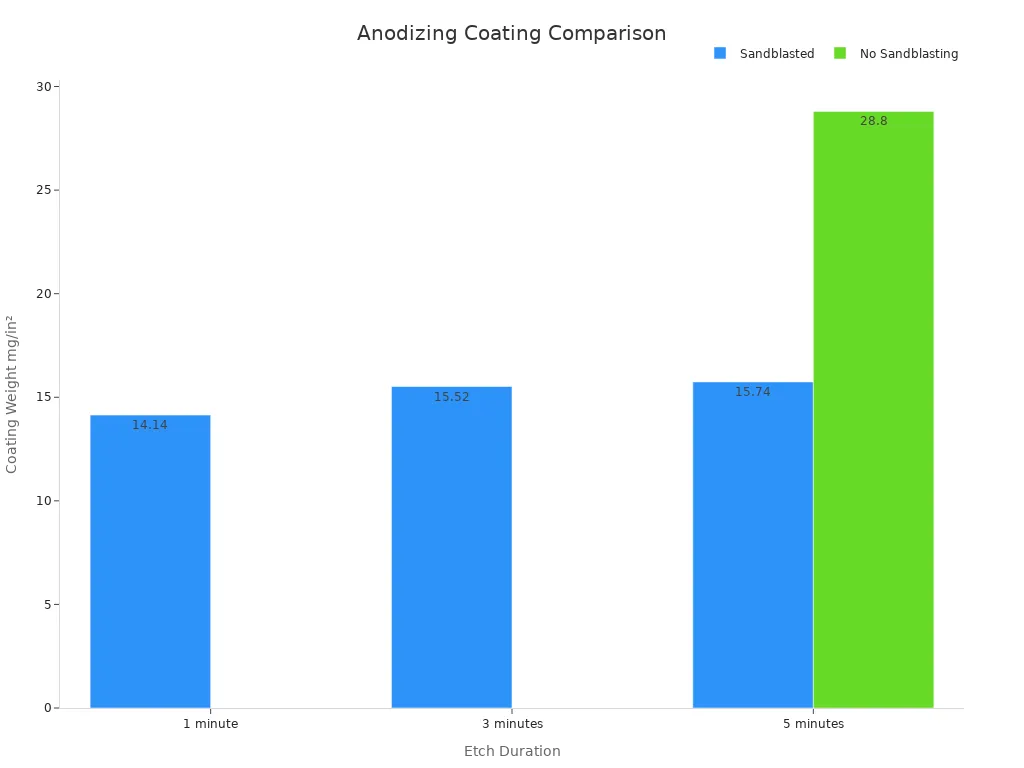

Sandblasting is popular in factories that build machines, cars, and heavy equipment. You use sandblasting to clean metal, remove old paint, or get a surface ready for welding or coating. In the automotive world, sandblasting helps prepare parts for painting or powder coating. It is also used in making implants, where a rough surface helps bone grow onto the metal.

Here are some common scenarios:

You want a bright, colored finish that resists scratches: Choose anodizing.

You need to clean rust or old paint before coating: Use sandblasting.

You want to improve how paint or glue sticks: Sandblast first, then anodize or coat.

You build vehicles for tough jobs (like trucks or off-road machines): Use both methods in sequence for the best durability.

Tip: Many industries combine both treatments. Sandblasting prepares the surface, and anodizing adds color and protection.

You can see that anodizing vs sandblasting is not always an either-or choice. Sometimes, you get the best results by using both methods together.

You need to start by understanding your project’s main goals. Every project has different needs, so you should ask yourself a few important questions:

Do you want a surface that looks colorful and decorative, or do you prefer a matte, non-reflective finish?

Will the part face harsh weather, chemicals, or heavy use?

Is your main goal to prepare the surface for painting or coating?

Do you need to keep costs low, or is long-term durability more important?

What type of metal are you working with—aluminum, steel, or something else?

Market surveys and technical guides can help you answer these questions. For example, industry reports and installation guides show how different surface treatments perform in real-world settings. You can find case studies that explain which method works best for specific jobs, such as improving safety on roads or protecting machine parts from rust. These resources also give you tips on cost, installation, and long-term results.

Tip: Write down your answers to these questions. This will help you match your needs to the right surface treatment.

You can use a step-by-step approach to choose between anodizing and sandblasting. Many engineers use structured frameworks, like the Ashby method, to make these decisions. This method helps you compare different options based on your goals and project limits. You can also use decision trees or flowcharts to visualize your choices.

Here is a simple table comparing decision trees and flowcharts for surface treatment selection:

| Aspect | Decision Trees | Flowcharts |

|---|---|---|

| Purpose | Decision-making, predictive modeling | Process analysis, documentation |

| Structure | Hierarchical tree-like, multiple decision paths | Sequential flow with loops and paths |

| Advantages | Simple language, flexible, supports quantitative and qualitative criteria, quick prediction | Visualization, standardization, process optimization, increased productivity |

| Disadvantages | Sensitive to data changes, requires large data, potential bias | Static representation, can oversimplify, risk of confusion if poorly designed |

| Applications | Technical selection, risk assessment, process optimization | Workflow visualization, process documentation, standardization across teams |

| Integration | Can be combined for complex processes, enhanced communication | Can be combined for complex processes, enhanced communication |

You can follow these steps to make your decision:

Define your main goal and list all important criteria (such as appearance, durability, cost, and application).

Build a simple model or chart that shows your goal, criteria, and possible choices.

Compare each criterion to see which is most important for your project.

Score each surface treatment based on how well it meets your criteria.

Add up the scores to see which option fits your needs best.

Many real-world case studies show that this method works well. Students and engineers have used it to solve tough industrial problems, and they often refine their choices as they learn more about the project.

Note: You can use questionnaires or expert systems to help guide your decision. These tools ask you questions and suggest the best surface treatment based on your answers.

You may still wonder which method to choose for your specific project. Here are some common scenarios to help you decide:

You want a colorful, decorative finish that resists scratches and corrosion. You should choose anodizing.

You need to remove rust, old paint, or prepare a surface for coating. Sandblasting is the best first step.

You work with aluminum parts that need both a matte texture and strong protection. Use sandblasting first, then anodize the surface.

You have a tight budget and only need to clean or roughen the surface. Sandblasting is the most cost-effective choice.

You build products for outdoor use or harsh environments. Anodizing gives you the best long-term protection.

You can also look at market surveys, technical documentation, and industry guides for more examples. These resources show how different industries use surface treatments to solve real problems, such as reducing accidents on roads or extending the life of machine parts.

Tip: If you are unsure, talk to a surface treatment expert or use a decision guide to help you choose.

You can see that choosing between anodizing vs sandblasting depends on your project’s needs, your goals, and the specific challenges you face. By following a structured decision process, you will find the best solution for your job.

When you compare Anodizing vs Sandblasting, you see that each method fits different needs. Choose anodizing if you want color, corrosion resistance, and a smooth finish. Pick sandblasting when you need to clean, roughen, or prepare a surface. Always match your choice to your project’s goals. Weigh the pros and cons before you decide. If you feel unsure, talk to a surface treatment expert for guidance.

You can anodize aluminum and its alloys most easily. Some other metals, like titanium and magnesium, also work, but aluminum gives the best results. Steel and iron do not respond well to anodizing.

Sandblasting removes most rust, old paint, and surface dirt. You may need to repeat the process for thick or stubborn rust. Always check the surface after blasting to make sure it is clean.

Yes, you can use sandblasting before anodizing. Sandblasting prepares the surface and helps the anodized layer stick better. This combination gives you a strong, durable, and attractive finish.

Anodized aluminum is safe for food-contact surfaces. The oxide layer does not react with food or drinks. Many cookware and kitchen tools use anodized aluminum for this reason.

Anodized surfaces can last for many years without fading or corroding. Sandblasted surfaces need extra protection, like paint or coating, to last as long. The environment and use affect how long each finish stays in good shape.

Navigation

Navigation

Contact Us

Tel: +86 13417419143

E-mail: [email protected]

Add:

2nd Floor, Building 7, 156 High Tech Industrial Park, Fuyuan 1st Road, Zhancheng Community, Fuhai Street, Baoan District, Shenzhen City, China.