Dec.

09, 2025

Contents

Alodine vs. Anodize: Choosing the Right Aluminum Coating

Alodine vs. Anodize Comparison

Choosing Between Alodine vs. Anodize

Choosing the right aluminum coating depends on what you need. If you want strong protection from rust, anodizing is a good choice. Anodizing also lets you pick from more colors. Polyurethane coatings work well outside. They can handle changes in temperature. Epoxy coatings stick very well. They also fight off chemicals in hard places. When you look at Alodine vs. Anodize, each one works best for certain jobs. Check the table below to find the best coating for your project.

Type of Coating | Benefits |

|---|---|

Anodizing | Stops rust, makes the surface tougher, lets you choose colors. |

Polyurethane Coatings | Bends easily, great for outdoor use with changing weather. |

Epoxy Coatings | Sticks well and fights chemicals, good for factories and tough places. |

When you look at Alodine and Anodize, you notice they are different. Each coating works in its own way and gives special benefits. The table below helps you see their main features side by side.

Feature | Alodine | Anodize |

|---|---|---|

Durability | Moderate | High |

Corrosion Resistance | Good (short to medium term) | Excellent (long term) |

Cost | Lower | Higher |

Appearance | Limited colors, subtle finish | Many colors, decorative finish |

Conductivity | Good | Poor (insulating) |

Common Uses | Primer, electrical, paint prep | Outdoor, marine, decorative |

You want your aluminum to last a long time. Anodize coatings make the surface harder and stop scratches. This helps protect from dents and wear. Alodine coatings do not make the metal thicker or harder. They protect but do not make it stronger. Anodized coatings can get tiny cracks called crazing. This happens when the coating bends or gets hot. If anodizing is done wrong, you may see pits or burns. Alodine coatings can wear off faster if you rub or scratch them a lot.

Failure Mode | Cause |

|---|---|

Crazing | Stress in the anodic oxide coating from heat or bending |

Anodizing Burn | Too much current or poor mixing during anodizing |

Pitting Corrosion | Thin or weak anodic film from poor processing |

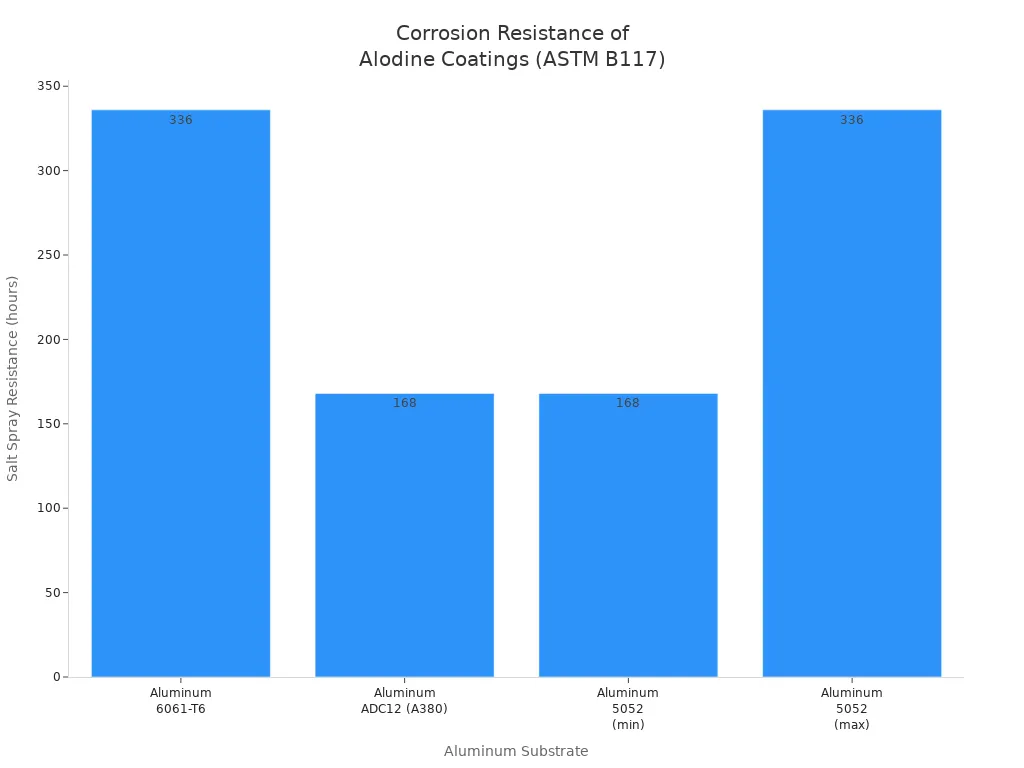

Both coatings help fight rust, but anodizing does more. Anodized aluminum stands up to rain, salt, and wet air. You can use it outside or in damp places. Alodine protects well but does not last as long in tough weather. Salt spray tests show Alodine can protect for up to 336 hours. This depends on the type and metal. Anodized coatings last longer in these tests.

Substrate | Recommended Alodine Type | Salt Spray Resistance (ASTM B117) |

|---|---|---|

Aluminum 6061-T6 | Hexavalent Chromate Coating | 336 hours |

Aluminum ADC12 | Non-Chromate Conversion Coating | 168 hours |

Aluminum 5052 | Trivalent Chromate Coating | 168–336 hours |

Anodized aluminum works well in wet and salty places. Over time, the anodized layer can get thinner. This happens more in salty or wet air. It can change how the metal looks and how well it fights rust. Still, for most outdoor uses, anodizing gives the best long-term protection.

You may wonder which coating costs less. Alodine is cheaper to use. It works well for big batches or quick jobs. Anodizing costs more, usually $2.00 to $5.00 per square foot. The price depends on color, thickness, and how tough you want it. If you want a strong, colorful, and long-lasting coating, anodizing is worth the extra money.

Alodine: Costs less, good for basic protection or as a primer.

Anodize: Costs more, best for strength and looks.

Alodine and Anodize look different. Alodine comes in a few colors like clear, gold, or pale yellow. It looks soft and does not stand out. Anodized coatings have many colors because you can dye them. You can pick clear, black, red, blue, and more. Anodized finishes keep their shine and color longer. Alodine can wear or scratch more easily, so the look may fade.

Coating Type | Color Options |

|---|---|

Alodine | Limited (gold, brown, clear) |

Anodizing | Wide range (clear, dyed) |

Feature | Alodine Coating | Anodized Aluminum |

|---|---|---|

Color | Colorless, transparent, pale yellow | Wide range of colors |

Decorative Options | Limited | Many choices |

Maintenance of Appearance | Prone to wear and scratching | Keeps color and shine longer |

If you need aluminum to carry electricity, Alodine is better. It keeps the metal able to conduct, which helps with grounding and shielding. Anodized aluminum does not conduct electricity well. The anodized layer acts like an insulator. This makes it a poor choice for electrical parts that need to pass current or block signals.

Alodine: Good for electrical conductivity, great for grounding and shielding.

Anodize: Poor conductivity, acts as an insulator.

Alodine and Anodize are used in many industries. Alodine works well when you need to paint aluminum or keep it conductive. It is common in aerospace and car parts, especially those that need to resist rust and help paint stick. Anodizing is popular for outdoor furniture, building parts, and marine gear. It gives strong, colorful, and long-lasting protection.

Alodine: Used for electrical parts, as a primer before painting, and in aerospace and car industries.

Anodize: Used for outdoor gear, marine hardware, decorative panels, and places where you want color and strength.

Tip: Pick Alodine if you need to paint the part or keep it conductive. Choose anodize if you want color, strength, and the best rust protection.

Alodine coating uses chemicals to protect aluminum. It helps stop rust and gets the metal ready for paint. Here are the steps:

Clean the metal part. Take off all oil and dirt.

Etch the surface. Use a solution to remove the oxide layer.

Deoxidize the metal. Get rid of leftover oxides and dirt.

Put on the Alodine solution. This makes a thin, strong film.

Rinse the part. Wash away extra chemicals and set the coating.

You need to watch the temperature and time for best results.

Alodine coating gives aluminum important benefits. It helps stop rust, even in wet or salty places. Paint sticks better, so the finish lasts longer. The coating keeps the metal able to carry electricity. This is good for grounding and shielding in electronics.

Performance Benefit | Description |

|---|---|

Corrosion Resistance | Lasts over 500 hours in salt spray tests. |

Improved Paint Adhesion | Makes the surface rough so paint sticks well. |

Maintained Electrical Conductivity | Needed for safety in audio and medical devices. |

Alodine coatings have some limits. They work mostly on aluminum alloys. The coating is thin and soft, so it scratches easily. You must watch the process closely. Some Alodine types use chemicals that can hurt the environment. These need strict rules.

Works mostly on aluminum.

Some chemicals can harm the environment.

Needs careful process control.

Thin and soft, not good for moving parts.

Only a few colors, like yellow or brown.

Does not make surfaces slippery.

Coating Type | Chromium Type | Environmental Impact |

|---|---|---|

Type 1 | Hexavalent Chromium | Needs strict rules because it can harm health |

Type 2 | Trivalent Chromium | Safer and better for the environment |

Pick Alodine coating for jobs that need paint to stick or good electrical flow. It is used in aerospace and cars for thin, strong protection. It works well for saving money and for parts like heat sinks.

Application Type | Description |

|---|---|

Pretreatment for Paint | Helps paint stick and last longer. |

Precision Fit Applications | Good for tight-fitting aerospace parts. |

Low Cost Applications | Saves money compared to anodizing. |

Thermal and Electrical Uses | Great for heat sinks and electrical parts. |

Alodine is best for electrical jobs and paint prep. Anodizing is better for color and outdoor strength.

Tip: Use Alodine if you want aluminum to stay conductive and ready for paint.

Anodizing makes aluminum stronger and better looking. The process uses electricity and special liquids. These help build a hard oxide layer on the metal. Here is a simple table that shows each step:

Step | Description |

|---|---|

Surface Cleaning and Degreasing | Wash the aluminum to get rid of oil and dirt. |

Mechanical Finishing | Sand or polish the metal to make it smooth. |

Masking | Cover parts you do not want to anodize. |

Setting Up the Anodizing Tank | Put the aluminum in a tank with a special liquid. |

Applying Electrical Current | Run electricity through the tank to make the oxide layer. |

Monitoring Key Variables | Check the temperature and chemicals to keep things safe. |

Sealing the Anodized Layer | Move the part to a bath to protect the new layer. |

Hot Water Sealing | Use hot water to close tiny holes in the surface. |

Alternative Sealing Methods | Try other sealants like nickel acetate for more strength. |

Testing the Quality of Sealing | Test the coating to make sure it is sealed and strong. |

Note: Anodizing uses water-based chemicals that are safe for the earth. Most factories recycle the leftovers, so this is a green choice.

Anodizing gives aluminum many good features. The surface lasts longer and needs less care. The oxide layer stops rust and scratches. Here is a quick table to show how anodized aluminum compares to plain aluminum:

Benefit | Anodized Aluminum | Untreated Aluminum |

|---|---|---|

Durability | Very tough, lasts a long time | Wears out faster |

Corrosion Resistance | Over 1000 hours in salt spray | 72-168 hours in salt spray |

Wear Protection | Over 2 million cycles before wear | 400,000-600,000 cycles |

Maintenance | Needs little care | Needs more frequent care |

Paint sticks better to anodized aluminum. It also blocks electricity. Anodizing can make aluminum last up to four times longer. The surface gets harder and does not stain easily.

Anodizing has some limits. If the coating is too thick, it can crack. It may break under heavy stress. In tough chemical or salty places, the protection may not last unless you seal it well. Sharp objects can scratch the oxide layer.

Can get scratched and scraped

Not as strong in very harsh places

May crack if the layer is too thick

Some metals do not work with anodizing, like iron, copper, and brass. Stainless steel already has its own protective layer, so it does not need anodizing.

Pick anodizing when you want a strong and colorful finish. It works well for building parts, outdoor furniture, electronics, and marine gear. Many architects use anodized aluminum for windows and doors. It meets strict rules for strength and looks.

Outdoor building materials

Marine hardware

Decorative panels

Electronic housings

When you look at Alodine vs. Anodize, anodizing is best for strength, color, and long-lasting protection. Always check that the finish meets the rules for your project.

Pick the coating that fits your project. Aerospace, electronics, and car parts need special coatings. Alodine is good for parts that must conduct electricity. It works well for electrical boxes and connectors. People use Alodine before painting because paint sticks better. It also saves money. Anodize is best when you want a strong and colorful finish. You see anodized coatings on outdoor furniture and building panels. Anodize helps moving parts slide easily.

Here is a table to help you choose:

Factor | Alodine | Anodize |

|---|---|---|

Durability | Not as tough, wears off faster | Very tough, thick protective layer |

Color Options | Only clear or yellow/brown | Many colors, can be dyed |

Lubricity | Not very slippery | More slippery for moving parts |

Cost | Costs less | Costs more, needs skill |

Conductivity | Good for electricity and heat | Does not conduct electricity |

Tip: Use Alodine for electrical parts and before painting. Pick anodize for outdoor things, color, and moving parts.

Think about where you will use the aluminum. If it faces rain or chemicals, anodizing protects best. Anodized coatings last in bad weather and tough places. You see anodized aluminum on boats and outdoor signs. Alodine works better inside, where air is clean and dry. You find Alodine in labs and electronics.

Anodizing is best for outside and harsh places.

Alodine works in indoor spaces with less moisture.

Electronics use Alodine for easy grounding and stopping rust.

Anodizing protects when you need strong rust resistance.

Note: If you expect lots of water or chemicals, anodize lasts longer.

Your budget helps you pick a coating. Alodine costs less, so it is good for big jobs or simple needs. You save money if you just need basic protection or a primer. Anodize costs more because it needs special tools and skill. You pay extra for color and strength.

Alodine: Cheaper, good for simple protection and paint prep.

Anodize: Costs more, best for strong and colorful finishes.

If you want to save money, Alodine is smart. If you want a finish that lasts and looks nice, anodize is worth it.

Think about what your project needs most. If you need aluminum to carry electricity, Alodine is best. It keeps the metal able to conduct, which helps with grounding. If you want aluminum to fight scratches and rust, anodize is strongest. Anodized coatings last longer and protect better.

Alodine: Good for electricity, paint prep, and saving money.

Anodize: Best for strength, color, and stopping rust.

When you compare Alodine and Anodize, think about your needs. Pick anodize for color and strength. Pick Alodine for conductivity and as a primer.

Reminder: Always match your coating to your project’s needs, where it will be used, and your budget.

You can use Alodine when you want fast and easy protection for aluminum. This coating helps you save both money and time. It lets electricity flow well, which is important for electronic parts. Alodine works great as a primer before you paint. You can put it on many pieces at once.

Key advantages of Alodine:

Fast to put on

Costs less than anodizing

Keeps aluminum able to conduct ⚡

Makes paint stick better

Works with many aluminum alloys

Tip: Pick Alodine if you need paint to stick or want the metal to stay conductive.

Alodine does not make aluminum much stronger. You might see scratches or wear after using it for a while. There are only a few color choices. Some Alodine types have chemicals that can hurt the environment. You must follow safety rules when you use it.

Drawbacks of Alodine:

Limitation | Impact on Your Project |

|---|---|

Thin and soft layer | Scratches and wears off easily |

Limited colors | Only gold, brown, or clear |

Environmental risks | Needs careful handling |

Shorter protection | Not good for tough outdoor use |

Anodizing gives you a hard and colorful finish. It protects well from rust and scratches. The coating lasts a long time, even outside in bad weather. You can choose from many colors for your project. Anodized aluminum does not need much care.

Why you might choose anodizing:

Very strong and hard to wear out 💪

Great at stopping rust

Many color choices 🎨

Lasts a long time

Easy to take care of

Note: Anodizing is best for things used outside, for decoration, or when you need extra strength.

Anodizing costs more money. The process takes longer and needs special tools. Anodized aluminum does not let electricity pass through well. If the coating is too thick, it can crack. Some metals cannot be anodized.

Possible disadvantages of anodizing:

Costs more

Takes more time to finish

Does not conduct electricity well

Can crack if too thick

Only works on some metals

Issue | What You Should Know |

|---|---|

Cost | More expensive than Alodine |

Conductivity | Acts as an insulator |

Compatibility | Only works on aluminum |

When you pick between Alodine and Anodize, think about what your project needs most.

Durability: Anodize is best if you want a strong surface that lasts.

Corrosion Resistance: Anodize works well outside or near water.

Cost: Alodine is good if you want to save money.

Appearance: Anodize lets you pick from many colors.

Conductivity: Alodine is better for electrical parts.

Tip: Look at where you will use your aluminum. Think about how strong and long-lasting you need it to be. Check the tables to help you pick the right coating for your project.

Alodine gets aluminum ready for paint or keeps it conductive. Anodize makes a tough, colorful layer that stops scratches and rust. Alodine costs less money. Anodize lasts longer and looks nicer.

You can paint on anodized aluminum. First, clean the surface well. Lightly sand the anodized layer. This helps paint stick better. Many people use a primer for best results.

Some Alodine types have chemicals that can hurt nature. You should follow safety rules and throw away waste the right way. New Alodine products use safer chemicals and make less waste.

Anodizing turns aluminum into an insulator. You should not use anodized aluminum for parts that need to carry electricity. Alodine keeps metal able to conduct, so it works better for electrical jobs.

Pick anodize for things used outside. It protects well from rain, sun, and salt. Alodine works best inside or under paint as a primer.

Navigation

Navigation

Contact Us

Tel: +86 13417419143

E-mail: [email protected]

Add:

2nd Floor, Building 7, 156 High Tech Industrial Park, Fuyuan 1st Road, Zhancheng Community, Fuhai Street, Baoan District, Shenzhen City, China.