Jan.

18, 2026

Contents

A Guide to Sheet Metal Riveting: Types and Applications

Sheet Metal Riveting lets you join metal parts in a strong way. The connections last a long time. This method works for many kinds of jobs. You can use it for repairs or making new things. When you look at welding and bolting, riveting is different. Riveting costs less for tools and training. Experienced manufacturers like HRDJM often use riveting for complex assemblies where heat distortion from welding must be avoided.

Feature | Welding | Riveting |

|---|---|---|

Equipment Costs | Costs more at first because you need special tools. | Costs less at first since you use simple hand tools. |

Labor Costs | Costs more because workers need special skills. | Costs less because workers do not need special skills. |

Training Costs | You spend a lot on training and getting certified. | You spend less because you learn on the job. |

If you know about different rivet types and tools, you can make better choices for your sheet metal work.

Riveting is a cheap way to join metal parts. It needs less training than welding. The tools for riveting are simpler than welding tools.

There are different rivet types, like solid, blind, and semi-tubular. Each type has its own job. Pick the right one for your project.

Rivets make strong joints that last a long time. They do not get damaged by heat. You can check and replace them easily.

It is important to pick the right rivet material. Aluminum and stainless steel are good choices. They help the joint last and stop rust.

Using the right tools makes riveting safer and faster. Hand riveters and pneumatic riveters work well for these jobs.

A rivet is a small metal fastener. It joins two or more sheet metal pieces. Rivets look like short rods with a head. You put the rivet through holes in the metal. Then you change the tail end so it holds tight. Rivets do not need threads or glue. They come in many shapes and sizes. Each type is best for certain jobs.

Tip: Rivets let you connect metal parts without special skills or expensive tools.

Rivets are important for fastening sheet metal. They help make strong and lasting joints. Sheet Metal Riveting keeps connections secure for a long time. Riveted joints do not get weak from heat like welded parts. You can check and replace rivets easily. This helps your project last for years.

Here are some reasons to pick riveting:

Riveted joints stay strong over time.

You avoid heat damage to metal.

You can take apart and replace parts.

Riveting works for joining different materials.

Advantage | Explanation |

|---|---|

Easy inspection and replacement | You can check and change rivets without hurting the main material. This makes things more reliable. |

Resistance to vibration | Riveting spreads out stress, so it works well where there is vibration. |

Capability to join dissimilar materials | Riveting lets you join different materials without heat, so the materials stay strong. |

Straightforward disassembly | You can take apart riveted joints easily, which helps with fixing and upgrades. |

You see riveting used in many industries. Some examples are:

Electronics Industry

Construction Industry

Marine Industry

You can use riveting for big projects or small repairs. This method is flexible and reliable.

When you work with Sheet Metal Riveting, you need to know about the different rivet types. Each type has special features and works best for certain jobs. Here is a guide to help you choose the right rivet for your project.

Solid rivets are the oldest and most reliable fasteners. You see them as a one-piece shaft with a head. You install them by deforming the tail end, which locks the rivet in place. These rivets give you strong and permanent joins. You often use solid rivets in bridges, ships, and steel structures. They work well when you need high strength and safety.

Solid rivets have a solid shaft and a head.

They last a long time and stay consistent in quality.

You need force and special tools to install them.

You can use a hammer or a warm process for mounting.

They work best in places where strength matters most.

If you use 2117-T4 aluminum alloy solid rivets, you get a tensile strength of 36,000 psi. Softer 'A' rivets offer 16,000 psi. These numbers show why solid rivets are trusted in heavy-duty jobs.

Tip: Choose solid rivets for projects that need maximum strength and durability.

Blind rivets help you when you can only reach one side of the workpiece. You insert the rivet and pull the mandrel to expand the body. This makes installation quick and easy. You do not need special skills or access to both sides.

You only need access from one side.

You can install them in tight spaces.

The process is fast and simple.

You get reliable and consistent results.

Blind rivets cost less than many other fasteners.

You often use blind rivets in electronics, cars, and aircraft. They make Sheet Metal Riveting possible in places where you cannot reach both sides.

Semi-tubular rivets have a hollow end. You install them by flaring out the hollow part, which takes less force than solid rivets. These rivets work well for light-duty jobs.

You use them in light fixtures.

They fit well in HVAC ducts.

Electronics often use semi-tubular rivets.

Ladders and brakes also use them.

You pick semi-tubular rivets when you want easy installation and do not need high strength.

Split rivets have a split shaft that spreads out when you drive them in. They work best for soft materials like wood and leather. You do not use split rivets for strong metal joints.

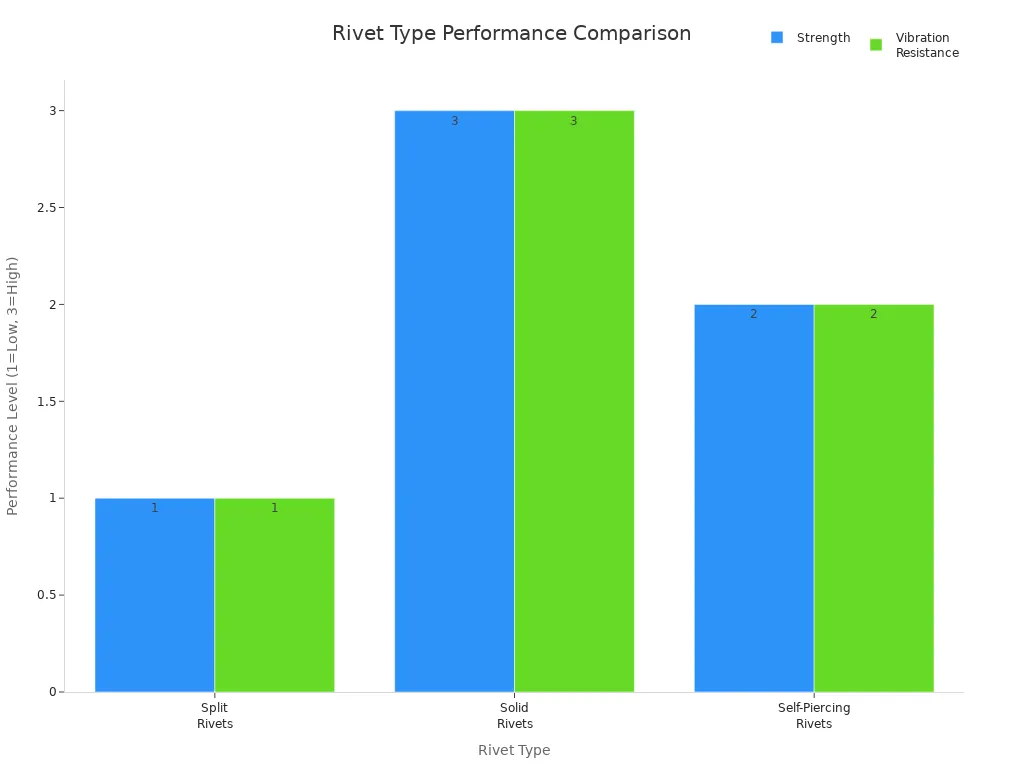

Rivet Type | Strength | Vibration Resistance | Suitable Materials |

|---|---|---|---|

Split Rivets | Low | Low | Wood, Leather |

Solid Rivets | High | High | Metals, Hard Materials |

Self-Piercing Rivets | Medium | Medium | Various Sheet Metals |

You should avoid split rivets for jobs that need strength or vibration resistance.

Drive rivets have a flat shaft with a scored or split end. You install them by driving a pin or nail into the split end. This expands the shaft and clamps the joint.

Feature | Description |

|---|---|

Design | Flat, unheaded shaft with a scored or split end. |

Installation Method | Installed by forcing a pin or nail into the split end to form a secure connection. |

Drive rivets have a small shank with a projection.

You insert them into a drilled hole.

You strike the projection with a hammer to expand the shank.

You do not need extra tools for installation.

Drive rivets work well for quick jobs and temporary fixes.

Specialty rivets give you solutions for unique needs. You find many types, each with a special purpose.

Rivet Type | Application Description |

|---|---|

Snap Head Rivet | Used in structural joints for strong clamping force in metal fastening. |

Pan Head Rivet | Ideal for furniture and sheet metal, with a broad top for load distribution. |

Countersunk Rivet | Used in aircraft panels and car bodywork for a flush finish and better aerodynamics. |

Blind Rivet | Perfect for hard-to-reach areas, found in aircraft and electronics. |

Tubular Rivet | Lightweight and cost-effective, used in leather and luggage industries. |

Cherry Rivet | High-strength blind rivet used in aviation and defense. |

Rivet Nuts | Provide permanent threads in thin materials, used in automotive and electronics. |

You choose specialty rivets when you need a special look, extra strength, or a flush finish. For example, countersunk rivets help you get a smooth surface on aircraft panels.

Note: Always match the rivet type to your project needs for the best results in Sheet Metal Riveting.

There are many materials used for rivets in sheet metal work. Each material has its own good points. The most common ones are steel, stainless steel, aluminum, brass, and copper. You can see what makes each one special in the table below:

Material | Advantages |

|---|---|

Steel | Low carbon steels bend easily and work for many jobs. |

Hard, strong, and does not rust, so it is good for tough jobs. | |

Light, easy to shape, and does not break down, so it fits many uses. | |

Brass | Does not rub much, does not tarnish, and does not spark, so it is good for gas tools. |

Copper | Moves heat and electricity well, so it is used for wires or plumbing. |

Steel rivets are good for most jobs. Stainless steel is best when you need strong rivets that do not rust. Aluminum rivets are great when you want to keep things light. Brass and copper rivets are picked for special jobs, like wiring or gas tools.

Tip: Pick the right rivet material for your job to get the best results.

When you pick a rivet material, you need to think about more than just how strong it is. You should also think about if it will rust, how heavy it is, and if it works well with the metals you are joining. The table below shows how well each rivet material fights rust:

Rivet Material | Corrosion Resistance Description |

|---|---|

Aluminum | Light and does not rust; works well with aluminum or stainless. |

Copper | Fights rust very well; good for wet or electric jobs. |

Stainless Steel | Strong and does not rust; needed for tough jobs that need both. |

Galvanized Steel | Fights rust on its own; works with zinc or aluminum rivets. |

Use aluminum or stainless steel rivets if you do not want rust. Copper rivets are good for wet places or where you need to move electricity. Galvanized steel helps stop rust in outside jobs.

You should also think about how much the rivet costs and how easy it is to put in. Some rivets cost more but last longer. Others are cheaper and easier to use but may not last as long. Sheet Metal Riveting works best when you think about all these things for your job.

Note: If you pick the wrong rivet material, your joint might break or rust fast.

You need the right tools for Sheet Metal Riveting. The tool you pick changes how fast you work. It also affects how strong your joints are. You can use hand riveters, pneumatic riveters, or hydraulic riveters. Each tool is good for different jobs and project sizes.

Hand riveters work by squeezing the handles. You use your hands to set the rivet. These tools are best for small jobs or home repairs. You do not need power or air to use them. Hand riveters are cheap and easy to carry. They are great for quick fixes or DIY projects.

Tip: Hand riveters help you work carefully on small jobs.

Pneumatic riveters use air to set rivets. You press a button, and the tool works fast. These tools are used in busy shops and factories. You see them in car repair and airplane work. Pneumatic riveters save time and make your hands less tired. They give you strong joints with little effort.

Note: Always wear safety glasses with pneumatic riveters. Small parts can fly and hurt your eyes.

Hydraulic riveters use pressure to set rivets. You get strong and neat joints with little work. These tools are best for big jobs like shipbuilding. Hydraulic riveters can handle thick and tough metal. Use them when you need strong and exact rivets.

Riveter Type | Efficiency | Application Areas |

|---|---|---|

Hand Riveter | Works slower, uses your hands | Good for small or home projects where you do not need perfect precision. |

Pneumatic Riveter | Works faster, uses air power | Used in car shops, airplane building, and construction for quick and strong joints. |

Hydraulic Riveter | Works fastest, uses strong force | Best for big jobs that need strong and exact rivets, like ships and large machines. |

When you use power tools for riveting, follow these safety rules: Wear safety glasses to keep your eyes safe. Stay at least 10 feet away from other people. Wear gloves to protect your hands from sharp metal.

Pick your tool by thinking about your job size, how fast you want to work, and how to stay safe.

Choosing the right rivet for your project makes a big difference in how strong and long-lasting your joint will be. You need to think about several important factors before you start. These include how much strength you need, how easy it is to reach the joint, what kind of environment the rivet will face, and how much the project will cost. This guide, curated with insights from HRDJM's fabrication experts, will help you make smart choices for Sheet Metal Riveting.

You should always match the rivet to the strength your project needs. Start by checking the grip range. This is the total thickness of the materials you want to join. If you pick a rivet with the wrong grip range, your joint may not hold well. Always use the hole size that the rivet maker suggests. This helps the rivet work at its best.

The material of the rivet matters too. Try to use a rivet made from the same metal as your workpiece. This helps stop corrosion and keeps your joint strong. Look at the rivet head style as well. A large flange works well for soft materials. A countersunk head gives you a flat finish, but you need to match the angle of the hole.

You also need to check the shear and tensile strength of the rivet. These numbers tell you how much force the rivet can take before it breaks. Different rivet materials and sizes have different strength levels. Always choose a rivet that meets or beats the strength your project needs.

Tip: If you are not sure, ask for the strength ratings from the rivet supplier. This helps you avoid weak joints.

Think about how easy it is to reach the spot where you need to place the rivet. Sometimes, you cannot get to both sides of the metal. In these cases, blind rivets work best. You can install them from one side only. This makes them perfect for tight spaces or complex shapes.

Rivet guns can fit into odd angles and hard-to-reach places.

Blind rivets let you make strong joints even when you cannot reach the back side.

The way you fasten the rivet changes how easy and fast your project will go.

If you have full access to both sides, you can use solid or semi-tubular rivets. For tricky spots, always check if your tool can fit and work safely.

You need to think about where your project will live. Will it face water, chemicals, or high heat? The right rivet material helps your joint last longer.

Stainless steel rivets work well in wet or chemical-heavy places.

Brass or stainless steel rivets handle high temperatures better than other metals.

If you use the wrong material, your rivet may rust or weaken over time. Always match the rivet to the environment for the best results.

Note: For outdoor or marine projects, pick rivets that resist rust and corrosion.

Cost plays a big role in picking rivets, especially for large jobs. Riveting often costs less than welding, especially for thin sheet metal. You also avoid problems like metal warping from heat.

For big projects, using pneumatic or automated rivet tools saves time and money. These tools help you finish faster and with less effort. The grip range of the rivet also affects cost. If you pick the right size, you avoid waste and get better performance.

You should balance the price of the rivet, the cost of tools, and the time needed for installation. Sometimes, a more expensive rivet saves money in the long run by lasting longer or making the job easier.

Tip: Plan your project and count how many rivets you need. Buying in bulk often lowers the price per rivet.

When you look at all these factors—strength, accessibility, environment, and cost—you can pick the best rivet for your job. Careful planning leads to safer, stronger, and more reliable Sheet Metal Riveting projects.

You can put in rivets by hand with simple tools. This way works best for small jobs or repairs. Here are the steps to help your joints stay strong:

Clean the Surface: Wash off dirt, oil, or dust with soap and water. Rinse and dry the metal before you start.

Mark the Holes: Use a center punch to make a mark. Drill holes that are a little smaller than the rivet.

Deburr the Holes: Smooth out sharp edges with a file or deburring tool.

Insert the Rivet: Put the rivet into the hole. Make sure the head is flat against the metal.

Set the Rivet: Use a riveting tool to flatten the tail. This makes a second head and locks the rivet in place.

Check the Installation: Make sure the rivet is tight and sits right.

Visual Inspection: Look for cracks, loose rivets, and check if everything lines up.

Tug Test: Pull on each rivet to see if it holds tight.

Destructive Testing: For important jobs, take out a rivet to check how well it worked.

Tip: Always check your work before you move to the next step.

You can use power tools like pneumatic, hydraulic, or electric riveters to work faster. Rivet guns help you make rivet heads quickly. Pneumatic tools use air and are faster than hand tools. Hydraulic tools are good for bigger rivets. Electric tools are easy to use. Machines are best for making lots of rivets at once.

Advantages | Limitations |

|---|---|

Flexible design | High overall cost |

Durable | Increased weight |

Easy maintenance | More noise |

Fast process | Possible corrosion |

Brittle board from drilled holes |

Note: Power tools save time but can cost more and make your project heavier.

You can stop problems if you watch out for these mistakes:

Picking the wrong size or type of rivet

Not cleaning the surface first

Forgetting to smooth the holes

Tightening too much and hurting the metal

Not checking each joint

Remember: Careful work helps your riveted joints last longer.

Rivets are used a lot in cars. They help fix holes in car floors and rusty spots. Many people use rivets to make old cars stronger. You can join thin metal panels with rivets for a strong hold.

Rivets are good for patching holes in car bodies.

You can use them to fix rusted parts.

Rivets make joints in thin metal that last.

Tip: Rivets let you fix cars without welding. This makes them popular for people who fix cars at home.

There are strict rules for using rivets in planes. You must follow standards like MIL-STD-403 for drilling and stopping rust.

You need to pick the right rivet for each job. Solid and blind rivets are used most for main parts.

Rivets must be spaced right—two times the rivet size from the edge and four times between each rivet.

Do not use solid rivets in composite materials. This helps stop damage.

Aerospace jobs need careful testing and exact work. You help keep planes safe by following these steps.

Rivets help make buildings stronger. They form tight connections that do not get loose.

Rivets work well where there is shaking or changing heat.

They spread out stress, so they handle heavy loads.

Riveting does not use heat, so the metal keeps its shape.

Benefit | Description |

|---|---|

Strong Joints | Rivets make connections that last a long time. |

Vibration Safe | Joints stay tight even when things move. |

No Heat Damage | Cold-forming keeps metal strong and shaped. |

You can use rivets for many fun projects at home. Rivets give strength and look nice.

You can join metal, wood, or fabric with them.

Rivets are easy to put in with simple tools.

People use them in metalwork, woodwork, leather, and jewelry.

Note: Rivets make your DIY projects strong and stylish.

Sheet Metal Riveting is an easy way to make strong joints in many areas.

Rivet Type | Material Used | Key Characteristics |

|---|---|---|

Aluminum | Aluminum | Lightweight, corrosion resistant |

Stainless Steel | Stainless Steel | High corrosion resistance |

Copper | Copper | Good conductivity |

Steel | Carbon Steel | Needs special installation tools |

Brass | Brass | Strong, corrosion resistant |

Choosing the right rivet and method helps your joints last longer.

You need to match the rivet to your project and where it will be used.

The right tools make your job safer and easier.

If you want to know more, look at these advanced tools and methods, or consult with HRDJM to explore professional riveting solutions.

Tool/Technique | Description |

|---|---|

Rivet Gun | Sets solid rivets quickly |

Rivet Squeezer | Works in tight spaces |

Drill Press | Makes accurate holes for rivets |

You should use blind rivets for thin sheet metal. They work well when you can only reach one side. Blind rivets give you a strong hold and easy installation.

You can remove a rivet by drilling out the center. Use a drill bit that matches the rivet size. This method lets you replace or repair parts without damaging the metal.

You do not need special training for basic rivet tools. Hand riveters and blind rivets are easy to use. You can learn by following instructions and practicing on scrap metal.

You should pick rivets made from stainless steel or aluminum. These materials resist rust. You can also apply a protective coating to the joint area for extra safety.

Rivets often give you a stronger and longer-lasting joint than screws. Rivets spread out stress and do not loosen from vibration. Use rivets when you need a permanent connection.

Navigation

Navigation

Contact Us

Tel: +86 13417419143

E-mail: [email protected]

Add:

2nd Floor, Building 7, 156 High Tech Industrial Park, Fuyuan 1st Road, Zhancheng Community, Fuhai Street, Baoan District, Shenzhen City, China.