Jan.

06, 2026

Contents

6061 vs. 6063 Aluminum: Which is Right for Your Project?

6061 vs. 6063 Aluminum: Key Differences

6061 vs. 6063 Aluminum: Applications

If you want a strong and tough metal for planes, cars, or big buildings, pick 6061 aluminum. In contrast, if you are making windows, doors, or furniture, 6063 aluminum is better suited for those applications. It does not rust easily and maintains an attractive appearance after anodizing. Experienced manufacturing partners like HRDJM can help you assess your specific needs to make the right choice. You can check the main uses in this table:

Alloy | Common Project Types |

|---|---|

6061 | Structural, industrial jobs like planes, cars, boats, and buildings |

6063 | Architectural and decorative jobs like windows, doors, furniture, and signs |

When you compare 6061 vs. 6063 aluminum, you notice some key differences. 6061 is stronger and easier to shape with machines, while 6063 does not rust as much and has a smoother look. You should choose the one that best fits your project’s strength requirements, aesthetic preferences, ease of shaping, and your budget.

Pick 6061 aluminum if you need strong parts. It works well for things like planes and cars. It can hold heavy weight without breaking.

Use 6063 aluminum for things that look nice, like window frames or furniture. It has a smooth surface and does not rust as easily.

Think about how easy it is to work with: 6061 is simple to cut and shape. This makes it good for parts that need to fit just right. 6063 is softer and works well for long, smooth pieces.

Look at your budget: 6063 aluminum usually costs less. This makes it a smart pick for big projects that need to look good.

Always pick the right aluminum alloy for your project. Think about how strong it needs to be, how it should look, and where you will use it.

When you compare 6061 vs. 6063 Aluminum, you see important differences in strength, corrosion resistance, and how easy each alloy is to shape or machine. These differences help you decide which alloy fits your project best.

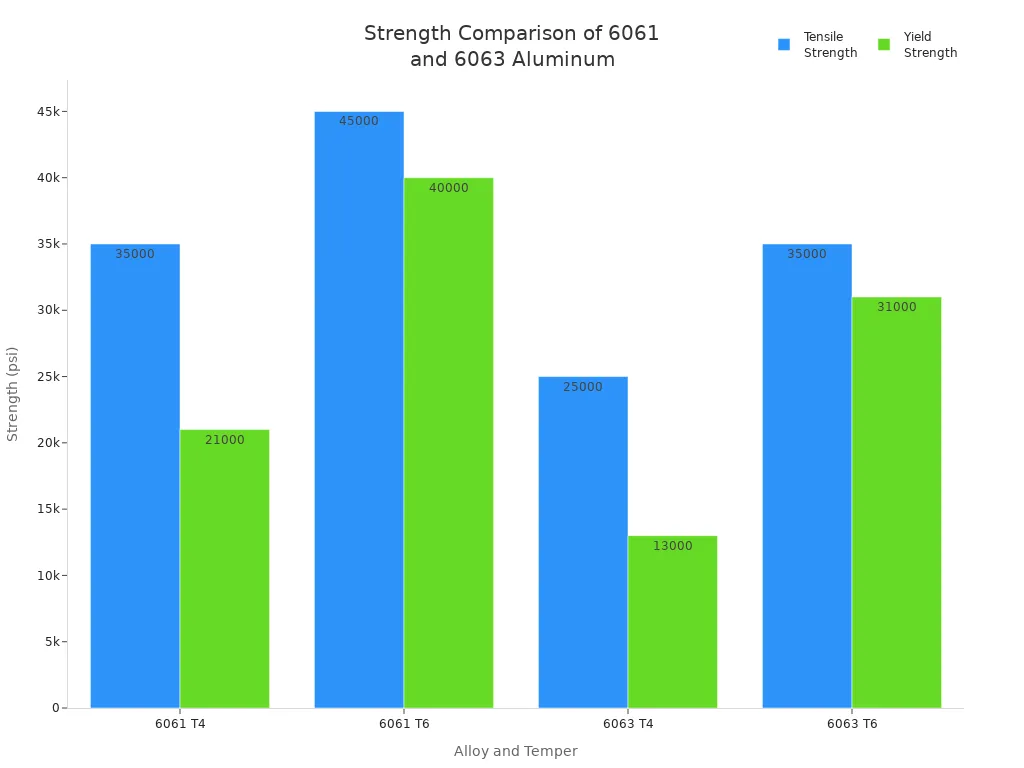

Strength is one of the biggest differences between these two alloys. If you need a metal that can handle heavy loads or stress, 6061 aluminum stands out. It has higher tensile and yield strength than 6063. This means 6061 can take more force before it bends or breaks.

Property | T4 6061 | T6 6061 | T4 6063 | T6 6063 |

|---|---|---|---|---|

Tensile Strength | 35,000 psi | 45,000 psi | 25,000 psi | 35,000 psi |

Yield Strength | 21,000 psi | 40,000 psi | 13,000 psi | 31,000 psi |

6061 also has a higher Brinell hardness rating (93) compared to 6063 (73). This means 6061 resists dents and scratches better. If you build something that needs to last a long time or face tough conditions, 6061 is usually the better choice.

Tip: For bridges, bike frames, or machine parts, 6061 aluminum gives you the strength you need.

Corrosion resistance tells you how well a metal stands up to water, air, or chemicals. Both 6061 and 6063 resist rust, but they perform a bit differently in harsh environments.

Alloy | Corrosion Resistance in Marine Environments | Notes |

|---|---|---|

6061 | Fair to Good | More likely to get pitting or crevice corrosion in salty or wet places. |

6063 | Good | Often used for windows, doors, and outdoor frames because it resists corrosion well. |

6063 aluminum has a slight edge in corrosion resistance, especially in outdoor or marine settings. It keeps its look and strength even when exposed to rain or salty air. You often see 6063 in window frames and railings for this reason.

Note: If your project will face a lot of moisture or needs a smooth, shiny finish after anodizing, 6063 aluminum is a smart pick.

Machinability means how easy it is to cut, drill, or shape the metal. Formability tells you how well the metal can be bent or formed into different shapes. Here is how 6061 vs. 6063 Aluminum compare:

Alloy | Machinability Rating | Characteristics |

|---|---|---|

6061 | Higher | Stronger, easier to machine, great for parts that need tight shapes |

6063 | Lower | Softer, more flexible, best for making long, smooth shapes like tubes or frames |

6061 aluminum is easier to machine. You can cut, drill, or tap it with less effort. This makes it a favorite for parts that need exact shapes or holes. 6063 aluminum, on the other hand, is softer and more flexible. You can extrude it into complex shapes with a smooth surface. That is why you see it in decorative trims and frames.

Alloy | Anodized Finish Quality |

|---|---|

6063 | Bright, uniform |

6061 | Fair to good |

6063 aluminum also gives you a brighter, more even finish after anodizing. If you want your project to look smooth and shiny, 6063 is the better choice.

Quick Fact: 6061 is called the "plain carbon steel of aluminum" because it is strong and cost-effective. 6063 is the go-to for decorative projects thanks to its smooth finish.

When you look at 6061 vs. 6063 Aluminum, think about what matters most for your project. Do you need strength and easy machining? Go with 6061. Do you want a smooth look and good corrosion resistance? Choose 6063.

6061 aluminum is strong and light. It does not break easily. This alloy has a density of 2.7 grams per cubic centimeter. That means it feels light but stays tough. You can check the main physical properties in this table:

Property | Metric | English |

|---|---|---|

Density | 2.7 g/cm³ | 0.0975 lb/in³ |

Modulus of Elasticity | 68.9 GPa | 10,000 ksi |

Thermal Conductivity | 180 W/m-K | 1,250 BTU-in/hr-ft²-°F |

6061 aluminum spreads heat fast. This helps parts that get hot work better. The modulus of elasticity shows how much the metal bends. 6061 aluminum keeps its shape under heavy loads.

Tip: If you want a metal that is easy to machine, weld, or form, 6061 aluminum works for many projects.

6061 aluminum is used in many industries. It is strong, resists rust, and is easy to shape. This alloy works for both industrial and consumer products. Here are some common uses:

Industry | Common Applications |

|---|---|

Helicopter rotor skins, wings, frames, engine mounts | |

Truck frames, wheels, chassis parts, structural supports | |

Marine | Shipbuilding, non-submerged boat components, railings |

Architecture | Frames, beams, handrails, curtain walls |

Consumer Products | Bicycle frames, electronics housings, sporting goods |

Industrial Equip. | Machine frames, jigs, enclosures, hydraulic system parts |

You might pick 6061 aluminum for a bike frame or boat railing. It resists saltwater, so it is good for marine projects. You also see it in truck frames and aircraft parts. These need strength and low weight.

When you compare 6061 vs. 6063 Aluminum, 6061 is often chosen for tough and flexible jobs.

Note: 6061 aluminum can be anodized or painted. This gives extra protection and makes it look better. It is great for outdoor and decorative projects.

6063 aluminum feels smooth and soft. It is lighter than many other metals. The density is 2.7 grams per cubic centimeter. This means it does not feel heavy. The tensile strength is lower than 6061. But 6063 aluminum still works for lots of jobs. You can bend and shape it without much trouble. It is great for making long tubes or frames.

Here is a table that shows the main physical traits of 6063 aluminum:

Property | Metric | English |

|---|---|---|

Density | 2.7 g/cm³ | 0.0975 lb/in³ |

Tensile Strength (T6) | 241 MPa | 35,000 psi |

Yield Strength (T6) | 214 MPa | 31,000 psi |

Thermal Conductivity | 201 W/m-K | 1,400 BTU-in/hr-ft²-°F |

Tip: 6063 aluminum is good for projects that need a shiny finish. It works well with anodizing. This makes the surface even smoother and more attractive.

6063 aluminum is used in many places. It is best for architectural and decorative projects. You can find it in window frames and door frames. Builders use it for curtain walls too. Railings, fences, and trim are often made from 6063 aluminum. It does not rust easily. It keeps looking nice for years.

Here are some common uses for 6063 aluminum:

Window and door frames

Storefronts and curtain walls

Railings and fences

Furniture and display stands

Sign frames and lighting fixtures

If you compare 6061 vs. 6063 Aluminum, 6063 is best for smooth finishes and good corrosion resistance. You can shape it into many different profiles. That is why it is popular for custom extrusions. 6063 aluminum is used outside a lot. It stands up well to rain and moisture.

Note: Pick 6063 aluminum if you want your project to look great and last a long time outside.

6061 aluminum is used in strong projects. It works well for jobs that need tough metal. This alloy is light but also very strong. It does not rust easily. You can find it in planes and satellites. Train cars use it too. These things need to be strong and light. 6061 aluminum weighs only 2.70 g/cm³. This helps make designs that are not heavy. Car chassis and battery trays use this alloy. These parts help cars stay safe and save fuel.

Aircraft frames and fuselage

Satellite parts

Car chassis and battery trays

Train and subway cars

Boat hulls and decks

Laptop and phone frames

6061 aluminum works well outside. It does not rust and can handle stress. You can shape it with machines. This helps make exact parts. Bridges, bikes, and machine parts use this alloy. It is tough and does not bend easily.

Tip: Pick 6061 aluminum for heavy jobs or hard places.

6063 aluminum is good for building and decoration. You see it in windows and doors. Railings use this alloy too. Builders like it because it looks smooth. It stays shiny after anodizing. It does not rust much, so it lasts outside. You can make many shapes with 6063 aluminum. This is great for custom designs.

Application Type | Description |

|---|---|

Architectural Aluminum | Used for looks and function in buildings |

Door Frames and Window Frames | Makes strong and nice frames |

Handrail and Fence | Adds safety and style inside and outside |

Custom aluminum extrusions | Gives special shapes for building and design |

You can weld 6063 aluminum easily. It is best when you want a smooth look. Railings, fences, and stores use this alloy outside. You do not need to fix it often. It does not rust as much as 6061 aluminum in wet places.

Note: Use 6063 aluminum when you want it to look good and last outside.

When you look at 6061 vs. 6063 Aluminum, each one is good for different jobs. Use 6061 for strong and tough work. Use 6063 for smooth looks and building designs.

You need to choose the right aluminum for your project. First, think about what your project needs most. Some projects need more strength. Others need a nice look or a lower price. The table below shows how 6061 and 6063 compare for these things:

Decision Factor | 6061 Aluminum | 6063 Aluminum |

|---|---|---|

Mechanical Properties | Higher strength, good for structures | Lower strength, best for looks |

Machinability | Faster to machine | Slower to machine |

Cost Factors | Usually more expensive | Often less expensive |

Application Needs | Best for strong parts | Best for smooth, decorative parts |

Think about how you will use the metal. 6061 is good for strong parts like frames. 6063 is better for windows, doors, and trim. It looks smooth and shiny. If you need to save money, 6063 costs less and is easy to find.

Aluminum is good for the planet. You can recycle it many times. 6061 is used in solar panels and electric cars. It is strong and light.

Tip: Do not pick only by price. Make sure the alloy fits your project’s needs.

Use this checklist to help you pick between 6061 and 6063:

Criteria | Aluminum 6061 | Aluminum 6063 |

|---|---|---|

Strength | High strength | Lower strength |

Corrosion Resistance | Good | Better for water and chemicals |

Workability | Moderate | Easier to shape and extrude |

Appearance | Rougher finish | Smoother, shinier finish |

Welding Needs | Good for welding | Less suitable for welding |

Cost | Higher | Lower, better for big projects |

Applications | Structural parts | Architectural and decorative |

Check your project’s strength needs.

Decide if you want a smooth or rough finish.

Think about your budget.

Consider how much shaping or machining you need.

Remember, both alloys are recyclable and good for the planet.

Some people pick the cheapest option without checking strength. Others choose the strongest alloy when they do not need it. Always match the alloy to what your project really needs.

When you compare 6061 vs. 6063 Aluminum, you get the best results by focusing on what matters most for your project.

You can look at this table to see how 6061 and 6063 aluminum are different:

Property | 6061 Aluminum | 6063 Aluminum |

|---|---|---|

Strength | Much stronger | Not as strong |

Workability | Easier to work with | Harder to work with |

Aesthetic qualities | Not best for looks | Looks better with coatings |

Typical applications | Used for strong things like bridges | Used for building parts like door frames |

Pick the alloy that fits what your project needs.

Use the checklist to help you choose.

If you are not sure, ask a materials expert at HRDJM. They can help you find the right mix of strength, looks, and how long it will last.

6061 aluminum is stronger and easier to shape. 6063 aluminum looks smoother and resists rust better. Pick the one that fits your project best.

You can weld both types of aluminum. 6061 welds well but can lose some strength. 6063 is easier to weld for things that look nice.

6063 aluminum is better for outdoor jobs. It does not rust much and stays shiny after anodizing. Use it for windows, doors, and railings.

6061 aluminum costs more than 6063. You pay extra for its strength and easy shaping. 6063 is cheaper for big, decorative projects. For cost-effective sourcing, companies like HRDJM can offer competitive rates for both alloys.

You can anodize both alloys. 6063 gives a brighter and smoother finish. 6061 can be anodized but may not look as shiny.

Navigation

Navigation

Contact Us

Tel: +86 13417419143

E-mail: [email protected]

Add:

2nd Floor, Building 7, 156 High Tech Industrial Park, Fuyuan 1st Road, Zhancheng Community, Fuhai Street, Baoan District, Shenzhen City, China.