May.

13, 2025

Contents

5-Axis Machining for Complex Drone Propeller Hubs

Understanding 5-Axis Machining

Advantages of 5-Axis Machining for Drone Propeller Hubs

Applications in Drone Propeller Hub Manufacturing

Challenges in Using 5-Axis Machining

The Future of 5-Axis Machining in Drone Technology

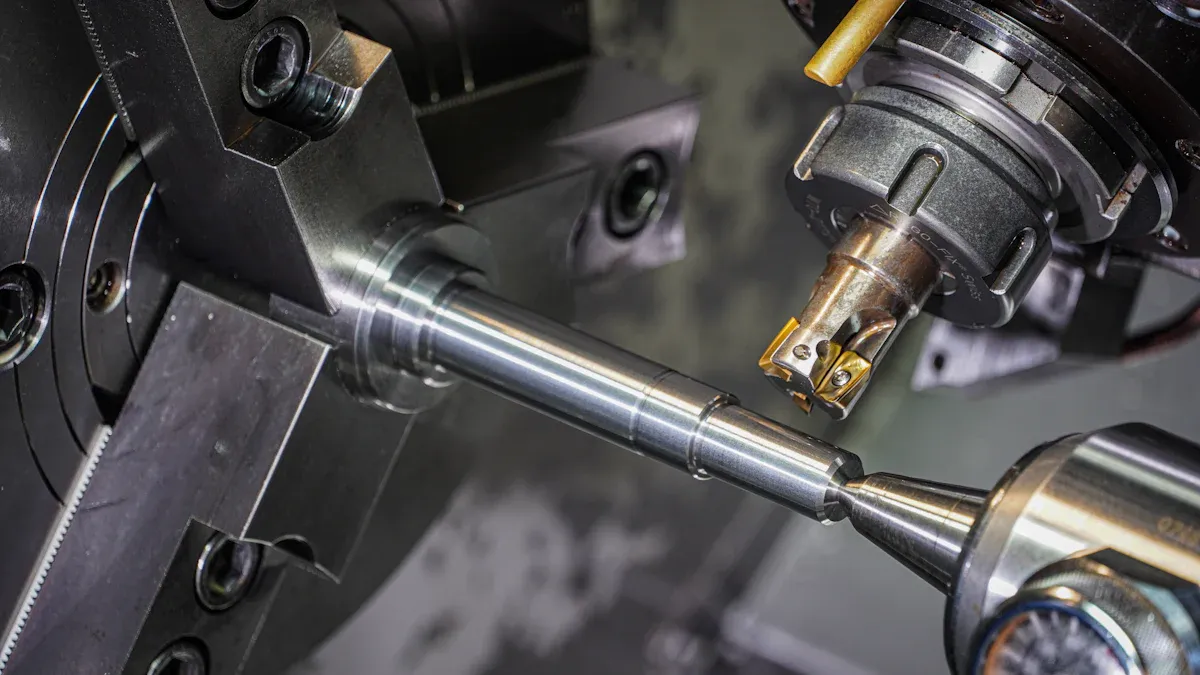

Drone propeller hubs need exact designs for smooth airflow and strength. A process is required to ensure high accuracy and save time. 5-Axis Machining can work with tolerances as tiny as 4 microns. It is perfect for making detailed shapes. It also cuts down on moving parts, boosting efficiency by 30%. This modern method creates strong, affordable, and innovative hubs for top performance.

5-axis machining is a modern way to make parts. It moves in five directions: three straight lines (X, Y, Z) and two spins (A and B). This lets you create detailed parts with great accuracy. Unlike older methods, it needs fewer setups. This saves time and lowers mistakes. Industries like aerospace and electronics use it for tricky shapes and smooth finishes.

It also works with different styles, like indexed 5-axis milling. This uses a 3+2 setup. Continuous 5-axis milling moves all axes at once. Continuous milling is quicker but needs special tools and skills.

Here’s how 5-axis machining compares to 3-axis machining:

| Feature | 3-Axis Machining | 5-Axis Machining |

|---|---|---|

| Complexity | Easier, good for simple shapes | Handles tricky, detailed designs |

| Speed | Slower, needs more manual adjustments | Faster, works nonstop |

| Precision | Fine for basic parts, not for complex | Very precise for hard shapes |

| Cost | Cheaper machines and running costs | Costs more due to special tools |

| Operator Training | Easier to learn | Needs more training |

With 5-axis machining, you get faster work and better accuracy. It’s great for making detailed drone propeller hubs. While it costs more upfront, the long-term savings and quality are worth it.

5-axis machining is great for tough shapes, like drone parts. It moves in five ways at once. This helps make undercuts, deep holes, and tricky parts in one go. You don’t need to clamp parts many times. This cuts down on mistakes and speeds up work.

Other benefits include:

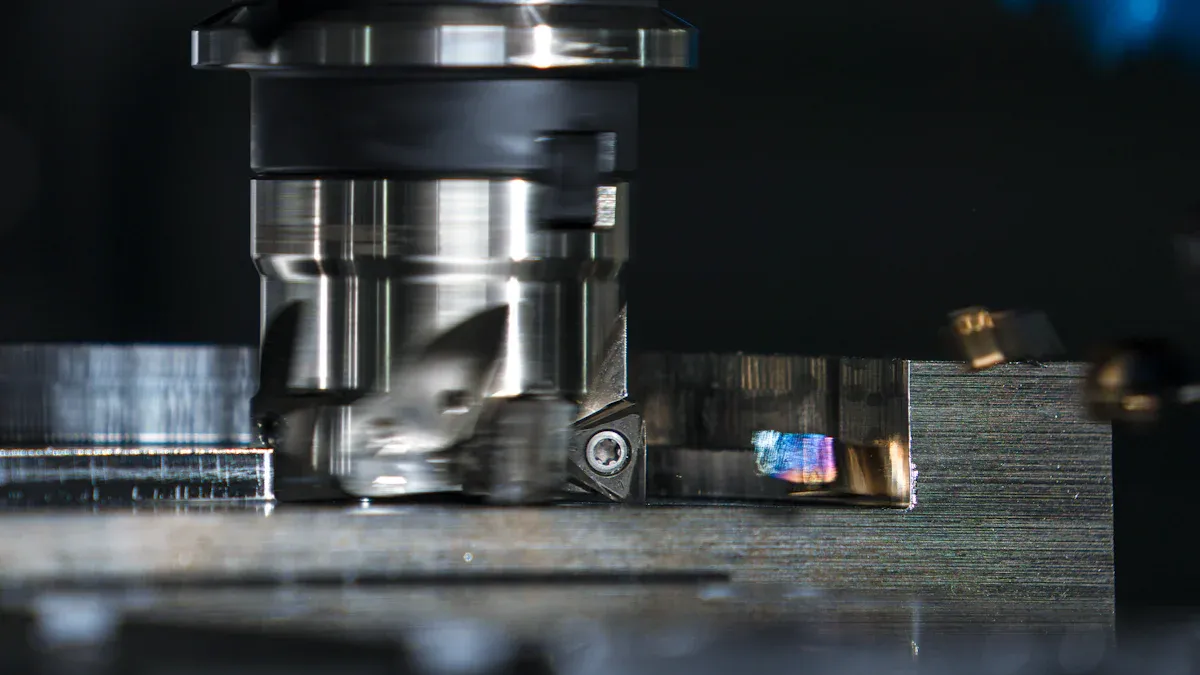

Better Surface Finish: Shorter tools shake less, giving smoother results.

Works with Many Materials: Use metals, plastics, ceramics, or composites.

Saves Time: Faster work means more efficiency.

For drone propeller hubs, these features make designs light, strong, and smooth. Top companies already use 5-axis machining for advanced drones. This shows how important it is for today’s drone tech.

Making drone propeller hubs needs high accuracy. Parts must fit well and work efficiently. 5-Axis Machining is great for making detailed and smooth designs. It adjusts tool angles to ensure perfect finishes and exact sizes. Industries like aerospace and cars use it for important parts like engines. Even tiny mistakes can cause big problems in these fields.

This method can handle tolerances as small as 4 microns. It reduces human errors by needing less manual work. With 5-Axis Machining, you can create tricky shapes like curves and undercuts. These were once too hard to make.

Did you know? CNC milling, including 5-Axis Machining, is common in aerospace. It ensures parts are made with high accuracy and consistency.

Saving time is key in manufacturing. 5-Axis Machining makes complex parts in one setup. This cuts setup time by up to 80%. For example, an aerospace company made turbine blades 30% faster using this method. It speeds up work and keeps quality steady.

Faster production means quicker market launches for drones. Whether making prototypes or mass-producing, 5-Axis Machining helps you stay competitive. It reduces delays and keeps projects on schedule without lowering quality.

Drone performance depends on weight. Lighter parts improve flight and save battery life. 5-Axis Machining helps make light but strong hubs using materials like titanium and carbon fiber. These materials allow detailed designs that cut weight but stay strong.

For example, aerospace engineers use this to make light parts for better fuel use. It’s also used for phone cases, smartwatch bodies, and jewelry molds. For drone hubs, this ensures strong, efficient, and long-lasting designs.

Pro Tip: Precise machining reduces waste and lowers costs while keeping quality high.

Making drone propeller hubs needs accuracy and smart use of materials. Wasting materials raises costs and hurts the environment. 5-Axis Machining helps cut waste and saves money. It removes only the needed material, avoiding extra waste.

This method makes tricky shapes in one setup. Older ways need many setups, causing mistakes and wasting materials. 5-Axis Machining ensures every cut is exact. This reduces errors, saving materials and cutting costs.

Using smart tech like IoT and AI improves machine work. These tools boost speed and reduce downtime, saving more money. Faster work and less waste make 5-Axis Machining great for light, strong drone parts.

Tip: Materials like titanium and carbon fiber work well with 5-Axis Machining. They are strong, light, and create less waste when used with this method.

With 5-Axis Machining, you get quality and

Drone propeller hubs need to be smooth and strong for better flight. 5-axis machining helps make these hubs with great accuracy. It creates tricky shapes that improve airflow and balance. This technology reduces drag and boosts thrust, making drones perform better.

Why it matters:

5-axis machining improves accuracy and speed for drone parts.

It makes detailed designs needed for smooth flying.

This method helps drones stay ahead in a fast-changing market.

Every cut and angle made with 5-axis machining adds to the hub's quality. This ensures drones fly well, even in tough conditions.

Fact: Making detailed shapes with high precision is why 5-axis machining is key for modern drones.

Each drone has special needs, so hubs must be customized. 5-axis machining lets you design hubs for all kinds of drones, like ones for fun, work, or industry. This flexibility helps drones do jobs like taking pictures or delivering packages.

| Feature | Details |

|---|---|

| Accuracy | Makes sure drone parts are made with exact measurements. |

| Quality | Ensures hubs are safe and work well. |

| Tools | Uses advanced 5-axis machining for top-quality parts. |

Custom hubs also use strong materials and finishes. For example, coatings like hard anodizing make hubs last longer. By focusing on quality, you can make hubs that users trust and love.

Benefits of custom hubs:

Better designs to meet user needs.

Longer-lasting hubs with special coatings.

Builds a reputation for great products.

Custom hubs help drones work well in many situations. This builds trust and keeps users happy.

Testing new ideas is important for making better drones. 5-axis machining helps create prototypes quickly and accurately. Whether it’s a new hub design or fixing an old one, this method ensures prototypes are made perfectly.

| Industry | Use Case | Method Used | Benefit | Example Result |

|---|---|---|---|---|

| Cars | Engine bracket testing | CNC Machining | Checks strength | Stops engine shaking problems |

| Medical Devices | Surgical tool prototype | CNC Machining | Ensures safety | Better tool design, passes regulations |

| Aerospace/Defense | Turbine blade testing | CNC Machining | Tests performance in tough conditions | Reliable engine efficiency |

Small-batch production is also useful for testing designs without making too many parts. For example, aerospace companies use 5-axis machining to make turbine blades with high accuracy. You can use this method to improve drone hubs faster and smarter.

Why it works:

Accurate machining makes prototypes match designs.

Small batches lower risks and encourage new ideas.

Quick production keeps you ahead in the market.

Using 5-axis machining for prototypes and small batches helps create new drone designs and improve technology.

Buying 5-axis machining tools costs a lot of money. These machines are more advanced than older 3-axis ones, so they are pricier. You also need special software to program them correctly. For small businesses, this can be tough, especially if they don’t make many parts.

These machines are also harder to maintain. Parts like rotary tables and spindles need regular care to work well. This adds to the cost and can feel overwhelming. But over time, the benefits are worth it. 5-axis machining lowers labor costs and reduces mistakes, saving money in the long run.

Tip: Even though it’s expensive at first, 5-axis machining saves money later with better accuracy and speed.

Running a 5-axis machine takes special skills. Programming these machines is harder than working with 3-axis ones. You have to control extra movements to get the right shapes and smooth finishes.

Main challenges:

Handling how each axis moves.

Writing programs for smooth and accurate results.

Making sure designs are precise and detailed.

Finding trained workers can be hard because there aren’t enough experts. Training your team is important to use these machines properly.

To keep 5-axis machining precise, you need to maintain and adjust it often. Things like heat changes and tool wear can affect how well it works. You must check these issues and fix them quickly.

Some industries, like medical tools, use systems to measure and adjust during work. Tools like the Renishaw MP 250 probe help track data and make fixes in real time. These tools keep the machine accurate for making tricky parts.

Note: Regular checks not only keep machines accurate but also help them last longer, making it a smart investment.

Automation and AI are making 5-axis machining smarter and faster. AI now chooses tools and adjusts cutting settings automatically. This reduces human work and keeps results consistent.

AI also checks parts for mistakes with great accuracy. It ensures only perfect pieces move to the next step. By studying machine data, AI predicts problems early. This helps avoid costly delays.

Tip: Let AI improve production speed and reduce wasted time. This gives you an advantage in drone-making.

Drones are needed more in delivery and security jobs. 5-axis machining with automation can help make many drones quickly without losing quality.

The drone camera market, worth USD 10.9 billion in 2024, may grow to USD 83.5 billion by 2033 at a CAGR of 23.42%. This shows how important precise machining is for meeting demand. Tools like digital twins improve accuracy and speed, helping make more drone parts.

By using these new tools, you can grow your production while keeping high standards for drones.

5-axis machining allows for new and better drone designs. It makes detailed parts with tolerances as small as ±0.001 inches. This ensures parts fit perfectly and work well.

| Advantage | What It Means |

|---|---|

| High Precision | Makes parts fit perfectly with tight tolerances. |

| Complex Shapes | Creates tricky designs not possible with old methods. |

| Faster Production | Needs fewer setups, saving time and reducing mistakes. |

| Smooth Finishes | Produces polished parts, cutting down on extra finishing work. |

These features help make drones lighter, faster, and more efficient. Whether for fun, work, or industry, 5-axis machining keeps drones ahead in technology.

5-Axis Machining changes how drone propeller hubs are made. It offers great accuracy, faster production, and creative designs. These features help make strong, light parts for better drone performance. As drones improve, this method will help create new designs and meet market needs. Using it keeps you ahead in making top-quality drone parts that follow industry rules.

5-axis machining gives better accuracy and works faster. It skips extra setups, saving time and lowering mistakes. You can make tricky shapes and smoother surfaces, which are great for drone propeller hubs.

Tip: Choose 5-axis machining for detailed designs needing exact measurements.

It costs a lot at first but saves money later. You spend less on workers, waste fewer materials, and speed up production. Some companies offer payment plans to help smaller businesses afford it.

You can use titanium, aluminum, carbon fiber, or plastics. These materials are strong and light, perfect for drone hubs. 5-axis machining works well with many types of materials.

It makes light, smooth hubs with exact sizes. This lowers air resistance and boosts power, helping drones fly efficiently. It also makes hubs tough, so drones work well in hard conditions.

Fact: Smooth designs from 5-axis machining can make drone batteries last longer.

Yes, it’s great for prototypes. You can quickly make accurate models to test ideas. It also works for small batches, letting you improve designs before making more.

Pro Tip: Use 5-axis machining to make prototypes fast and stay ahead in creating new ideas.

Navigation

Navigation

Contact Us

Tel: +86 13417419143

E-mail: [email protected]

Add:

2nd Floor, Building 7, 156 High Tech Industrial Park, Fuyuan 1st Road, Zhancheng Community, Fuhai Street, Baoan District, Shenzhen City, China.