Jul.

29, 2025

Contents

How Burrs Affect the Performance of CNC Machined Parts

You might see that even small burrs affect performance in CNC machined parts. Burrs can cause incorrect sizing, make assembly more difficult, and leave sharp edges that can injure people. Additionally, burrs can result in a rougher surface finish and increased costs if not addressed. Being vigilant about burrs helps ensure your parts remain accurate, safe, and durable.

Burrs are tiny, unwanted bits of material. They stick out from the edges of CNC machined parts. Burrs happen when the cutting tool pushes or rips the material. This means the cut is not smooth. Burrs can show up in milling, drilling, engraving, and punching. It is very hard to stop burrs from forming. But you can make fewer burrs if you know how they form.

Many things can cause burrs during machining:

Too much cutting force bends the material and makes bigger burrs.

Slow cutting speeds make heat, which causes more burrs.

Old tools make more burrs.

Hardness changes in the material make uneven burrs.

Not enough lubrication makes heat and more burrs.

Tip: You can get fewer burrs by using sharp tools, the right speed, and good lubrication.

How you set up your machining process is important too. The tool’s angle when it enters or leaves the part matters. The order of tool moves and the type of material also affect burrs.

There are different types of burrs. Each type has its own shape and is hard to remove in its own way. The most common types are:

Rollover burrs: These are small, curled pieces that stick out from the edge.

Breakout burrs: These look like raised bumps that might break off.

Poisson burrs: These stick out sideways from the cut.

Tear burrs: These form when the material rips, often during side milling or punching.

Burrs can also be sorted into classes by size and how tight they stick to the part. The table below shows a common way to sort them:

| Burr Class | Description | Key Characteristics |

|---|---|---|

| Class 1 | Micro burrs | You can only see them with a magnifier |

| Class 2 | Feather burrs | Thin roots, you can remove them with a fingernail |

| Class 3 | Small, well-attached burrs | You need force to take them off |

| Class 4 | Large, well-attached burrs | Thick roots, very hard to remove |

| Class 5 | Extruded burrs | Very large, made by drilling |

Knowing the type and class of burr helps you pick the best way to remove them. This keeps your CNC parts working well.

Burrs affect performance by changing the true size of your CNC machined parts. When burrs form, they create small bumps or edges that stick out from the surface. These extra bits of material can make your parts measure larger than they really are. If you use a coordinate measuring machine (CMM) or a digital caliper, burrs can touch the probe or jaws first. This causes the tool to record a wrong measurement. Studies show that burrs, especially exit burrs, lead to less precise and less repeatable measurements. Harder materials or those that are tough to machine often show even more errors. Burrs also make it harder to keep tight tolerances, which is important for high-quality parts. If you remove burrs, you can improve accuracy, but this takes extra time and money.

Burrs affect performance by making the surface of your parts rougher. A smooth surface is important for many reasons. It helps parts slide together, reduces friction, and looks better. Burrs, along with tool wear and vibrations, change the way the cutting tool meets the part. This makes the surface rougher than planned. When burrs remain, the surface finish does not match the design. This can cause problems in parts that need a tight seal or a smooth look. Even if you cannot see the burrs, they can still change the way the surface feels and works.

Burrs affect performance during assembly. Even a tiny burr, as small as 0.05 mm, can stop parts from fitting together. Burrs can block sliding fits, jam threads, or damage seals. If you try to force parts together, burrs can break off and cause more problems. In automated assembly lines, burrs can catch on guides or fixtures, causing jams and delays. The table below shows some common assembly problems caused by burrs:

| Assembly Feature | Problem Caused by Burrs | Risk Level |

|---|---|---|

| Sliding fits | Parts do not fit or move smoothly | High |

| Threaded connections | Cross-threading, jamming | High |

| Gasket interfaces | Leaks, seal damage | High |

| Press fits | Misalignment, extra force needed | Medium |

| Non-functional edges | Cosmetic defects | Low |

Burrs can also increase the cost of rejected assemblies. If you do not remove burrs, you may have to scrap or rework expensive parts.

Burrs affect performance by making it hard to measure your parts correctly. When burrs are present, they create uneven surfaces and false edges. This confuses both machines and people who check part sizes. You may see parts that look like they meet the drawing, but in reality, the burrs hide the true size. Burrs can also block small holes or grooves, making it hard to check if the part is made right. In micro-machining, burrs are so small that only special cameras can see them. If you do not control burrs, you risk sending out parts that do not meet quality standards.

Burrs cause tolerance issues and misalignments.

Burrs block or disrupt fluid passages.

Burrs complicate finishing and inspection.

Burrs increase the risk of measurement mistakes.

Burrs can cause faults in aerospace, automotive, and electrical parts.

Burrs affect performance by increasing tool wear and reducing the lifespan of your parts. When burrs form, they often mean the cutting tool is dull or the machining settings are not right. Dull tools make more burrs, and more burrs make the tool work harder. This cycle leads to faster tool wear and more frequent tool changes. Burrs can also cause extra friction and heat, which damages both the tool and the part. If you do not control burrs, your tools will not last as long, and your parts may fail sooner. Burrs can also cause problems in parts that carry fluids, like valves or pipes. They can block flow, damage seals, and cause leaks.

Note: Burrs affect performance in many ways. They reduce accuracy, harm surface quality, cause fit problems, and shorten the life of both tools and parts. By controlling burrs, you protect your products and save money.

You can help control burrs by picking the right tools and keeping them sharp. The tool’s material is important. High-speed steel, carbide, and polycrystalline diamond (PCD) tools stay sharp longer. These tools also do not wear out as fast. Sharp cutting edges make cleaner cuts and help stop burrs. If your tools are dull or worn, they make more burrs and can hurt your parts. You should sharpen and clean your tools often. This keeps them working well. Store your tools in cases to protect the edges from damage.

The shape of your tool changes how burrs form. The table below shows how different drill features affect burr size:

| Drill Geometry Parameter | Impact on Burr Formation |

|---|---|

| Helix Angle | Changes how tall and thick burrs are. |

| Point Angle | Changes burr size when drilling. |

| Lip Relief Angle | Changes what burrs look like. |

| Drill Point Type | Split point or helical point changes burr patterns. |

| Tool Wear | More wear means bigger burrs. |

Tip: Always check your tools before you use them. If you see chips or dull spots, sharpen or replace them.

You can make fewer burrs by changing your machining settings. Feed rate and cutting speed are very important. Faster spindle speeds usually make smaller burrs. This is because the tool touches the material for less time. Lower feed rates can help too, but you need to find the best setting for your job. Using coolants or lubricants keeps things cool and smooth. This helps keep burrs small.

Use faster spindle speeds to make smaller burrs.

Change feed rate to fit your tool and material.

Use coolants to keep things cool and reduce tool wear.

Try ultrasonic vibration or special cutting tricks for hard jobs.

If you control these settings, you get smoother parts and fewer burrs.

You can design your parts to help stop burrs from forming. Smooth shapes and rounded edges lower stress and tearing when cutting. Plan your tool paths so the tool enters and leaves the material gently. Use many small cuts instead of one big cut. Hold your workpiece tight so it does not move or shake.

Use fillets and chamfers instead of sharp corners.

Pick machining steps that help weak spots.

Use arc-in and arc-out tool paths to avoid sudden force.

Clamp your workpiece tight to keep it steady.

Good design, smart tool choices, and the right settings help you make better parts with fewer burrs.

Manual deburring is good when you need careful work or have only a few parts. You can use hand tools like files, scrapers, sandpaper, or abrasive cloths to take off burrs in small places. Many shops use special deburring knives for plastic, thin files, or sandpaper on a stick. These tools are best for simple parts or when you do not want to hurt soft surfaces. Use gentle, smooth moves so you do not make new burrs or scratches. Manual deburring takes more time and skill, but you can be very exact. This way works best for small jobs or parts with tricky shapes.

Hand tools: files, scrapers, sandpaper, abrasive pads

Best for: small batches, simple or delicate parts, tight spaces

Key tip: use gentle, controlled movements

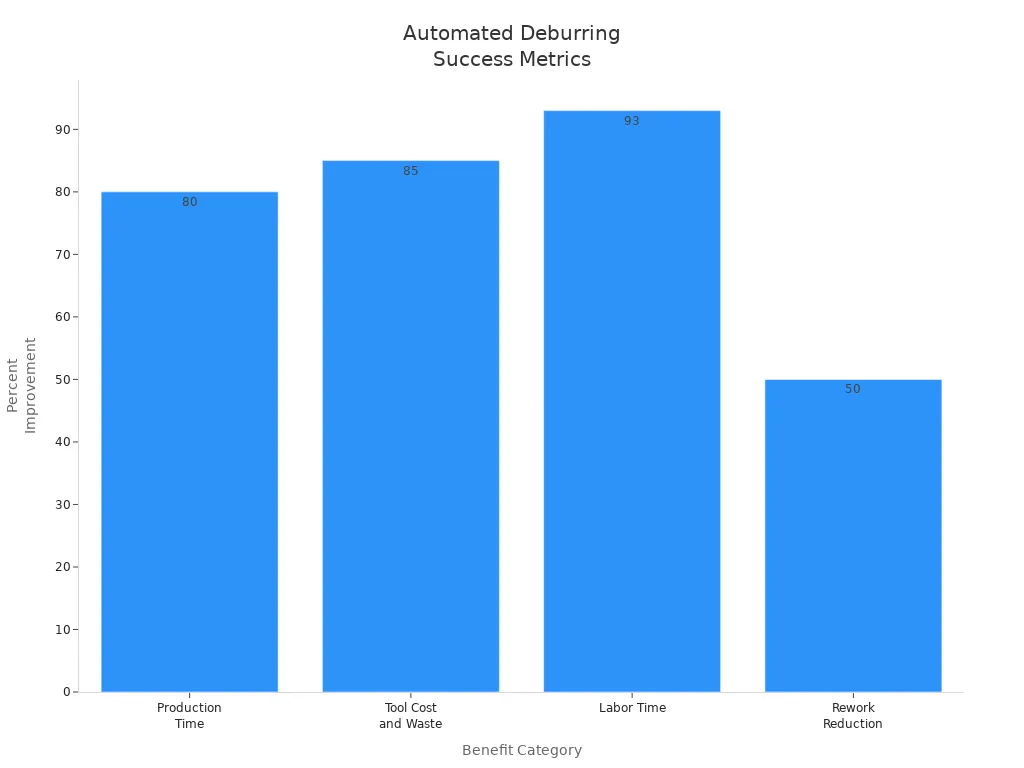

Automated deburring saves time and makes results more even, especially if you make lots of parts. You can use machines with brushes, grinding wheels, or even robots. Some companies, like Orange Vise, use disc brushes that fit inside CNC machines. These brushes mix ceramic and silicon carbide to take off burrs and smooth the part in one step. Automated tools, like Xebec ceramic fiber brushes, can make deburring much faster. They also help you use fewer tools and pay less for labor. You can see the changes in the chart below:

Automated deburring also keeps workers safer because they do not have to handle sharp parts as much. You get steady results and your team can do other jobs.

You should pick the deburring method that fits your job. Manual deburring lets you be flexible and careful, but it is slow and depends on your skill. You might get different results or damage parts by mistake. Automated deburring costs more at first, but you save money later because you need less work, throw away fewer parts, and use fewer tools. It is best for big batches and gives you the same good results each time. The table below shows how both ways compare:

| Aspect | Manual Deburring | Automated Deburring |

|---|---|---|

| Cost | Low upfront, high labor | High upfront, low labor |

| Flexibility | High for complex parts | Best for simple, high-volume parts |

| Consistency | Depends on operator | Very consistent |

| Safety | Higher risk | Lower risk |

| Best Use | Small batches, custom work | Large batches, repeat jobs |

Picking the right way helps you save money, get good parts, and keep workers safe.

You play a key role in making sure burrs do not harm your CNC parts. Burrs Affect Performance by lowering quality, causing extra work, and raising costs. You can prevent these problems by keeping tools sharp, using the right speeds, and checking parts after machining. Good burr control means less rework, better part reliability, and more savings over time. Stay alert to burr issues and keep improving your process for the best results.

You get burrs when the cutting tool pushes or tears the material instead of slicing it cleanly. Dull tools, wrong speeds, or poor lubrication make burrs worse. Hard or uneven materials also lead to more burrs.

Burrs can block parts from fitting together. You may see jams, misalignment, or damaged threads. Even small burrs can stop smooth assembly or cause leaks in seals.

You cannot stop all burrs, but you can reduce them. Use sharp tools, set the right speeds, and design parts with smooth edges. Good planning helps you keep burrs small and easy to remove.

Manual tools like files or abrasive pads work well for small parts. For many parts, try automated brushes or tumbling machines. Always check the part after deburring to make sure you removed all burrs.

Yes, burrs can cut hands or cause splinters. Always wear gloves and use tools safely. Removing burrs makes your shop safer for everyone.

Navigation

Navigation

Contact Us

Tel: +86 13417419143

E-mail: [email protected]

Add:

2nd Floor, Building 7, 156 High Tech Industrial Park, Fuyuan 1st Road, Zhancheng Community, Fuhai Street, Baoan District, Shenzhen City, China.