May.

22, 2025

Contents

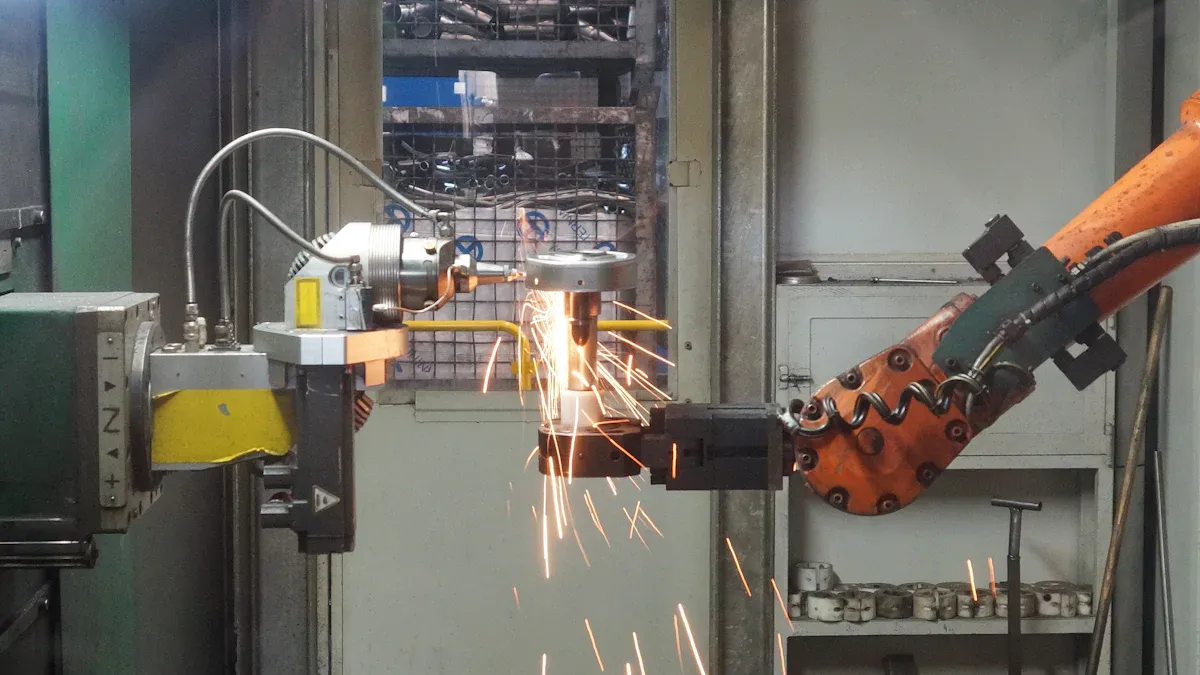

How Custom Fixtures Improve Repeatability in Robotic Base Plate Machining

The Role of Repeatability in Robotic Base Plate Machining

How Custom Fixtures Improve Repeatability

Benefits of Using Custom Fixtures

In machining, repeatability means how well a robot returns to the same spot during repeated tasks. It is very important for making accurate cuts and avoiding mistakes. For robotic base plate machining, repeatability matters more because the robot moves in many directions. Research shows that things like weight and the number of parts affect accuracy. For example:

Heavier weights, like 10 kg, make positioning less accurate, especially on the X- and Z-axes.

Adding more parts can double errors, with the Z-axis being the most unstable.

Custom fixtures solve these problems by holding parts tightly and reducing mistakes from weight or part changes. They help robots work accurately, even in tough situations.

Repeatability means robots do the same task the same way. It helps robots return to the same spot with little change. This is important for cutting, drilling, or building base plates. Without repeatability, mistakes can pile up and ruin parts. Wasted materials also become a problem.

Industries using robotic machining get big benefits from repeatability. For example:

CNC plasma cutting makes HVAC work faster.

Robots in medical device factories and breweries save time.

Microelectronics and sports gear production stay accurate with robots.

These examples show how repeatability improves quality and speed. When results are steady, fixing mistakes becomes easier. This keeps machining accurate and reliable. Repeatability is key for robotic base plate machining success.

Getting repeatability isn’t always easy. Many problems can stop robots from working the same way. For example:

Heat changes can make machine parts grow or shrink.

Worn tools lose their sharpness and cause mistakes.

Part holders can shift and make parts unstable.

Machine upkeep matters too. Bad care lowers performance.

Tool setup errors can make machines less steady.

These problems show why strong solutions like custom fixtures are needed. Custom fixtures hold parts tightly to stop shifting. They work well with robots, even if tools wear out or temperatures change. Fixing these issues helps robots stay accurate and repeatable for better machining results.

Custom fixtures help robots place parts in the right spot. They make sure each piece lines up with cutting tools. This reduces mistakes from parts being out of place. Using custom fixtures removes guessing and makes tasks more accurate. This is very important for tricky machining jobs. Even small errors can ruin parts.

Fixtures made for specific tasks help robots return to the same spot. They guide the base plate to stay in the right position. This keeps machining steady and reliable. It also makes production smoother and more consistent.

Holding parts tightly is key for steady machining. Custom fixtures use strong clamps to keep parts from moving. This stops shaking and helps robots work accurately, even in tough conditions.

Custom fixtures use special features for better clamping. These include strong materials, designs that last, and coatings that stop rust. The table below shows what makes clamping work well:

| Key Aspect | Description |

|---|---|

| Material Strength | Strong materials handle cutting and clamping forces. |

| Wear Resistance | Tough materials like tool steel last longer. |

| Corrosion Resistance | Rust-proof materials like stainless steel prevent damage. |

| Clamping Mechanisms | Good clamps hold parts tight without bending them. |

| Quick-Acting Clamps | Fast clamps save time and make work quicker. |

Using custom fixtures with these features keeps machining steady. This steadiness lowers mistakes and gives the same results every time. It works well even when making many parts in a row.

Custom fixtures fit well with robotic systems. They work smoothly with robotic arms and other machines. This makes production faster and more accurate.

Robots often need fixtures for different tasks. Custom fixtures are flexible and can be changed for different sizes or shapes. They work with many materials too. This makes sure robots do their job well, no matter the task.

Custom fixtures made for your robots improve repeatability. They also cut down on delays from changing equipment. This makes machining better and saves time.

Custom fixtures help make products better. They keep parts steady and in the right place. This stops mistakes like parts moving or being misaligned. The result is smoother finishes, cleaner cuts, and consistent sizes for all parts.

Industries like aerospace and medical device manufacturing have seen big improvements with custom fixtures. For example:

Aerospace factories cut setup time by 40% and improved precision.

Medical device makers reduced part distortion, lowering rework and scrap by 20%.

These examples show how custom fixtures improve product quality. They keep machining accurate and reduce waste. When your products are reliable, customers are happier, and your reputation grows stronger.

Custom fixtures make robotic machining faster and cheaper. They save time by reducing setup steps and keeping tasks repeatable. This speeds up production. For example, a batch that used to take 48 hours now takes only 33 hours with custom fixtures.

The savings are impressive. The table below shows how custom fixtures improve efficiency and cut costs:

| Metric | Value |

|---|---|

| Cost Savings | 20% |

| Efficiency Boost | 30% |

| Less Rework Costs | 78% |

| Lower Processing Costs | 22% |

| Yearly Savings | $120,000 |

| Tool Cost Reduction | 40% |

| Batch Time | From 48 hours to 33 hours |

Custom fixtures save money by reducing tool wear and fixing fewer mistakes. They also work well with robotic systems, cutting downtime when switching equipment. Investing in custom fixtures makes machining better and saves money over time.

Repeatability is very important in robotic base plate machining. It helps robots make steady cuts, avoid mistakes, and work faster. Custom fixtures improve this by holding parts still and in place. They stop parts from moving during checks and reduce human errors. This makes the process more reliable.

Custom fixtures keep parts in the same position for accurate checks.

They save time by making loading and unloading quicker.

Using custom fixtures makes machining smoother and results better. Try these tools to improve your production quality and speed.

Custom fixtures are special tools that hold parts firmly during machining. They help robots do tasks correctly by keeping parts steady and in the right spot. These tools are made for specific jobs or parts, which makes work more accurate and reduces mistakes.

Custom fixtures stop parts from moving or being out of place. They hold parts tightly so robots can return to the same spot every time. Their careful design reduces errors from shaking, worn tools, or changes in the environment. This leads to steady and reliable machining results.

Yes, custom fixtures can be used with many robotic systems. They can be changed to fit parts of different sizes, shapes, or materials. This makes them useful for many tasks and helps save time by reducing delays.

Custom fixtures save money by cutting down on mistakes, tool damage, and fixing bad parts. They also make work faster by reducing setup steps. Over time, the money saved is more than the cost of buying them, making them a smart choicefor machining.

Industries like airplane building, medical tools, and car factories gain a lot. These jobs need very accurate and repeatable work. Custom fixtures help by keeping quality high, lowering waste, and making production faster and better.

Navigation

Navigation

Contact Us

Tel: +86 13417419143

E-mail: [email protected]

Add:

2nd Floor, Building 7, 156 High Tech Industrial Park, Fuyuan 1st Road, Zhancheng Community, Fuhai Street, Baoan District, Shenzhen City, China.