Jun.

24, 2025

Contents

How to Choose the Best CNC Supplier for Non-Standard Parts in 2025

Choose CNC Supplier: Key Criteria

Evaluate and Compare Suppliers

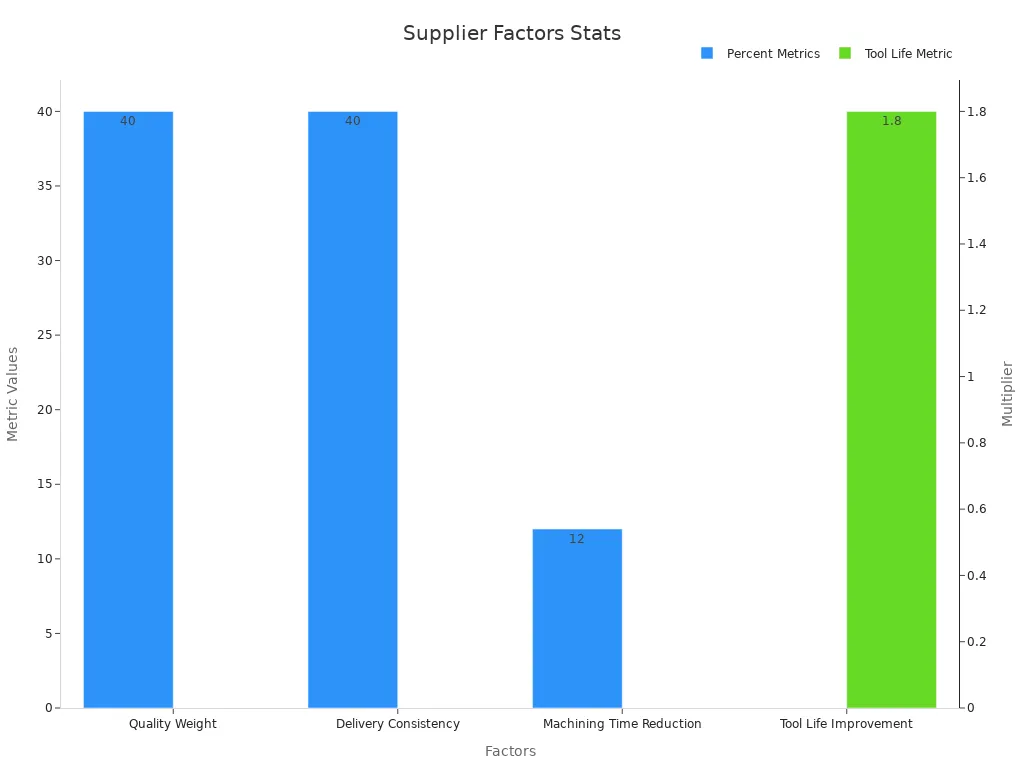

When you choose CNC supplier options for non-standard parts in 2025, it’s crucial to focus on technical skill, quality, and trust. These three factors are key to your project’s success. For instance, quality accounts for 40% of the total score when you choose CNC supplier candidates. Multinational suppliers deliver results that are 40% more consistent, even though their prices are higher. Adopting new CNC technology can help you save up to 90% on part costs in industries like aviation and medical manufacturing. The table below highlights why these factors matter when you choose CNC supplier partners:

When you choose CNC supplier options for non-standard parts in 2025, it’s crucial to focus on technical skill, quality, and trust. These three factors are key to your project’s success. For instance, quality accounts for 40% of the total score when you choose CNC supplier candidates. Multinational suppliers deliver results that are 40% more consistent, even though their prices are higher. Adopting new CNC technology can help you save up to 90% on part costs in industries like aviation and medical manufacturing. The table below highlights why these factors matter when you choose CNC supplier partners:

Factor / Metric Numerical Statistic / Data Point Explanation / Relevance to Supplier Selection Quality Weight in Supplier Scoring 40% Quality makes up 40% of the score when you choose CNC supplier options, emphasizing processing accuracy and inspection skills. Delivery Consistency 40% more consistent delivery by multinational providers This shows that on-time and reliable delivery is important when you choose CNC supplier, even if it costs more. Cost Difference 15% to 25% higher costs for multinational providers You may pay more to choose CNC supplier options that offer better quality and trust. Machining Time Reduction 12% reduction through design optimization Technical skill from the CNC supplier can speed up production. Tool Life Improvement 1.8 times longer tool life with design changes Better quality and reliability when you choose CNC supplier partners.

Tip: When you choose CNC supplier options with strong technical skills and reliable delivery, you can avoid major issues and ensure your parts meet strict requirements.

Non-standard parts are different because they do not match usual sizes. These parts are used when a project needs special shapes or materials. They need custom designs and skilled workers to make them.

The allowed error in machining changes with the material. Metals usually have a limit of ±0.005”. Plastics have a limit of ±0.010”.

Some materials, like copper and steel, change size with heat. You must change the limits to keep the part correct.

Tight limits do not work well for materials that change shape easily, like aluminum alloys or plastics.

Making these parts is hard. Rough materials can break tools fast. Soft materials are hard to cut with high accuracy. Heat can also make parts lose their shape.

You need skilled workers and special tools. Tight limits cost more and need more skill.

Aspect Non-Standard Parts Characteristics Standard Parts Characteristics Design Parameters Personalized designs for specific needs; no fixed standards Follow industry standards (DIN, ISO, ANSI); fixed sizes Manufacturing Complexity Intricate shapes, advanced materials, complex processes like EDM, CNC, 3D printing Simple shapes, large-scale production Tolerances Very fine, sometimes as tight as ±0.001 mm Standard tolerances Production Volume Small batches, custom tooling Mass production Quality Control Advanced inspection (CMM, optical profilometers) Standard inspection Design Challenges Thin walls, deep cavities, multi-axis machining Less complex geometries

Note: Non-standard parts often need special computer models and machines to make their tricky shapes.

Picking the right CNC supplier is important for your project. You need someone who knows how to make hard designs and use tough materials. The best suppliers use new machines and have skilled workers.

Suppliers with digital tools, like real-time checks and smart machines, make better parts faster.

Aerospace suppliers with special certificates, like NADCAP, have strong control and can track materials.

Knowing how to use advanced materials, like composites and superalloys, keeps quality high and costs low.

Using robots and trained workers helps the supplier work faster and make better parts.

It is important to balance accuracy and speed. Good suppliers help you save money by picking the right limits and ways to make parts.

Tip: If you choose a supplier with the right skills and machines, you get parts that fit, save money, and avoid delays.

You should check if the supplier has strong technical skills. A good supplier knows how to use complex standards like MSA:2010, VDA 5:2011, and ISO 22514–7:2021. These standards help them see how well their machines make parts. Sometimes, different standards give different results. The supplier must know how to handle this. They also need to pick the right tools and ways to measure parts. This helps them make sure your parts are always right. Suppliers with new machines and smart technology work faster and make fewer mistakes.

Tip: Ask if the supplier has made non-standard or precision parts before. Check if they have their own tools and can meet tight limits.

Quality and precision are very important when picking a supplier. You want your parts to fit and work every time. Look for suppliers with certifications like:

ISO 9001 for quality

AS9100 for aerospace

ISO 13485 for medical devices

These show the supplier follows strict rules and checks their work. Good suppliers track every part and use advanced measuring tools. Outside experts visit to make sure they keep up their standards. You should also ask about:

Checking materials before making parts

Checking parts during machining

Final checks with CMMs and gauges

Looking for surface problems

Special tests like hardness or leak checks

Suppliers who do these things make fewer mistakes and are more trusted.

You need a supplier who knows how to work with many materials. Non-standard parts often use special metals, plastics, or ceramics. A skilled supplier knows how each material acts when making parts. For example, additive manufacturing uses metals, ceramics, polymers, and composites. The supplier must know how to turn these into strong parts. If your project uses hard metals or rare alloys, ask about their experience. Good material knowledge helps them avoid mistakes and make parts that last.

Note: Knowing about materials is key for making tricky, non-standard parts for aerospace and medical use.

Modern machines help suppliers make better parts. New CNC machines cut parts faster and more accurately. Suppliers with 5-axis machines, AI, and real-time feedback can handle tough shapes and tight limits. Digital feedback helps them find problems early and fix them fast. These tools also help them make the same part many times without mistakes. Look for suppliers with:

5-axis CNC machines for hard parts

Real-time monitoring and feedback

Fast lathes and milling machines

AI and IoT for smart work

These things help suppliers finish jobs faster and make better parts.

Getting your parts on time keeps your project moving. When you pick a supplier, check how often they deliver on time and how long it takes. On-time delivery means you get your parts when promised. Lead time is how many days from order to delivery. Suppliers with short lead times and high on-time rates help you avoid delays. Many companies use scorecards to track these numbers. You should ask for these numbers before you choose.

Tip: Getting parts on time is just as important as price or quality. A late part can stop your whole project.

Good communication helps you avoid mistakes and fix problems fast. You want a supplier who answers questions quickly and explains things simply. Good suppliers give updates on your order and tell you if anything changes. They also help with design ideas and ways to save money. Look for suppliers who offer:

Fast replies to emails or calls

Online order tracking

Design feedback to help you

Support during both testing and full production

Good support makes your job easier and builds trust.

Price is important, but value matters more. You want a supplier who gives a fair price and extra help for your project. Clear pricing lets you compare suppliers and see what you get. Some suppliers offer extra services like data analysis, design help, or market reports. These extras can save you money later. Companies like Amazon use real-time pricing and data to keep costs low. Look for suppliers who:

Give clear and detailed quotes

Offer extra services, not just machining

Use data to help you choose

Work with you to save money

Note: Clear pricing and extra value help you build a strong partnership with your supplier.

A good reputation means a supplier keeps their promises. Before you pick a supplier, check reviews, testimonials, and industry tips. Ask for examples of past work, especially with non-standard parts. Look for suppliers who have worked with big companies or won awards. A strong track record means you can trust them to deliver quality parts on time.

Criteria What to Check For Why It Matters Experience Years in business, past projects Shows reliability and skill Reviews Online ratings, customer feedback Reveals strengths and weaknesses Certifications ISO, AS, or industry awards Proves quality and trust References Contact info for past clients Lets you check their work

Tip: A supplier with a good reputation is more likely to meet your needs and fix problems fast.

Begin by finding out about possible suppliers. Search for companies with good quality certificates and strong testing. Pick those with a history of doing good work. You can use this table to compare important things:

Metric / Performance Review Criteria Description / Purpose Quality Certifications ISO 9001, CE marks, and other certifications that show strong quality systems. QC Testing Methods CMM inspections, laser calibration, and endurance testing for reliable parts. Supplier Audits and Site Visits Visits or audits to check machinery, staff training, and process documentation. Inspection Reports Detailed records of part checks for accuracy and consistency. Lead Time Adherence How often the supplier delivers on time. Communication Responsiveness How quickly and clearly the supplier responds to your questions.

Also, look for suppliers who are open and fix problems fast. They should share your business values. Keeping more than one supplier on your list gives you more choices.

Ask each supplier for a full quote. Compare their prices, delivery times, and quality certificates. Use this table to help you keep track:

Category Quantitative Data Examples Explanation Price Quoted price, supplier size, capacity Check if the supplier can keep prices stable and fill your orders. Delivery Times Percentage of on-time deliveries, capacity utilization See how reliable and fast the supplier can deliver. Quality Certifications ISO 9001, inspection reports, material certifications Make sure the supplier has strong quality control systems.

Look at each quote for clear prices and extra services. This helps you find the best deal, not just the cheapest one.

Good communication is very important when picking CNC supplier partners. You want suppliers who answer fast and give clear updates. To check this, you can:

Set simple rules for how you want to talk.

Find suppliers who send helpful info and answer quickly.

Watch how often they reply and how clear they are.

Use email tracking or customer tools to see how well they follow up.

Tip: Suppliers who talk well help you avoid mistakes and keep your project moving.

Before you decide, check the supplier’s background carefully. Visit their site if you can, or ask for a video tour. Look at their inspection reports and certificates. Make sure they follow rules for the environment and ethics. Check if they have good support after sales and use digital tools to track orders. Keep checking their work to make sure quality stays high.

Note: Careful checks and regular reviews help you build strong, long-lasting supplier partnerships.

You need to look out for weak quality control. If a CNC supplier has lots of scrap, that is a bad sign. Getting broken or wrong parts means they do not check well. This can happen if they do not talk clearly about what you need. If you get parts that are not right, you might have to fix them. Fixing parts costs money and time. Sometimes, your whole project can stop because of this. That can hurt your business and slow everything down.

Quality Control Issue What It Means for You High scrap rates More wasted material and money Defective deliveries Delays and extra work Failed tensile tests Parts may not be strong enough

Note: If a supplier fails tensile tests, there could be big problems. They might use the wrong steps or even fake papers. Always ask to see their test results. Make sure they test parts often and follow a schedule.

Being open is important for trust. If a supplier does not tell you how they make parts, that is risky. You might not know where they get their materials. Some companies only watch their main suppliers. They do not check smaller ones. This can hide problems with quality or rules. If you cannot see where parts come from, it is hard to fix issues. You may not be able to act fast if something goes wrong.

Tip: If a supplier will not share info or is slow with papers, be careful. Good suppliers show records and answer questions fast.

Be careful if a supplier says they can deliver super fast or very cheap. If it sounds too good, it might not be true. Some suppliers promise more than they can do. They might rush or spend too much to finish on time. This can make costs go up and cause problems with contracts. You might see delays and spend more money.

Look for these warning signs:

Delivery times much faster than normal

Prices much lower than others

No clear answers about how they will help you

Remember: Promises that are too big can cause late parts and extra costs. Pick suppliers who are honest and explain how they work.

When you pick CNC supplier partners for non-standard parts, use simple steps. First, look at their technical skills and certifications. Make sure they talk with you clearly. Compare each supplier by using a list of what matters most, like quality, cost, and delivery. Research shows this way helps you get better parts, faster shipping, and lower prices. Try to find a good mix of quality, skill, and value. Take your time and check each supplier well before you decide.

You should check the supplier’s quality control. Good quality means your parts will fit and work well. Ask for their certifications and see if they test parts often.

Look for proof of past work with custom parts. Ask for examples or photos. You can also check if they have special machines and skilled workers.

Suppliers with better machines, skilled workers, and strong quality checks often charge more. You pay for better parts, fewer mistakes, and faster delivery.

Contact the supplier right away. Ask for a clear update and a new delivery time. Good suppliers will explain the delay and help you plan your next steps.

Navigation

Navigation

Contact Us

Tel: +86 13417419143

E-mail: [email protected]

Add:

2nd Floor, Building 7, 156 High Tech Industrial Park, Fuyuan 1st Road, Zhancheng Community, Fuhai Street, Baoan District, Shenzhen City, China.