Oct.

23, 2025

Contents

Bead Blasting vs. Sandblasting

The main difference between bead blasting and sandblasting is how they treat surfaces. Bead blasting uses soft glass beads. It is best for smooth and nice-looking finishes on delicate or exact parts. Sandblasting uses rougher materials. It works well for hard jobs, like removing rust or strong coatings.

Picking the right method is important. It changes how your finished product looks, how long it lasts, and how well it works.

Bead blasting is gentle and good for nice finishes.

Sandblasting is strong and best for tough jobs.

The method you pick can change how your project looks and feels.

Bead blasting helps clean and finish metal parts. You need to follow some easy steps. First, get your metal parts ready. Make sure they are not dirty or oily. Clean them well. Next, put the part inside a blasting chamber. Then, use air pressure to shoot small beads at the part’s surface. After blasting, collect the used beads. Clean away dust and leftover bits. You can use the beads again. Last, check the part to see if it looks good. Fix anything that needs it.

This method makes the surface smooth and even. It can cover up marks from tools. It also takes away sharp edges. Bead blasting is great if you want a matte or satin look.

Tip: Bead blasting hides tool marks better than brushing. It also helps paint stick to the surface.

There are different types of media for bead blasting. Most people use glass beads. These beads come in many sizes. Small beads make a smoother finish. Big beads clean faster but leave a rougher surface. Here is a table that shows common media and their sizes:

Media Type | Typical Particle Size (inches) |

|---|---|

Steel Shot | S-70 (0.125mm) to S930 (3mm) |

Aluminum Oxide | Varies with grit size |

Plastic Media (Urea) | Angular-shaped grains |

Glass Beads | No. 7 or No. 8 for cleaning/stripping |

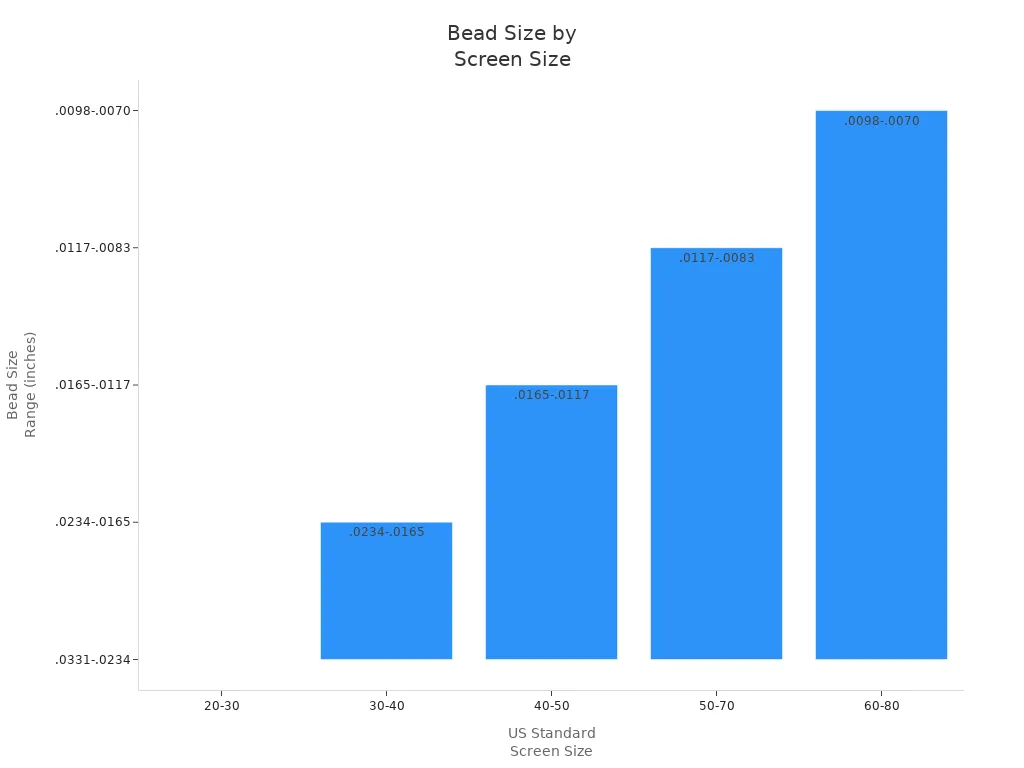

US Standard Screen Size | Bead Size Range (Diameter in Inches) |

20-30 | .0331-.0234 |

30-40 | .0234-.0165 |

40-50 | .0165-.0117 |

50-70 | .0117-.0083 |

60-80 | .0098-.0070 |

Bead blasting is used in many jobs. It is common in aerospace and car work. You can use it on outside and inside parts. Here are some examples:

Sector | Component Type | Specific Applications |

|---|---|---|

Aerospace | External Components | turbine blades, wing components, fuselage panels, landing gear parts |

Aerospace | Interior Components | cabin fixtures, control panels, seat adjustment mechanisms, storage compartment hardware |

Automotive | Engine Parts | heat dissipation, corrosion resistance |

Automotive | Exhaust Systems | aesthetic finish, temperature regulation |

Automotive | Brake Components | friction improvement, wear resistance |

Automotive | Suspension Parts | surface preparation, durability enhancement |

Bead blasting gets surfaces ready for paint or coating. It also makes metal parts look and feel better. The process takes off old coatings and covers up tool marks. You get a matte finish that looks neat and even.

Sandblasting uses a strong blast of abrasive material. It cleans or shapes surfaces. This method is much stronger than bead blasting. It works best for removing tough rust or thick paint. You should follow some steps to get steel or other surfaces ready:

Assess the Surface: Look at the material and what you want gone. This helps you pick the right abrasive and pressure.

Do a Preliminary Clean: Wipe off dirt and loose stuff. This makes blasting work better.

Protect Sensitive Areas: Cover parts you do not want blasted. This keeps them safe from harm.

Choose the Right Sandblasting Media: Pick the best abrasive for your job. The surface and what you want to remove help you decide.

Safety First: Wear safety gear and make sure air flows well. This protects you from dust and flying bits.

Sandblasting can quickly take off years of rust or paint. It is a top choice for tough cleaning jobs.

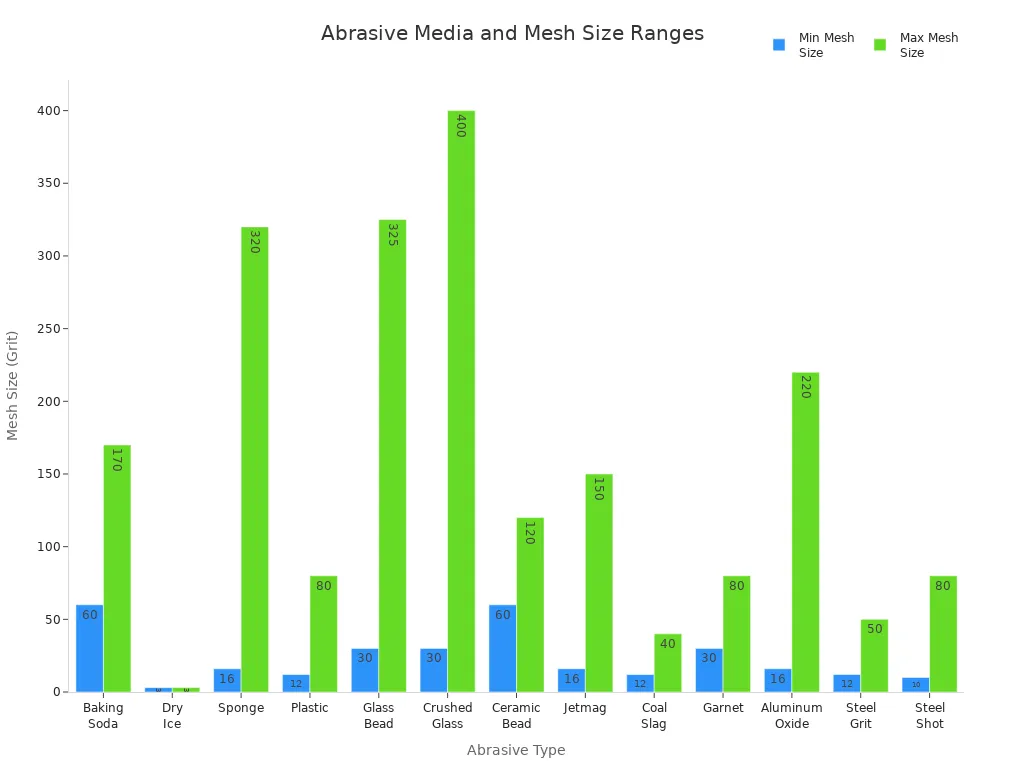

Many types of abrasive media work for sandblasting. Each type has its own grit size and best use. Here is a table to compare some common choices:

Abrasive | Mesh Sizes | Typical Application |

|---|---|---|

Baking Soda | 60-170 | Gentle peening, mold cleaning, paint removal |

Dry Ice | 3 mm | Mold cleaning, special industrial cleaning |

Sponge | 16-320 | Gentle cleaning, old building restoration |

Plastic | 12-80 | Paint removal, cleaning, smoothing edges |

Glass Bead | 30-325 | Engine work, coating removal |

Crushed Glass | 30-400 | Rust, paint, and dirt removal |

Ceramic Bead | 60-120 | Engine work, coating removal |

Jetmag | 16-150 | Outdoor blasting, rust removal |

Coal Slag | 12-40 | Outdoor blasting, rust removal |

Garnet | 30-80 | Outdoor blasting, metal, aluminum |

Aluminum Oxide | 16-220 | Blast cabinet, cleaning, finishing |

Steel Grit | 12-50 | Blast rooms, cleaning, heavy scale removal |

Steel Shot | 10-80 | Cleaning, peening, airless blasters |

Sandblasting is used for many tough jobs. Here are some common uses:

Cleaning and getting concrete ready in building work.

Removing graffiti from walls and surfaces.

Fixing up old buildings and monuments.

Cleaning ship hulls and taking off sea growth.

Getting metal ready for coatings in shipyards.

When building ships, you must prepare the surface well. Sandblasting removes rust, old paint, and dirt. This gives you a clean surface that helps coatings stick.

Sandblasting is powerful. If you need to get rid of thick rust or get a surface ready for new paint, this method works fast and well.

You will notice the biggest difference between bead blasting and sandblasting when you look at the media each method uses.

Sandblasting uses sharp sand or other hard abrasives like garnet and aluminum oxide.

Bead blasting uses round glass beads.

The shape and hardness of the media change how each process works. Sand particles have rough, jagged edges. These edges cut into surfaces and leave deeper marks. Glass beads are round and smooth. They gently tap the surface instead of cutting into it. This difference in media makes each method better for certain jobs.

Tip: If you want a gentle clean, choose glass beads. For tough jobs, sharp sand works best.

The finish you get from each method looks and feels different. Sandblasting leaves a rough surface. The sharp sand digs into the material and creates tiny grooves. These grooves can trap dirt and make the surface feel gritty. You might see more marks and scratches after sandblasting.

Bead blasting gives you a smoother finish. The round beads do not dig in as much. They leave the surface even and soft to the touch. You will see fewer marks and a nice matte look. Dirt does not stick as easily to a bead blasted surface.

Method | Surface Texture | Dirt Retention | Typical Look |

|---|---|---|---|

Sandblasting | Rough | High | Gritty, marked |

Bead Blasting | Smooth | Low | Matte, even |

You need to think about cleaning power when you pick a blasting method. Sandblasting is much stronger than bead blasting. The sharp sand cuts through thick paint, rust, and heavy coatings. You can use sandblasting for big jobs that need a lot of force.

Bead blasting is less aggressive. It works well for cleaning light dirt, removing small burrs, or hiding tool marks. You should use bead blasting when you want to protect the surface and avoid damage.

Note: Sandblasting removes paint from metal surfaces quickly. It is the best choice for heavy-duty cleaning.

Material removal is another key difference. Sandblasting takes off more material with each pass. The sharp edges of the sand cut away layers fast. This makes sandblasting good for stripping surfaces or shaping rough parts.

Bead blasting removes less material. The round beads bounce off the surface and do not cut deeply. You can use bead blasting when you want to keep the original shape and size of your part. This method is safer for thin or delicate items.

If you need to keep fine details or avoid changing the size of your part, bead blasting is the better choice. For jobs where you need to strip away a lot of old material, sandblasting works faster.

Bead blasting is best when you need to be gentle. This method lets you control how you clean parts. It helps protect parts that are easy to damage. Here are some main good things about it:

You can change the air pressure or nozzle size for more control.

This method keeps your parts safe. It cleans and finishes without hurting the main material.

You get a smooth finish. The part keeps its shape.

Bead blasting is great for parts that need care. You can hide tool marks and make a matte look without hurting the surface.

But bead blasting also has some problems, especially with hard metals. The table below shows the main bad things:

Disadvantage | Description |

|---|---|

Time Required | Harder surfaces take more time to clean or finish. |

Material Removal | It removes a little material. This may not work for parts that must stay the same size. |

Skilled Operators | You need someone trained. The result depends on their skill. |

Sandblasting is good when you need power and speed. You can clean big surfaces fast. Here are some main good things about it:

You can take off coatings and dirt easily.

The process gives you a surface that looks the same everywhere.

You can use it on many materials.

It helps you finish big jobs quickly.

Sandblasting often uses less water and chemicals, so it is better for the environment.

Sandblasting works better than chemical stripping or power washing. The abrasive particles clean tight corners and small spaces that are hard to reach.

But sandblasting also has some risks:

You might hurt soft materials like wood or thin metal.

High pressure can make marks, bend, or even make holes if not controlled.

You must pick the right abrasive and set the pressure right to avoid damage.

You should always pick the blasting method that fits your project. Think about the material, the finish you want, and how clean you need it to be.

You should think about equipment costs when picking a method. Both bead blasting and sandblasting need a cabinet or booth. You also need an air compressor and safety gear. Sandblasting machines must handle higher pressure and rougher materials. This can make them cost more at first. Bead blasting machines use lower pressure. They might last longer and break less often. If you want to blast big areas or use tough abrasives, you may need stronger machines and bigger compressors. These can cost more money.

The blasting media you pick changes how much you spend. Glass beads are a cheaper choice. They are made from recycled stuff, so they cost less than garnet sand or special abrasives. You can use glass beads many times before they wear out. This means you do not have to buy new media as often. It saves you money over time. Sand and other abrasives like aluminum oxide or steel grit can cost more. You may need to replace them after each use. Here is a table to compare:

Media Type | Initial Cost | Reusability | Long-Term Savings |

|---|---|---|---|

Glass Beads | Low | High | High |

Garnet Sand | Medium | Medium | Medium |

Aluminum Oxide | High | Medium | Medium |

Steel Grit | High | High | Medium |

Tip: Glass beads help you save money and make less waste.

You must take care of your blasting equipment to avoid extra costs. Clean dust collectors and change air filters often. Check your air compressor to make sure it works well. Nozzles wear out fast, so replace them to keep blasting strong. Ventilation and dust systems need care too. You will spend money on power, new filters, and fixing things. If you use dangerous abrasives, you must pay to throw them away safely. These steps keep you safe and help you follow the rules.

Buy new blasting media when you need it.

Clean and change dust collectors and filters.

Check and replace nozzles that are worn out.

Keep ventilation working for safety.

Throw away used media the right way, especially if it is dangerous.

Good care helps your equipment last longer and stops big problems.

Picking the right blasting method depends on your project. You should think about what you want to do. The type of material, the finish you want, and your goals all matter. These things help you choose bead blasting or sandblasting for your job.

The material you use changes which blasting method is best. Harder materials can take stronger blasting. Softer or delicate materials need a gentle method. Here is a table to help you match materials with the right abrasive media:

Material Type | Suitable Abrasive Media | Hardness/Sensitivity Consideration |

|---|---|---|

Metals | Steel grit, aluminum oxide, garnet | Hard metals can take strong media. Softer metals need gentle care. |

Wood | Plastic abrasive, walnut shells, glass beads | Soft woods need soft media. Hard woods can use glass beads or aluminum oxide. |

Concrete | Garnet, crushed glass, silicon carbide | Pick media based on how deep you want to clean or profile. |

If you use stainless steel, bead blasting makes it look smooth and matte. This finish hides fingerprints and scratches. Sandblasting is good for mild steel. It takes off rust and gets the surface ready for paint. For thin or delicate parts, like audio equipment faceplates or medical device prototypes, bead blasting keeps the shape and size safe. Sandblasting might hurt these parts.

Tip: If you are not sure, test a small spot first to see what happens.

The finish you want is also important. Bead blasting and sandblasting make different looks and textures. Use this table to compare the effects:

Blasting Method | Effect on Finish | Material Suitability |

|---|---|---|

Bead Blasting | Uniform, matte, and smooth appearance | Best for stainless steel and delicate parts |

Sandblasting | Rough, ready for paint or coating | Best for mild steel and tough surfaces |

Shot Blasting | Cleans and roughens for coatings | Works for both mild and stainless steel |

Stainless steel needs a finish that does not show marks and stays clean. Bead blasting is best for this. Mild steel needs a rough surface so paint sticks well. Sandblasting gives you that rough texture. If you want a shiny look without damage, bead blasting is safer.

Note: The media you use, like glass beads or aluminum oxide, also changes how the surface looks and feels.

Think about what you want your project to do. Some jobs need strong cleaning. Others need a perfect finish. Here is a table to show common goals for each method:

Method | Common Goals |

|---|---|

Sandblasting | Remove rust, strip tough coatings, prepare for painting |

Glass Bead Blasting | Get a smooth, polished finish without harming the material |

Use sandblasting if you need to take off old paint or heavy rust. This method works fast and gets surfaces ready for new coatings. Bead blasting is better if you want to keep the part’s shape and size. It is great for thin or delicate parts. For example:

Bead blasting is good for audio equipment faceplates. It keeps the surface smooth and does not bend the part.

Medical device prototypes use bead blasting. You can change the design and blast again without losing detail.

Prototype projects save money with bead blasting. You can reuse parts many times without worry.

Remember: Your project goal helps you pick the best method. If you want speed and power, use sandblasting. If you need care and a nice finish, bead blasting is better.

By thinking about your material, the finish you want, and your project goals, you can choose the right blasting method. This helps you get the best results for your work.

You need to pick bead blasting or sandblasting for your project. Bead blasting is good for soft materials. It makes surfaces smooth and nice. Sandblasting takes off thick coatings fast. It can make surfaces rough.

Criteria | Sandblasting | Bead Blasting |

|---|---|---|

Surface Finish | Rough, may damage material | Smooth, gentle on surfaces |

Material Removal | Removes rust and tough coatings | Ideal for precision and smoothness |

Speed | Fast | Slower, more controlled |

Safety | Needs more protection | Safer, less dust |

Pick sandblasting for cleaning hard jobs or removing rust.

Pick bead blasting if you want a shiny look and do not want damage.

Make sure your blasting method matches your material and finish needs for the best outcome.

You should wear safety goggles, gloves, and a dust mask. Use ear protection if the process is loud. Always cover your skin to protect against flying particles.

You can reuse glass beads several times if they stay clean and whole. Sand and other sharp abrasives break down faster. Replace them more often for best results.

Yes, you can use bead blasting on some plastics. Use low pressure and fine beads. Test a small area first to avoid damage.

Sandblasting removes rust faster and more completely. You should use it for heavy rust or thick coatings. Bead blasting works for light surface rust but not for deep corrosion.

Navigation

Navigation

Contact Us

Tel: +86 13417419143

E-mail: [email protected]

Add:

2nd Floor, Building 7, 156 High Tech Industrial Park, Fuyuan 1st Road, Zhancheng Community, Fuhai Street, Baoan District, Shenzhen City, China.